The development of industrial robots in the automotive industry. Part 1

Since the invention of cars, people have been trying to optimize all the processes in the production of cars. After all, the faster and easier the car will be assembled and put on the market, the sooner the manufacturer will receive its Dollar / Ruble / Euro.

Robots are being introduced into production gradually and deliberately. They have a great advantage over any person in strength and consistency, they can work 3 shifts without stopping for a weekend, lunch break or vacation. What is very important for continuous production.

Welcome under the cat, where a lot of pictures and video.

')

Many have already seen a video about how two robots twist television sets in different directions. Such robots are widely used in car assembly lines.

At what stages do robots help to quickly release cars from the conveyor? Today I would like to describe the first stage of the production of cars and the participation of industrial robots in it.

STAGE 1: BODY ASSEMBLY AND WELDING

The production process of the car begins with the manufacture and assembly of the body. Practically all the other components of the car are made by the supplier companies and sent to the assembly line.

At the factory, everything starts with the stamping of parts with their subsequent assembly, welding and gluing.

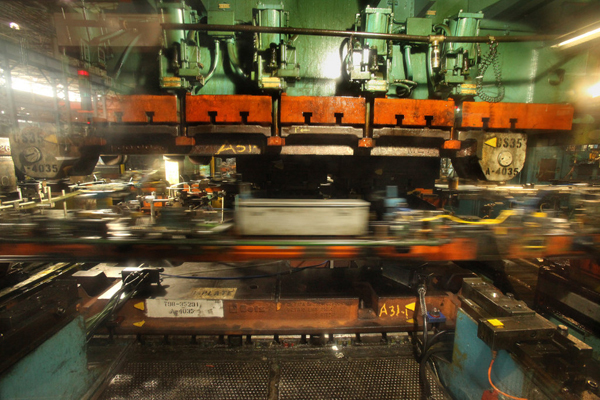

Stamping / body parts manufacturing

People

The entire task of the staff in the stamping line is to move parts between presses, quality control, storage of finished products and control presses. The work is monotonous and dangerous. The press produces strong vibrations, a person may not have time to remove his hand, a drop-down part may fall to his feet, etc. It is possible to develop the topic “how to be killed about an industrial press” for a long time

(from 0:49)

Automatic Transmission Lines

To reduce the risk of injury, or the cost of staff, the plants began to install automatic lines at the stage of stamping parts.

The tasks are quite simple, but because of the bulkiness of the presses and the miniature of the parts, it was difficult and cumbersome to implement the initial replacement of people.

(from 2: 7)

Robots

When stamping, the advantage of the robot is that it does not drop the workpiece, but very accurately places it. In time will remove a hand, since synchronized with the stamp.

(from 1:22)

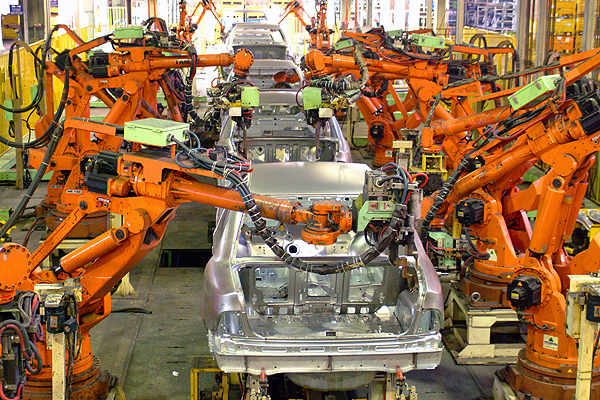

Assembly and welding

Welding is a very dangerous and unhealthy process, so it makes sense to put in place a robot person who will hold the weld evenly and will not overuse the welding material. At the factory, the assembly and welding zones are very limited and people do not have free access to these territories.

At the stage of testing the quality of parts are people. Personally, I am pleased with the fact that it is impossible to do without people.

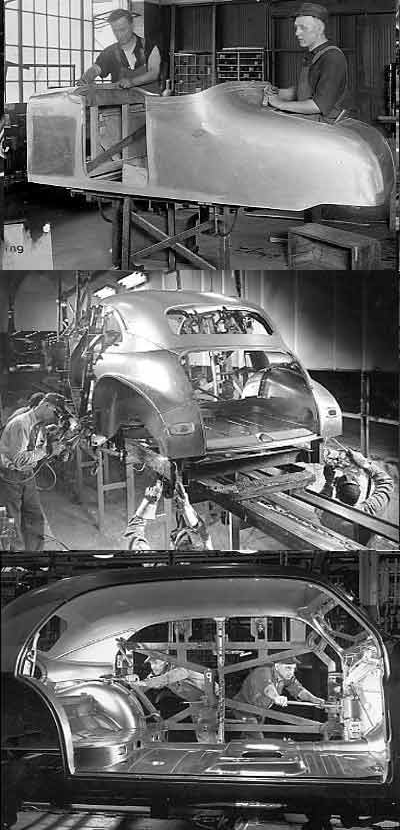

People

Unfortunately, or rather, fortunately, at this stage, People have been replaced for a very long time. I did not even find a suitable picture. Found only for assembly. As you can see in the video, people did the welding in many small steps to speed up the process of making parts.

(from 1:47)

Adaptations and Robots

Robots do their work together with devices that, for example, substitute the necessary parts, hold together the entire structure and move the welded car body away. All such work is synchronized.

(from 0:12)

Production of components from carbon fiber

More recently, BMW launched the i3 and i8 series cars. Soon there will be i1 and i5. The features of cars are that they are partially or fully electric and their bodies are made of carbon fiber. The production technology of such parts is new, so people basically perform the control of processes and quality.

Production of parts from carbon fiber.

(from 4:20)

Skeleton and body soldering

(from 0:11)

Conclusion:

What is the development?

The most important thing is that robots have been introduced into production for a long time and are constantly improving for different tasks. The robot can get into enough (delicate) bottlenecks with a heavy load, while not touching the skin and not hit his head.

ps

In the near future I would like to publish the subsequent stages of the production of cars where robots are involved:

STAGE 2: PAINT BODY

STEP 3: INSTALLATION OF THE FRONT AND REAR GLASS

STAGE 4: INSTRUMENT PANEL INSTALLATION / FINAL AUTO ASSEMBLY

Source: https://habr.com/ru/post/361995/

All Articles