Control of the hardware product: the path of heavy compromise

Over the past few years, a new profession has emerged and shaped itself in Russia - a product manager. Of course, 10 years ago there were specialists who performed the duties of a product manager or these duties were distributed among several people. Now there are quite a few ready-made specialists on the market, the demand for them, as well as a host of various training courses, articles on this topic, and so on.

Unfortunately, 99.9% of all these useful materials and courses are related to software management. Moreover, most of them focus on online services and mobile applications. They discuss MAU and other metrics, as well as tools that help to work with them. Unfortunately, most of these metrics do not work for enterprise products or for hardware products.

')

Information on the management of hardware-products is very small, I will try to fix it. Let's start with a small article about the differences in the management of hardware-products from the management of software products.

Complexity

Most hardware products are more complex than most software products. No, I do not in any way want to reduce the complexity of large software products or web services. Just very often a web service, this is just a web service. A hardware product is almost always not only the hardware itself, but also drivers, application software and even additional web services for working with this piece of hardware. In the worst case (in terms of complexity of course) you need to create an Apple iPhone, when in addition to application software you need to build a whole ecosystem.

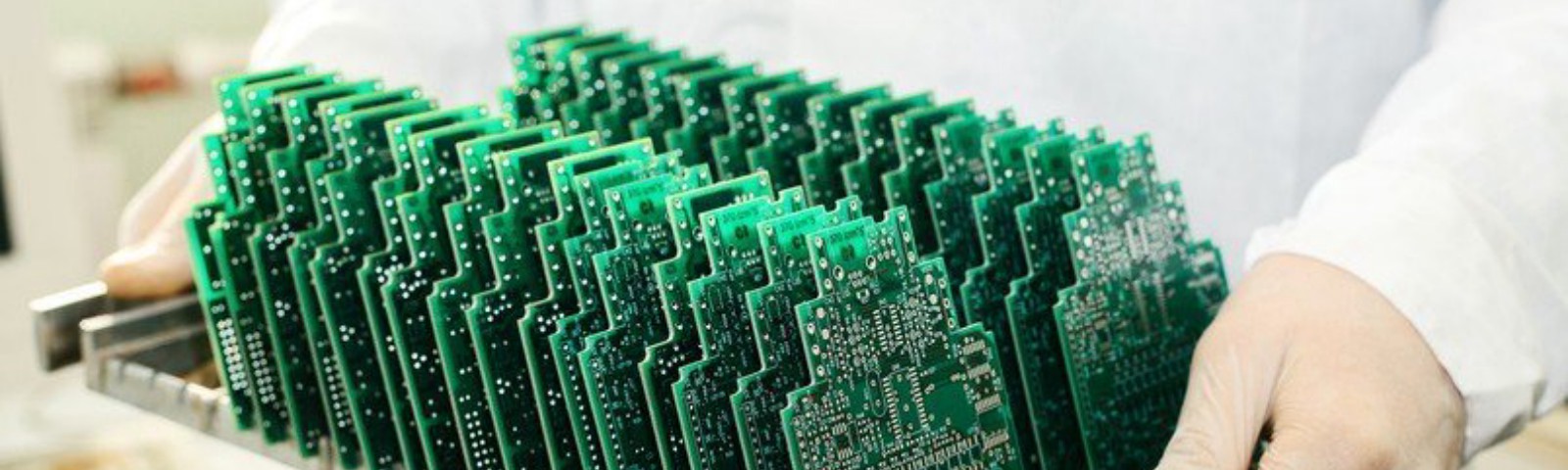

For example, our company is engaged in the production of electronic identifiers for authentication and digital signatures. In our case, the product is not only a piece of hardware, but also drivers for Windows, Linux and MacOS + application libraries + SDK + application software + browser extension + applications for mobile phones (Android and iOS). It is also necessary to support various open-source software that works with such devices (openssl, opensc, openct and so on). Plus documentation and knowledge base.

This leads to the fact that when creating such a hardware product, you have to work with many different teams: from mobile developers to circuit engineers. Even designers need at least two for such a product - for software and the so-called industrial designer.

Design

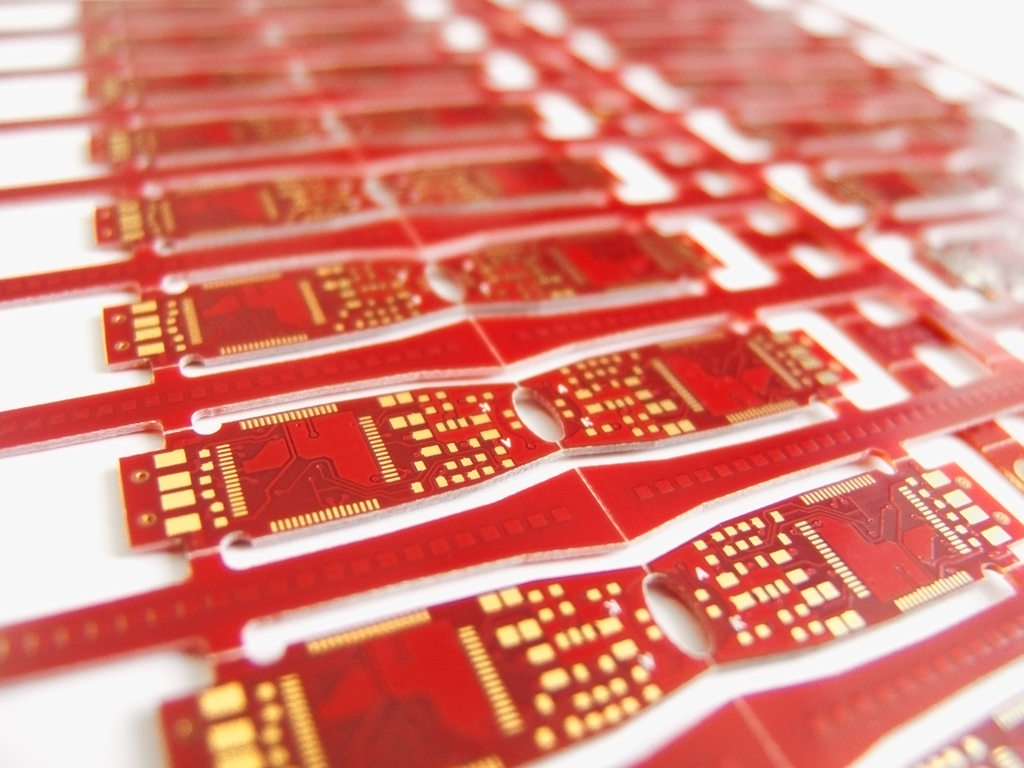

Design and engineering are important in any development. In the modern world, products are increasingly beginning to compete with each other not only and not so much with functionality as with ease of use. Fortunately, for software developers, design can be redone. And in most cases it is not such a difficult task. With hardware products, everything is much more complicated - the exterior design is directly related to what is inside, for example, a printed circuit board. And the desire to slightly alter the exterior design can lead to a complete rework of the product inside. So this change requires much more time and specialists. Plus hardware design is closely related to the production and future maintainability of the product. Recall the sad story with the Galaxy Note 7 cases, when the decision to shrink the case by a few millimeters led to massive fires.

Launch and rhythm releases

Adding new features or product releases while managing a software product depends only on the people of your company - developers, marketers, lawyers, and so on. And the production of a hardware product includes proper coordination and work with a host of other companies. The development of "iron" includes natural life cycles, which means that once crossing a certain milestone, you find yourself at a point of no return when changes can lead to very large delays in your roadmap - not to mention a significant increase in cost.

For example, Rutoken tokens have a limited set of colors and body shapes. Imagine that in the middle of developing a product manager decided to make a device of a new non-standard color and shape. Such a process will require not only redesign and prototyping, but also check that the production can actually produce such a product, search for suppliers of plastic of the desired color with suitable characteristics, supply of plastic for production (at the right time and at the right price), production of the first batch, additional testing, and adding something to the firmware is possible. This process can take months! Compare this with the addition of a button or a change of color in the user interface in a software product, where the whole process before the release may be less than a week.

The release of a completely new product can take more than a year from the moment of the idea to delivery to end users, and this is an absolutely typical story. Much can happen in the market during this time and without good research you can end up with a product that the market does not need at all. When developing an online product, you can enter the market in less than 6 months (but even this can change a lot).

Even software update iterations for hardware can require a combination of server, client, firmware, changes to the OS, and all this can take a lot of time.

Metrics and hypothesis testing

Hypothesis testing in hardware products is much more complicated. Very often you can monitor the effectiveness of a particular feature, just by watching sales and then indirectly. Imagine that you added a button to a vacuum cleaner or refrigerator for a new mode of operation. How to understand its effectiveness?

Even after conducting a direct survey and finding out that users do not use this button, it is not so easy to understand why - was the marketing of this function bad? Was the instruction poorly written? Or users do not need this feature at all? This is further complicated by the fact that there is often retail between you and the end user, who may have their own interests. For example, users have been aggressively promoted with an additional warranty on a device for which you have just raised reliability.

There are fantastic situations at all. Imagine you are producing drinking water filters. Tomorrow you developed a new technology and released a filter that needs to be changed one and a half times less than that of competitors. On the one hand, it looks like the advantage of the product. On the other hand, it is more profitable for a retailer to say that all filters are the same and should be changed with the same frequency, as this allows him to sell more and therefore earn more. And your competitive struggle interests him a little.

It is more difficult for you to feel yourself as a user of the system, so you need to communicate with real users as often as possible. Moreover, it is necessary to communicate not only with B2B clients, but also with end users. And tech support should be your best friend. For example, if you produce electronic signature tools, then part of the test scenarios is available only for certain groups of legal entities. In the case of the EGAIS system - only for suppliers or sellers of alcoholic beverages. And none of the participants in such a system wants to give you combat certificates for full-scale testing and identifying any problems.

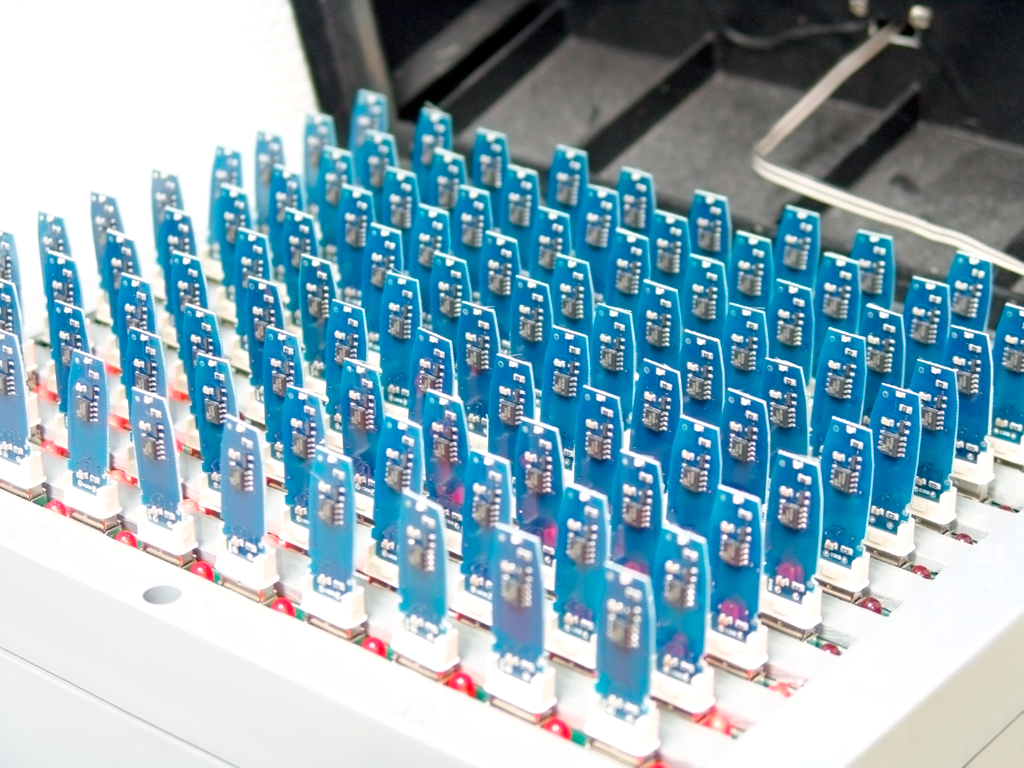

When developing a software product, you can experiment with the team and add only the right things to the final release, while easily cutting out unnecessary ones. When developing a hardware product, prototyping and receiving feedback can be time consuming and very expensive. “Iron” products almost never get a real beta period and cannot be patched after release if a critical problem was discovered.

You can touch the product

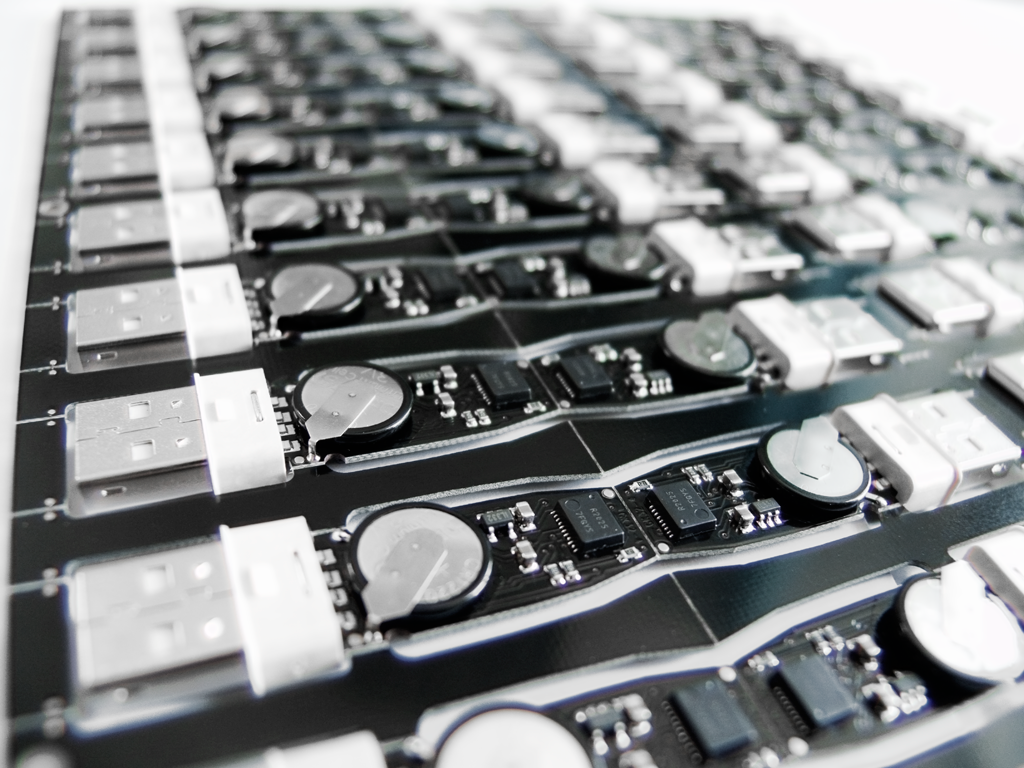

A hardware token is a tangible product that is delivered to end customers. This means that the manager of such a product gets additional work - delivery and warranty service.

Clients cannot simply download a new token or log in by clicking a button. It doesn't matter if you deliver to your business partner or negotiate with retail, the product manager gets an extra pack of headaches - supply and demand, logistics, packaging and retail partnership.

Product packaging often plays a very important role - this is the first user experience in interacting with your product. As in the product development, Apple is setting a significant trend in this direction. Her iPhone boxes forever changed the packaging of the smartphone. Good packaging should be attractive, functional, reliable, it is worth mentioning good instructions. A return of products is the opposite of logistics - warranty repair, diagnostics, replacement, and so on.

Certification

If you are developing products in the field of information security, then you know about the various certifications and requirements for those or other products. This applies to both software and hardware products. FSTEK, FSB and the Ministry of Defense is only a small list of certification bodies in the field of information security in Russia.

Even if you are not working in the field of information security, and produce products for the general consumer you will need to meet the mass requirements. Surely you have seen various badges and stickers on the instructions of household appliances about compliance with various standards and fulfilling the conditions of various certification. What is even sadder is that this certification is usually tied to specific regions, which means that when delivering a product to several countries, you need to consider their requirements. And since these requirements may be contradictory, you may find yourself in a situation where you need to release several versions of the same product for different regions.

Standards are a great thing, but sometimes they have a specific set of requirements that dictates the behavior of the product or limits it. This adds challenge to the product team, which must make a product that satisfies all requirements while creating a good user experience.

This challenge is especially strong when developing products related to security in general and information security in particular, where most of the security requirements reduce user experience in some way. Unfortunately, the majority of domestic products in this area make users not to enjoy the new product, but to suffer.

Product life

If you are developing an online service, then all your users use its latest version. And you need to support only her. In the case of heavy software support may take years. But in the case of “iron” products, it almost always amounts to years or even decades. And the device should not only work physically, but in most cases be supported by your new software. The load is increasing not only on developers, but also on technical support staff. All this you need to consider when releasing a new version.

You need a strategy in advance to complete the life cycle and complete product support. And you need to prepare in advance as smoothly as possible for the transition.

Reliability

Even the first version of your product should be 100% working. When you write software, especially if we are talking about various online services, you do not have any problems with temporarily non-working components or errors. You can fix them and quickly roll out. When you buy an iron product, making corrections is almost impossible. Plus, the users themselves, when buying something material, are extremely relying on the fact that there will be no problems with work.

If the online service falls by 5 minutes, then the maximum that will happen is a couple of bad news on the Internet. If for 5 minutes the piece of hardware in the critical infrastructure fails, you will have big problems.

Economy and cost

Usually, the development of hardware products requires much more money. In addition to the cost of development - it is also the cost of components, production capacity, production staff, the cost of storage (both components and finished products).

As a product manager, you need to think about reducing manufacturing costs. It is necessary to design new products using ready-made solutions or standard components. This is important not only to reduce the cost of your product, but also allows you to standardize production. Which in turn will further reduce the cost of production and, more importantly, increase the speed of entry into the market of a new product.

Sales forecasting

It is very important to forecast sales not only for estimating revenue, but also for the supply chain and production load. Proper communication with your sales managers, and their correct communication with customers are necessary for analyzing the effectiveness and evaluating future investments.

Forecasting volumes allows supply chain and production groups to create a production plan and maintain optimal inventory levels of components and finished products for savings. The supply chain additionally uses forecasting to optimize the cost of the components needed to produce your product.

Logistics and production

Watch production, suppliers and logistics. As a product manager, you absolutely don’t want to do this, but it is definitely vital to understand current operating expenses that help avoid such unexpected expenses as recalling a product or not having it in stock.

For example, is the logistics process automated or not? Do they have their own point of testing at each stage? How does the plant make decisions on vital components? These are just a few examples, but don't be afraid to dive deeper and ask questions. Even asking questions the team will be involved and if some problem happens, you will know the right people with whom you can solve it.

Short summary

I hope that the difficulties and problems that I’ve been encountering with the hardware manager are not going to scare away those who decided to take this path, but only to spur them on. After all, creating products that you can touch with your hands is really great!

Yes, there will be many difficult tasks, difficult decisions and difficult compromises on this path. But without this, a good product, whatever it is — hardware, software or service — will not work. The main thing is to be as close as possible to your end users in order to create a truly useful product. And to be as close as possible to the production process so that the creation of your product is cost-effective.

Source: https://habr.com/ru/post/352336/

All Articles