The Internet of Things: From Designing a Backend to Energy Absorption

Clever everything, should be supposed to relieve a person from all worries, but for now, so that everything can become smarter, the developers of the Internet of things have to think a lot and solve a variety of tasks.

Which ones were discussed at InoThings ++ . Since this was our first, and we are sure - far from the last, a conference on the Internet of things, the program didn’t fit in one day, but was very diverse. Of course, there were reports on software and hardware design and network interaction (for example, such ); participants told about how things might break , and what legal issues arise, and that it was time to attend to the cultivation of personnel .

')

The conference was open, therefore records of all reports are available on the channel , there are also records of the corresponding section on RIT ++ 2017. And below are reviews of some interesting reports.

Antipattern software development for the Internet of Things

This is how Sergey Aksenov outlined his company from Strizh, and really talked about the principles common for IoT without reference to any specific case.

Although “funny” stories from practice also led, for example, how radio modems from one lot sent in one of 16 packages total nonsense: 21 m 3 , 22 m 3 , and then the temperature on the ISS paneling. Several hundreds of such devices were released and some of them still work for live paying customers, i.e. I had to find some solution after the fact.

The discussion begins with one of the questions that need to be solved at the preparatory stage of the backend design, the choice of the database. The specifics of the Internet of things is that devices never send data in the same format (even Strig’s water meters have different firmware versions and a different structure of the data being sent). At the same time, there are tens / hundreds of millions of rows of data, which is a lot for relational databases out of the box, on the other hand, you can lose a little bit of data and do not need complex calculations. In the end, we chose MongoDB, apparently having missed holivars like this , and are satisfied. Now the actual option is ClickHouse, especially for finite business data distributed over time.

Turning to testing, Alexey gives an example of an error in data transmission from a microcontroller to a modem in electricity meters, which are used off the beaten path 300 km from the city of Perm, which can only be reached via a winter road or KrAZ, i.e., it is impossible to quickly replace devices. This, coupled with the fact that the devices are used by living people and real businesses that depend on them, radically reduces the right to make mistakes. And Swift is taking really serious measures, ranging from end-to-end testing of data passing through to paranoid monitoring.

Last but not least, the aspect that was consecrated in the report is security. According to Alexey, safety is the main thing that potential consumers will pay attention to in the near future. And manufacturers should be guided by the principle of "security first", that is, immediately think about how you can hack the device and how to resist it, and if you do not come up with a method of protection, then maybe such a device should not be released.

As a result, Alexey compares the developers of the backend with the last line of defense, because they realize the last opportunity to correct the erroneous data, filter, sort and do something else, and transfer the customer the data that he vitally needs.

Digital livestock: how and why?

The report of Evgeny Belov and Oleg Artamonov on joint work in the best of its manifestations, when everyone is busy with his own business and at the same time aims at a common result.

The competence center of the MTS group on the Internet of Things received the task of making a product in the agricultural sector, and in order for the project to turn out to be in demand, it turned to the agro-industrial complex with the question “where is it hurting and how to help?” To get a detailed response, the company's specialists landed on the farm and lived there for two weeks. A sort of consulting, on the contrary, understood the device of the farm to the full extent and started to automate the processes related to the diagnosis of cow health. After all, the detection of diseases at an early stage will allow taking measures in time, to avoid a significant drop in milk yield and, as a result, to increase the margins of production.

In order to collect data, which can then be analyzed, they turned to Unwired Devices with the task: "Help us count the movement of the cow and its appetite." Because if a cow walks less and eats less, then it’s time to start her treatment. Oleg was already talking about the part of the project related to the manufacture of sensors. It is impossible to lose sight of this moment, the data necessary for analysis should be physically possible to collect, and by reasonable means. For example, you can’t hang a gps-module on a cow, because with an average power consumption of 5 mA, for 3 years of work it needs 95.4 Ah, which is approximately the accumulator - cows will object.

In addition to weight (30 g per ear - maximum), there are other requirements for the sensor: 3-6 years from the battery, at least IP67 protection, data transmission distance up to 10 km, identification of a specific cow, positioning on the ground. Thus, the design of the sensor is reduced to the search for an equilibrium state, taking into account all limitations and the possibility of physical implementation.

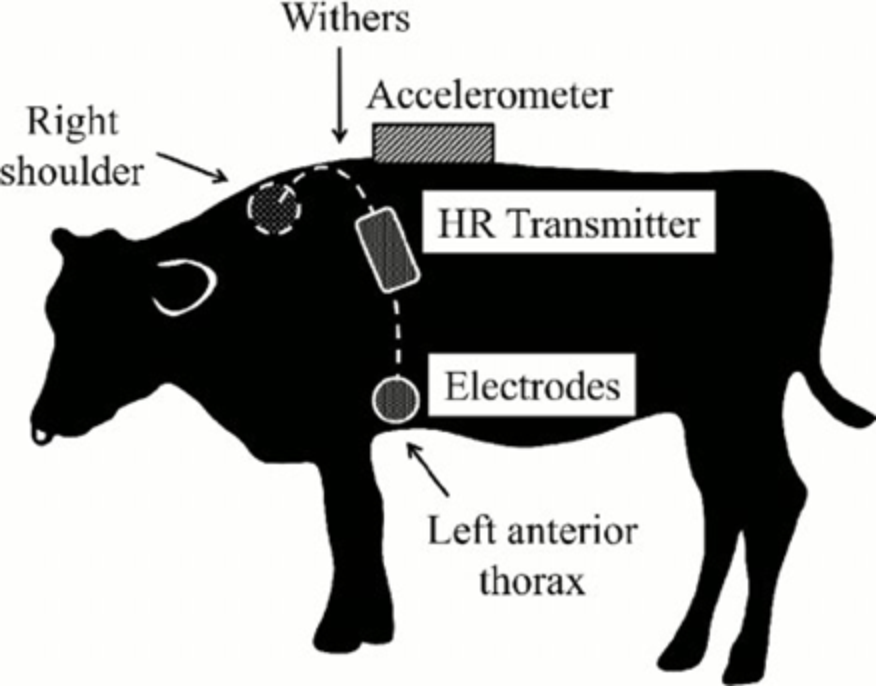

It is not known whether cows were asked directly, but nevertheless, the developers believe that the equipment scheme, as in the figure, they will not like.

The project is in a pilot stage, but an ear sensor has already been implemented, and a cervical one is in process, which, in particular, with the help of a laryngophone will determine that the cow is now chewing. While the technology is being developed in closed stalls without positioning, data transfer is carried out using the LoRa protocol, 6LoWPAN is planned for the future. Although intrusions in data transfer are unlikely in the barn, information security is built into the default: encrypting user data in AE128, signing messages SHA256, protecting against replay attacks, etc.

Answering the question about the possible consumer of such a digital farm, Eugene confidently speaks about the demand for the system. Moreover, MTS plan to connect to the “Smart Farming” processing, storage and logistics stages, so that the buyer can read the QR code and find out not only that the storage mode was strictly observed, but also what the cow was vaccinated with. Perhaps soon, it will be possible to put huskies to cows, share recommendations and other madness.

Energy absorption for powering autonomous sensors

The story of Andrey Dyusmikeev can be called a greeting from the future. The national expert on solar energy for the United Nations Development Program in Belarus spoke about the possibilities of absorbing energy from our environment to power autonomous IoT devices.

For an example of why the problem is relevant, there is no need to go far: in a review released by IoT aNalytics at the end of 2017, Samsung said that 600,000 devices had been withdrawn, which according to the announcement should have worked for 10 years on batteries, but withstood only 3 to 6 months. The situation is further complicated by the fact that the installed sensors may be difficult to replace, as in the case of the “Monitoring of environmental parameters” in the Chernobyl zone, when the team of specialists had to change the batteries for the whole season, which were supposedly designed for the same 10 years.

Battery technologies are not keeping pace with the miniaturization rate and processor performance, and the generation of electricity from renewable sources reduces the burden on the environment. Although in Russia, unfortunately, are not very concerned about the issue of recycling batteries, for those who are not indifferent, this is a very important point.

As a solution, the speaker proposes to rob the multitude of unused energy that is around us. The most profitable technologies in terms of energy density are solar cells, thermoelectric and electromagnetic, and the combination of these types allows for even more efficiency. On the insolation map, it can be seen that the sun in Russia is even there, and its energy can be safely used as the main one in various combinations.

Familiar to all of us seasonality, in the form of low winter temperatures, SolarEnrg compensates for the Peltier element, which collects thermal power and almost doubles the solar energy at a difference of ambient temperatures and the solar module of 40 degrees. The laboratory device is ready and everyone present could look at it and even, perhaps, touch it.

Like other speakers, Andrei provides several important recommendations for manufacturers of IoT devices:

- Using the latest versions of microprocessors and chips with the lowest power consumption.

- Flexible setting of the frequency of data transmission, where possible.

- Mandatory use of sleep modes of processors and communication modules.

- Adaptive power consumption (for example, changing the transmission frequency, depending on the voltage on the battery).

And the conclusion is that it is possible to build IoT systems and platforms based on sensors using energy harvesting devices. However, since the harvester cannot provide excessive consumption, it is necessary to design systems that are balanced in terms of power consumption and absorbed power.

And for a snack, the audience was shown another developed device - an integrated heart monitor, collecting energy for recording an ecg signal which is produced from the potential of human hands, without using any kind of battery.

Accurate positioning of personnel on the example of particularly dangerous production

The object for the implementation of the positioning system, which was told by Konstantin Nekhaev from Geyser-Telekom, is a metallurgical plant. It contains a whole set of complicating factors for radio systems: a large amount of metal, high voltage and electromagnetic noise in which. In addition to the main goal, increasing the level of industrial safety and increasing production discipline, the project has other goals, such as improving public opinion and increasing the authority of the city-forming enterprise.

In earlier projects, Geyser Telecom already faced positioning in metal containers, lack of visibility, low temperatures, underground positioning and other difficulties.

At the first sites, nanoLoc technology was used, but when the UWB (Ultra-Wide Band) stabilized in 2016, they switched to it. Its most important advantage in this case is the wide frequency band of 500 MHz or 900 MHz, which allows not only not to notice the iron, but nevertheless not bad with cope. To determine the coordinates used both basic methods: TDoA (Time Difference of Arrival) and ToF (Time of Flight). Such a technological bundle at the moment extends the lifetime of the label to 12 months of work during the second survey. This, coupled with pre-testing on the most difficult part of the object, prompted the decision to take on a new, so complex project.

Strangely enough, a lot of complexity was added by bureaucracy, but this is normal for high-risk facilities. In addition, it was required to install all the equipment, and these are 70 base stations. From the first time, there would be no possibility to shift the necessary cables.

According to the results of the four-month operation of the system in the statistics collection mode, it turned out that 40% of the staff commit at least one violation every day, such as leaving the post, entering an unacceptable zone or boldly walking with a squeaking gas sensor. And yet, on average, 66% of the time, the staff is located outside the hazardous areas, and this largely corresponds to the goals of the customer to optimize payroll - the project payback is very good. Well, safety cannot be overestimated, although it can not be paid for.

Concluding his speech, Konstantin recalls that accurate information about the capabilities of technologies or devices can only be obtained in practice and that testing in difficult areas will ultimately do everything right the first time.

And completing our review, we want to note that the Internet of Things is not the only topic outside of high-load systems with which we dedicate and plan to dedicate our events. So follow the news and see you again.

PS: You can ask questions and discuss your own cases not only in the comments to this article, but also in the Telegram-chat , in which there are most of the speakers and participants of the conference and just a lot of interesting people.

Source: https://habr.com/ru/post/350180/

All Articles