New Li-Ion batteries charge up to 70 percent in 2 minutes and last 20 years.

The theme of batteries and batteries does not let go. I have not had time to "cool down" the post about the fastest-charged battery - Pronto , as scientists from Singapore rolled out a real revolution.

A team of researchers from Nanyang Technological University (NTU Singapore) has developed a new battery that can be charged up to 70 percent in just 2 minutes. And the battery life is over 20 years.

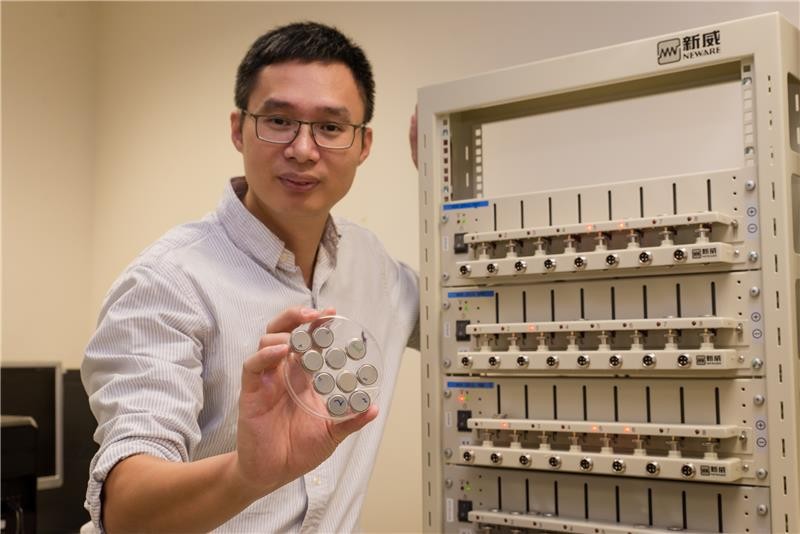

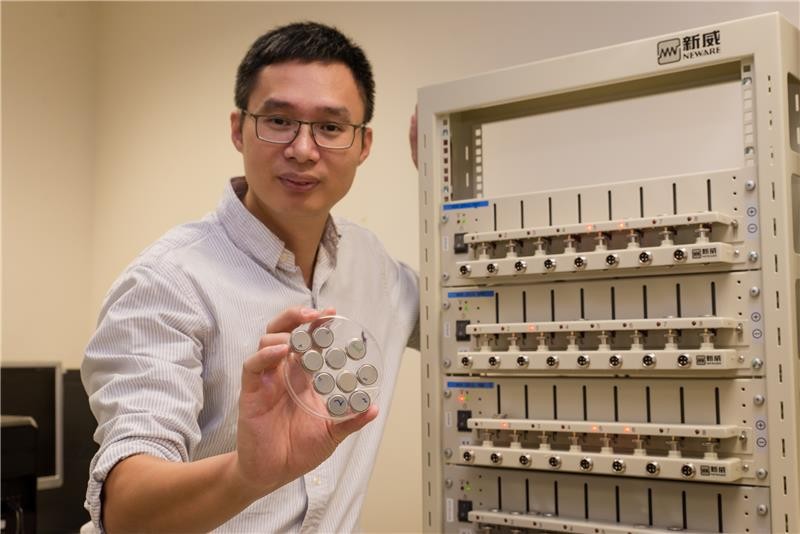

In the photo, Chen Xiaodong, Tang Yuxin, and graduate student Dang Jiuang

')

This breakthrough has far-reaching consequences, especially in the field of electric vehicles ( if you’re too lazy to read further, you can already buy Tesla stocks at this point ), which suffer from a long recharge time (more than 4 hours) and a limited battery life. The developed generation of lithium-ion batteries will allow electric vehicles to recharge 20 times faster than modern batteries. Frequent battery replacement will also be a thing of the past. The new battery will be able to withstand more than 10,000 charge cycles - 20 times more than the 500 cycles of today's batteries.

In the photo, Chen Xiaodong is the head of a group of scientists who discovered a new technology of lithium-ion batteries.

The answer to the question “How is this possible?” Is in the form of nanostructures.

Singaporean scientists replaced the traditional graphite used for the anode (negative pole) in lithium-ion batteries with a gel made of titanium dioxide (this material is extremely common and is used, for example, in sunscreens to absorb ultraviolet rays).

Typically, titanium dioxide is in a spherical shape, but scientists from Singapore have developed a simple method to give titanium dioxide particles and the shape of tiny nanotubes, which are a thousand times thinner than the diameter of a human hair. The form of nanostructures is responsible for the rate of chemical reactions occurring in the new battery.

The discovery of the influence of the nanostructure form on the rate of chemical reactions belongs to NTU Singapore associate professor, Chen Xiaodong. To achieve a breakthrough, a team of four scientists led by Professor Chen took 3 years. Professor Rashid Yazami, who was one of the inventors of the lithium-graphite anode 34 years ago, which is used in most lithium-ion batteries today, marked Professor Chen’s invention as the next big leap in battery technology.

“The cost of lithium-ion batteries has declined significantly and productivity has improved since Sony commercialized this technology in 1991, the market is rapidly expanding towards new applications in electric mobility and energy storage,” says Prof. Yazami.

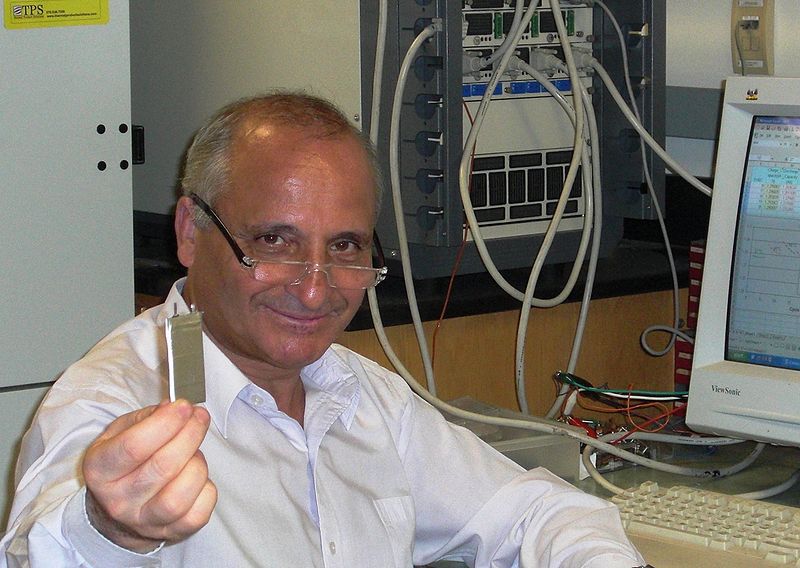

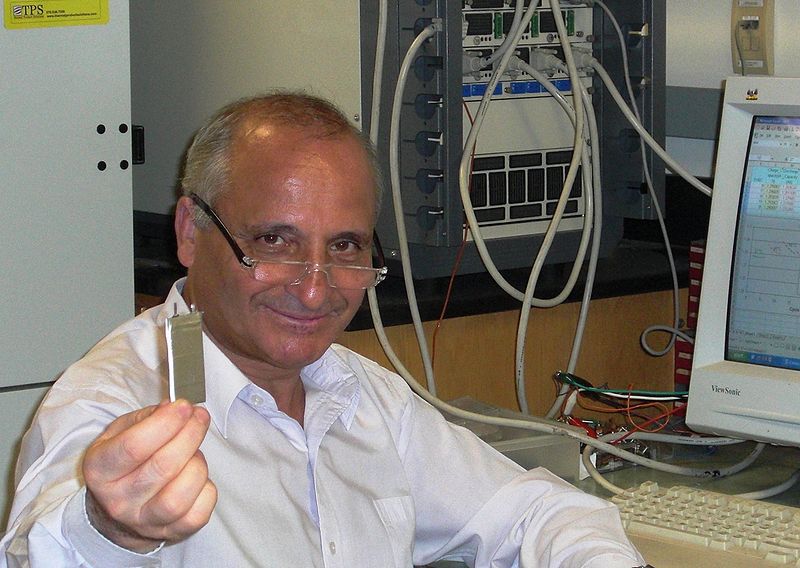

In the photo is Professor Rashid Yazami. In 1980, he invented the technology of graphite electrodes used in modern lithium-ion batteries.

“There is still room for improvement in technology and one of the key areas is power density - how much energy can be stored in a certain amount of space, which directly relates to the ability of fast charging. Ideally, battery charging time in electric vehicles should be less than 15 minutes, and Professor Chen's nanostructured anodes have proven that this is possible. ”

The next step for the research group of Professor Chen will be a grant application to prove the correctness of the concept of the grant by creating a full-fledged prototype battery. The patented technology has already attracted industry interest.

At the moment, battery technology is licensed and Chen expects the new generation of quick-charge batteries to enter the mass market within two years. “With our nanotechnology, electric cars will be able to significantly increase the power reserve after just five minutes of charging, which is comparable to the time required to refuel gasoline cars,” added Professor Chen. “Equally important, we can now drastically reduce the waste generated by recycled batteries, since our batteries will last dozens of times longer than the current generation of lithium-ion batteries.”

The long life of the new battery also means that drivers will be able to save on replacing the battery, which is now about $ 5,000 USD.

Lithium-ion batteries typically use additives to bind cathodes to anodes, which affect the rate at which electrons and ions can transfer to and from batteries. Nevertheless, the new electrodes connected by the gel in the form of nanotubes based on titanium dioxide, the team of Professor Chen, eliminate the need for these additives and allow you to pack more energy in the same amount of space.

“The production of this nanotubular gel is relatively easy,” said Professor Chen. “Titanium dioxide and sodium hydroxide are mixed and stirred at a certain temperature. Battery manufacturers will easily integrate our new gel into their current manufacturing processes. ”

We look forward to 2016, when the first commercial samples of new batteries should appear.

If you have such an opportunity, run to buy Tesla shares. They will be the first to benefit from the use of new batteries. Let me remind you, today Tesla solved the problem of fast reloading cars by the fact that the process is an operation to extract a discharged battery and install a charged one and takes 90 seconds. Charging from the mains takes more than 5 hours.

A team of researchers from Nanyang Technological University (NTU Singapore) has developed a new battery that can be charged up to 70 percent in just 2 minutes. And the battery life is over 20 years.

In the photo, Chen Xiaodong, Tang Yuxin, and graduate student Dang Jiuang

')

This breakthrough has far-reaching consequences, especially in the field of electric vehicles ( if you’re too lazy to read further, you can already buy Tesla stocks at this point ), which suffer from a long recharge time (more than 4 hours) and a limited battery life. The developed generation of lithium-ion batteries will allow electric vehicles to recharge 20 times faster than modern batteries. Frequent battery replacement will also be a thing of the past. The new battery will be able to withstand more than 10,000 charge cycles - 20 times more than the 500 cycles of today's batteries.

In the photo, Chen Xiaodong is the head of a group of scientists who discovered a new technology of lithium-ion batteries.

The answer to the question “How is this possible?” Is in the form of nanostructures.

Singaporean scientists replaced the traditional graphite used for the anode (negative pole) in lithium-ion batteries with a gel made of titanium dioxide (this material is extremely common and is used, for example, in sunscreens to absorb ultraviolet rays).

Typically, titanium dioxide is in a spherical shape, but scientists from Singapore have developed a simple method to give titanium dioxide particles and the shape of tiny nanotubes, which are a thousand times thinner than the diameter of a human hair. The form of nanostructures is responsible for the rate of chemical reactions occurring in the new battery.

The discovery of the influence of the nanostructure form on the rate of chemical reactions belongs to NTU Singapore associate professor, Chen Xiaodong. To achieve a breakthrough, a team of four scientists led by Professor Chen took 3 years. Professor Rashid Yazami, who was one of the inventors of the lithium-graphite anode 34 years ago, which is used in most lithium-ion batteries today, marked Professor Chen’s invention as the next big leap in battery technology.

“The cost of lithium-ion batteries has declined significantly and productivity has improved since Sony commercialized this technology in 1991, the market is rapidly expanding towards new applications in electric mobility and energy storage,” says Prof. Yazami.

In the photo is Professor Rashid Yazami. In 1980, he invented the technology of graphite electrodes used in modern lithium-ion batteries.

“There is still room for improvement in technology and one of the key areas is power density - how much energy can be stored in a certain amount of space, which directly relates to the ability of fast charging. Ideally, battery charging time in electric vehicles should be less than 15 minutes, and Professor Chen's nanostructured anodes have proven that this is possible. ”

Technology commercialization

The next step for the research group of Professor Chen will be a grant application to prove the correctness of the concept of the grant by creating a full-fledged prototype battery. The patented technology has already attracted industry interest.

At the moment, battery technology is licensed and Chen expects the new generation of quick-charge batteries to enter the mass market within two years. “With our nanotechnology, electric cars will be able to significantly increase the power reserve after just five minutes of charging, which is comparable to the time required to refuel gasoline cars,” added Professor Chen. “Equally important, we can now drastically reduce the waste generated by recycled batteries, since our batteries will last dozens of times longer than the current generation of lithium-ion batteries.”

The long life of the new battery also means that drivers will be able to save on replacing the battery, which is now about $ 5,000 USD.

Production

Lithium-ion batteries typically use additives to bind cathodes to anodes, which affect the rate at which electrons and ions can transfer to and from batteries. Nevertheless, the new electrodes connected by the gel in the form of nanotubes based on titanium dioxide, the team of Professor Chen, eliminate the need for these additives and allow you to pack more energy in the same amount of space.

“The production of this nanotubular gel is relatively easy,” said Professor Chen. “Titanium dioxide and sodium hydroxide are mixed and stirred at a certain temperature. Battery manufacturers will easily integrate our new gel into their current manufacturing processes. ”

We look forward to 2016, when the first commercial samples of new batteries should appear.

If you have such an opportunity, run to buy Tesla shares. They will be the first to benefit from the use of new batteries. Let me remind you, today Tesla solved the problem of fast reloading cars by the fact that the process is an operation to extract a discharged battery and install a charged one and takes 90 seconds. Charging from the mains takes more than 5 hours.

Source: https://habr.com/ru/post/361783/

All Articles