Fire, water and copper pipes: how we created the new ATOL Opol POS-terminal

We thought about developing a new, innovative device for trading in the fall of 2016. It took a whole year to create: 8 options for appearance, 3 options for technical specifications, and personal negotiations with 4 manufacturers. Five months took the stage of testing and improvement. As a result, ATOL company was born a new product - ATOL Optima.

')

In this review, we will describe how we created the ATOL Optima , how our terminal differs from similar devices, show it from all sides, consider its inner world, tell you how it was tested for strength before mass production, and introduce you to the test results.

Collaboration with Intel and Microsoft

It was important for us to make a professional device specifically for the retail and catering industry, which can work with all specialized programs. Therefore, we decided to design the motherboard from scratch and carefully monitor the quality of the components used. Of course, we understood that the price of the device would be slightly higher than the popular “tablet” type terminals, for example, PiPO. But deliberately bet on the high quality, professional level of the device and its maintainability.

The design of the terminal began in collaboration with experts from Intel and Microsoft.

The heart of the terminal was the Intel Celeron N3350 processor, the 7th generation (Apollo Lake). The key advantage of this processor is high performance with low power consumption. In addition, Intel guarantees long-term support and the long-term availability of this model on the market. For comparison, the PiPO uses an Intel Atom x5-Z8350 processor - in fact, the last member of this processor family, while the other Atoms have already been discontinued by Intel.

Intel 7th generation processors officially support only Windows 10. This OS does not suit some users due to the presence of mandatory updates that cannot be disabled. ATOL Optima comes with a special version - Windows 10 IoT Enterprise, created by Microsoft specifically for industrial use, including in retail. It is significantly cheaper than other versions and is good because:

Together with Microsoft, we tested Windows 10 IoT Enterprise with all trade equipment and made a special assembly for ATOL Optima.

We will also supply ATOL Optima with Linux OS Ubuntu 16.04 64 bit.

Specifications

For fast and high-performance work, we complete the terminal with 4 GB of RAM and an internal storage of eMMC 64 GB (a cheaper version with Linux Ubuntu OS will come with 2 GB of RAM and 32 GB of eMMC). This is more than enough even for demanding 1C type commodity accounting applications. If necessary, an additional 2.5 ”HDD / SSD drive can be used to store information or as a system disk for the OS. For this purpose, a typical SATA connector is installed under the service cover.

Design and design features

In the process of working on the ATOL Optima, we paid a lot of attention to the exterior of the POS-terminal and the convenience of its use in a limited space. Our goal was to make the terminal compact and beautiful, but at the same time productive, reliable and stable. For this, we have long verified the internal layout of the terminal. On the screen of the 3D layout of the hull, dozens of ATOL employees clicked. We made sure that the legs hold the case well on the table, even with a strong push the terminal does not tip over, and the screws securely hold the device in the VESA mount.

They did not save on the quality of the screen: they decided to make a terminal with a large and bright display, so that the user would be comfortable working with all the programs and that his eyes would not get tired. According to our calculations, a screen with a diagonal of 11.6 ”, a resolution of Full HD (1920 * 1080) and a brightness of 350 cd / m2 is ideal. It is suitable for work with trading software, such as 1C, Frontol, Mercata, etc., and with programs for cafes and restaurants: iiko, R-Keeper, Frontol Restaurant, Tavern, etc.

Capacitive touch screen type increases the service life of the device, so we decided to use it.

The arrangement of all holes in the terminal case was carefully thought out in order to efficiently remove heat and prevent overheating of the processor. Cooling is passive, unlike the same PiPO, which uses a fan. That is, the dust does not drag into the case, the terminal runs silently. By the way, even despite the absence of a fan, ATOL Optima adequately withstood the test in a heat chamber. The terminal worked for 8 hours without failures and errors at a temperature of + 50 ° C with running a stress test. You can’t say about active cooling PiPO - we also “fried it” (detailed test results are below).

The next step was laying the wires. During the design it turned out that the depth of the 65 mm wire compartment is enough to neatly put everything, including the bulky DB9 connectors, cover it all with a lid and hide it somewhere under the counter or hold them in the hole in the table.

Even in a very limited space, the terminal with the connected devices looks neat.

Many entrepreneurs, especially those who work at the box office on their own and at the same time advise buyers, are afraid that they can steal a computer. For protection, we made it possible to mount the terminal to the table using a standard Kensington lock, which can be bought for 150-200 rubles in any specialized store. The ATOL Optima has two holes for fastening the lock: at the back on the right for the option when the terminal is on the table and on the bottom left when the terminal is attached to the VESA mount.

Ports

According to surveys of our partners, we came to the conclusion that for a modern POS terminal, three COM ports are already many, and one is still not enough. Optimally - two full-fledged COM ports. But the number of USB-ports, as well as porridge butter, modern POS-terminal is difficult to spoil. ATOL Optima - as many as 10 USB ports. Therefore, you can connect all the necessary trading equipment.

Some devices (bank terminals, USB modems, customer displays, barcode scanners), without having their own power supply, can consume (peak or permanently) more than 0.5A recommended by the USB specification. For the correct operation of such devices, we laid 4 USB ports supporting current up to 2A. Therefore, if you use the terminal in the base supply with a 3 amp power supply, you can connect one peripheral device that constantly draws 2A to one of the four USB ports. If your devices consume a current of about 2 amperes not constantly, but only at peak load (for example, USB-modem when searching for a network), then you can connect more similar devices. If you need to use two devices that constantly consume 2A current from USB and do not have their own power sources, you need to separately purchase a more powerful 5A power supply.

On the side there are two USB 3.0 ports that allow you to conveniently connect USB drives and quickly copy information.

Additional "chips"

The terminal provides the ability to install a second drive: 2.5-inch HDD / SDD SATA. What is it for? First, to store the database. Not all business owners trust cloud services, but prefer to keep all information on physical media. Secondly, for convenience, you can install a primary or secondary OS on an additional disk. Thus, ATOL Optima can be simultaneously used with two operating systems (Windows 10 on eMMC and Linux on HDD / SDD) and two sets of cash register software. In real life, this is not very important, but at the testing stage you can quickly evaluate different versions of the OS and software.

Also, knowing the Russian realities, namely - frequent interruptions in the power grid, we provided for the possibility of the terminal operating from the battery. ATOL Optima can install 2 or 4 batteries.

From two batteries, the terminal operates autonomously for 2 hours at full load, from four to 4 hours.

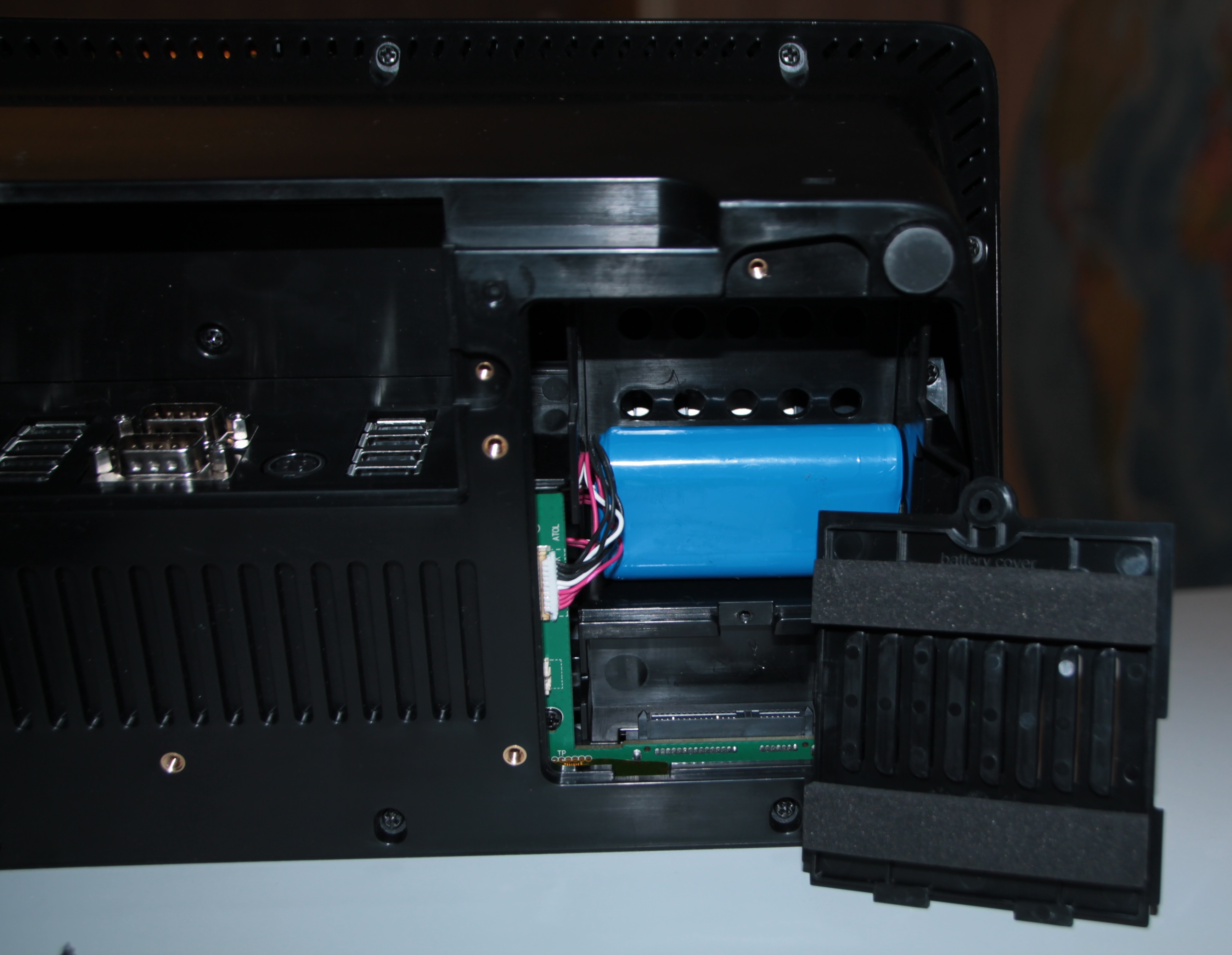

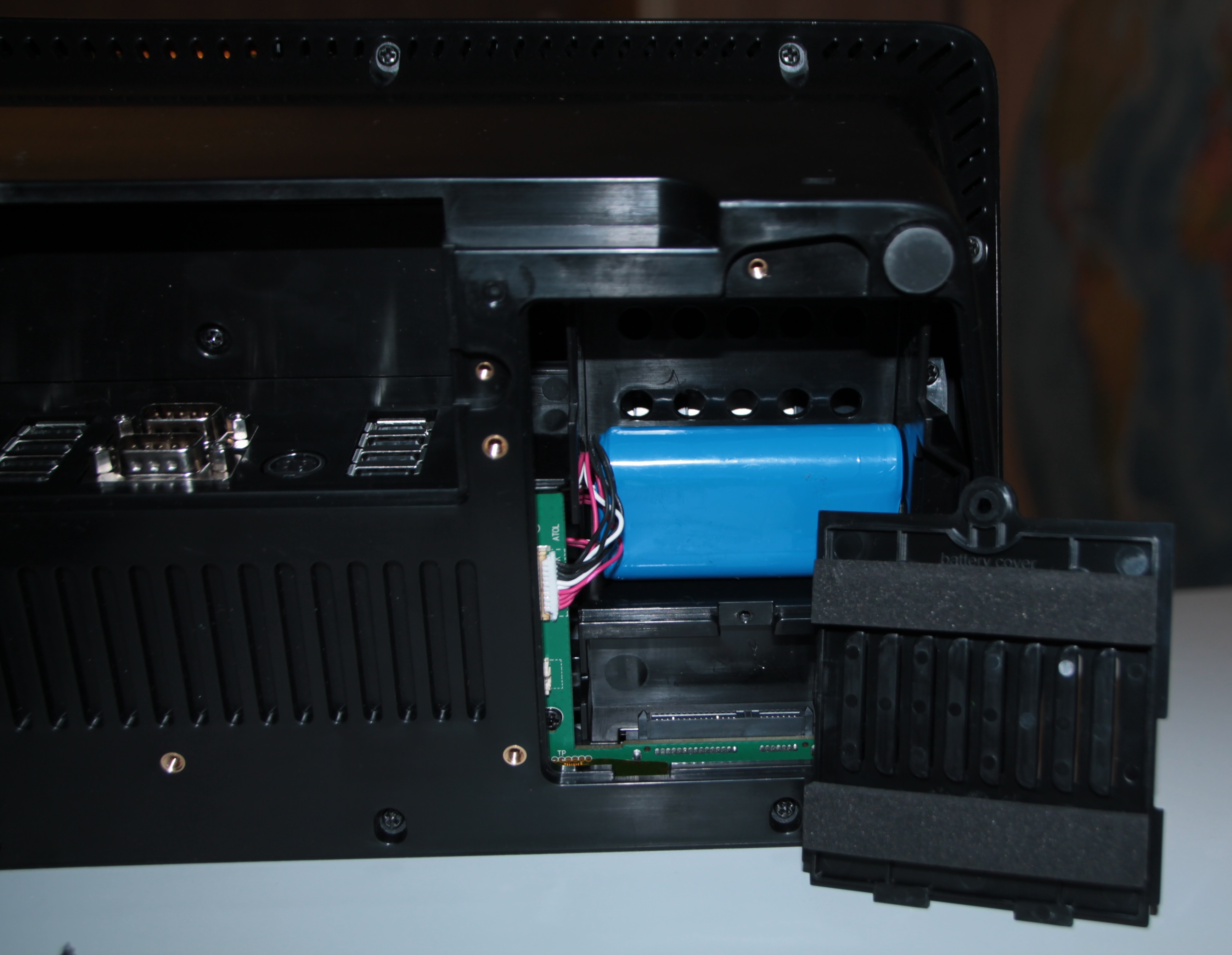

In the photo - the battery assembly at 2600 mAh (19.24 WCH 7.4V).

The connection diagram of the battery connector to the motherboard is applied by silk-screen printing.

But even if you mix up the polarity, the battery will not explode, but will only stop charging. At the same time, the battery icon in the OS interface on the right in the Windows taskbar will disappear.

Maintainability

The terminal was originally designed with the possibility of quick repair. Very easy to disassemble for repair and going after. We guarantee the availability of spare parts for 2-3 years from the date of withdrawal from the terminal production, the period of free warranty service - 1 year.

Production quality control

To guarantee quality, we control the entire manufacturing process. Our engineers personally go to the production and check the batch of terminals before shipment to Russia.

Assembly line

Factories that collect ATOL Optima have their own quality control points on the production line. It:

Optical control unit of motherboard components

SMT line assembly

4-hour stress test of all system components

After receipt of the goods in Moscow, each terminal undergoes pre-sales training: we once again check the performance and install the operating system.

In addition, when accepting a finished batch, our engineer personally selects randomly 1% of devices and checks them additionally. Below is a list of tests 1% of devices from the first batch with the results.

1. Monitor check

2. Test I / O port health

3. Determination of the exchange rate with drives

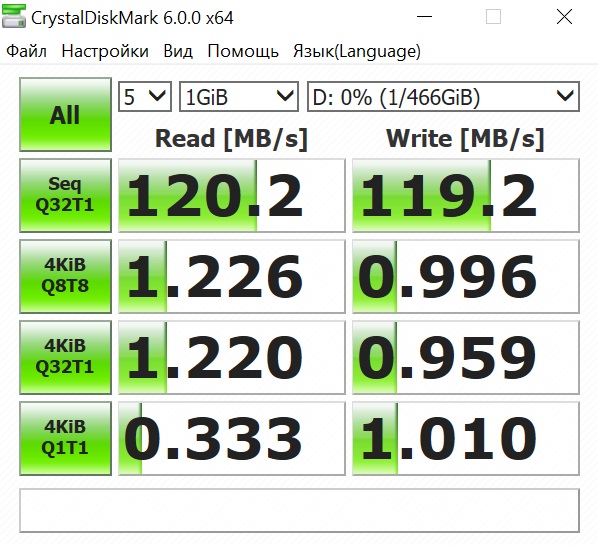

To determine the speed of the drives, the CristallDiskMark 6.0 software was used. The speed was determined in the sequential read / write mode.

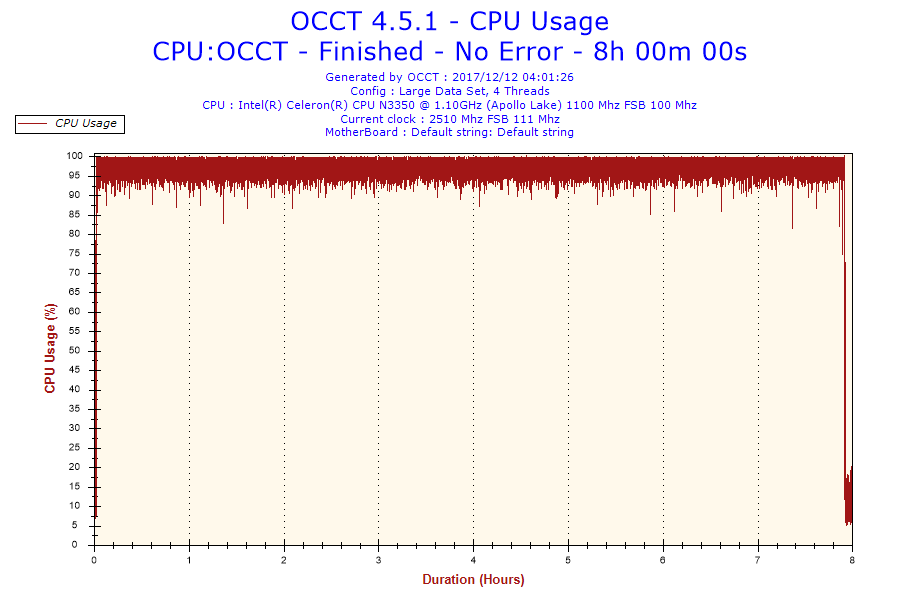

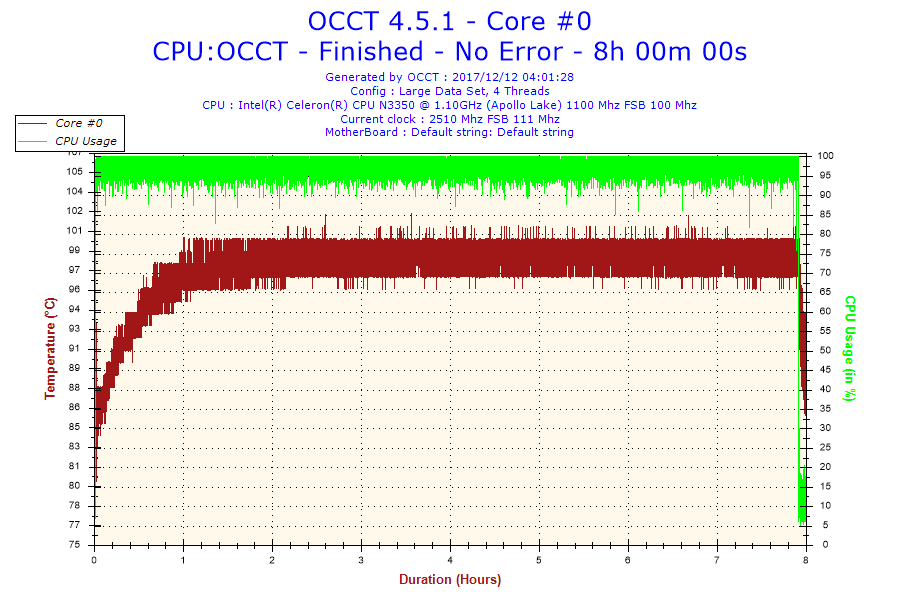

4. Conducting stress testing of the terminal in a heat chamber at +50 ° C for 8 hours at 100% processor load

Before the start of sales, it was important for us to understand whether the terminal will be able to work in difficult temperature conditions.

Terminal in heat chamber

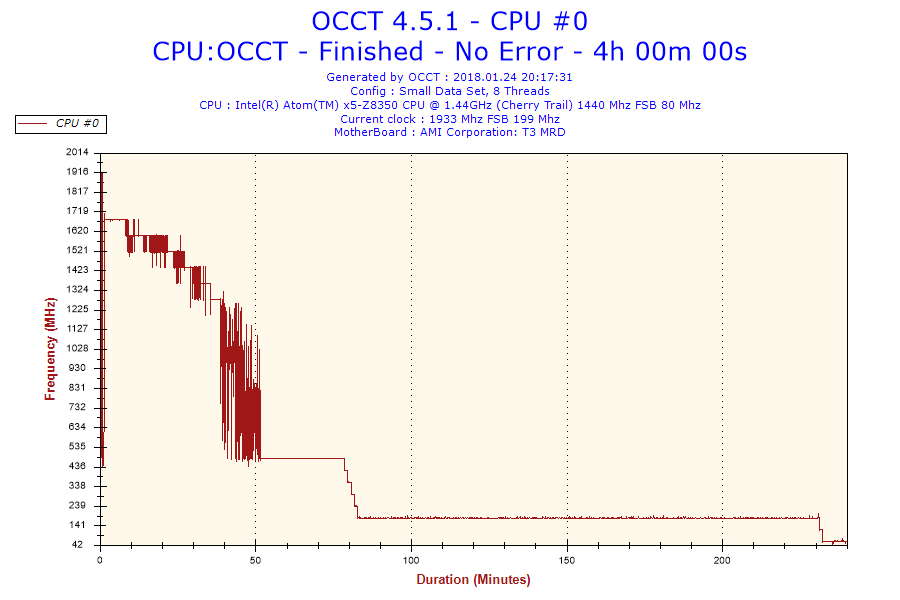

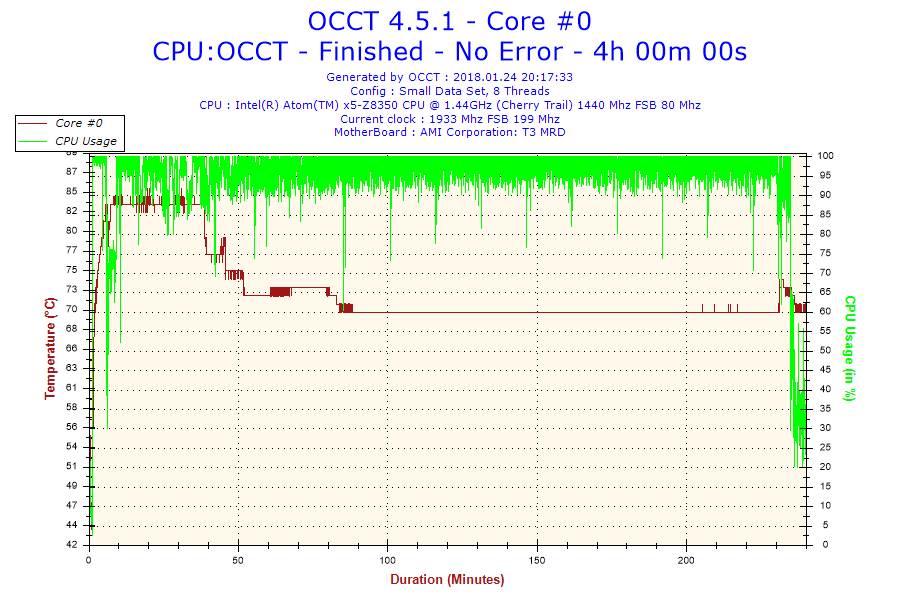

Stress test was performed using the utility OCCTPT4.5.1

Conclusion: ATOL terminal Optima successfully completed all 8 hours of the stress test in a heat chamber without sacrificing performance.

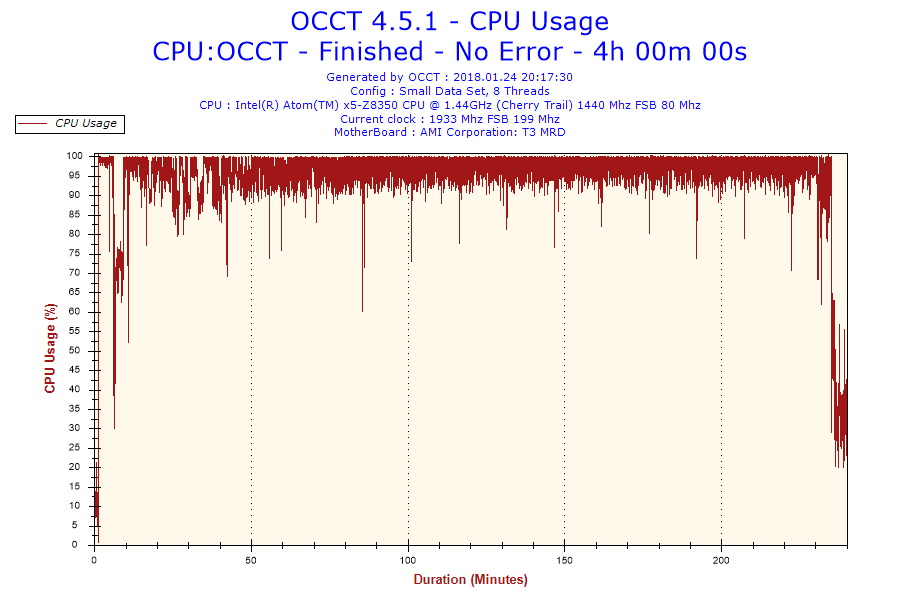

For comparison, we put in a heat chamber and a PiPO x10 terminal (Intel Z8350), which has active cooling.

The stress test was performed using the OCCTPT4.5.1 utility in a heat chamber at + 50 ° C. Results:

As can be seen from the graph of the processor frequency, after 50 minutes of the stress test, the PiPO X10 processor goes to throttling, reducing the frequency to 60 MHz.

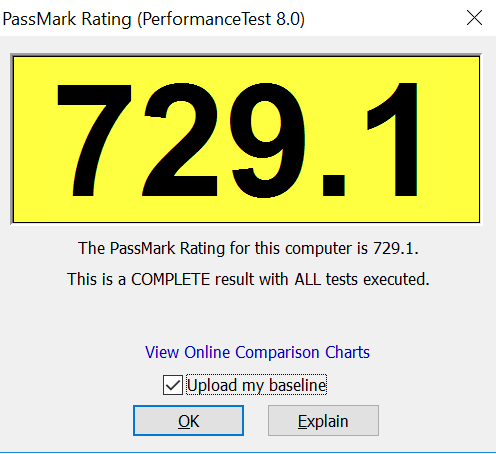

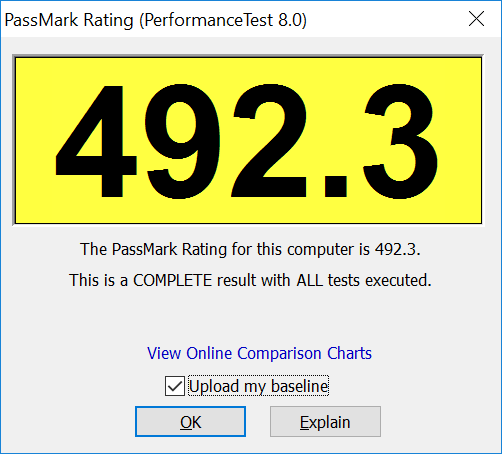

5. Determine the overall performance of the terminal

Conducted using the PassMark 08 test.

6. Testing battery terminal battery life

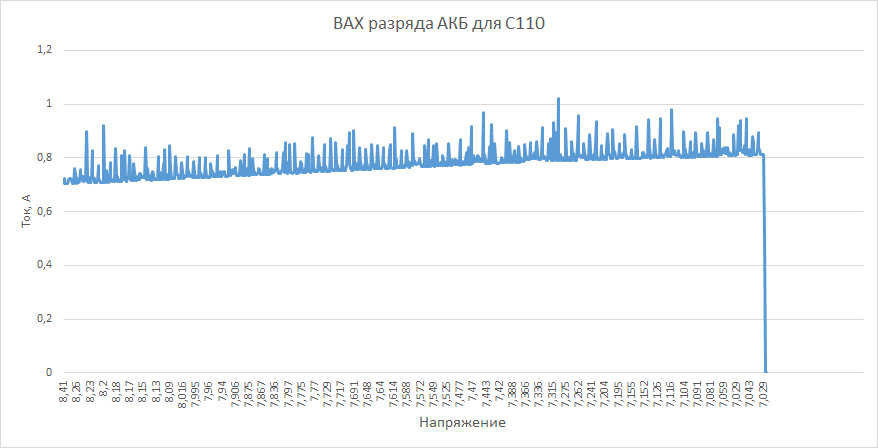

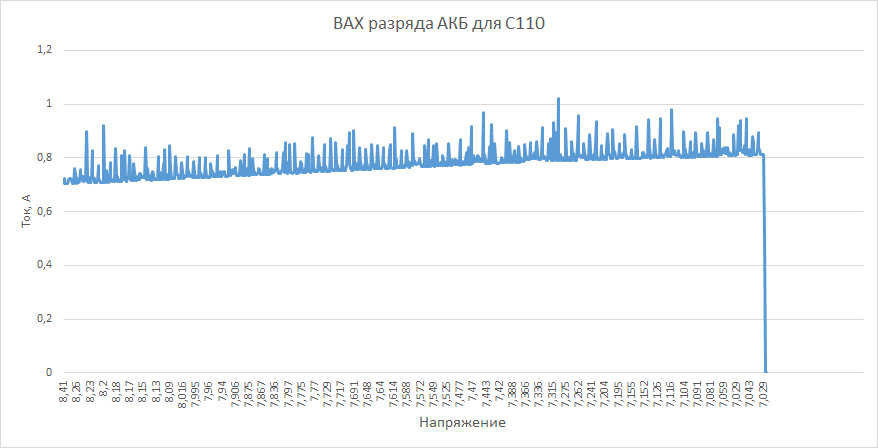

The process of testing the battery looked like this. The batteries were charged, the battery indicator in the OS showed 100%. Frontol 5 software running on the terminal, keyboard and mouse and CMC are connected. The screen brightness is set to 100%. 1 time in 5 minutes in Frontol sales of goods were carried out. In this mode, the terminal worked 120 minutes. At 20% of the charge, the power saving mode was activated, which was immediately manually turned off. After reaching the indicator level of 5%, the device turned off. This is the current-voltage characteristic of the battery discharge:

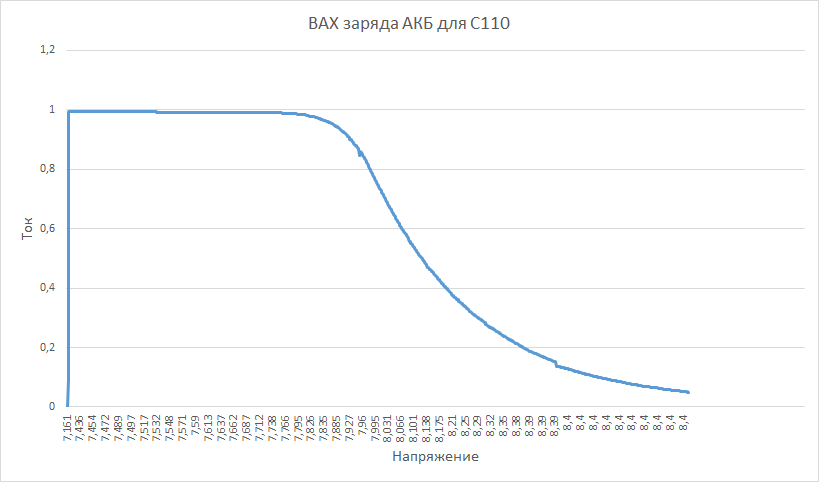

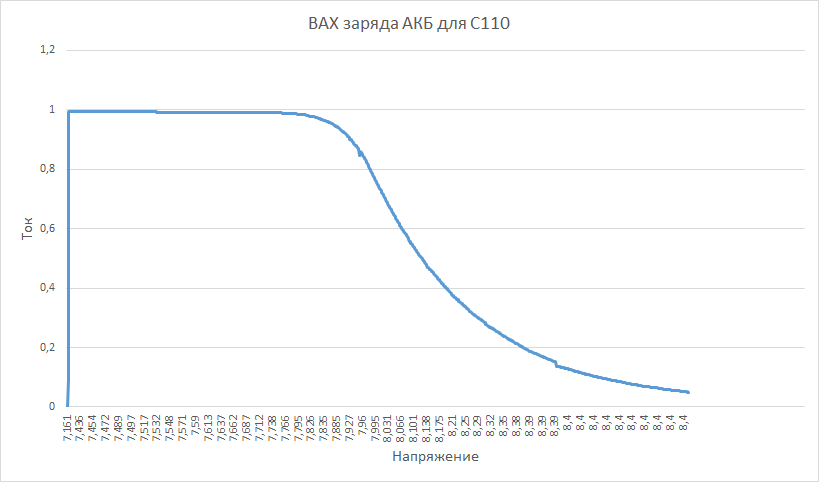

Battery charge was carried out with the terminal turned off. The limit voltage of 8.4V was reached in 164 minutes.

Voltage-ampere characteristic of the battery charge:

Volt-ampere charge / discharge characteristics were taken with the help of two multimeters connected to the gap of the battery wires.

We are very proud of our new product. ATOL Terminal Optima was presented at all ATOL conferences, at external conferences of Intel, Microsoft, Quart, Orange and received only positive feedback from customers and partners.

This is a reliable, professional device for retail and HoReCa. It can be used for equipment of electronic lines or for automation of such segments as hotel business, medical clinics, service.

ATOL Optima will help entrepreneurs to easily automate trade and comply with 54-.

')

In this review, we will describe how we created the ATOL Optima , how our terminal differs from similar devices, show it from all sides, consider its inner world, tell you how it was tested for strength before mass production, and introduce you to the test results.

Collaboration with Intel and Microsoft

It was important for us to make a professional device specifically for the retail and catering industry, which can work with all specialized programs. Therefore, we decided to design the motherboard from scratch and carefully monitor the quality of the components used. Of course, we understood that the price of the device would be slightly higher than the popular “tablet” type terminals, for example, PiPO. But deliberately bet on the high quality, professional level of the device and its maintainability.

The design of the terminal began in collaboration with experts from Intel and Microsoft.

The heart of the terminal was the Intel Celeron N3350 processor, the 7th generation (Apollo Lake). The key advantage of this processor is high performance with low power consumption. In addition, Intel guarantees long-term support and the long-term availability of this model on the market. For comparison, the PiPO uses an Intel Atom x5-Z8350 processor - in fact, the last member of this processor family, while the other Atoms have already been discontinued by Intel.

Intel 7th generation processors officially support only Windows 10. This OS does not suit some users due to the presence of mandatory updates that cannot be disabled. ATOL Optima comes with a special version - Windows 10 IoT Enterprise, created by Microsoft specifically for industrial use, including in retail. It is significantly cheaper than other versions and is good because:

- has the ability to disable updates completely if necessary. If you once tested your software with this version of the OS, there is no need to conduct a new test after the new update;

- Windows 10 IoT Enterprise is binary compatible with the desktop version of Windows 10. If you have drivers for your device for regular Windows 10, they are guaranteed to work in Windows 10 IoT Enterprise;

- The system is modular and can be customized to meet user requirements: you can allow only specific USB peripherals to be connected, set “Read only” mode for connected devices, block pop-up dialog boxes and system notifications, control application launch and much more;

- Windows 10 IoT Enterprise support will be provided by Microsoft for 15 years.

Together with Microsoft, we tested Windows 10 IoT Enterprise with all trade equipment and made a special assembly for ATOL Optima.

We will also supply ATOL Optima with Linux OS Ubuntu 16.04 64 bit.

Specifications

For fast and high-performance work, we complete the terminal with 4 GB of RAM and an internal storage of eMMC 64 GB (a cheaper version with Linux Ubuntu OS will come with 2 GB of RAM and 32 GB of eMMC). This is more than enough even for demanding 1C type commodity accounting applications. If necessary, an additional 2.5 ”HDD / SSD drive can be used to store information or as a system disk for the OS. For this purpose, a typical SATA connector is installed under the service cover.

Design and design features

In the process of working on the ATOL Optima, we paid a lot of attention to the exterior of the POS-terminal and the convenience of its use in a limited space. Our goal was to make the terminal compact and beautiful, but at the same time productive, reliable and stable. For this, we have long verified the internal layout of the terminal. On the screen of the 3D layout of the hull, dozens of ATOL employees clicked. We made sure that the legs hold the case well on the table, even with a strong push the terminal does not tip over, and the screws securely hold the device in the VESA mount.

They did not save on the quality of the screen: they decided to make a terminal with a large and bright display, so that the user would be comfortable working with all the programs and that his eyes would not get tired. According to our calculations, a screen with a diagonal of 11.6 ”, a resolution of Full HD (1920 * 1080) and a brightness of 350 cd / m2 is ideal. It is suitable for work with trading software, such as 1C, Frontol, Mercata, etc., and with programs for cafes and restaurants: iiko, R-Keeper, Frontol Restaurant, Tavern, etc.

Capacitive touch screen type increases the service life of the device, so we decided to use it.

The arrangement of all holes in the terminal case was carefully thought out in order to efficiently remove heat and prevent overheating of the processor. Cooling is passive, unlike the same PiPO, which uses a fan. That is, the dust does not drag into the case, the terminal runs silently. By the way, even despite the absence of a fan, ATOL Optima adequately withstood the test in a heat chamber. The terminal worked for 8 hours without failures and errors at a temperature of + 50 ° C with running a stress test. You can’t say about active cooling PiPO - we also “fried it” (detailed test results are below).

The next step was laying the wires. During the design it turned out that the depth of the 65 mm wire compartment is enough to neatly put everything, including the bulky DB9 connectors, cover it all with a lid and hide it somewhere under the counter or hold them in the hole in the table.

Even in a very limited space, the terminal with the connected devices looks neat.

Many entrepreneurs, especially those who work at the box office on their own and at the same time advise buyers, are afraid that they can steal a computer. For protection, we made it possible to mount the terminal to the table using a standard Kensington lock, which can be bought for 150-200 rubles in any specialized store. The ATOL Optima has two holes for fastening the lock: at the back on the right for the option when the terminal is on the table and on the bottom left when the terminal is attached to the VESA mount.

Ports

According to surveys of our partners, we came to the conclusion that for a modern POS terminal, three COM ports are already many, and one is still not enough. Optimally - two full-fledged COM ports. But the number of USB-ports, as well as porridge butter, modern POS-terminal is difficult to spoil. ATOL Optima - as many as 10 USB ports. Therefore, you can connect all the necessary trading equipment.

Some devices (bank terminals, USB modems, customer displays, barcode scanners), without having their own power supply, can consume (peak or permanently) more than 0.5A recommended by the USB specification. For the correct operation of such devices, we laid 4 USB ports supporting current up to 2A. Therefore, if you use the terminal in the base supply with a 3 amp power supply, you can connect one peripheral device that constantly draws 2A to one of the four USB ports. If your devices consume a current of about 2 amperes not constantly, but only at peak load (for example, USB-modem when searching for a network), then you can connect more similar devices. If you need to use two devices that constantly consume 2A current from USB and do not have their own power sources, you need to separately purchase a more powerful 5A power supply.

On the side there are two USB 3.0 ports that allow you to conveniently connect USB drives and quickly copy information.

Additional "chips"

The terminal provides the ability to install a second drive: 2.5-inch HDD / SDD SATA. What is it for? First, to store the database. Not all business owners trust cloud services, but prefer to keep all information on physical media. Secondly, for convenience, you can install a primary or secondary OS on an additional disk. Thus, ATOL Optima can be simultaneously used with two operating systems (Windows 10 on eMMC and Linux on HDD / SDD) and two sets of cash register software. In real life, this is not very important, but at the testing stage you can quickly evaluate different versions of the OS and software.

Also, knowing the Russian realities, namely - frequent interruptions in the power grid, we provided for the possibility of the terminal operating from the battery. ATOL Optima can install 2 or 4 batteries.

From two batteries, the terminal operates autonomously for 2 hours at full load, from four to 4 hours.

In the photo - the battery assembly at 2600 mAh (19.24 WCH 7.4V).

The connection diagram of the battery connector to the motherboard is applied by silk-screen printing.

But even if you mix up the polarity, the battery will not explode, but will only stop charging. At the same time, the battery icon in the OS interface on the right in the Windows taskbar will disappear.

Maintainability

The terminal was originally designed with the possibility of quick repair. Very easy to disassemble for repair and going after. We guarantee the availability of spare parts for 2-3 years from the date of withdrawal from the terminal production, the period of free warranty service - 1 year.

Production quality control

To guarantee quality, we control the entire manufacturing process. Our engineers personally go to the production and check the batch of terminals before shipment to Russia.

Assembly line

Factories that collect ATOL Optima have their own quality control points on the production line. It:

- Automated optical monitoring of the installation of SMD components: the system receives an image of the board from a digital camera, compares it with a template from the base and marks areas with incorrectly installed components.

- Monitoring the performance of all components of the motherboard: each board connects power and connectors to all ports (USB, COM, HDMI, LVDS, Ethernet). Then the program of functional testing of all ports is started.

- The input quality control of the components of the case, LCD screen, touch panel and connecting loops at the assembly production: a visual check of the components is carried out by the production technician before starting the line.

- The final performance monitoring of each finished terminal with the help of a 4-hour load stress test: the BurningTest 8.1 Pro utility is used, which simultaneously loads the graphics subsystem as much as possible, the processor, the disk drive and the RAM. The results of the stress test are stored in the log and after the end of testing are analyzed by the technologist.

Optical control unit of motherboard components

SMT line assembly

4-hour stress test of all system components

After receipt of the goods in Moscow, each terminal undergoes pre-sales training: we once again check the performance and install the operating system.

In addition, when accepting a finished batch, our engineer personally selects randomly 1% of devices and checks them additionally. Below is a list of tests 1% of devices from the first batch with the results.

1. Monitor check

- Verifying touchscreen functionality using Frontol touchscreen layout. The touch screen allows you to conveniently work with a touch layout across the entire screen area. All buttons are “pressed” equally well.

- Verifying the performance of the main display using the Portable_TFT_test_1.52_US software. Gradients of colors are transmitted smoothly, without steps. There are no hidden LCD defects.

- Check the operation of an additional display connected via HDMI-interface. The monitor BENQ GW-2270T was used as an additional display. A high-quality image with a resolution of 1920 x 1080p (Full HD) was obtained on the monitor.

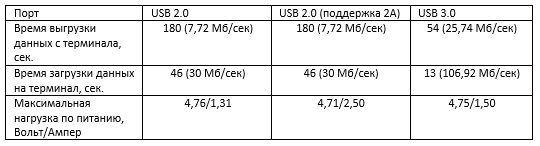

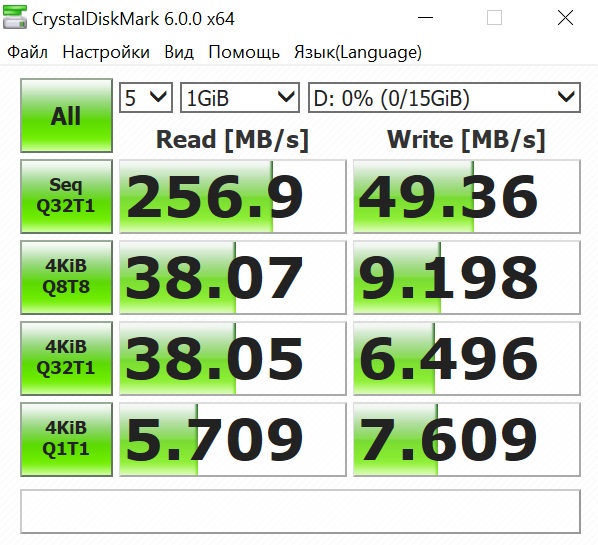

2. Test I / O port health

- USB ports were tested for compliance with supported exchange rates and power requirements of the USB specification. To determine the speed of data loading / unloading, an arbitrary file with a volume of 1.39 GB was used.

To determine the value of the maximum load on the power supply, a 1-100 ohm rheostat was connected to the ports.

- COM ports were checked for correct exchange with the ATOL 30F CCV through the trade equipment driver (DTO). Throughout the entire speed range of 4800-115200, the baud exchange with KKT is stable.

- Checking the exchange rate over WiFi (10 m distance without obstacles) and Ethernet was carried out by copying a file of 1.39 GB.

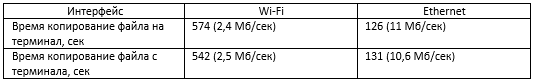

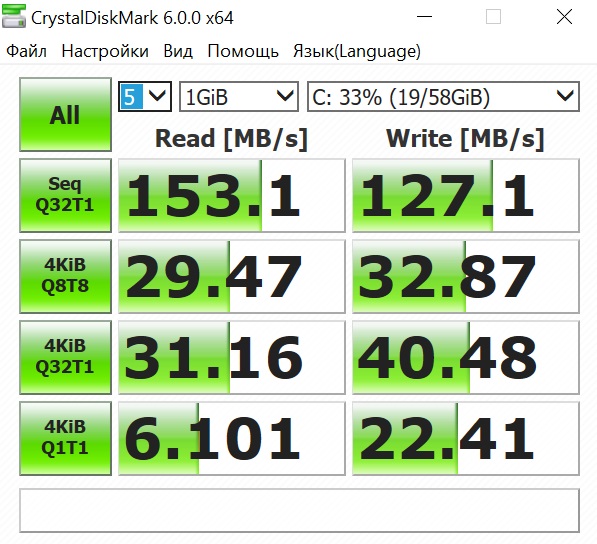

3. Determination of the exchange rate with drives

To determine the speed of the drives, the CristallDiskMark 6.0 software was used. The speed was determined in the sequential read / write mode.

- Internal EMMC Samsung CJNB4R

- SSD-SDSA6AM-016G

- Seagate Video 2.5HDD 500Gb

4. Conducting stress testing of the terminal in a heat chamber at +50 ° C for 8 hours at 100% processor load

Before the start of sales, it was important for us to understand whether the terminal will be able to work in difficult temperature conditions.

Terminal in heat chamber

Stress test was performed using the utility OCCTPT4.5.1

- CPU Load Graph

- CPU frequency graph

- CPU Temperature Chart

Conclusion: ATOL terminal Optima successfully completed all 8 hours of the stress test in a heat chamber without sacrificing performance.

For comparison, we put in a heat chamber and a PiPO x10 terminal (Intel Z8350), which has active cooling.

The stress test was performed using the OCCTPT4.5.1 utility in a heat chamber at + 50 ° C. Results:

- CPU Load Graph

- CPU frequency graph

- CPU Temperature Chart

As can be seen from the graph of the processor frequency, after 50 minutes of the stress test, the PiPO X10 processor goes to throttling, reducing the frequency to 60 MHz.

5. Determine the overall performance of the terminal

Conducted using the PassMark 08 test.

- PassMark results for ATOL Optima

- By tradition, we compare it with the performance of the PiPO X10 using the same benchmark PassMark 2008

6. Testing battery terminal battery life

The process of testing the battery looked like this. The batteries were charged, the battery indicator in the OS showed 100%. Frontol 5 software running on the terminal, keyboard and mouse and CMC are connected. The screen brightness is set to 100%. 1 time in 5 minutes in Frontol sales of goods were carried out. In this mode, the terminal worked 120 minutes. At 20% of the charge, the power saving mode was activated, which was immediately manually turned off. After reaching the indicator level of 5%, the device turned off. This is the current-voltage characteristic of the battery discharge:

Battery charge was carried out with the terminal turned off. The limit voltage of 8.4V was reached in 164 minutes.

Voltage-ampere characteristic of the battery charge:

Volt-ampere charge / discharge characteristics were taken with the help of two multimeters connected to the gap of the battery wires.

We are very proud of our new product. ATOL Terminal Optima was presented at all ATOL conferences, at external conferences of Intel, Microsoft, Quart, Orange and received only positive feedback from customers and partners.

This is a reliable, professional device for retail and HoReCa. It can be used for equipment of electronic lines or for automation of such segments as hotel business, medical clinics, service.

ATOL Optima will help entrepreneurs to easily automate trade and comply with 54-.

Source: https://habr.com/ru/post/347976/

All Articles