Germicidal emitters for smartphones. Prospects for the integration of these systems in gadgets

Mankind has long learned to fight unwanted microorganisms using elevated temperatures or disinfectants. However, all these methods are not always possible to apply. In addition, their effectiveness is limited. This is especially true of our technology - an infinite number of smart devices, on which, as on everything that exists in our real world, invisible, but all harmless creatures accumulate. But the way out of this situation suggests itself.

There are also ultraviolet germicidal emitters that are more effective and versatile in use. But until now, all our equipment does not have built-in disinfection methods. And this is against the background of dozens of studies that bring to us the importance of regularly cleaning the screens of our gadgets from uninvited “guests”. I will describe my vision of an integrated bactericidal system (we will call it: IntBas) for a smartphone - the most favorite for our hands on the device. First of all, we need to determine how this structure can be implemented.

1. First look at your face - the front of any smartphone / other device. This is where the screen is located - the component most often used by our hands. What to do with it so that it ceases to be a hub of harmful bacteria. It is obvious that the most adequate will be to introduce ultraviolet LEDs with a certain long wavelength (we will talk about this later) than to invent a bicycle again.

2. The main task is to arrange a conventional line of such LEDs in the most rational way, in relation to the contact zone. Embedding in the screen itself meaning no more than zero, under the screen - in the most common on the market IPS-matrices is impossible. Against the background of this recent news about the built-in fingerprint sensor in the OLED-matrix, this solution may suggest, but so far there is no point in talking about it. And most of the effect will be lost in the subscreen area, which does not make sense at all. While the matrices of modern displays are made using current technologies, there is no point in talking about this method.

')

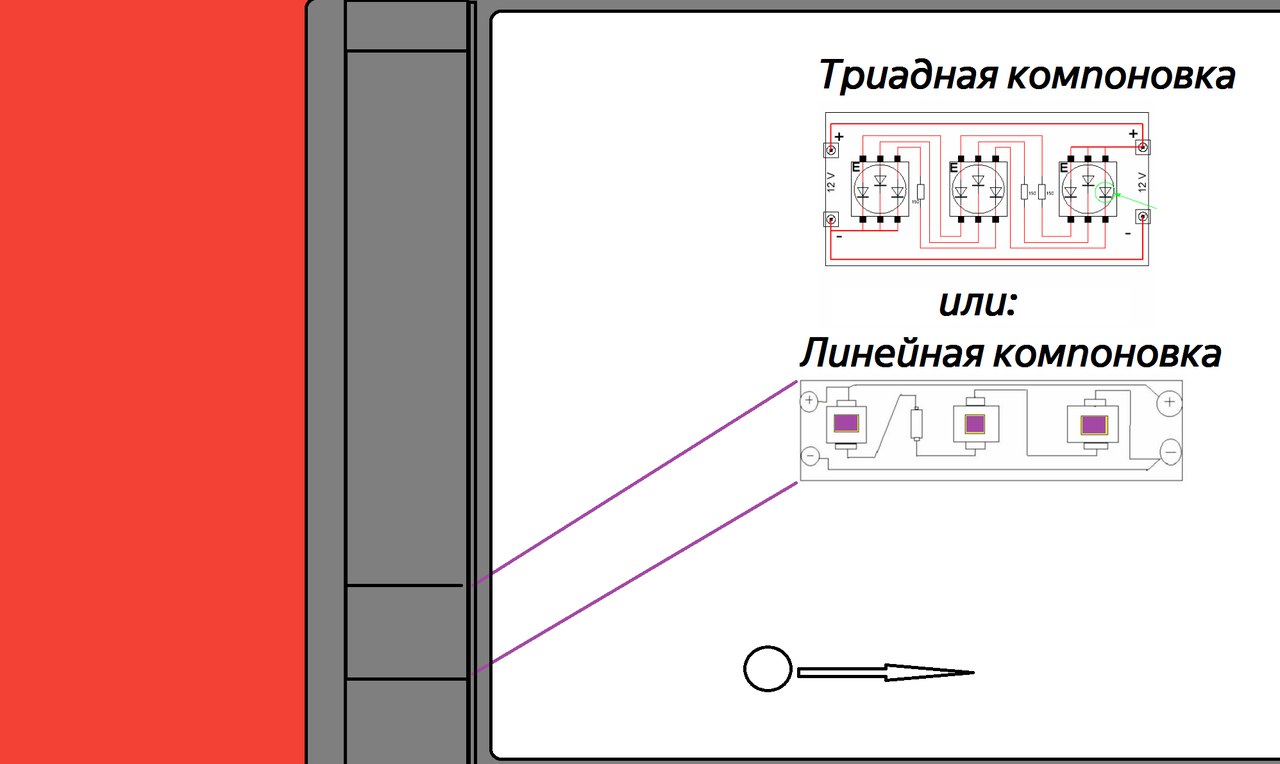

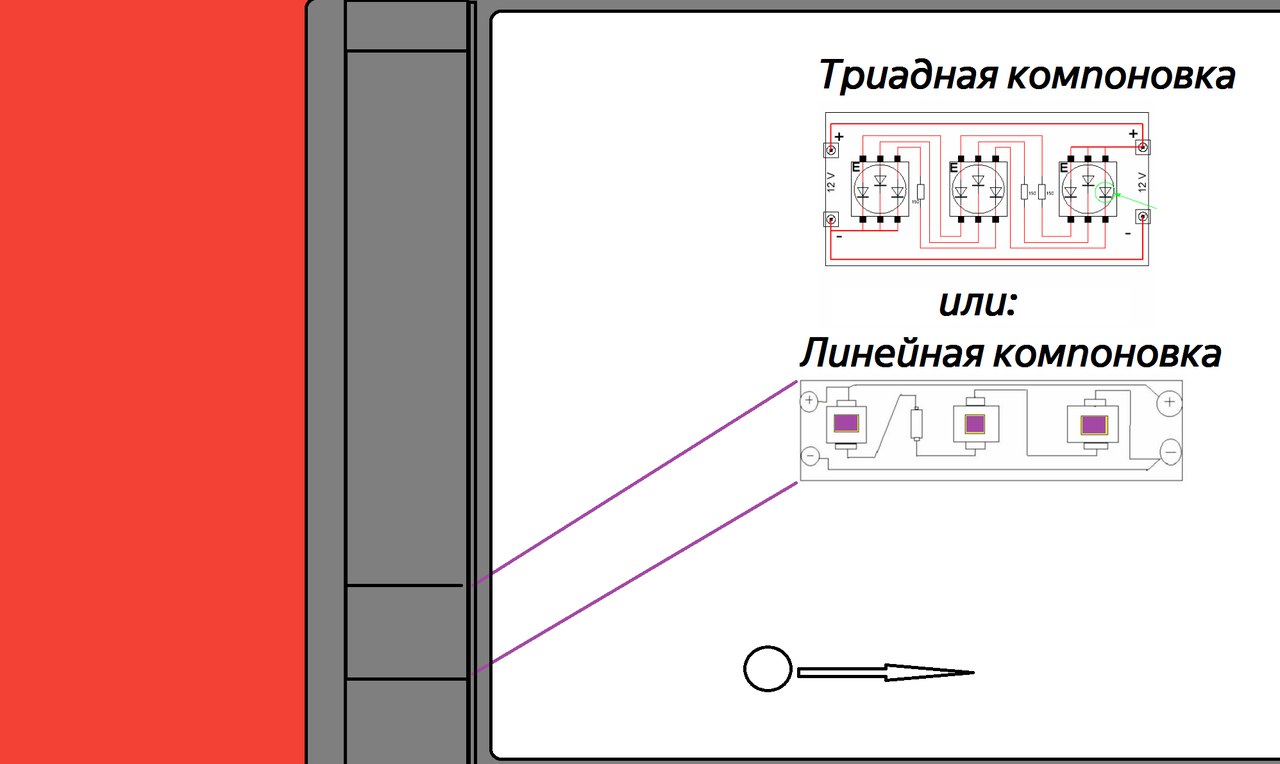

3. The most reasonable decision would be to place IntBas perpendicular to the screen surface. Indeed, to create a module - a line consisting of hundreds or thousands of LEDs of this type, say 1920 LEDs, the size of which coincides with the FullHD pixel of the matrix in a vertical arrangement. It makes no sense really. It is possible, to the extent that the market does not meet such miniature ultraviolet LEDs, their number per unit length of the display, or the entire space of the “full face” component can be reduced, thereby increasing the power and effective range of a particular element.

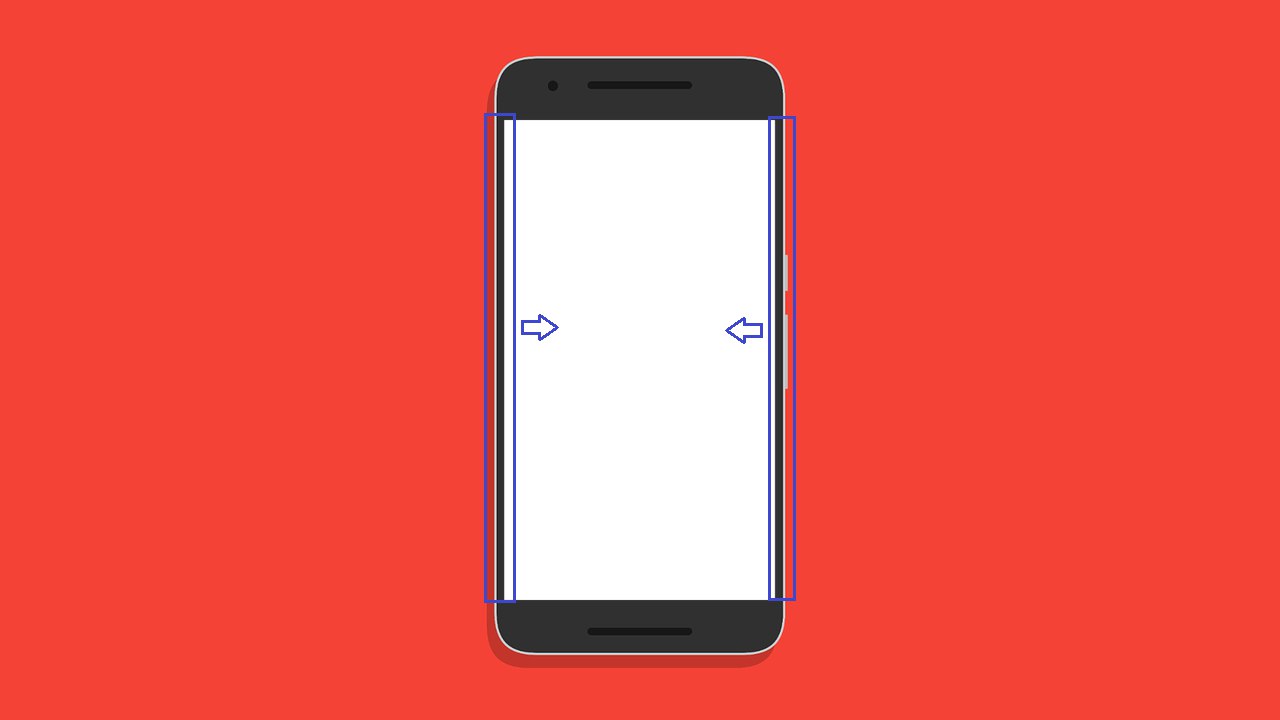

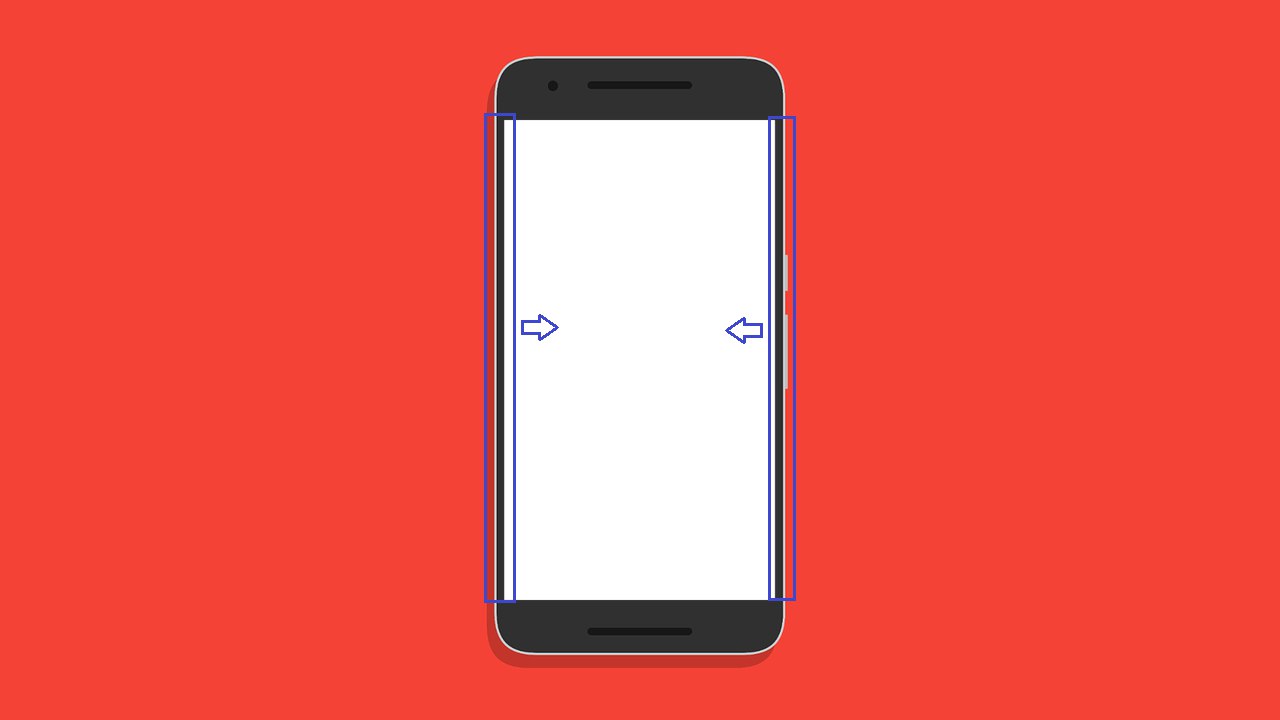

4. How to arrange the “line” in the best way? My opinion is to duplicate vertically.

What for? For the best effect, first, and for any symmetry. Even in the most ideal cases, a miniature strip of LEDs will bulge for at least 1mm. It is necessary to arrange on the side frames. The trends to rounded screens (Edge) have long since disappeared, and almost all smartphone manufacturers conditionally produce “regular screens”. The reasons for the failure of these screens - phantom clicks, high cost of production, low semantic load. In such cases, IntBas would need to be ported around the horizontal framework - which, like the vertical, still exists and will exist, despite the assurances of the manufacturers.

Thickening cannot be avoided - but it is precisely the progress in the design that makes it possible to create such solutions now without much discomfort for use and it will be difficult to feel. However, at the current moment there is not a single line that creates a line of LEDs on such a process for such needs. It is understandable, where did you see the mass devices with such a function? Why two lines? Very simple - due to the TTX of the LEDs at such sizes. Although maybe I'm wrong. Connecting to power is not difficult to implement, afterwards or in parallel - also a matter entirely for designers.

A good option could be the introduction of a line of LEDs in such a device as a stylus, on one of its faces, but now only Samsung creates this, and only in the flagship line of Note. And what - spent a couple of times on the same screen of the smartphone and made a much more favorable "atmosphere". It is not a matter of human disgust and pureliness - but in terms of anticipating the occurrence of unnecessary problems. As for the back surface, this is already the manufacturer’s decision. Ideally, the whole or large surface of any device to which an individual is too actively using should have such a tool as IntBas. On the back of the phone you can do the same, but the active wearing of covers reduces the effect to zero. And to use ultraviolet lamps, or something else, man, in the bulk will not be due to laziness.

But if the system itself, at regular intervals, or by other parameters - say, after the expiration of the screen activity (always a direct sign of obvious use), conduct radiation that a person does not notice, but removes most of the screen surface from “unwanted components” - perfectly. And the strangest thing is that so far it has not been introduced into our life. As in the same keyboards for computers, etc.

And all this can fill the usual microcontroller, with the direct support of the CPU in case of settings by a specific user.

The wavelengths of UV radiation are in the range from 10 to 400 nm. The interval is large, but it is not difficult to determine the required wavelength. Ultraviolet radiation of the mid-wavelength range (280–315 nm) is suitable by the way. Ultraviolet of this range is almost imperceptible to human eyes and is mainly absorbed by the corneal epithelium. There will be no permanent UV radiation, so there should be no negative effects. It is recommended to turn on the operation mode when the screen is not active. This will certainly protect a person's vision from radiation - perpendicularly directed to him. And it makes no sense to create a completely sterile environment, which never will be so. and conduct UV radiation at least 3-4 times a day. This option is somewhat reminiscent of dust and moisture protection - in the literal sense, it does not give a person anything, but in general it gives some safety margin. No, if you love to collect material from the screen of your smartphone and continue to watch the growth of "fauna" under the Petri dish, then the flag is in your hands. Ultraviolet radiation has a negative effect on some polymeric materials, however, if we talk about modern smartphones, the surface of their screens has a different structure. But in cases of producers' interest and in a more serious analysis, all different aspects can be identified and solved, or almost all of them.

All this was a simple assumption, how it is very easy to make the world cleaner. I did not say anything revolutionary new, but I suggested that, at first glance, the most adequate way to solve this problem. What do you think about this?

Technical component

There are also ultraviolet germicidal emitters that are more effective and versatile in use. But until now, all our equipment does not have built-in disinfection methods. And this is against the background of dozens of studies that bring to us the importance of regularly cleaning the screens of our gadgets from uninvited “guests”. I will describe my vision of an integrated bactericidal system (we will call it: IntBas) for a smartphone - the most favorite for our hands on the device. First of all, we need to determine how this structure can be implemented.

1. First look at your face - the front of any smartphone / other device. This is where the screen is located - the component most often used by our hands. What to do with it so that it ceases to be a hub of harmful bacteria. It is obvious that the most adequate will be to introduce ultraviolet LEDs with a certain long wavelength (we will talk about this later) than to invent a bicycle again.

2. The main task is to arrange a conventional line of such LEDs in the most rational way, in relation to the contact zone. Embedding in the screen itself meaning no more than zero, under the screen - in the most common on the market IPS-matrices is impossible. Against the background of this recent news about the built-in fingerprint sensor in the OLED-matrix, this solution may suggest, but so far there is no point in talking about it. And most of the effect will be lost in the subscreen area, which does not make sense at all. While the matrices of modern displays are made using current technologies, there is no point in talking about this method.

')

3. The most reasonable decision would be to place IntBas perpendicular to the screen surface. Indeed, to create a module - a line consisting of hundreds or thousands of LEDs of this type, say 1920 LEDs, the size of which coincides with the FullHD pixel of the matrix in a vertical arrangement. It makes no sense really. It is possible, to the extent that the market does not meet such miniature ultraviolet LEDs, their number per unit length of the display, or the entire space of the “full face” component can be reduced, thereby increasing the power and effective range of a particular element.

4. How to arrange the “line” in the best way? My opinion is to duplicate vertically.

What for? For the best effect, first, and for any symmetry. Even in the most ideal cases, a miniature strip of LEDs will bulge for at least 1mm. It is necessary to arrange on the side frames. The trends to rounded screens (Edge) have long since disappeared, and almost all smartphone manufacturers conditionally produce “regular screens”. The reasons for the failure of these screens - phantom clicks, high cost of production, low semantic load. In such cases, IntBas would need to be ported around the horizontal framework - which, like the vertical, still exists and will exist, despite the assurances of the manufacturers.

Thickening cannot be avoided - but it is precisely the progress in the design that makes it possible to create such solutions now without much discomfort for use and it will be difficult to feel. However, at the current moment there is not a single line that creates a line of LEDs on such a process for such needs. It is understandable, where did you see the mass devices with such a function? Why two lines? Very simple - due to the TTX of the LEDs at such sizes. Although maybe I'm wrong. Connecting to power is not difficult to implement, afterwards or in parallel - also a matter entirely for designers.

A good option could be the introduction of a line of LEDs in such a device as a stylus, on one of its faces, but now only Samsung creates this, and only in the flagship line of Note. And what - spent a couple of times on the same screen of the smartphone and made a much more favorable "atmosphere". It is not a matter of human disgust and pureliness - but in terms of anticipating the occurrence of unnecessary problems. As for the back surface, this is already the manufacturer’s decision. Ideally, the whole or large surface of any device to which an individual is too actively using should have such a tool as IntBas. On the back of the phone you can do the same, but the active wearing of covers reduces the effect to zero. And to use ultraviolet lamps, or something else, man, in the bulk will not be due to laziness.

But if the system itself, at regular intervals, or by other parameters - say, after the expiration of the screen activity (always a direct sign of obvious use), conduct radiation that a person does not notice, but removes most of the screen surface from “unwanted components” - perfectly. And the strangest thing is that so far it has not been introduced into our life. As in the same keyboards for computers, etc.

And all this can fill the usual microcontroller, with the direct support of the CPU in case of settings by a specific user.

About the wavelength and other features.

The wavelengths of UV radiation are in the range from 10 to 400 nm. The interval is large, but it is not difficult to determine the required wavelength. Ultraviolet radiation of the mid-wavelength range (280–315 nm) is suitable by the way. Ultraviolet of this range is almost imperceptible to human eyes and is mainly absorbed by the corneal epithelium. There will be no permanent UV radiation, so there should be no negative effects. It is recommended to turn on the operation mode when the screen is not active. This will certainly protect a person's vision from radiation - perpendicularly directed to him. And it makes no sense to create a completely sterile environment, which never will be so. and conduct UV radiation at least 3-4 times a day. This option is somewhat reminiscent of dust and moisture protection - in the literal sense, it does not give a person anything, but in general it gives some safety margin. No, if you love to collect material from the screen of your smartphone and continue to watch the growth of "fauna" under the Petri dish, then the flag is in your hands. Ultraviolet radiation has a negative effect on some polymeric materials, however, if we talk about modern smartphones, the surface of their screens has a different structure. But in cases of producers' interest and in a more serious analysis, all different aspects can be identified and solved, or almost all of them.

What is the result?

All this was a simple assumption, how it is very easy to make the world cleaner. I did not say anything revolutionary new, but I suggested that, at first glance, the most adequate way to solve this problem. What do you think about this?

Source: https://habr.com/ru/post/350724/

All Articles