Battery change: UPS on Li-Ion technology

Rechargeable batteries (battery) - a vulnerable link in many uninterruptible power systems data center. The problems are a lot of weight, requiring reinforcement of the supporting structures of the rooms where such batteries are placed, a strong dependence of their characteristics on temperature, which forces the use of air conditioning, fragility - a quick failure leads to frequent replacement with corresponding costs. All this applies to traditional, lead-acid batteries, which currently dominate the projects.

Specialists have hoped for a new generation of batteries, primarily for lithium-ion, which are devoid of many of the disadvantages of lead-acid batteries and have excellent prospects for use in various fields, including industry, communication systems, data centers, etc.

Over the past few years, prices for lithium-ion batteries have declined significantly, making them gradually becoming an expedient choice for use as a UPS for a data center. Analysis of the total cost of ownership over 10 years shows that lithium-ion batteries have a 39% lower TCO than traditional lead-acid batteries with a control valve (VRLA), despite the initial price difference.

Lithium-ion batteries (Li-Ion) have been used in various devices for more than two decades, however, they began to be used as UPS batteries for data centers relatively recently, when balanced price, specific energy, power, safety and reliability were achieved. The development of lithium-ion technology was largely stimulated by the needs of the electric vehicle industry.

')

Industrial lithium-ion batteries differ from those used in consumer devices, where LCO (lithium-cobalt) batteries with a capacity of several ampere-hours in a foil case are most commonly used. In the UPS, batteries with an internal LMO structure (lithium-manganese) with a capacity of one battery of more than 60 Ah in a durable aluminum case are installed. Batteries of this type have long been successfully used in electric vehicles.

In this battery, there are several stages of protection against adverse situations. It takes several years to develop and run-in such technologies, while batteries for consumer devices are brought to the market in a few months.

UPS devices require batteries capable of providing more power for 5-10 minutes, that is, supplying a large current for a short period of time, while maintaining the safe temperature of each element. Lithium-ion batteries are characterized by high power per unit of weight - specific energy (Wh / h / kg) and specific power (W / kg).

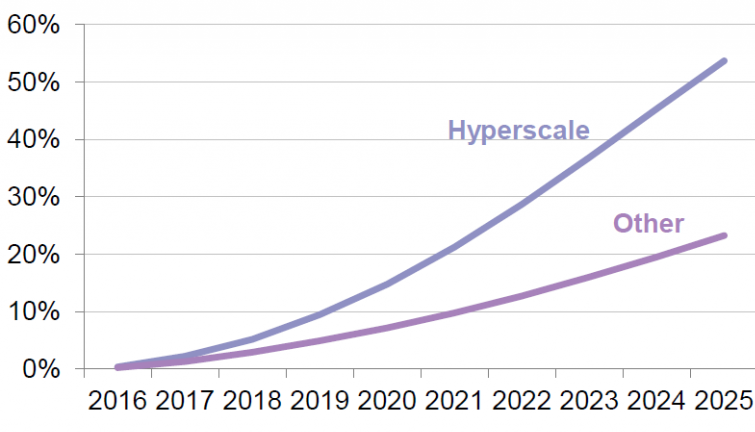

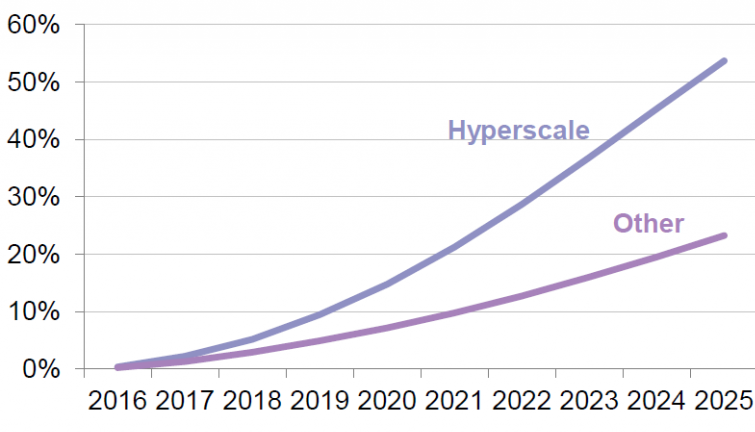

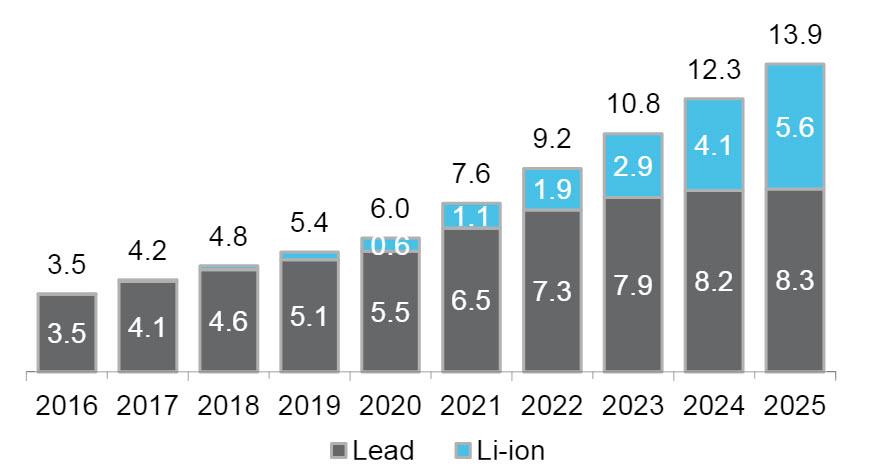

Growth in demand for central data center power redundancy in North America and Europe in 2016-2025, according to a Bloomberg New Energy Finance report. It is expected that by 2025 about 55% of the reserved capacity will be concentrated in the largest data processing centers (hyperscale).

Currently, lithium-ion batteries have, perhaps, only one serious drawback compared to lead-acid batteries with a control valve: capital expenditures for the same amount of energy are two to three times more due to the higher manufacturing cost and cost of the battery management system . But they have a lot of advantages.

We list the advantages of lithium-ion batteries over traditional lead-acid batteries with an adjustable valve (Valve-Regulated Lead-Acid, VRLA) in terms of application in UPS:

However, it is perhaps too early to talk about switching from traditional lead-acid batteries to lithium-ion batteries as a trend in the field of uninterruptible power supply systems. This is just one of the alternatives, but it is quickly gaining popularity.

According to IMS Research, already in 2016, the share of systems using lithium-ion batteries accounted for slightly less than 10% of sales. According to experts, in the next few years, about 30% of all UPSs will be equipped with lithium-ion batteries.

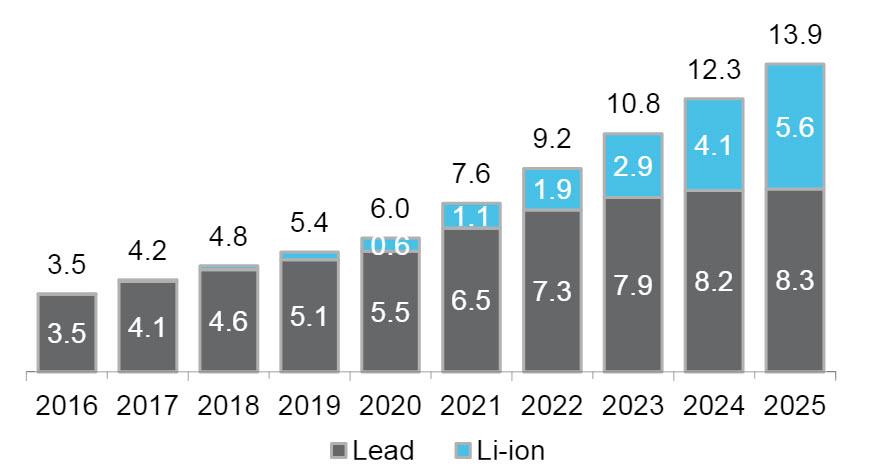

According to the Bloomberg New Energy Finance report , in 2025, lithium-ion batteries will account for 5.6 GWh of redundant data center capacities, compared to 8.3 GWh of traditional VRLA technology. This means that lithium-ion technology will conquer 40% of the market in just 8 years.

Among the first such solutions for their UPS offered the company Schneider Electric, collaborating with Samsung. Lithium-ion batteries are used in its Galaxy 7000, VM, VX and Symmetra MW UPSs. Since 2016, she launched such solutions in the series.

Samsung lithium-ion batteries. Samsung SDI, a leader in the global market for batteries used in uninterruptible power supplies (UPS), relied specifically on lithium-ion solutions.

Schneider Electric systems have already been installed at more than 20 facilities with a total capacity of over 10 MW * h. Interestingly, lithium-ion UPSs are used in projects of various sizes - from large companies, including colocation / hosting service providers and companies from the financial services segment with enterprise-level data centers to industrial applications and server rooms. Obviously, the technology is applicable to a wide range of scenarios.

Comparison of Galaxy 7000 UPS with Li-Ion and VRLA batteries (Schneider Electric data).

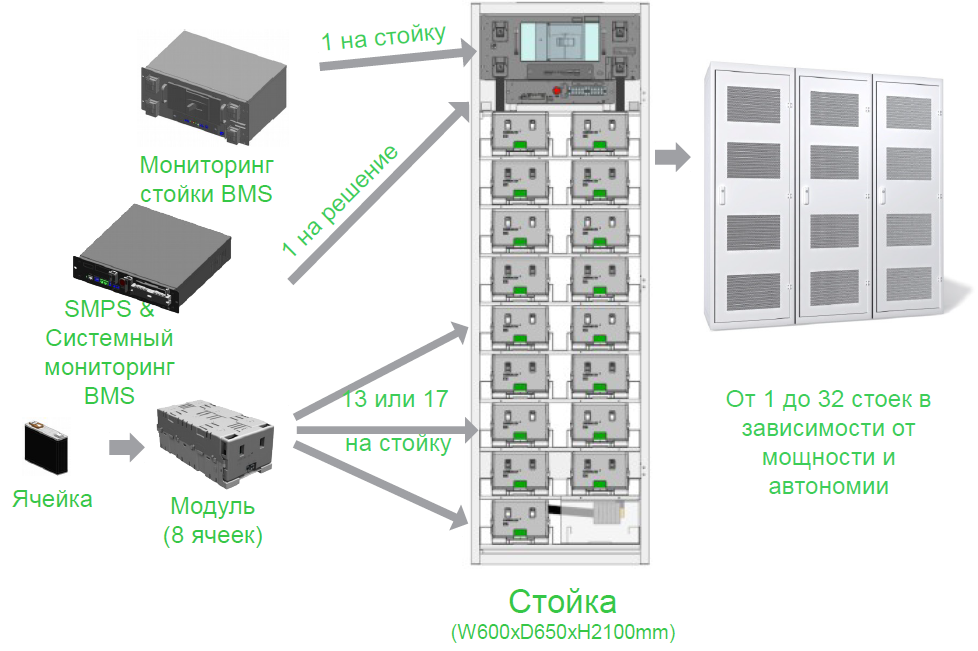

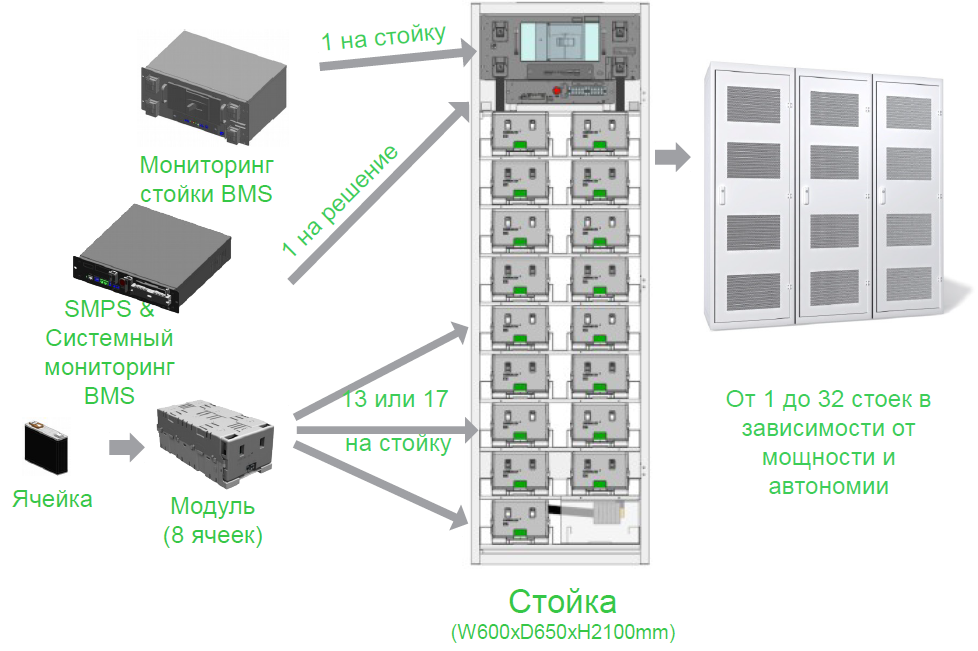

The new solution from Schneider Electric meets such battery requirements for UPS as security (full monitoring), high power density (up to 35 kWh / h and up to 230 kW per rack), long autonomous operation (within 5-30 minutes) and long service life (15 years). Schneider Electric UPSs use a three-level monitoring system: at the level of an individual module, cabinet and system.

Li-ion batteries in a modular solution from Schneider Electric.

Currently, 30% of the supply of batteries for UPS is provided by Samsung. It supplies the lithium-ion batteries to the three largest UPS manufacturers: Schneider Electric, Vertiv and Eaton, which control more than half of the global UPS market.

The new Eaton 1500VA UPS doubles battery life compared to a conventional UPS. Thanks to the new Li-Ion technology, customers can expect a significant reduction in the total cost of ownership of the energy infrastructure, say developers.

So, due to the higher energy consumption, lithium-ion batteries not only occupy less space, but also have a lower weight compared to lead-acid batteries - the cost of transportation is reduced. However, the regulatory requirements for transportation of lithium-ion batteries are more stringent due to the high energy intensity and activity of some chemical components.

Resource lead-acid batteries with a control valve - 3-6 years, while the resource lithium-ion can be more than 10 years. Replacing batteries is a serious additional cost and even stopping the data center if its power supply scheme does not provide redundancy or additional work during which the reliability of the data center power is reduced. Obsolete batteries must be removed and disposed of, and new ones must be installed to replace them. All this takes time and money. The use of lithium-ion batteries eliminates such problems and costs.

The fast recharge rate and longer service life of the lithium-ion battery is due to both its technology and the presence of an obligatory monitoring system. It monitors the state of each battery cell (temperature, voltage, current) and the entire cabinet. The monitoring system of lithium-ion batteries is equipped by default, since they require full control of charging and discharging, which prevents the temperature in lithium-ion cells from overheating.

Lithium-ion batteries and lead-acid batteries: some key differences.

Since lithium-ion batteries offer improved control capabilities, including integrated controls at the cell, module, and cabinet levels, this results in predictable, stable performance and battery safety. Reduced cooling requirements in the data center: Lithium-ion batteries take up less space and, unlike traditional VLRA batteries, can operate at higher temperatures without sacrificing battery life.

All of these benefits help reduce costs, resulting in lower total cost of ownership of lithium-ion UPSs over time compared to VLRA. That is why data center owners pay attention to lithium-ion technology.

For lithium-ion batteries, certain chemical solutions and power cell technologies provide an attractive total cost of ownership for a period of more than 10-15 years - the typical lifetime of the UPS. According to Schneider Electric, the total cost of ownership for 10 years for a solution with a lithium-ion battery is almost 40% lower than for a solution with a lead-acid battery with a control valve. Its payback period is 3.4 years, despite the higher capital costs of lithium-ion batteries.

TradeOff Tool , a calculator for comparing lithium-ion batteries with lead-acid batteries, allows you to change various source data and see what effect they have on the total cost of ownership of two types of batteries.

When choosing lithium-ion batteries for a UPS device, it is important to consider several factors depending on whether you are re-equipping an existing UPS or buying a new one. It is assumed that the expected lifetime of the UPS is about 10–15 years, the life of the lead-acid battery with a control valve is about 3–6 years, and the life of the lithium-ion battery is 10 years or more. There are three possible scenarios for retrofitting a lead-acid battery UPS: the beginning, middle or end of the life of the UPS. Here are the recommendations given by Schneider Electric.

At the beginning of the life of the UPS (usually less than 5 years), it may make sense to replace the lead-acid batteries with lithium-ion batteries, since they are very likely to reach the end of their lifetimes simultaneously with the UPS.

In the middle of the life of the replacement of batteries for lithium-ion may not make sense from an economic point of view, because The lifetime of lithium-ion batteries will exceed the remaining lifespan of the UPS by more than 5 years. However, given the decline in prices for lithium-ion batteries, economic factors can still play in favor of replacement.

When approaching the end of the life of the UPS (more than 10 years) it may make sense to completely replace the UPS with a new one that uses lithium-ion batteries. This decision depends on the ratio of the cost of maintaining and maintaining the old UPS (i.e. service contracts, parts, etc.) and the cost of the new system.

Even if the lithium-ion battery has the same nominal voltage as the existing lead-acid battery, it may be necessary to update the software and the hardware of the UPS. This, among other things, is due to the fact that the battery charging characteristics may change, the formula for the duration of operation may differ, and the estimate of the operating time may be incorrect. In addition, the supplier may need to integrate the battery monitoring system into the UPS.

For example, you can embed lithium-ion batteries in an already purchased Galaxy 7000 solution. You will need to update the firmware of the control module in the UPS and replace some boards.

Buying a new UPS is the simplest scenario, provided that the supplier has effectively integrated lithium-ion technology into the UPS. The integration of the UPS and the lithium-ion battery management system greatly depends on the operation of this system.

Schneider Electric Galaxy VM UPSs, equipped with lithium-ion batteries. Such batteries allow minimizing operating costs due to a large number (up to 5000) charge-discharge cycles and a service life extended to 15 years. They can be used with other Schneider Electric UPSs, including the Galaxy VX from 500 to 1500 kW.

The use of lithium-ion batteries will be very good help in reducing operating costs for uninterruptible power systems. Meanwhile, there remains a significant part of the market, which will continue to use VRLA technology, and the technology of lead-acid batteries is also being improved.

Vertiv, previously Emerson Network Power, has announced the completion of a line of uninterruptible power systems compatible with lithium-ion batteries. UPS Liebert EXM 480V (50-250 kW / kVA) with lithium-ion batteries extend the storage of energy in a medium-sized data center.

However, lithium-ion systems will become even more widely used in large data centers, such as those owned by Internet giants such as Amazon, Facebook and Google, where even a small gain in energy consumption and space efficiency means huge savings.

For those who want to minimize capital costs, lithium-ion batteries will not work, since they are more expensive than lead-acid batteries by about 15% (for a typical UPS). But it is safe to say that the prices of lithium-ion batteries will continue to decline, new chemical solutions and technologies will appear on the market, and existing ones will be improved. Despite the fact that the prices of some lithium-ion solutions are still too high to switch to them from lead-acid batteries with a control valve, they have an attractive total cost of ownership over 10 years with a payback period of less than 4 years. If we take into account operating expenses, then their choice may be fully justified.

Specialists have hoped for a new generation of batteries, primarily for lithium-ion, which are devoid of many of the disadvantages of lead-acid batteries and have excellent prospects for use in various fields, including industry, communication systems, data centers, etc.

Over the past few years, prices for lithium-ion batteries have declined significantly, making them gradually becoming an expedient choice for use as a UPS for a data center. Analysis of the total cost of ownership over 10 years shows that lithium-ion batteries have a 39% lower TCO than traditional lead-acid batteries with a control valve (VRLA), despite the initial price difference.

Li-Ion in the UPS

Lithium-ion batteries (Li-Ion) have been used in various devices for more than two decades, however, they began to be used as UPS batteries for data centers relatively recently, when balanced price, specific energy, power, safety and reliability were achieved. The development of lithium-ion technology was largely stimulated by the needs of the electric vehicle industry.

')

Industrial lithium-ion batteries differ from those used in consumer devices, where LCO (lithium-cobalt) batteries with a capacity of several ampere-hours in a foil case are most commonly used. In the UPS, batteries with an internal LMO structure (lithium-manganese) with a capacity of one battery of more than 60 Ah in a durable aluminum case are installed. Batteries of this type have long been successfully used in electric vehicles.

In this battery, there are several stages of protection against adverse situations. It takes several years to develop and run-in such technologies, while batteries for consumer devices are brought to the market in a few months.

UPS devices require batteries capable of providing more power for 5-10 minutes, that is, supplying a large current for a short period of time, while maintaining the safe temperature of each element. Lithium-ion batteries are characterized by high power per unit of weight - specific energy (Wh / h / kg) and specific power (W / kg).

Growth in demand for central data center power redundancy in North America and Europe in 2016-2025, according to a Bloomberg New Energy Finance report. It is expected that by 2025 about 55% of the reserved capacity will be concentrated in the largest data processing centers (hyperscale).

Currently, lithium-ion batteries have, perhaps, only one serious drawback compared to lead-acid batteries with a control valve: capital expenditures for the same amount of energy are two to three times more due to the higher manufacturing cost and cost of the battery management system . But they have a lot of advantages.

The advantages of lithium-ion batteries

We list the advantages of lithium-ion batteries over traditional lead-acid batteries with an adjustable valve (Valve-Regulated Lead-Acid, VRLA) in terms of application in UPS:

- Three times less weight with similar stored energy. The system of lithium-ion batteries for UPS weighs 60–80% less than a comparable lead-acid system.

- Compactness typical of lithium-ion batteries. They occupy up to 50-80% less area.

- High specific energy. Specific energy indicators for lithium batteries available today are from 70 kWh / kg to 260 kWh / kg. Typical lead-acid batteries are in the range of 30-50 kWh / kg.

- Approximately four times less self-discharge (i.e. slow discharge of the battery when not in use) - 1-2% per month.

- Significantly faster charge - four or more times, and this is a key advantage in case of numerous interruptions in the supply of energy (from 30 minutes to one hour).

- Long service life. Up to ten times more charge-discharge cycles, depending on the chemistry, technology, temperature and depth of the discharge. Some modern lithium-ion batteries can withstand up to 5,000 cycles.

- Fewer (or no) battery replacement is required during the life of the UPS, eliminating the risk of downtime due to battery replacement.

- Lithium-ion batteries require no maintenance.

- Savings on TCO for 10 years is 10-40%.

However, it is perhaps too early to talk about switching from traditional lead-acid batteries to lithium-ion batteries as a trend in the field of uninterruptible power supply systems. This is just one of the alternatives, but it is quickly gaining popularity.

According to IMS Research, already in 2016, the share of systems using lithium-ion batteries accounted for slightly less than 10% of sales. According to experts, in the next few years, about 30% of all UPSs will be equipped with lithium-ion batteries.

According to the Bloomberg New Energy Finance report , in 2025, lithium-ion batteries will account for 5.6 GWh of redundant data center capacities, compared to 8.3 GWh of traditional VRLA technology. This means that lithium-ion technology will conquer 40% of the market in just 8 years.

Among the first such solutions for their UPS offered the company Schneider Electric, collaborating with Samsung. Lithium-ion batteries are used in its Galaxy 7000, VM, VX and Symmetra MW UPSs. Since 2016, she launched such solutions in the series.

Samsung lithium-ion batteries. Samsung SDI, a leader in the global market for batteries used in uninterruptible power supplies (UPS), relied specifically on lithium-ion solutions.

Schneider Electric systems have already been installed at more than 20 facilities with a total capacity of over 10 MW * h. Interestingly, lithium-ion UPSs are used in projects of various sizes - from large companies, including colocation / hosting service providers and companies from the financial services segment with enterprise-level data centers to industrial applications and server rooms. Obviously, the technology is applicable to a wide range of scenarios.

Comparison of Galaxy 7000 UPS with Li-Ion and VRLA batteries (Schneider Electric data).

The new solution from Schneider Electric meets such battery requirements for UPS as security (full monitoring), high power density (up to 35 kWh / h and up to 230 kW per rack), long autonomous operation (within 5-30 minutes) and long service life (15 years). Schneider Electric UPSs use a three-level monitoring system: at the level of an individual module, cabinet and system.

Li-ion batteries in a modular solution from Schneider Electric.

Currently, 30% of the supply of batteries for UPS is provided by Samsung. It supplies the lithium-ion batteries to the three largest UPS manufacturers: Schneider Electric, Vertiv and Eaton, which control more than half of the global UPS market.

The new Eaton 1500VA UPS doubles battery life compared to a conventional UPS. Thanks to the new Li-Ion technology, customers can expect a significant reduction in the total cost of ownership of the energy infrastructure, say developers.

Lead-acid vs Li-Ion batteries

So, due to the higher energy consumption, lithium-ion batteries not only occupy less space, but also have a lower weight compared to lead-acid batteries - the cost of transportation is reduced. However, the regulatory requirements for transportation of lithium-ion batteries are more stringent due to the high energy intensity and activity of some chemical components.

Resource lead-acid batteries with a control valve - 3-6 years, while the resource lithium-ion can be more than 10 years. Replacing batteries is a serious additional cost and even stopping the data center if its power supply scheme does not provide redundancy or additional work during which the reliability of the data center power is reduced. Obsolete batteries must be removed and disposed of, and new ones must be installed to replace them. All this takes time and money. The use of lithium-ion batteries eliminates such problems and costs.

The fast recharge rate and longer service life of the lithium-ion battery is due to both its technology and the presence of an obligatory monitoring system. It monitors the state of each battery cell (temperature, voltage, current) and the entire cabinet. The monitoring system of lithium-ion batteries is equipped by default, since they require full control of charging and discharging, which prevents the temperature in lithium-ion cells from overheating.

Lithium-ion batteries and lead-acid batteries: some key differences.

Since lithium-ion batteries offer improved control capabilities, including integrated controls at the cell, module, and cabinet levels, this results in predictable, stable performance and battery safety. Reduced cooling requirements in the data center: Lithium-ion batteries take up less space and, unlike traditional VLRA batteries, can operate at higher temperatures without sacrificing battery life.

All of these benefits help reduce costs, resulting in lower total cost of ownership of lithium-ion UPSs over time compared to VLRA. That is why data center owners pay attention to lithium-ion technology.

For lithium-ion batteries, certain chemical solutions and power cell technologies provide an attractive total cost of ownership for a period of more than 10-15 years - the typical lifetime of the UPS. According to Schneider Electric, the total cost of ownership for 10 years for a solution with a lithium-ion battery is almost 40% lower than for a solution with a lead-acid battery with a control valve. Its payback period is 3.4 years, despite the higher capital costs of lithium-ion batteries.

TradeOff Tool , a calculator for comparing lithium-ion batteries with lead-acid batteries, allows you to change various source data and see what effect they have on the total cost of ownership of two types of batteries.

Change or not?

When choosing lithium-ion batteries for a UPS device, it is important to consider several factors depending on whether you are re-equipping an existing UPS or buying a new one. It is assumed that the expected lifetime of the UPS is about 10–15 years, the life of the lead-acid battery with a control valve is about 3–6 years, and the life of the lithium-ion battery is 10 years or more. There are three possible scenarios for retrofitting a lead-acid battery UPS: the beginning, middle or end of the life of the UPS. Here are the recommendations given by Schneider Electric.

At the beginning of the life of the UPS (usually less than 5 years), it may make sense to replace the lead-acid batteries with lithium-ion batteries, since they are very likely to reach the end of their lifetimes simultaneously with the UPS.

In the middle of the life of the replacement of batteries for lithium-ion may not make sense from an economic point of view, because The lifetime of lithium-ion batteries will exceed the remaining lifespan of the UPS by more than 5 years. However, given the decline in prices for lithium-ion batteries, economic factors can still play in favor of replacement.

When approaching the end of the life of the UPS (more than 10 years) it may make sense to completely replace the UPS with a new one that uses lithium-ion batteries. This decision depends on the ratio of the cost of maintaining and maintaining the old UPS (i.e. service contracts, parts, etc.) and the cost of the new system.

Even if the lithium-ion battery has the same nominal voltage as the existing lead-acid battery, it may be necessary to update the software and the hardware of the UPS. This, among other things, is due to the fact that the battery charging characteristics may change, the formula for the duration of operation may differ, and the estimate of the operating time may be incorrect. In addition, the supplier may need to integrate the battery monitoring system into the UPS.

For example, you can embed lithium-ion batteries in an already purchased Galaxy 7000 solution. You will need to update the firmware of the control module in the UPS and replace some boards.

Buying a new UPS is the simplest scenario, provided that the supplier has effectively integrated lithium-ion technology into the UPS. The integration of the UPS and the lithium-ion battery management system greatly depends on the operation of this system.

Schneider Electric Galaxy VM UPSs, equipped with lithium-ion batteries. Such batteries allow minimizing operating costs due to a large number (up to 5000) charge-discharge cycles and a service life extended to 15 years. They can be used with other Schneider Electric UPSs, including the Galaxy VX from 500 to 1500 kW.

The use of lithium-ion batteries will be very good help in reducing operating costs for uninterruptible power systems. Meanwhile, there remains a significant part of the market, which will continue to use VRLA technology, and the technology of lead-acid batteries is also being improved.

Vertiv, previously Emerson Network Power, has announced the completion of a line of uninterruptible power systems compatible with lithium-ion batteries. UPS Liebert EXM 480V (50-250 kW / kVA) with lithium-ion batteries extend the storage of energy in a medium-sized data center.

However, lithium-ion systems will become even more widely used in large data centers, such as those owned by Internet giants such as Amazon, Facebook and Google, where even a small gain in energy consumption and space efficiency means huge savings.

findings

For those who want to minimize capital costs, lithium-ion batteries will not work, since they are more expensive than lead-acid batteries by about 15% (for a typical UPS). But it is safe to say that the prices of lithium-ion batteries will continue to decline, new chemical solutions and technologies will appear on the market, and existing ones will be improved. Despite the fact that the prices of some lithium-ion solutions are still too high to switch to them from lead-acid batteries with a control valve, they have an attractive total cost of ownership over 10 years with a payback period of less than 4 years. If we take into account operating expenses, then their choice may be fully justified.

Source: https://habr.com/ru/post/351140/

All Articles