PVS-Studio and GOST. How the KOMPAS-Expert application for checking drawings appeared

Recently we released a new application KOMPAS-Expert for finding errors in drawings and models developed in KOMPAS-3D. The idea for it was the PVS-Studio code analyzer. What is common in products for programmers and engineers and how design errors are classified, says Oleg Volkov.

At one time, I was inspired by Viva64 to check C ++ code (now this wonderful product is called PVS-Studio ). It performs code analysis on various rules: logical / non-logical, constructor / destructor, comparison of variables and others. The idea arose to apply a similar ideology in KOMPAS-3D: at the output, check the result — the drawing or the 3D model — by certain rules. Moreover, in other CAD systems such checks are implemented.

In general, IT infrastructure development is much better established than in engineering design. It describes in detail how to pass the code, how to verify it, how to version it, at what points what checks to carry out (SWEBOOK to help you). Why not apply this approach to the work of the designer in CAD?

At one time, when computers were large and the work time was expensive, it was customary for programmers to avoid making mistakes at the stage of writing code so that it passes the first time. Now we will once again compile, it will give out a bunch of errors, correct, re-conduct. So in the work of the designer - do not try to get the perfect drawing from the first time. Before you go to get a signature, check, correct, check again. You need to think about your product, and not over the design of the drawing, “Expert” will help.

')

We broke all possible mistakes (document defects) into areas of knowledge and began to “underlay” specific checks for them. At the moment, the project made more than 140 checks.

The first to be implemented were selected design checks. Starting to work on "Expert", we naturally looked at what solutions competitors currently have. Mostly similar systems perform standard checks on the styles: line style, layer names and colors, type of arrow, font style, etc. In our application, we decided to go ahead and really check by standards, since KOMPAS-3D has always been notable for its proximity to them. The developers of the application decided to support this tradition and make full checks based on ESKD standards.

In checking for compliance with a particular standard, the norms of this standard are prescribed. If the document contains elements related to the standard, then they are checked for compliance - for example, design of dimensions, design style, setting of maximum deviations, qualifications, setting of roughness, welded designations. As reference materials in the checks are references to standards. We work with the TechExpert website (http://www.cntd.ru/), on which the fundamental base of the GOST standards is laid out. If the user wants to make sure of the error shown by KOMPAS-Expert, he can go to a specific standard, his particular point on which the check was performed.

The design checks have done a lot of work on the intellectualization of text analysis. In any design document must contain technical requirements. The GOST recommends a certain sequence in their enumeration: first, data on the material, then dimensions, surface quality and coating, adjustment of the product, and further to special operating conditions. We made a check on the correctness of the technical requirements. There are a set of keywords that are searched for in the technical requirements. If it turns out that the keyword on coverage is earlier than on the material, an error warning is issued.

Enterprises can set their own standards for the design of documents: layer templates, uniform corporate styles (those who work with construction drawings in AuotCAD will understand).

The user can also narrow the requirements recommended by GOST on the basis of disposable tools and equipment. This applies both to dimensions and their tolerances, threads, roughness parameters (if the machine park does not allow), and sheet formats for printing documents (if there is a trite plotter). Such internal “narrowing” of standards can be set in KOMPAS-Expert by the users themselves.

This is the class of errors that norm-checking, checking “paper” will never see. Even if the document apparently conforms to the standards, the incorrect use of the tool complicates the work of the designer himself and those professionals who receive documents from him.

One of these rules is the “Centerline” object instead of the “Centerline” style segments. When using parametrization, the object is immediately correctly parametrized, correctly fitting into the model. The segment does not have these properties and will load the parametric model in the sketch, making it difficult for the user to work.

By the way, in the old versions of KOMPAS-3D, the “Centerline” object was not yet available. Therefore, it makes sense to check the drawings taken from the archive in order to avoid duplicating such forced errors.

Other similar rules are the use of associativity in annotation objects, the inclusion of text auto-sort, the use of textual hyperlinks, where appropriate.

Well, if you consider yourself to be professionals, then use the tool professionally.

Practically at all enterprises there are specially trained people whose main task is “Bdit” (in some places they are even collected in “Special Departments” and are representatives of “Organs”). So, KOMPAS-Expert will help to stay away from those in their professional interest.

To prevent inadvertent information leaks, checks are provided for unremoved "drafts", hidden objects, links to closed resources of the enterprise.

For example, a potential error is to insert the view from the document with the file name C: \\ AAA Division \ BBB Project \ Product Drawing No. .cdw and send it to the “side” (do you have a “project structure”?).

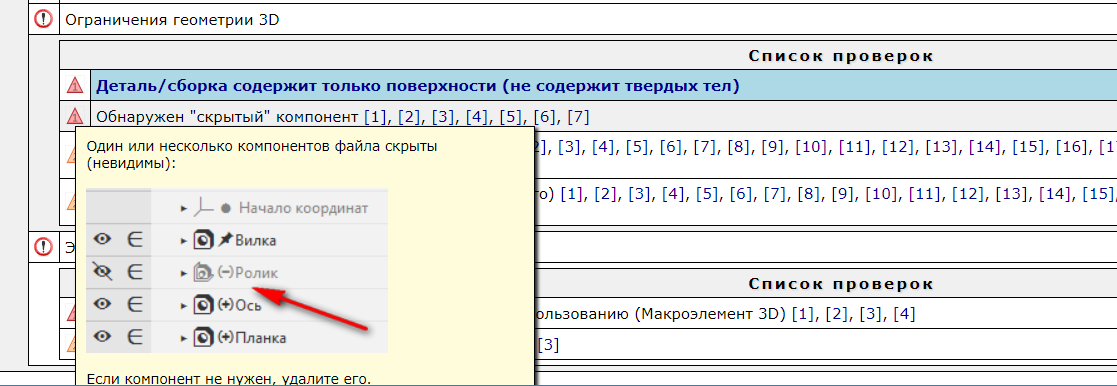

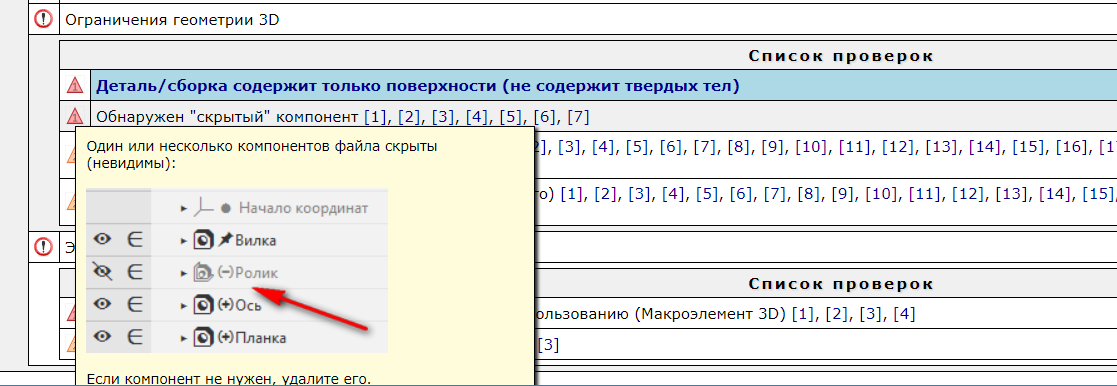

Hidden component detected

It's all like a programmer: the main problem is the use of copy-pasting. Even worse - “copy-pasting” from a drawing that contains errors. As a rule, its author "The Great Guru" and his competence in all matters are not subject to doubt, and the documentation released by Him "by default" is not checked for errors.

Another problem - they draw a little “not by hand”: not in size, without attachments, etc., and then they hand over this “sketch” as a drawing. However, the contours are not collected, the dimensions are not rebuilt, the callout lines fall off. But "passed" on time.

In this direction, we are just starting to move. I would especially like to do technological checks in 3D-models in order to identify potential difficulties with its manufacture at the design creation stage. And for this you need to know the production technology. For example, if the part will be made by casting, it is necessary to analyze the thickness of its walls.

And actually, the product looks and works. For the user, "Expert" is implemented as a web application. It works independently of KOMPAS-3D, but its presence in the workplace is necessary. After launch, a page is loaded containing a toolbar and a result window.

The document can be checked directly in the process of working on it in KOMPAS-3D, in the “two windows” mode (or better, two monitors). Or specify the list of files or the working folder of your project and run the check. On an 8-core processor, checking 200 documents takes 3-5 minutes.

Test results

The result is given in the form of a list of errors, divided into groups. If you select a specific error, the scanned document will open in KOMPAS-3D indicating the place / object where this error was found. Agreeing with the recommendation of the "Expert", the user can immediately proceed to make corrections.

Conclusion

1. Immediately after the release of the application, we began to receive requests: "We want to receive statistics - how many documents are checked, how many errors have been detected." Theoretically, “Expert” could give such an assessment, but we deliberately refuse to make it a punitive tool and do not recommend using it in the regulatory control. Let the designer himself check, correct and give the document without errors.

2. Does the use of KOMPAS-Expert in any way cancel other techniques / methods for checking technical documentation? existing (or planned) in the enterprise. Especially since there is a mysterious graph in the title block that says “Checked”. But more about that next time.

Oleg Volkov, Head of Programming, Applications Division, Ascon.

Oleg Volkov, Head of Programming, Applications Division, Ascon.

At one time, I was inspired by Viva64 to check C ++ code (now this wonderful product is called PVS-Studio ). It performs code analysis on various rules: logical / non-logical, constructor / destructor, comparison of variables and others. The idea arose to apply a similar ideology in KOMPAS-3D: at the output, check the result — the drawing or the 3D model — by certain rules. Moreover, in other CAD systems such checks are implemented.

In general, IT infrastructure development is much better established than in engineering design. It describes in detail how to pass the code, how to verify it, how to version it, at what points what checks to carry out (SWEBOOK to help you). Why not apply this approach to the work of the designer in CAD?

At one time, when computers were large and the work time was expensive, it was customary for programmers to avoid making mistakes at the stage of writing code so that it passes the first time. Now we will once again compile, it will give out a bunch of errors, correct, re-conduct. So in the work of the designer - do not try to get the perfect drawing from the first time. Before you go to get a signature, check, correct, check again. You need to think about your product, and not over the design of the drawing, “Expert” will help.

')

We broke all possible mistakes (document defects) into areas of knowledge and began to “underlay” specific checks for them. At the moment, the project made more than 140 checks.

Design documentation standards (GOST / ESKD)

The first to be implemented were selected design checks. Starting to work on "Expert", we naturally looked at what solutions competitors currently have. Mostly similar systems perform standard checks on the styles: line style, layer names and colors, type of arrow, font style, etc. In our application, we decided to go ahead and really check by standards, since KOMPAS-3D has always been notable for its proximity to them. The developers of the application decided to support this tradition and make full checks based on ESKD standards.

In checking for compliance with a particular standard, the norms of this standard are prescribed. If the document contains elements related to the standard, then they are checked for compliance - for example, design of dimensions, design style, setting of maximum deviations, qualifications, setting of roughness, welded designations. As reference materials in the checks are references to standards. We work with the TechExpert website (http://www.cntd.ru/), on which the fundamental base of the GOST standards is laid out. If the user wants to make sure of the error shown by KOMPAS-Expert, he can go to a specific standard, his particular point on which the check was performed.

The design checks have done a lot of work on the intellectualization of text analysis. In any design document must contain technical requirements. The GOST recommends a certain sequence in their enumeration: first, data on the material, then dimensions, surface quality and coating, adjustment of the product, and further to special operating conditions. We made a check on the correctness of the technical requirements. There are a set of keywords that are searched for in the technical requirements. If it turns out that the keyword on coverage is earlier than on the material, an error warning is issued.

Corporate standards of paperwork

Enterprises can set their own standards for the design of documents: layer templates, uniform corporate styles (those who work with construction drawings in AuotCAD will understand).

The user can also narrow the requirements recommended by GOST on the basis of disposable tools and equipment. This applies both to dimensions and their tolerances, threads, roughness parameters (if the machine park does not allow), and sheet formats for printing documents (if there is a trite plotter). Such internal “narrowing” of standards can be set in KOMPAS-Expert by the users themselves.

Terms of use KOMPAS-3D

This is the class of errors that norm-checking, checking “paper” will never see. Even if the document apparently conforms to the standards, the incorrect use of the tool complicates the work of the designer himself and those professionals who receive documents from him.

One of these rules is the “Centerline” object instead of the “Centerline” style segments. When using parametrization, the object is immediately correctly parametrized, correctly fitting into the model. The segment does not have these properties and will load the parametric model in the sketch, making it difficult for the user to work.

By the way, in the old versions of KOMPAS-3D, the “Centerline” object was not yet available. Therefore, it makes sense to check the drawings taken from the archive in order to avoid duplicating such forced errors.

Other similar rules are the use of associativity in annotation objects, the inclusion of text auto-sort, the use of textual hyperlinks, where appropriate.

Well, if you consider yourself to be professionals, then use the tool professionally.

Protection of information

Practically at all enterprises there are specially trained people whose main task is “Bdit” (in some places they are even collected in “Special Departments” and are representatives of “Organs”). So, KOMPAS-Expert will help to stay away from those in their professional interest.

To prevent inadvertent information leaks, checks are provided for unremoved "drafts", hidden objects, links to closed resources of the enterprise.

For example, a potential error is to insert the view from the document with the file name C: \\ AAA Division \ BBB Project \ Product Drawing No. .cdw and send it to the “side” (do you have a “project structure”?).

Hidden component detected

Negligence and design in the "let's hurry" mode

It's all like a programmer: the main problem is the use of copy-pasting. Even worse - “copy-pasting” from a drawing that contains errors. As a rule, its author "The Great Guru" and his competence in all matters are not subject to doubt, and the documentation released by Him "by default" is not checked for errors.

Another problem - they draw a little “not by hand”: not in size, without attachments, etc., and then they hand over this “sketch” as a drawing. However, the contours are not collected, the dimensions are not rebuilt, the callout lines fall off. But "passed" on time.

Technological control

In this direction, we are just starting to move. I would especially like to do technological checks in 3D-models in order to identify potential difficulties with its manufacture at the design creation stage. And for this you need to know the production technology. For example, if the part will be made by casting, it is necessary to analyze the thickness of its walls.

How it works

And actually, the product looks and works. For the user, "Expert" is implemented as a web application. It works independently of KOMPAS-3D, but its presence in the workplace is necessary. After launch, a page is loaded containing a toolbar and a result window.

The document can be checked directly in the process of working on it in KOMPAS-3D, in the “two windows” mode (or better, two monitors). Or specify the list of files or the working folder of your project and run the check. On an 8-core processor, checking 200 documents takes 3-5 minutes.

Test results

The result is given in the form of a list of errors, divided into groups. If you select a specific error, the scanned document will open in KOMPAS-3D indicating the place / object where this error was found. Agreeing with the recommendation of the "Expert", the user can immediately proceed to make corrections.

Conclusion

1. Immediately after the release of the application, we began to receive requests: "We want to receive statistics - how many documents are checked, how many errors have been detected." Theoretically, “Expert” could give such an assessment, but we deliberately refuse to make it a punitive tool and do not recommend using it in the regulatory control. Let the designer himself check, correct and give the document without errors.

2. Does the use of KOMPAS-Expert in any way cancel other techniques / methods for checking technical documentation? existing (or planned) in the enterprise. Especially since there is a mysterious graph in the title block that says “Checked”. But more about that next time.

Oleg Volkov, Head of Programming, Applications Division, Ascon.

Oleg Volkov, Head of Programming, Applications Division, Ascon.Source: https://habr.com/ru/post/345152/

All Articles