Not soon the fence is built, especially a beautiful data center. How we build the data center "Avantage". Part 2

Hello! We continue our story about how the construction of a new data center “Avantage” is going on from a clean field, which will become one of the largest commercial sites in the Moscow region. Today we will thoroughly walk through the server rooms, go to the cold center, the power center, go up to the roof of the data center - it will be interesting. Who missed - the first part of our story can be found here . Attention, there are a lot of photos ahead!

Stride to the goal

Let's see what our object looks like today. And we will start with the server rooms (germozon / machine halls). There will be 16 server rooms in total, they are located on 2 floors of the technological block, with 8 server rooms per floor. Each server room has dimensions in terms of 13.1 x 30.2 m (S = 396 sq. M) and a height (from floor to ceiling) of 5.0 m, capable of holding up to 140 server cabinets 800 x 1200 mm in size. The design capacity of the server room is 700 kW.

Cooling server rooms provide precision air conditioners , which are installed both inside and outside the machine room. In 13 server rooms out of 16, precision air conditioners are installed outside the machine rooms - made in the selected technological corridors. This is done in order to restrict and / or exclude the facility personnel’s access to the gyms and ensure that the security service requirements of the facility and / or the client are met. The air-conditioning system of the turbine hall includes 8 air conditioners, while providing redundancy according to the N + 1 scheme, where N corresponds to 7 air conditioners capable of diverting heat gains from the process equipment in the amount of 735 kW and maintaining the temperature of the air supplied at + 24 ° C. In total, the project provides for the installation of 128 precision air conditioners in server rooms and four air conditioners in 2 cross rooms.

Let's take a look at one of our tight areas with maximum readiness for launch. Air conditioners for it are located outside in the technological corridor (external location of air conditioners) - below in the photo.

The installation of the trunk and distribution buslines was completed in the machine halls, due to which power will be supplied to the client servers. The trunk busbar with a nominal value of 1600 A provides power from the main switchboard (MSB) directly to the machine room to the distribution busbars. The distribution busbar, with a nominal value of 160A, provides power from the busbar to the client servers. To connect the IT racks on the distribution busbar, power take-off units with automatic switches are mounted. For each turbine hall, the power supply is made in a two-beam scheme, from two different main switchboards.

It is worth noting that the decision to build distribution systems is universal: if the client needs to shift the rows of IT racks, change the dimensions of the aisles and / or change the width of a row of IT racks, the overhead distribution system can move along the ceiling rail system.

')

A little about the security system . The facility is equipped with a video surveillance system, an access control system with a custom mode / level of access for customers and service personnel. The modular video surveillance system is implemented in the machines. Depending on the needs of the client, this allows you to add video cameras.

In addition, a sound and light warning system for a fire and any other h / s, an aspiration system (an early smoke detection system) and, of course, a centralized gas fire extinguishing system (in the photo - yellow gas fire suppression pipelines) are implemented in the engine rooms.

Also installed a system of exhaust ventilation, which provides redundancy of pressure and the required level of humidity in the machine rooms.

Since the air conditioners for this “red” containment zone are located outside the hall (we showed them at the very beginning), to meet the fire safety requirements, there are fire dampers (fire retardant valves, OZK) installed on the air conditioner air supply and intake air.

In the photo: the valve flap actuator in the open position (top), ventilation boxes for the intake and air supply.

Another of our tight areas - "Yellow", where air conditioners are mounted directly in the room itself. In this containment, we started to load tests, for this purpose we installed 7 heat guns and connected them to the standard power supply network. Each heat gun is 100 000 W (for comparison: iron - 1500 W). Testing is carried out on the estimated power of the turbine hall - this is 700 kW. Seven warm guns can provide heat generation in the amount of 700 kW. Load tests last 72 hours.

In addition, now there is a creation of internal infrastructure to accommodate customers' IT facilities. In particular, there is installation of cabinets for client servers. Cabinets domestic production Masterwork-telecom. Cold corridor insulation system is also domestic, produced by C3 Solutions. By the way, in September they conducted tests of its fire dampers - they proved to be excellent.

Precision air conditioners in the server room 7 + 1 pieces produced by Tecnair LV. 7 air conditioners completely provide the entire containment room with cold. 8th air conditioner backup. Each air conditioner provides cooling capacity of 105 kW.

Let's take a look at another tight area, it is also “Yellow”. Readiness here is lower than the rest, there are no raised floors. But visible mounted gas extinguishing system, which is located not only under the ceiling of the server room, but also under the raised floor. Air conditioners are installed in the technological corridor (in the photo you can see fire-prevention valves (OZK) installed on the air supply from the air conditioner under the raised floor).

Since the air-conditioning of the nearby pressure zones is external, the air conditioners are located in the technological corridor and are located on its both sides. The tests for the first start-up machine rooms have already been conducted (in the photo below, the right-hand row of air conditioners). The conditioners of the engine rooms of the second start-up complex (on the left side) are mounted, mounted and the hydraulic system of the cold supply, prepared for hydraulic tests.

By the way, here you can well consider the sprinklers of the automatic water fire extinguishing system.

In "Avantage" there are two centralized gas extinguishing stations . Together they cover the entire volume of the data center. The stations are absolutely identical, one of them is in the photo below. Construction and installation work here ended in February 2017.

In each station there are 24 gas fire extinguishing modules, main and distribution pipelines, through which the gas extinguishing agent is sent along a distributed route, covering half of all the premises of the data center. Each red module (cylinder) with a volume of 180 liters contains 150 kg of fire extinguishing agent FC-5-1-12 (Novec 1230), currently the safest for people, equipment and the environment and most effective for eliminating fires. Modules of gas fire extinguishing of the second row form a hot reserve, which is triggered by a failure in the operation of the main, first row of cylinders. The manufacturer of this fire safety system is domestic - ASPT Special automatics.

Fire cabinets with hydrants, sleeves and fire extinguishers are located in all corridors of the data center.

The cold center is the heart of the air conditioning system of the data center server rooms. It is organized in a separate one-story block. To date, refrigerators (chillers) have been mounted here, commissioning works of the first start-up complex have been carried out, the cooling system is being tested with a test heat load on the design capacity. In parallel with this, the installation work of the second starting complex is underway.

Refrigerating machines (chillers) imported, manufactured by Cofely (Germany). Indoor chillers with liquid cooled condenser with Turbocore centrifugal compressors. In the photo below is one of the cold supply circuits and the chillers themselves.

Air ducts of the system of technological ventilation of the cold center.

Each chiller has its own power supply panel. Each chiller is provided with two independent power inputs. The power take-off of the chiller power supply box is visible on the busbar.

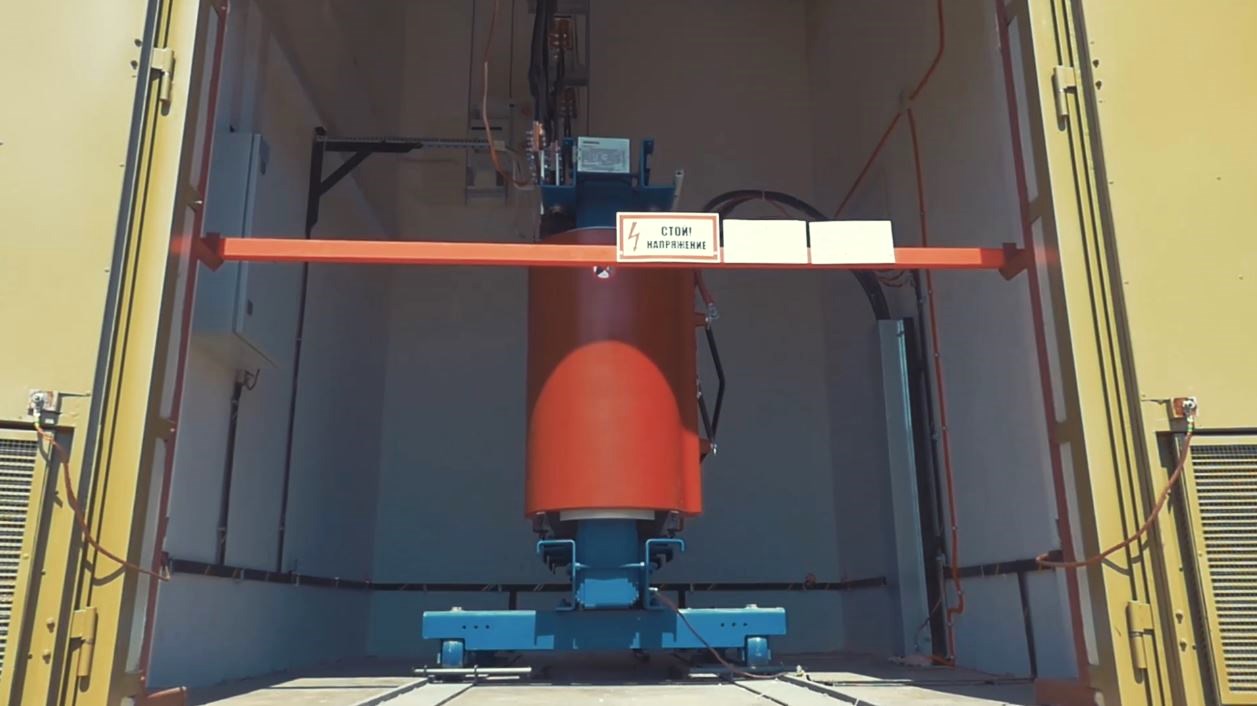

Now let's talk a little about the power supply system "Avantage". In case of a blackout in the data center there is an uninterrupted and uninterrupted power supply system (SBGE). It is organized on the basis of diesel-rotor uninterruptible power supply units (DRIBP) , manufactured by Hitec Power Protection (Holland), mounted on the 1st floor of a 2-storey power center unit. DRIBPs have been introduced into the 10 kV power supply system. A total of 14 installations will be installed at the facility in two stages. The level of redundancy SBGE N + 1. At the first stage, 5 installations are put into operation: the 4th main (N), the fifth backup (+1). At the second stage, all 14 installations are introduced: 13 basic (N), fourteenth backup (+1).

The commissioning of the first phase of DRIBP was completed in November. Installations operate continuously, providing filtration of electrical energy coming from the network to the consumer and from the consumer to the network.

When the external power supply fails, the facility is provided with fuel for the DRIBP, which ensures the autonomy of the facility for a period of at least 12 hours at 100% of the facility load. All engine / diesel rooms are equipped with a gas fire extinguishing system from the same centralized stations that we have already shown above.

Opposite the DRIBP premises there are halls with step-up transformers , where the voltage level increases from 0.4 kV from the DRIBP (the DRIBPs themselves are made to 0.4 kV) to 10 kV to the distribution network of the power center. The facility provided and installed 14 power step-up transformers of 0.4 / 10 kV manufactured by Siemens.

The distribution of power supply at an average voltage of 10 kV is based on the medium voltage cells manufactured by Siemens. They were mounted on the 1st floor of the power center unit. At this voltage level, power is received from the city network, the DRIBP is connected and distributed to two independent parallel bus sections of the uninterrupted and uninterrupted power supply system, and the downstream consumer transformers are connected. In total, the project provides for and installed 11 medium-voltage sections.

Today, the power supply system for the medium - 10 kV and low - 0.4 kV voltage is debugged and is in trial operation. We have 6 of such premises with voltage distribution cells, a total of 112 10 kV cells of the NXair, Simosec and 8DJH series.

In the photo below is the control cabinet of the generator set of the parallel system. From here the visual control of the operation of the DRIP machines is carried out. Next to it, through the aisle, a DC operating current cabinet with a battery pack is installed, which provides independent power supply to the control circuits of the medium voltage cells and the control panels of the DRIB units.

At the facility, 27 10 / 0.4 kV power reduction transformers manufactured by Siemens are installed and installed.

On the second floor of the power center unit, there is a technological ventilation system and a diesel rotary uninterruptible power supply control system.

Let's go up to the roof and look at the data center above. Here, above the premises of the process unit, 18 dry coolers manufactured by Cabero company are located. In the project, dry coolers are used to remove excess heat into the atmosphere. When the ambient air temperature is below + 6C, the data center cooling system goes into direct cooling (Freecooling) mode, in which no chillers are used.

Lightning masts are clearly visible here as well. The object is protected by a lightning protection system. The equipment placed on the roof is protected from direct lightning by a combined solution made on the lightning receiving grid and lightning receiving masts. Inside the object, on the input lines from the city network and the cable lines of the equipment taken out on the street, surge protection devices have been used.

Below the photo shows the exhaust pipes from the generator set of the power center and its ventilation system (mine intake and discharge).

A few words about the fuel storage . Its volume is 180 m³, it is designed for 24 hours of autonomous work at full load. The photo shows the neck of the fuel tanks for diesel fuel embedded in the ground. Drain from the tanker to the tanks through the filling station.

The first telecommunications facility appeared on the Avantazh construction site in March 2017. The mobile operator MTS has installed a mobile base station at the construction site of the data center. Thus, a good mobile coverage is provided in all the premises of the facility under construction.

At the site "Avantage" closed the physical security loop that meets the highest requirements. The works were completed in July 2017. The reasons for choosing such protection:

- rigid welded construction;

- minimal penetration;

- anti-digging device prevents unauthorized intrusion of intruders under the main protective fence.

The next stage was installed video cameras and vibration sensors.

Beauty matters

Well, of course, a year ago there was no talk about any beauty. For comparison with KDPV, there are several photos about how our data center looked a year ago. The buildings are already standing, but the improvement of the territory is not a rumor or a spirit.

We started to do landscaping even in the winter of 2016, but before the snowfall there was little to catch. So, as soon as the snow fell in the spring of 2017, we quickly took up the territory. What has changed today? Now we have smooth roads, green lawns (in summer, of course) ... well, in general, everything is as it should be.

The building of the data center now can not be overlooked. At the end of the administrative building there was a huge logo with the name - Avantage Data Processing Center.

In May 2017, work began on the architectural lighting of the data center. And gradually he became handsome both by day and by night. By September, work on subsystems of outdoor and architectural lighting was completed at the site.

That's all for today. For questions please in the comments. And for all who are interested to see it live - welcome to the free tour. Sign up here .

Source: https://habr.com/ru/post/345218/

All Articles