Simulation systems: choose the appropriate

Modern chemical-technological processes are so complex that to change them we have to use not only analytics, but also the results of simulation modeling. In this case, it is necessary to work with a model of a physical object, and it is on the model to investigate its properties and behavior in all situations. For this there are many software packages. In order to understand the specifics of such software, I collected analytical information about the systems that are most common in the world and are popular with requests in Internet search engines. The results of the study - in this review. It will be useful to designers, technologists and machine operators - to all those who analyze technological processes, build management systems for them, perform engineering calculations of technological devices.

Working with a simulation model helps, first, to more fully examine objects than during a real experiment (in practice, we basically can’t create all situations to explore the properties and behavior of an object).

And secondly, simulation modeling makes it possible to more efficiently perform research, design and optimization of the technological process: since working with the model takes into account the influence of many different parameters on the chemical-technological process (CTP), the technologist will be able to find those qualitative and quantitative characteristics that will save time and money to change the CTP, as well as reduce the likelihood of errors.

')

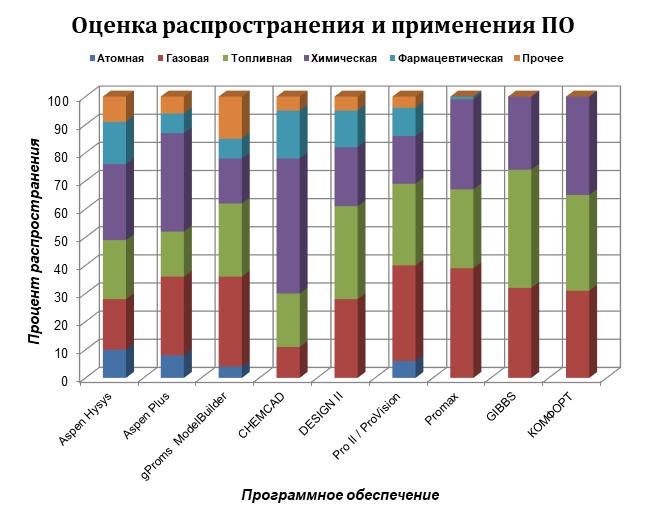

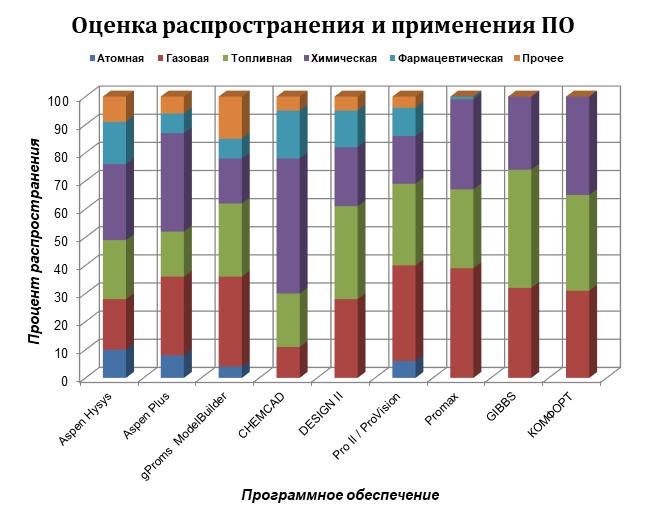

For example, in the fuel industry, simulation software products are used for the processing of heavy sour crude oil and oil preparation. Application in the pharmaceutical industry is designed to simulate the reaction and periodic distillations of hydrocarbons.

As part of building an automatic heat management system for an enterprise (one of its complex processes), our specialists , First Engineer, needed to investigate the technological process: analyze transients and identify critical technological areas, as well as analyze the possibilities of using a software product in the control system (to develop optimal heating system operation modes in automatic mode). So I had to study the market in search of a complete software tool. I share the results of software analysis with you. Below will be a lot of tables.

When preparing an article for Habr, I tried to contact all manufacturers of the specified software and clarify the data, because over time they could improve their products. But the answer came only from GIBBS. So I will be glad to clarify your comments.

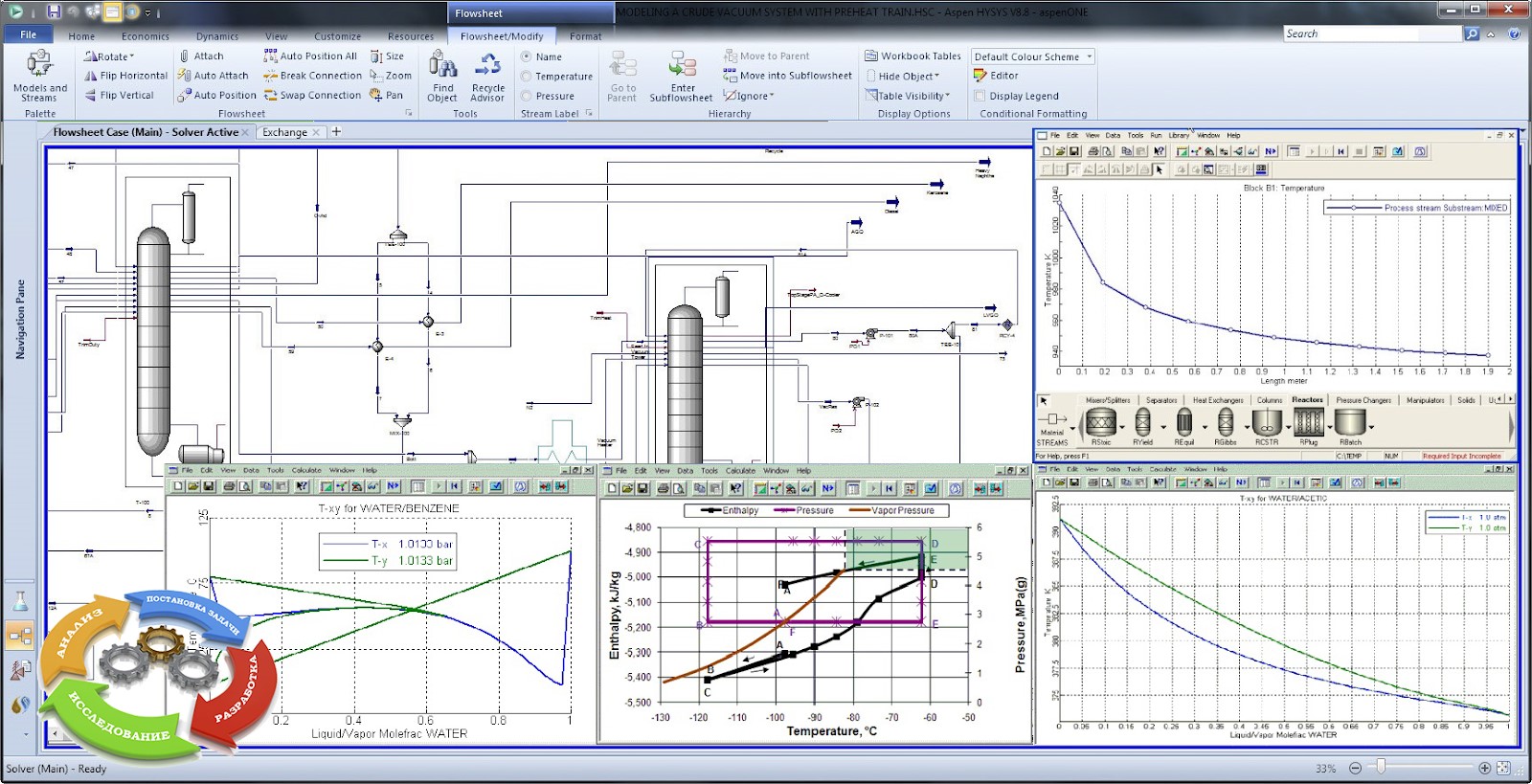

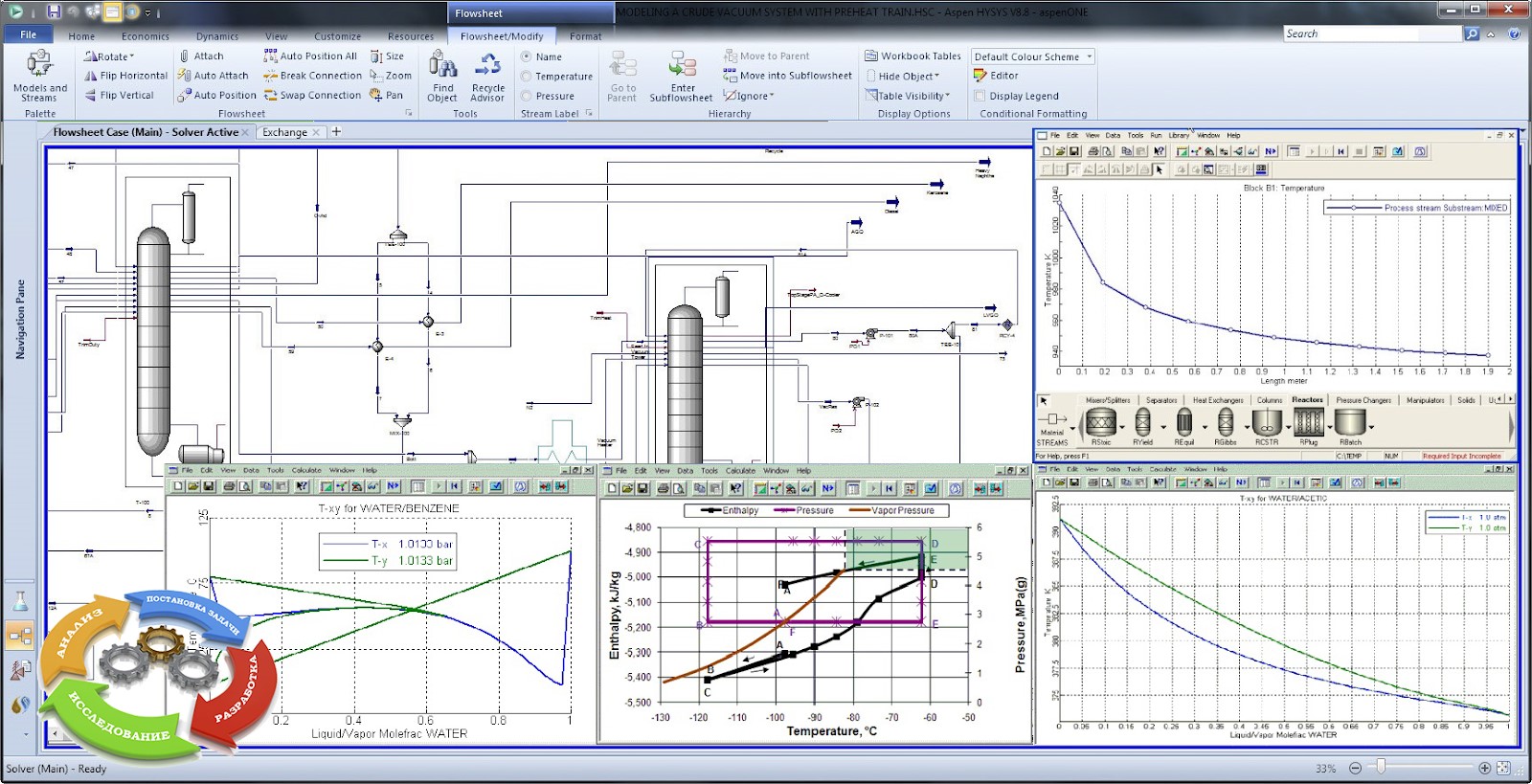

Hysys software is designed to simulate HTP to optimize the design of circuit solutions for the technological process. In addition to static modeling of technological schemes, the program allows in the same environment to produce dynamic modeling of individual processes and the entire technological chain, as well as to develop and debug control schemes of processes. It is possible to perform calculations of the main structural characteristics of the equipment.

In 2002, Hyprotech Ltd acquired Aspen Technologies. Hysys entered the AspenONE Engineering module package of the AspenONE package under the name Aspen Hysys.

The Aspen Plus software package (developed by Aspen Technologies) is designed for stationary modeling, designing chemical technology plants, equipment performance monitoring, optimization and business planning in the field of hydrocarbon production and processing and petrochemistry.

gPROMS ModelBuilder is a simulation environment for stationary and dynamic systems that is focused on applications in the process industry.

The program complex CHEMCAD is focused on the modeling of HTP. The package includes tools for static modeling of the main processes based on phase and chemical transformations, as well as tools for calculating the geometric dimensions and design characteristics of the main devices.

Design II is a software product of WinSim Inc. - has all the tools for full modeling in gas and oil refining and includes a set of 880 different components.

The PRO / II process simulation software is a stationary simulator that improves the design and operational analysis processes. The PRO / II simulator is designed for accurate mass and energy balance calculations for a wide range of manufacturing processes. Industries of application: oil refining, gas processing, petrochemistry, chemistry.

ProMax is a powerful and versatile software package for designing and optimizing gas processing, oil refining and chemical industries.

GIBBS software product has the means to simulate the process of natural gas treatment, including conventional low-temperature separation plants, low-temperature expander installations with partial or full fractionation of liquid hydrocarbons, ethane and LPG separation processes, gas treatment processes with injection, collection and regeneration of hydrate inhibitors, field and gas factory preparation and processing of gas condensate and oil, including de-ethanization, stabilization and fractionation of fuels to the gas variant, gas fractionation, liquefaction plants for natural gas, separation and purification of helium.

The “Comfort” modeling system is a tool for the verification and design calculations of the material and heat balances of various chemical plants. “Comfort” consists of a control program and modules for calculating devices. The control program with a specific set of technological modules forms a subject-oriented modeling program that allows you to perform calculations for a specific class of chemical-technological schemes. The program has the means to calculate all the major fractionation processes for gas processing.

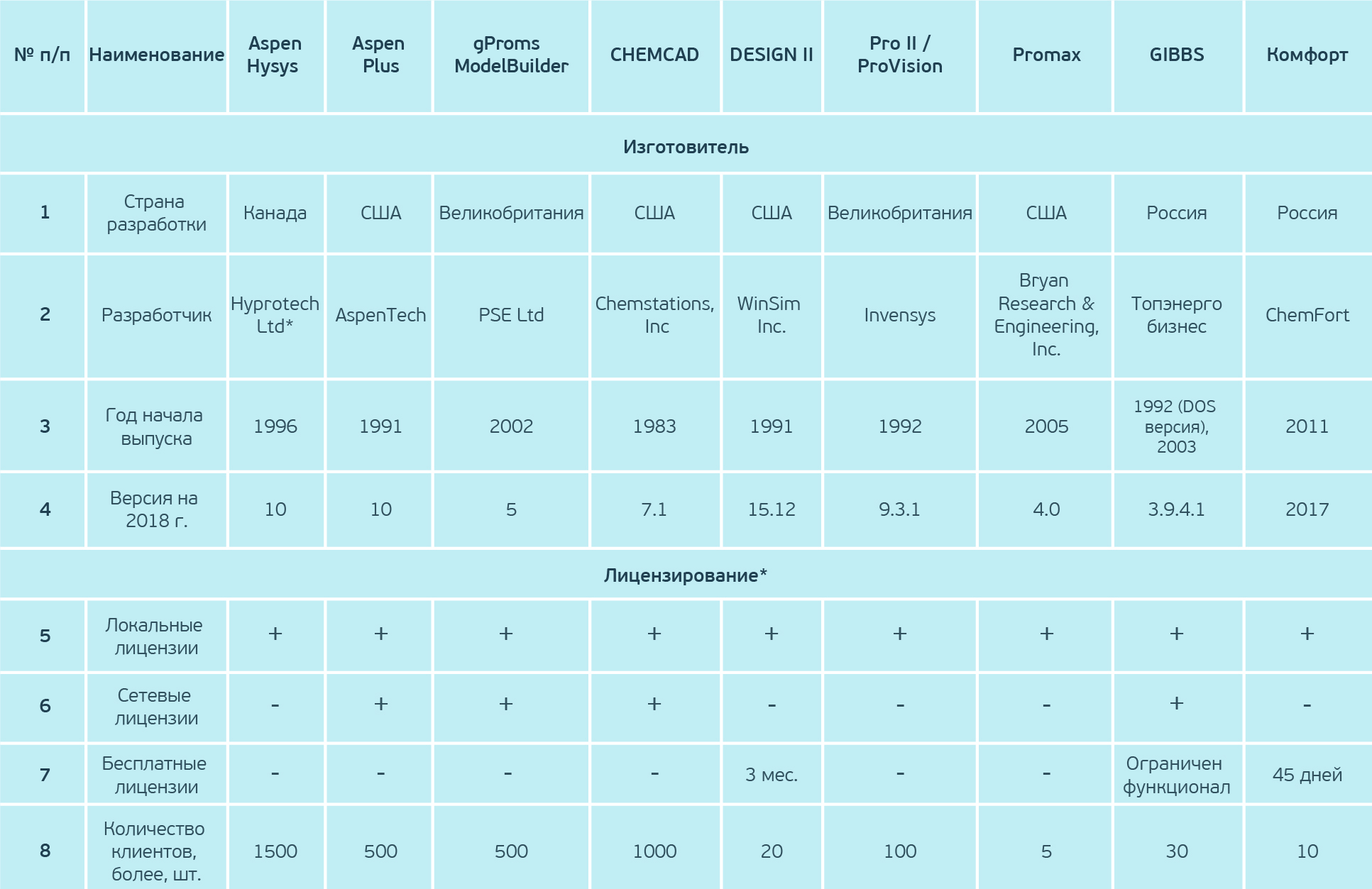

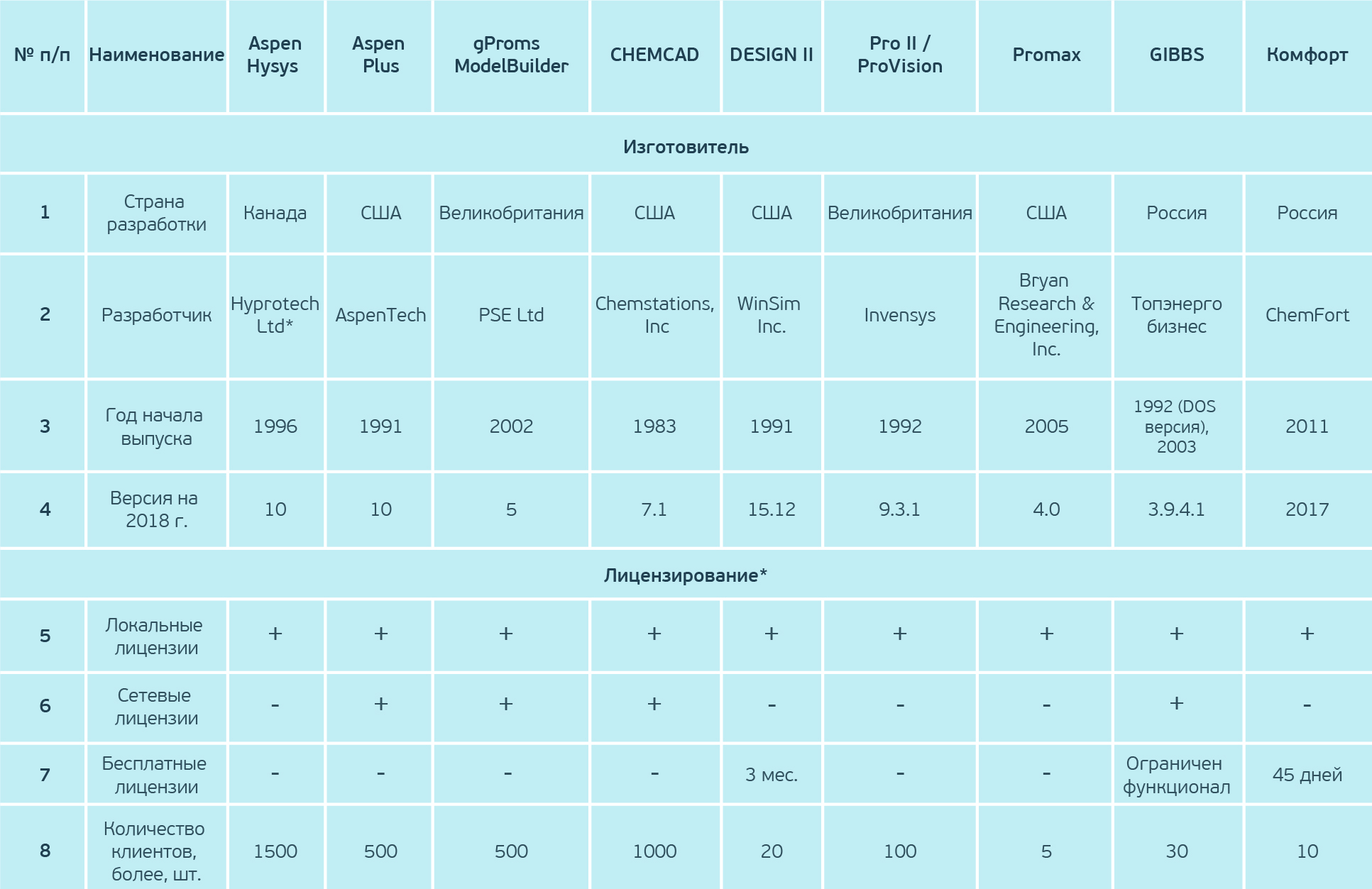

* Software systems in the table have various forms of licensing: local, network and free. A local license provides for the installation of a program on a specific computer, is authorized and works only on it. A network license is intended to install the product on several computers, but the number of simultaneous users should not exceed the number of licenses purchased. The free license is distributed for “familiarization” with software features that have temporary or functional limitations.

* Software systems in the table have various forms of licensing: local, network and free. A local license provides for the installation of a program on a specific computer, is authorized and works only on it. A network license is intended to install the product on several computers, but the number of simultaneous users should not exceed the number of licenses purchased. The free license is distributed for “familiarization” with software features that have temporary or functional limitations.

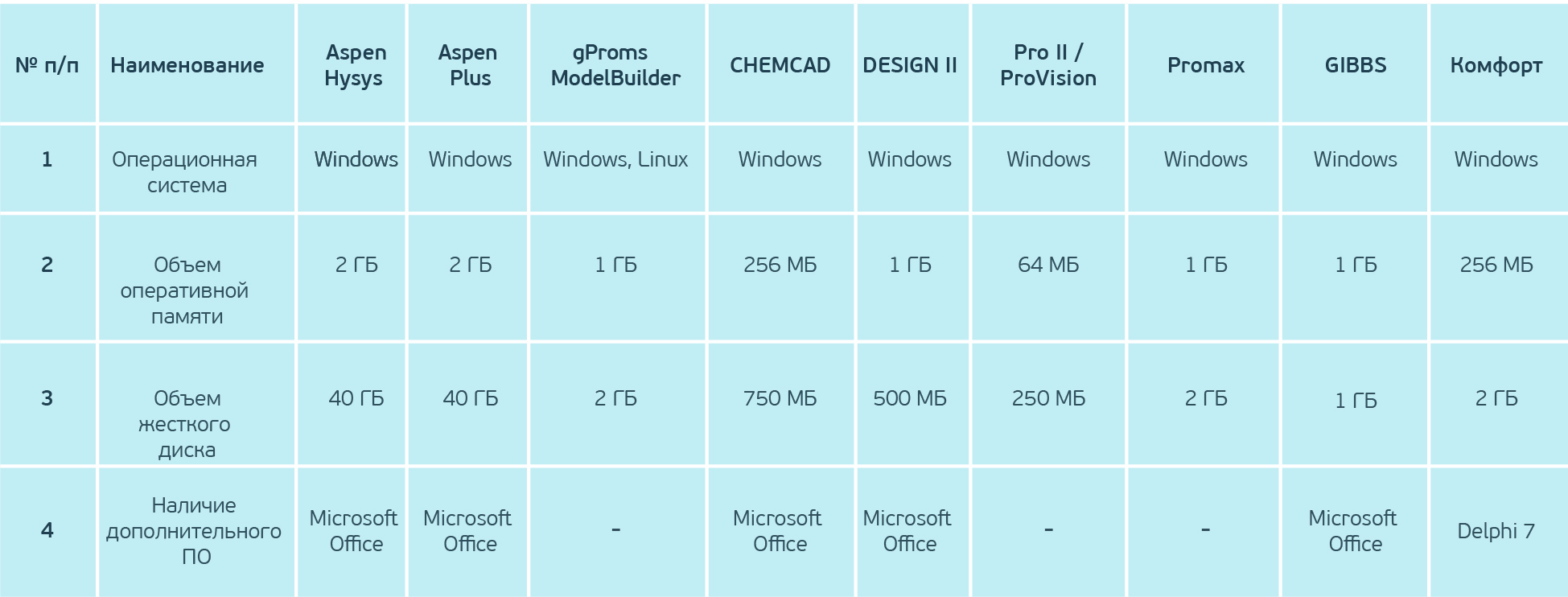

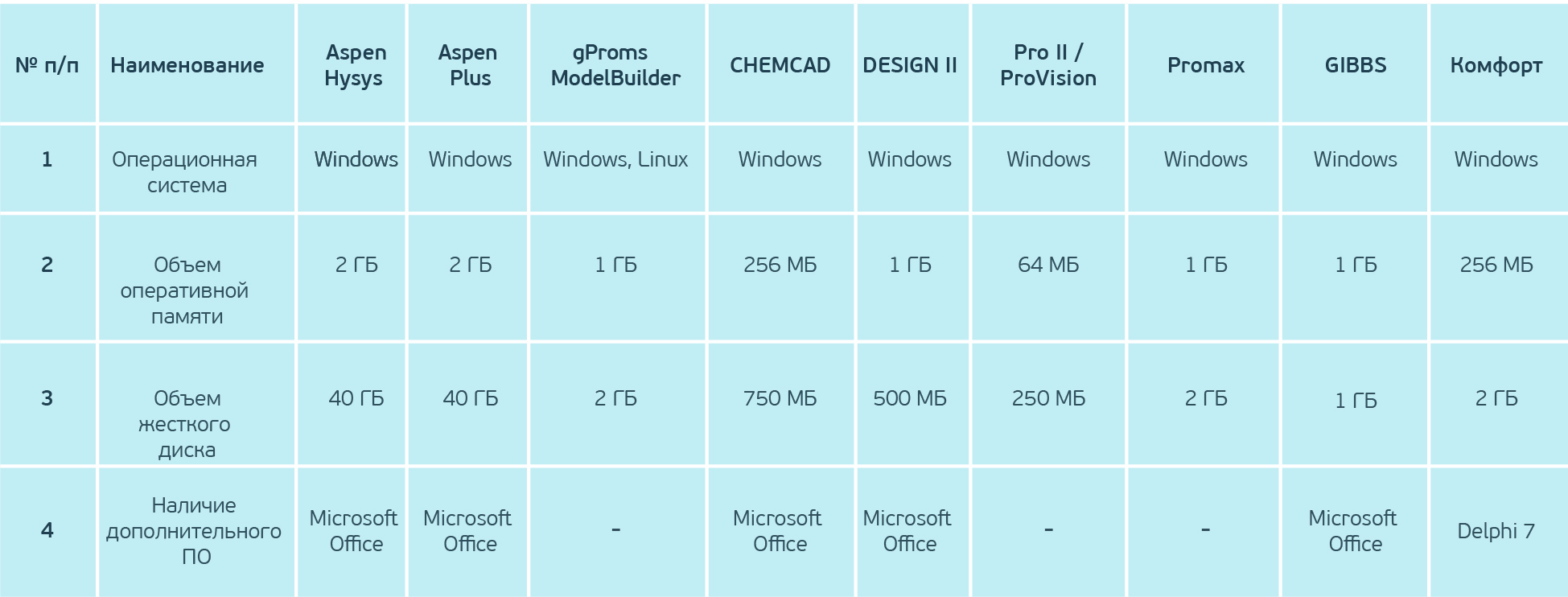

Each of the presented software products assumes the minimum system requirements for its full operation - the presence of Microsoft OS and a license.

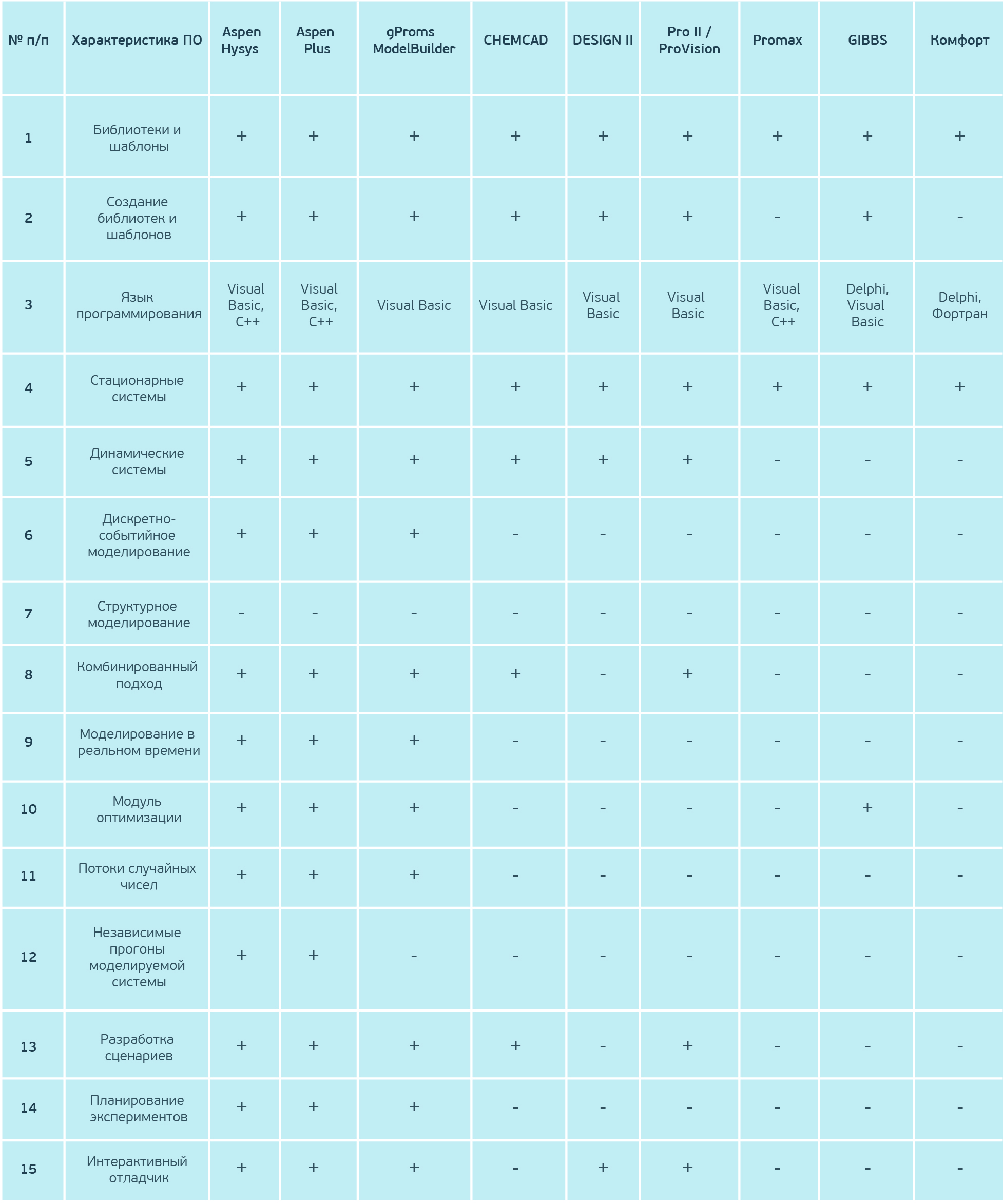

On the Russian and foreign markets, there are a lot of tools for simulation modeling of CTP with various functions and purposes. To assess the potential of the software product, several key characteristics were identified. Immediately, the limitations of software capabilities became obvious: a small functionality of interactive debuggers, a small number of typical models, the absence of structural modeling, a large error in the calculations, and others.

These restrictions require the user of the software special knowledge in the field of mathematical description of processes and programming.

The impossibility of modeling in real time and the impossibility of optimizing software taking into account various factors is a serious deterrent to its application in automatic control systems for complex and fast-flowing processes.

Software products that do not provide accurate and timely information are not very promising, which is especially important in the face of fierce competition in price / quality / quantity, energy consumption, and the efficiency of production equipment.

The structure of software products includes ready-made modules that describe technological devices, physical and chemical properties of components, allowing to simplify the construction of technical solutions of the technological process for their calculations.

If the number of modules is limited, the software will not allow to model complex technical solutions, since this requires continuous improvement of the programs.

A key feature of any software is a user-friendly graphical interface, which reduces the effort required to perform certain functions and provides the result in an intuitive way for the user. The presence in the program of such features as graphical construction, interactive debugger, documentation, allows to reduce the time for the development of schemes.

The analysis made it possible to identify the leaders within the framework of the task: in these products the functions of modeling the technological process and the optimization of the flow of processes in real time are combined.

The task is not completely solved. The software product allowed us to find some optimal conditions for current processes and identify the main critical areas in the process. In order to more deeply investigate the flow of technological processes in the heat supply system, it is necessary to develop a mathematical description of the processes in individual sections of the technological solution, as well as to find an opportunity to integrate the software product into the automatic control system.

Whatever decision you choose, based on your tasks and capabilities, in conclusion, I note: any software is designed to minimize the financial and time costs of building the CTP, but no software tool will give guaranteed results without specialists with knowledge of technology, mathematics, physics and chemistry.

Experiment vs imitation

Working with a simulation model helps, first, to more fully examine objects than during a real experiment (in practice, we basically can’t create all situations to explore the properties and behavior of an object).

And secondly, simulation modeling makes it possible to more efficiently perform research, design and optimization of the technological process: since working with the model takes into account the influence of many different parameters on the chemical-technological process (CTP), the technologist will be able to find those qualitative and quantitative characteristics that will save time and money to change the CTP, as well as reduce the likelihood of errors.

')

For example, in the fuel industry, simulation software products are used for the processing of heavy sour crude oil and oil preparation. Application in the pharmaceutical industry is designed to simulate the reaction and periodic distillations of hydrocarbons.

Leading Systems for ChTP Simulation

As part of building an automatic heat management system for an enterprise (one of its complex processes), our specialists , First Engineer, needed to investigate the technological process: analyze transients and identify critical technological areas, as well as analyze the possibilities of using a software product in the control system (to develop optimal heating system operation modes in automatic mode). So I had to study the market in search of a complete software tool. I share the results of software analysis with you. Below will be a lot of tables.

When preparing an article for Habr, I tried to contact all manufacturers of the specified software and clarify the data, because over time they could improve their products. But the answer came only from GIBBS. So I will be glad to clarify your comments.

Brief descriptions of solutions

Hysys software is designed to simulate HTP to optimize the design of circuit solutions for the technological process. In addition to static modeling of technological schemes, the program allows in the same environment to produce dynamic modeling of individual processes and the entire technological chain, as well as to develop and debug control schemes of processes. It is possible to perform calculations of the main structural characteristics of the equipment.

In 2002, Hyprotech Ltd acquired Aspen Technologies. Hysys entered the AspenONE Engineering module package of the AspenONE package under the name Aspen Hysys.

The Aspen Plus software package (developed by Aspen Technologies) is designed for stationary modeling, designing chemical technology plants, equipment performance monitoring, optimization and business planning in the field of hydrocarbon production and processing and petrochemistry.

gPROMS ModelBuilder is a simulation environment for stationary and dynamic systems that is focused on applications in the process industry.

The program complex CHEMCAD is focused on the modeling of HTP. The package includes tools for static modeling of the main processes based on phase and chemical transformations, as well as tools for calculating the geometric dimensions and design characteristics of the main devices.

Design II is a software product of WinSim Inc. - has all the tools for full modeling in gas and oil refining and includes a set of 880 different components.

The PRO / II process simulation software is a stationary simulator that improves the design and operational analysis processes. The PRO / II simulator is designed for accurate mass and energy balance calculations for a wide range of manufacturing processes. Industries of application: oil refining, gas processing, petrochemistry, chemistry.

ProMax is a powerful and versatile software package for designing and optimizing gas processing, oil refining and chemical industries.

GIBBS software product has the means to simulate the process of natural gas treatment, including conventional low-temperature separation plants, low-temperature expander installations with partial or full fractionation of liquid hydrocarbons, ethane and LPG separation processes, gas treatment processes with injection, collection and regeneration of hydrate inhibitors, field and gas factory preparation and processing of gas condensate and oil, including de-ethanization, stabilization and fractionation of fuels to the gas variant, gas fractionation, liquefaction plants for natural gas, separation and purification of helium.

The “Comfort” modeling system is a tool for the verification and design calculations of the material and heat balances of various chemical plants. “Comfort” consists of a control program and modules for calculating devices. The control program with a specific set of technological modules forms a subject-oriented modeling program that allows you to perform calculations for a specific class of chemical-technological schemes. The program has the means to calculate all the major fractionation processes for gas processing.

System requirements

Each of the presented software products assumes the minimum system requirements for its full operation - the presence of Microsoft OS and a license.

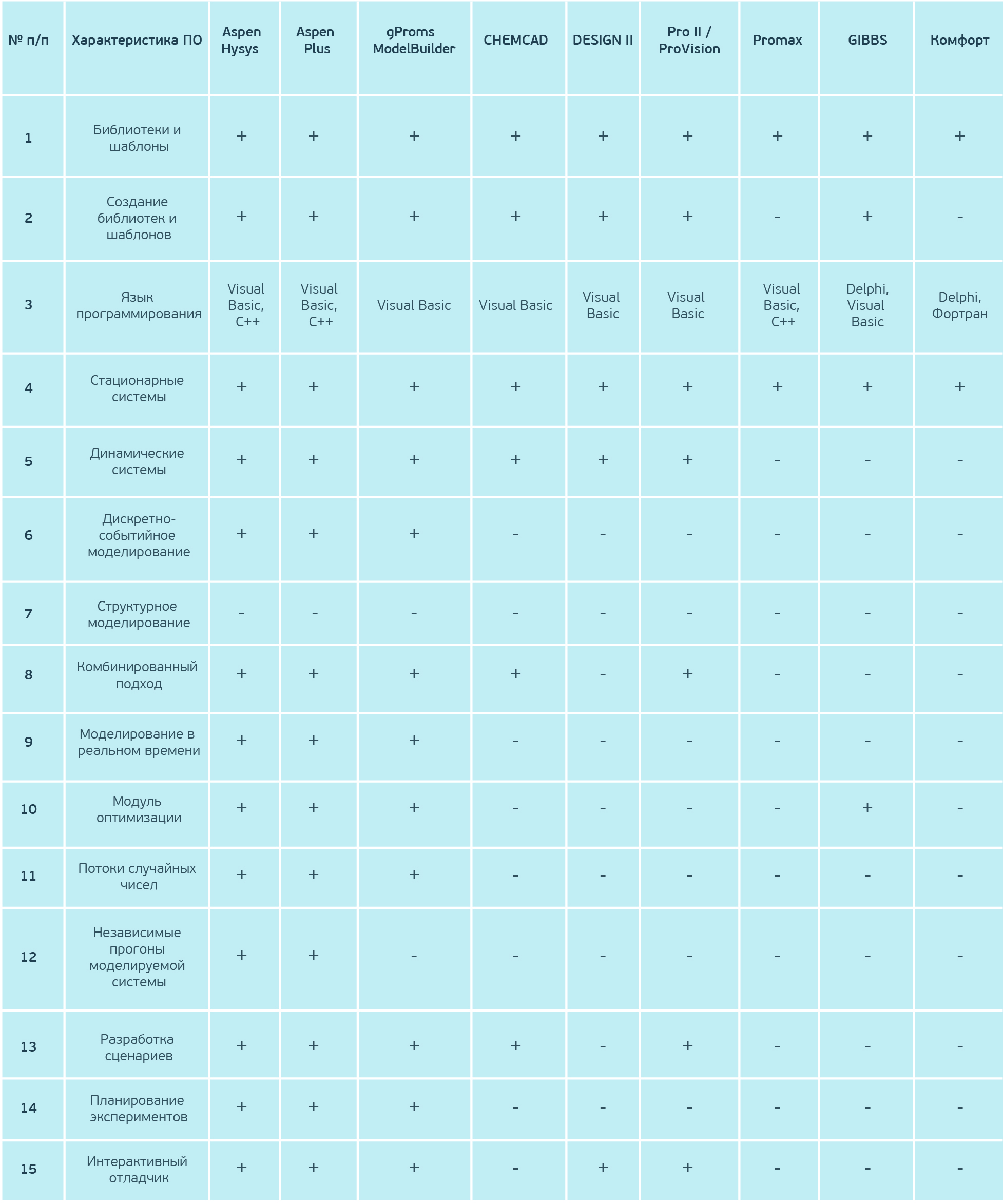

Characteristics of software systems

On the Russian and foreign markets, there are a lot of tools for simulation modeling of CTP with various functions and purposes. To assess the potential of the software product, several key characteristics were identified. Immediately, the limitations of software capabilities became obvious: a small functionality of interactive debuggers, a small number of typical models, the absence of structural modeling, a large error in the calculations, and others.

These restrictions require the user of the software special knowledge in the field of mathematical description of processes and programming.

The impossibility of modeling in real time and the impossibility of optimizing software taking into account various factors is a serious deterrent to its application in automatic control systems for complex and fast-flowing processes.

Software products that do not provide accurate and timely information are not very promising, which is especially important in the face of fierce competition in price / quality / quantity, energy consumption, and the efficiency of production equipment.

Modules in the software package

The structure of software products includes ready-made modules that describe technological devices, physical and chemical properties of components, allowing to simplify the construction of technical solutions of the technological process for their calculations.

If the number of modules is limited, the software will not allow to model complex technical solutions, since this requires continuous improvement of the programs.

Interface of software systems

A key feature of any software is a user-friendly graphical interface, which reduces the effort required to perform certain functions and provides the result in an intuitive way for the user. The presence in the program of such features as graphical construction, interactive debugger, documentation, allows to reduce the time for the development of schemes.

The analysis made it possible to identify the leaders within the framework of the task: in these products the functions of modeling the technological process and the optimization of the flow of processes in real time are combined.

The task is not completely solved. The software product allowed us to find some optimal conditions for current processes and identify the main critical areas in the process. In order to more deeply investigate the flow of technological processes in the heat supply system, it is necessary to develop a mathematical description of the processes in individual sections of the technological solution, as well as to find an opportunity to integrate the software product into the automatic control system.

Whatever decision you choose, based on your tasks and capabilities, in conclusion, I note: any software is designed to minimize the financial and time costs of building the CTP, but no software tool will give guaranteed results without specialists with knowledge of technology, mathematics, physics and chemistry.

Source: https://habr.com/ru/post/351870/

All Articles