The evolution of hard drives: how have the hard drives changed over 60 years of existence?

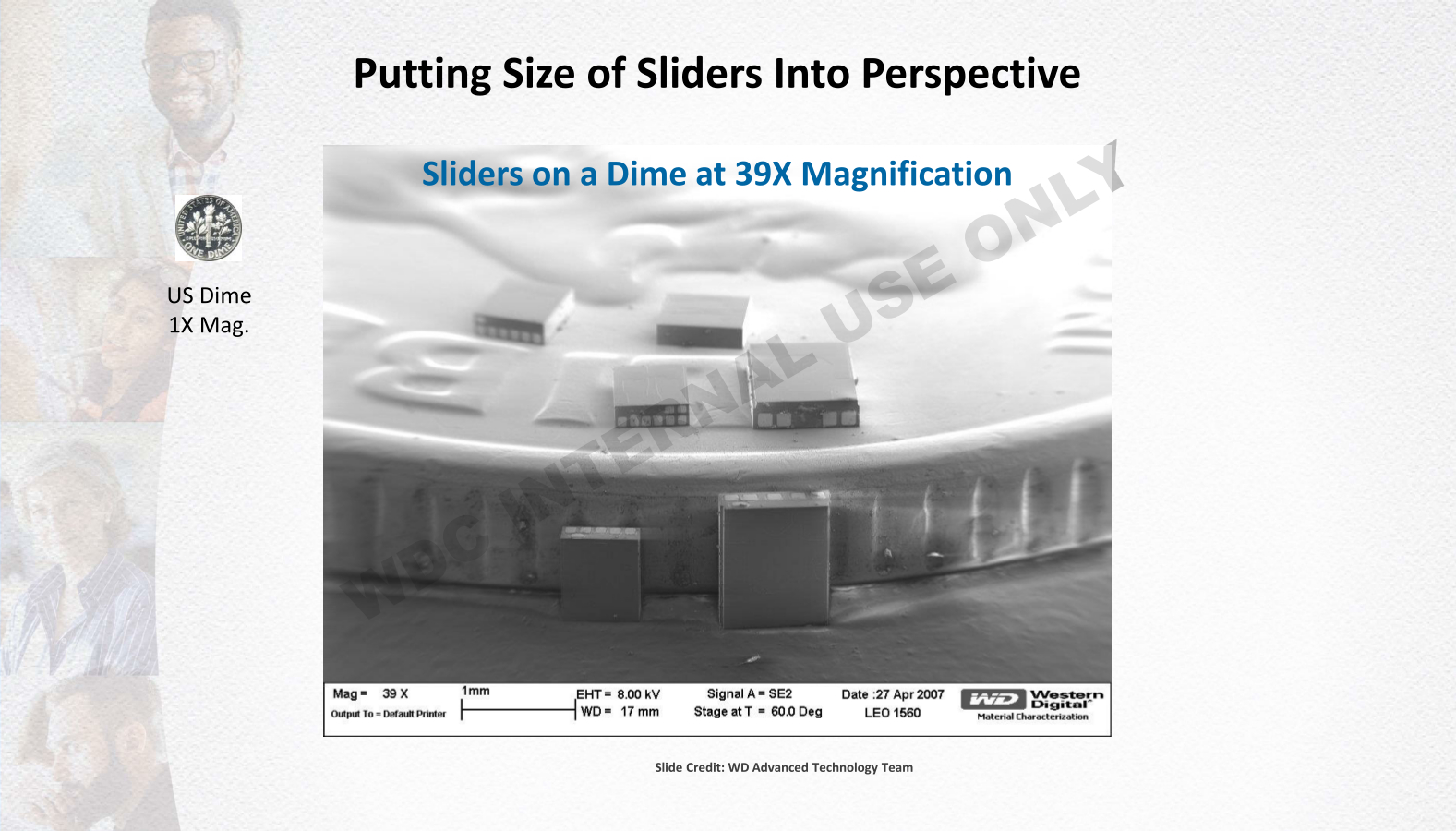

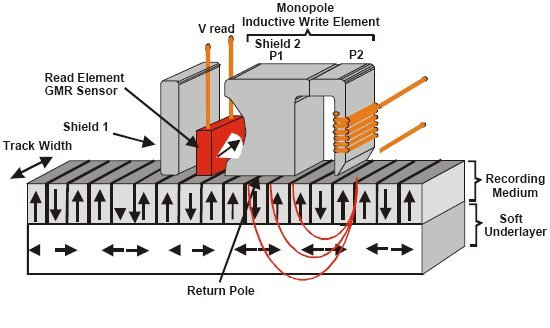

Modern hard drives are the most sophisticated high-tech devices. Just imagine: the size of the writing part of the magnetic head is only 120 nanometers, and the reading part is only 70 nanometers. To imagine a similar scale, just look at what a block of heads looks like with a 39-fold increase against the background of a coin of 10 cents.

Comparison of the size of the block of heads and coins of 10 cents

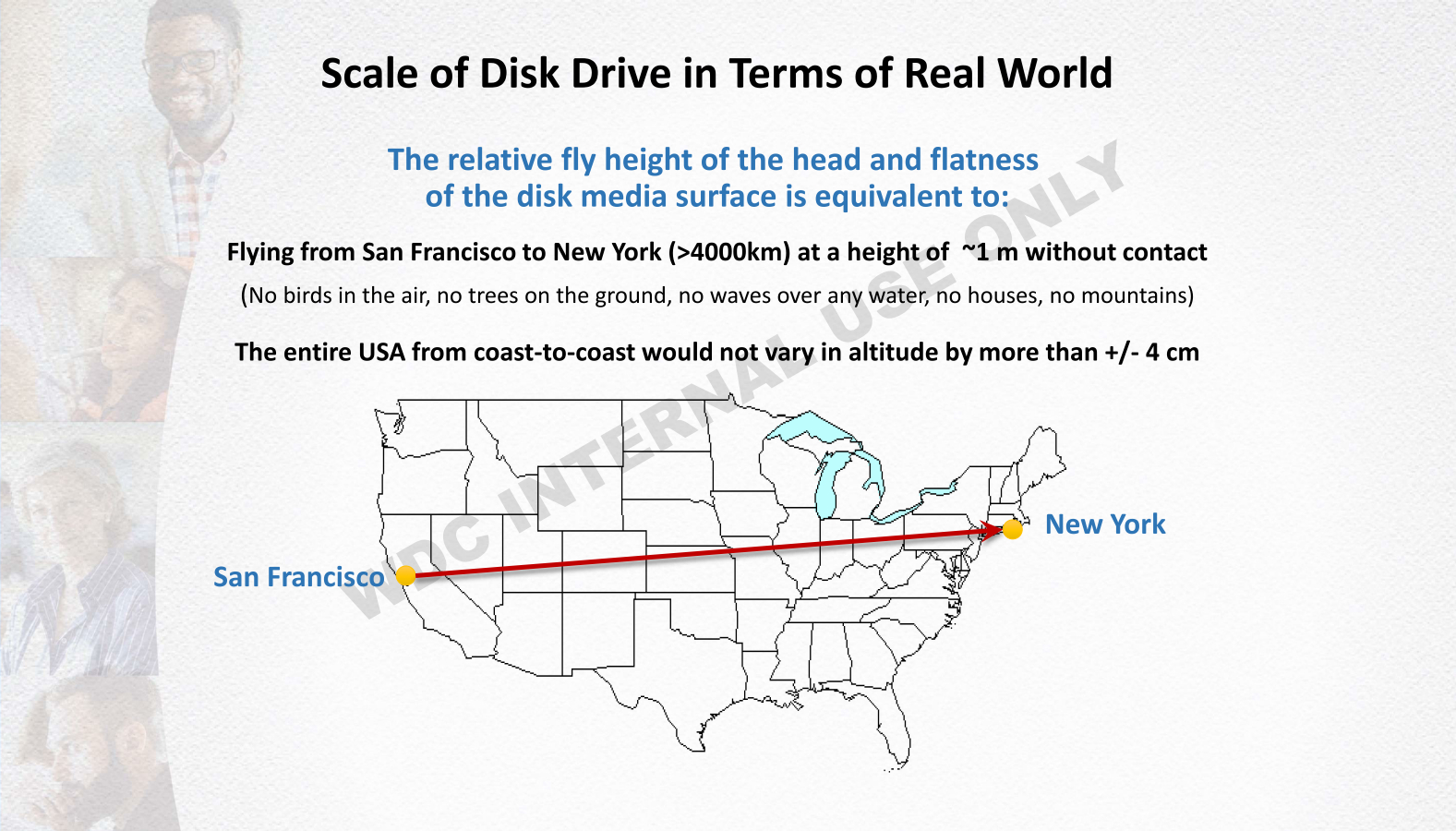

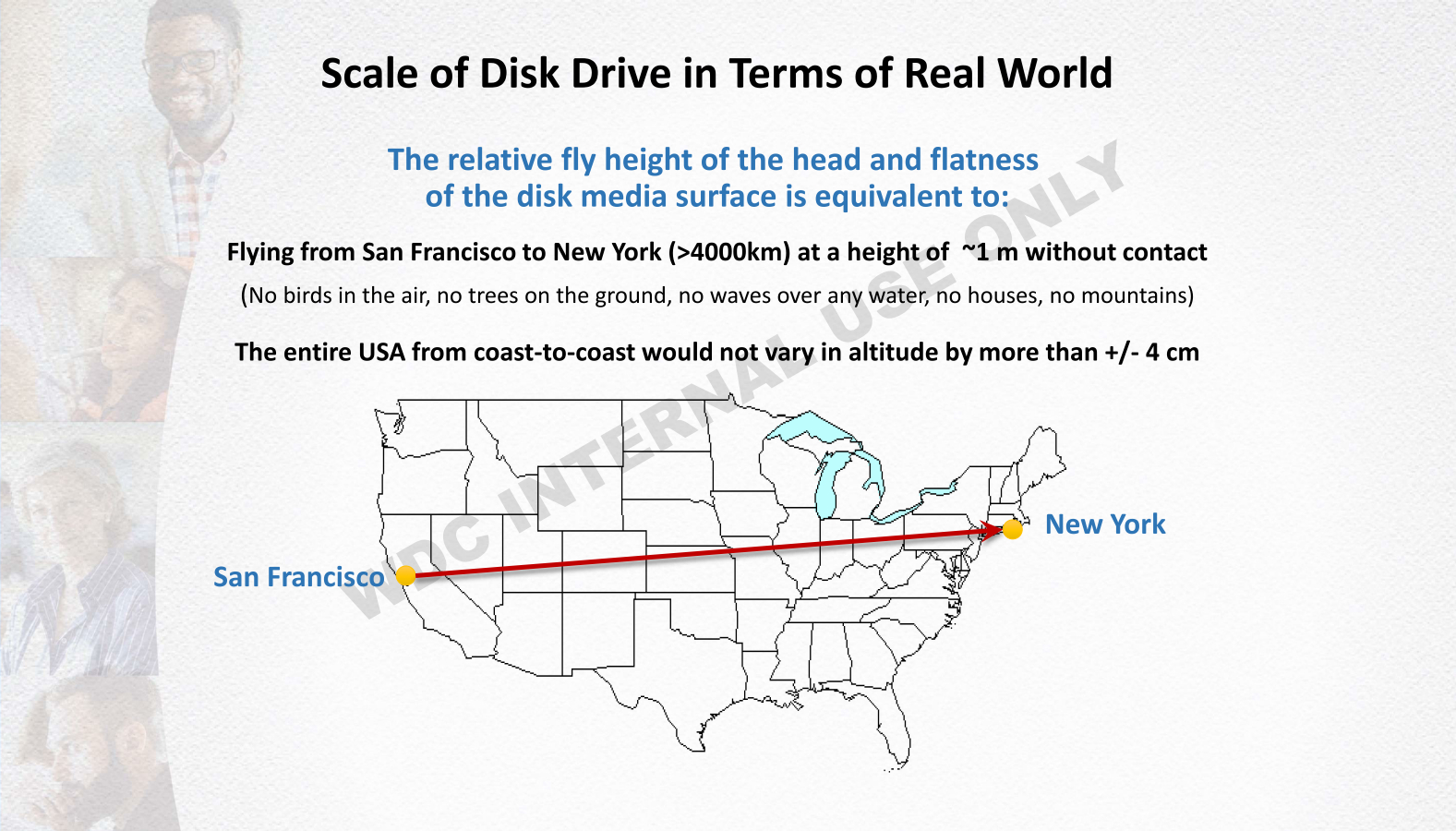

At the same time, magnetic heads soar above the plates at a height of about 12–15 nanometers, which is achieved due to the screen effect: under each of them, as if under a wing of a Boeing on takeoff, an air (or helium, if it comes to solutions on the HelioSeal platform) providing the necessary lifting force. Given such a meager distance, the surface of the pancakes themselves should be perfectly smooth, because the slightest unevenness will lead to irreversible damage to the components of the device. The accuracy of the manufacture of plates is easy to estimate using the following example.

')

If we could increase the 2.5-inch drive about 13 million times so that the gap between the plate and the magnetic head reaches 1 meter, then the latter would overcome a path comparable to the distance between New York and San Francisco (> 4000 kilometers ), and the height difference throughout its length would not exceed 4 centimeters.

The accuracy of the performance of modern HDD in the real world

All the more surprising is the simple fact that the basic principles of HDD construction have not changed for the past 60 years! About what a thorny path has overcome the hard drives from the time of the monstrous RAMAC to the present, we will describe in today's publication.

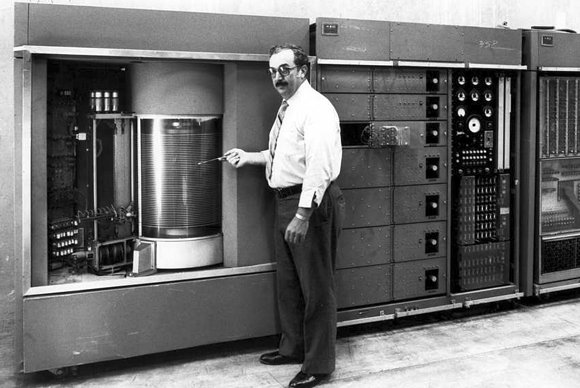

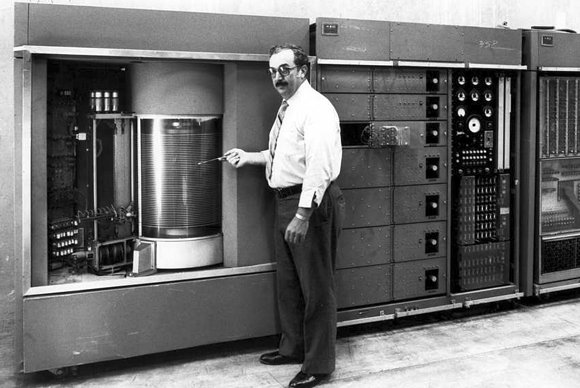

The first hard drive in the world appeared 15 years before the invention of a floppy disk - in 1956. The progenitor of modern HDD was the brainchild of IBM - Model 305 RAMAC, the name of which is an abbreviation of "Random Access Method of Accounting and Control" ("Method of random access to accounting and control"). The unit had enormous dimensions comparable to the dimensions of an industrial refrigerator, weighed almost a ton (or, to be exact, 970 kilograms) and was a system of 50 aluminum plates coated with a ferromagnet, each with a diameter of 24 inches (61 centimeters).

The progenitor of modern hard drives - IBM RAMAC 305

The speed of rotation of pancakes reached 1200 revolutions per minute, impressive for those times, which provided an access time of about 600 milliseconds and an information transfer rate of 8.8 bytes per second. These figures are averaged. The thing is that the device had only one reader moving between the plates with the help of a stepper motor. This approach caused constant delays in the event that the computer needed to receive data recorded, for example, on the first and fiftieth disks. Another weak point of the RAMAC 305 was the reliability of the system: since the writing head directly touched the surface of the plates, this led to strong heating and rapid mechanical wear of both parts.

Despite these shortcomings and the high cost (the price of the issue was $ 10,000, but customers could get a lease - “just” for $ 3,200 per month), IBM was able to sell about 1,000 products, because the cabinet, capable of saving 5 megabytes, successfully replaced 64,000 punch cards and worked much faster than tape drives, also actively used in the IT industry for archiving data since 1951. By the way, after the acquisition of HGST (the former division of Hitachi), the Western Digital production complex of IBM, located in Live Oaks, was at the disposal of Western Digital - it was here that the first devices of the RAMAC 305 series were developed, several of which have remained operational up to the present.

In 1961, the RAMAC 305 was discontinued - it was replaced by the IBM 1301, which embodied a number of important innovations. The main innovation was the implementation of the Air Bearing technology - a gap of 5 micrometers appeared between the pancakes and the recording head, which made it possible to increase the reliability and durability of the device. The plates themselves were now bilateral, and each of them received its own reader.

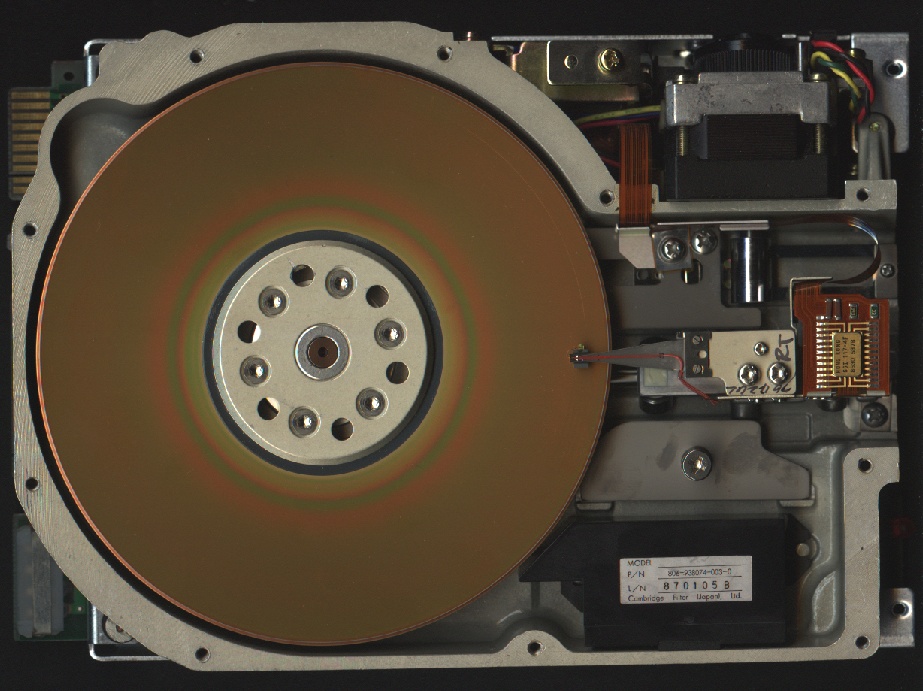

On the cutting edge: the IBM 1301 drive

Thanks to these features, the IBM 1301 turned out to be almost 3 times more productive than its predecessor, as well as more capacious: the access time was reduced to 180 milliseconds, the spindle speed increased to 1800 revolutions per minute, and the amount of stored information reached 28 megabytes (i.e. the recording density was 520 bits per square inch). In addition, IBM somewhat adjusted the pricing policy for the new model: now it was possible to rent equipment for $ 2,100, and this at a price of $ 115.5 thousand.

The next very important step was made already in 1962. Modification of 1311 was fundamentally different in that it received replaceable cassettes. Each of them, with a weight of 4.5 kg, had in its composition 6 “compact” (only 14 inches) magnetic disks. Only 10 planes were available for recording (external surfaces were devoid of a ferromagnetic layer) with a total capacity of 2.6 megabytes, which is comparable to 25 thousand punched cards or 1–5 standard coil. Due to the portability of the IBM 1311, it turned out to be less productive: although the recording density increased by 2 times (1025 bits per square inch), the rotational speed had to be reduced to 1500 revolutions per minute, as a result, the average access time to the sector that could hold 100 bytes increased up to 250 milliseconds. Despite this, the model has gained immense popularity in the corporate environment, since the replaceable cartridges have significantly reduced the cost of storing a unit of information.

This is how the cassette replacement for IBM 1311 looked like.

Due to commercial success, IBM 1311 was released over 10 years - until 1975, and although during this period the model range of hard drives was supplemented by improved models 2302, 2305 and 1311, none of them became equally widespread.

But in the history went to the device under the symbol 3340, which was released in 1973. First of all, the existing technologies were brought to mind. Thanks to the efforts of the corporation engineers, the access time to the sector was reduced by 10 times compared to its predecessor, reaching 25 milliseconds, while the data transfer rate reached 885 kilobytes per second. To improve aerodynamics, cassette casings were made completely airtight, which made it possible to level the influence of environmental factors on the magnetic plates, increasing their reliability.

The world's first "hard drive" - drive IBM 3340 30-30

The device itself acquired a microchip, which more accurately calculated the trajectory of the magnetic heads and corrected the spindle rotation speed, which made it possible to improve positioning accuracy, reduce the distance between tracks and, as a result, increase the capacity of each cartridge to 30 MB. In addition, the device has learned to maintain two disk modules - stationary and removable, as indicated by the suffix "30-30". It was thanks to this marking from the light hand of Kenneth E. Houghton, the project manager, that the slang name “Winchester” clung to the device in honor of the world-famous Winchester rifle using 30-30 ammunition. In the original, these figures signified a bullet caliber (0.3 inches) and a powder charge weight (30 grains). Today, the hard drive has become the common name for hard drives of any model.

An important milestone in the evolution of hard drives is the creation of a thin-film magnetic coating. Although research in this area began as early as the late 1960s based on a research center in Yorktown Heights (New York), iron oxide was used in the production of pancakes until the late 80s. The coating was prepared as follows: a rapidly rotating aluminum billet was poured with a slurry of Fe2O3 powder in a polymer solution. Under the action of centrifugal forces, the composition is evenly distributed over the surface. Then followed the stage of grinding and applying an outer, protective layer characterized by a low coefficient of friction, which was also polished.

The main disadvantage of such a coating is mechanical fragility: in the event of a collision with a head, it easily crumbled, and the disc itself became unusable. However, due to the simplicity of the technology and its cheapness, the oxide coating was safely used in data carriers for almost a quarter of a century.

Consequences of "sticking" of the writing head: the disc received irreversible damage

The transition to a thin-film working layer made possible the emergence of an innovative model of IBM 3370 drives, marketed in 1979. The system, consisting of 7 disks with a diameter of 14 inches, could boast a recording density of up to 7.53 megabits per square inch and already had a volume of 571.3 megabytes. The data transfer rate increased to 1.86 megabytes per second, and the average access time was reduced to a record 20 milliseconds. The price of the device also turned out to be very democratic - the device could be purchased for only $ 35,100, and the rental rate dropped to $ 900 per month. This solution was developed specifically for the IBM System / 38 server platform — up to four hard drives could be connected to each machine, which provided a total storage capacity of 2.28 gigabytes, which at that time could only be dreamed of.

IBM System / 38 Server Platform

All of the above was made possible thanks to the use of thin-film coating. Initially, galvanization was used to create it, which was replaced by a more advanced method of vacuum deposition. The technological process itself is as follows: the used substances and alloys are transferred to a gaseous state in vacuum chambers, then they are deposited on a substrate, in the role of which an aluminum disk acts.

Regardless of the method, in the first stage nickel phosphorus was deposited on the metal surface, followed by a cobalt alloy with magnetic properties, the last was a protective carbon layer comparable in strength to diamond. Due to its presence, it was possible to almost completely eliminate the possibility of damage to the working surface in case of its contact with the recording head (for example, due to a sharp jolt). But the main thing is that the use of a thin-film coating made it possible to significantly reduce the distance between the magnetic head and the pancake, which helped to increase the recording density tenfold. It was thanks to the thin-film coating technology that in 1980 IBM introduced the first hard drive, which overcame a gigabyte boundary. Model 3380 had a capacity of 2.52 gigabytes, while the data transfer rate reached an acceptable 3 megabytes per second.

All the above HDDs were focused exclusively on the corporate sector. And even if you close your eyes to the price, hardly anyone, except for very ideological enthusiasts, would agree to put a wardrobe in their own house of impressive size, even if it contains a huge amount of information. Until the end of the 70s, hard drives remained the prerogative of large commercial and state enterprises. At that time, the PCs were packaged with one or two disk drives for 5.25-inch floppy disks, each of which was capable of storing up to 1200 kilobytes of data, which the average user would have enough.

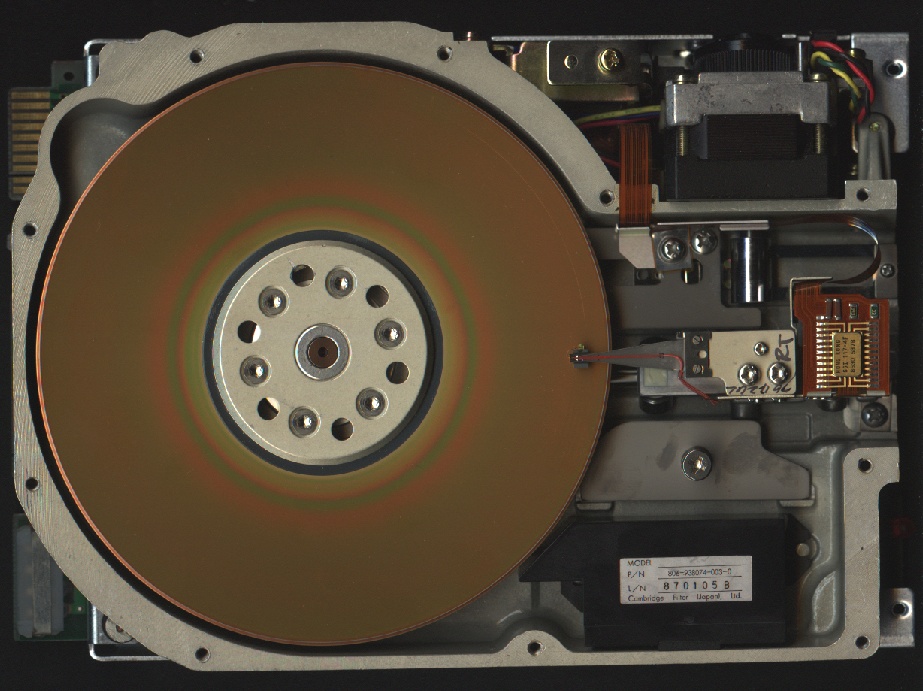

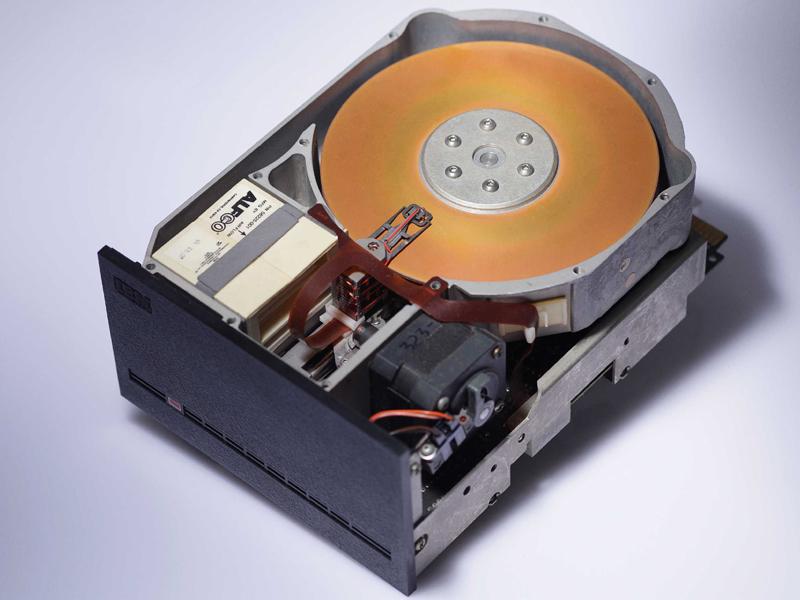

But the computer revolution was relentless - more and more customers were introduced to information technology, which means that an increasing number of picky customers appeared who were no longer satisfied with the 1.2 megabyte framework. Demand creates supply, but this time IBM was out of work: focusing on the business segment, the company missed the retail market, and a small firm Seagate, founded by Al Shugart and several other employees who had previously left the cozy offices of the world-famous corporation, occupied the empty niche. It was they who created in 1980 the world's first consumer-grade HDD, received the unobtrusive name of the ST-506.

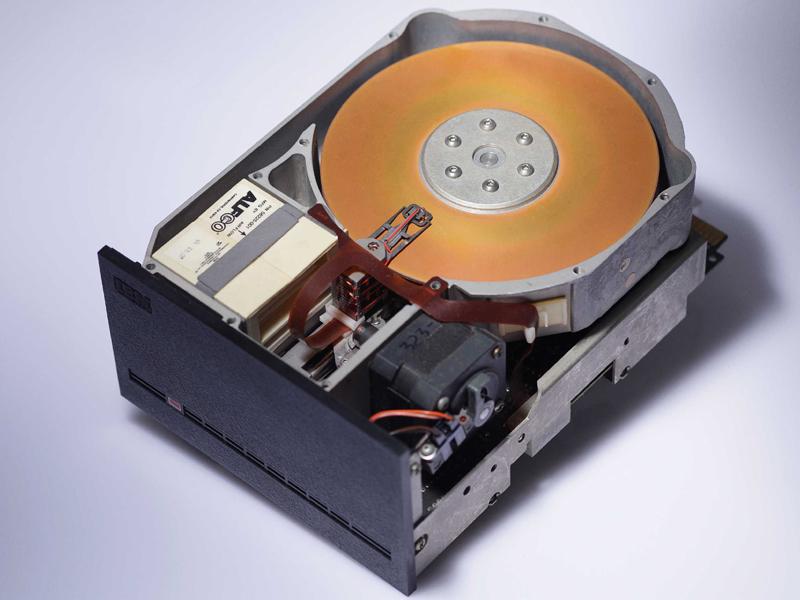

Seagate ST-506 - the world's first HDD for personal computers

The device was intended for installation in a standard 5.25-inch bay (mounted in place of a floppy disk drive) and had a volume of only 5 megabytes, which cannot be compared with industrial models. But the hard drive could boast a good speed, and all thanks to the impressive spindle speed, which reached 3600 revolutions per minute. The price of the drive was $ 1,700 - thus, each megabyte of information cost the owner of the new product $ 340.

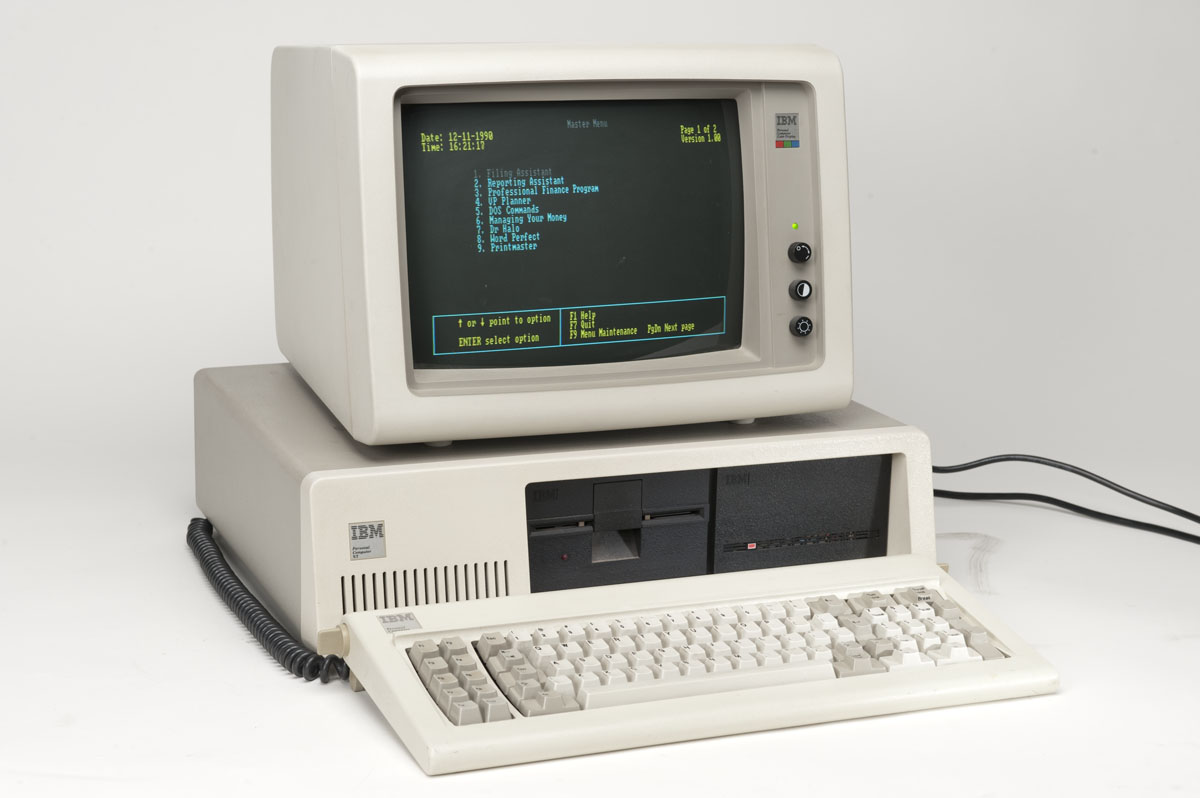

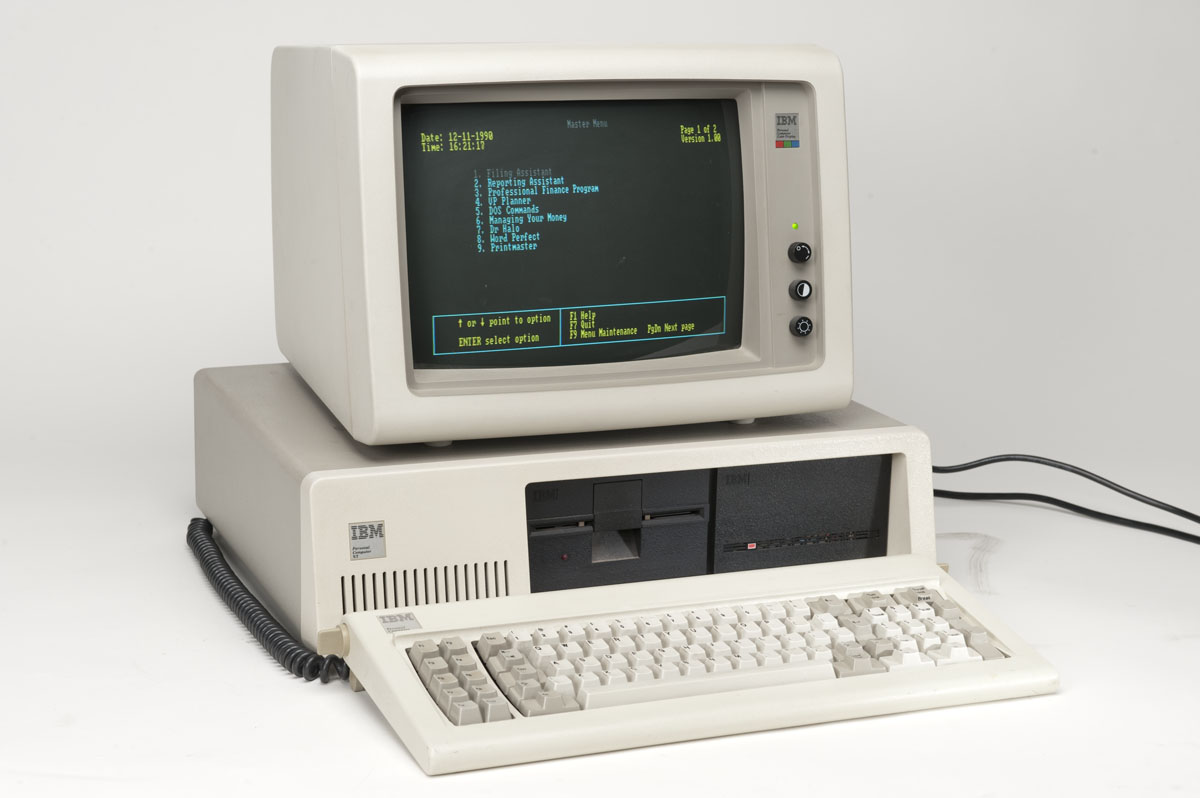

As for IBM, the corporation decided not to get involved in the struggle for the mass user, on the contrary - it entered into a strategic agreement with the latter-day competitor. As a result, on March 8, 1983, a modification of the legendary IBM PC, the IBM 5160 or IBM PC / XT (the postfix XT was short for eXtended Technology), appeared on the market. They were equipped with an improved modification of the ST-412 hard drive, which already contained 10 megabytes of data. How successful this decision turned out to be, it is easy to understand from the numbers: by 1988, over 25 million personal computers of this series were sold.

IBM 5160 equipped with a Seagate ST-412 hard drive

The trend for miniaturization was picked up by other enterprises. So, already in 1983, the Scottish firm Rodime introduced a device called RO351. Not only did this drive get two plates of 10 megabytes each, but it also turned out to be much more miniature than its competitors: the HDD was made in the usual 3.5 ”form factor. And the progenitor of modern solutions used in laptops and portable storage media appeared already in 1988 - it was then that PrairieTek began mass production of 2.5-inch disks of 5 and 10 megabytes, designed for use in laptops. It's funny that very few people remember about the enterprise from Longmont (Colorado) considering the Tamba-1 model, released by Toshiba only three years later, as the first miniature hard drive. Perhaps the reason lies in deliberate marketing - a compact drive that can boast a capacity of 63 megabytes and weighed only 200 grams, was served as the cardinal trump card of the owner, which they successfully beat on advertising posters.

Toshiba Tamba-1 - your trump card!

By and large, the further evolution of hard drives is reduced to three simple words - faster, more capacious, more reliable. Anything happened on this path: often the desire to create as productive devices as possible brought to a standstill both small companies and large corporations. A vivid example of the unpromising direction of development can be called the increase in the speed of rotation of the spindle. If in the late 80s such reached the turn of 3600 revolutions per minute, then already in 1992, the Seagate Barracuda 2LP appeared on the market - the first hard drive capable of boasting an indicator of 7200 revolutions per minute.

The first drive with a spindle speed of 7200 revolutions per minute - Seagate Barracuda 2LP

We should stop at this, but the “arms race” dictated its own rules. Following the "Barracuda" followed by "Cheetah", already accelerated to 10,000 rpm. Western Digital also did not lag behind, soon presenting the world with a ten-thousandth codename Raptor. And although the above drives had much more impressive performance, such high speeds significantly increased the final cost of products due to the need for more expensive bearings, and also contributed to a noticeable reduction in time between failures, which for server solutions (namely, the listed models were positioned) was unacceptable. With the onset of the SSD era, the need for “resourceful” HDDs almost completely disappeared, and now the top bar still remains at 7200 revolutions per minute, and the “racing” hard drives are no longer needed by either the IT industry or the enthusiasts.

However, cases similar to those described above are rare - most often the desire to improve hard drives led to surprising scientific discoveries or the emergence of new standards. Consider the most significant events in chronological order.

Initially, expansion cards with an ST-506 or more advanced ST-412 interface were used to connect hard drives to computers, which received support for the buffered search function (this helped reduce access time to 15–30 milliseconds) and the RLL recording method (recording with group coding), which allowed to double the capacity of the same hard drives manufactured by Seagate.

In 1986, Western Digital, together with Compaq, completed the development of a fundamentally new standard called IDE (Integrated Drive Electronics). From this point on, an AT-compatible controller using a 16-bit ISA bus became an integral part of the drive, which favorably affected the cost of the disk subsystem as a whole: although the price of the device increased slightly, the user no longer needed to purchase additional modules. In turn, the channel controller became universal, and the drive controller was already designed for a specific HDD model, which simplified the production process, also opening up virtually unlimited possibilities for vendors with firmware to vendors.

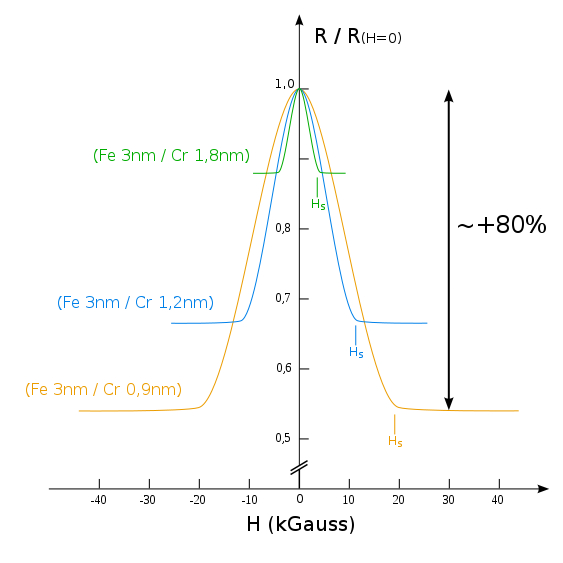

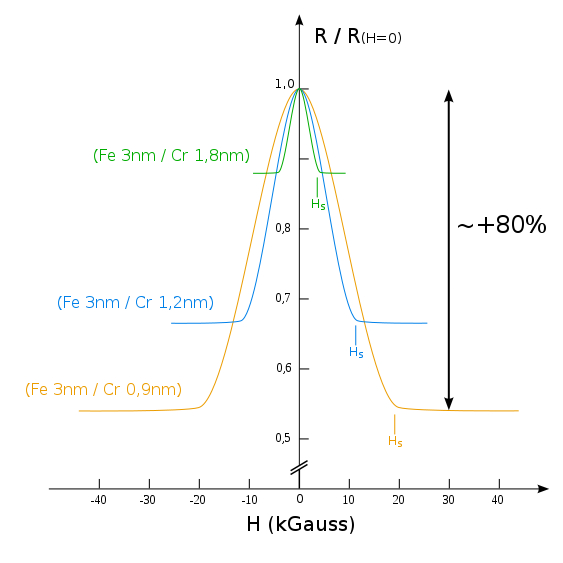

The giant magnetoresistive effect (Giant magnetoresistance, or GMR) was discovered in 1988 by the French physicist Albert Firth and the German scientist Peter Grünberg. They found that when samples of chromium and iron with a clear crystal structure were placed, a sharp increase in the electrical resistance of the material was recorded in a strong electromagnetic field, which is explained by the mismatch of the magnetic field vector and the spin of the electrons of the material. On the contrary, if the direction of rotation of the electrons corresponds to the orientation of the magnetic field, the resistance is significantly less.

The change in electrical resistance under the action of a magnetic field

IBM engineers quickly realized that this phenomenon can be used in practice. The result of their work was the appearance in 1994 of a sensor element (by the way, the thin-film spraying described above was used for its creation), which was based on the GMR effect, and the first commercial hard drives that used this technology were the IBM Deskstar 16GP of 16 gigabytes.

The new generation of magnetic heads was able to pick up much weaker signals generated by the surface of the magnetic plate, which made it possible to increase the recording density several times by reducing the sensor area and, as a result, more compact arrangement of tracks. Already in 1998, IBM announced it was overcoming the line of 11.6 gigabit per square inch, while the upper threshold for classical MR recording was only 3.09 gigabit per square inch (this 2.5-inch drive could boast such a recording density). notebooks IBM Travelstar 8GS volume of 8.1 gigabytes). It is thanks to this discovery in the next four years, the capacity of hard drives increased by almost 5000%, breaking the psychological barrier of 100 gigabytes.

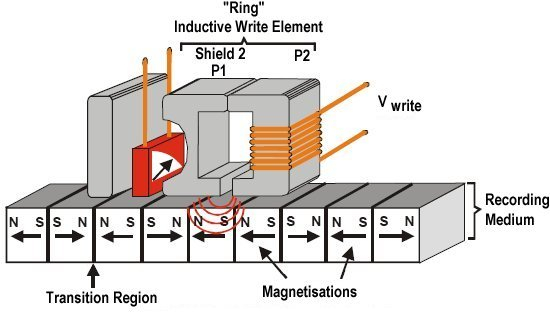

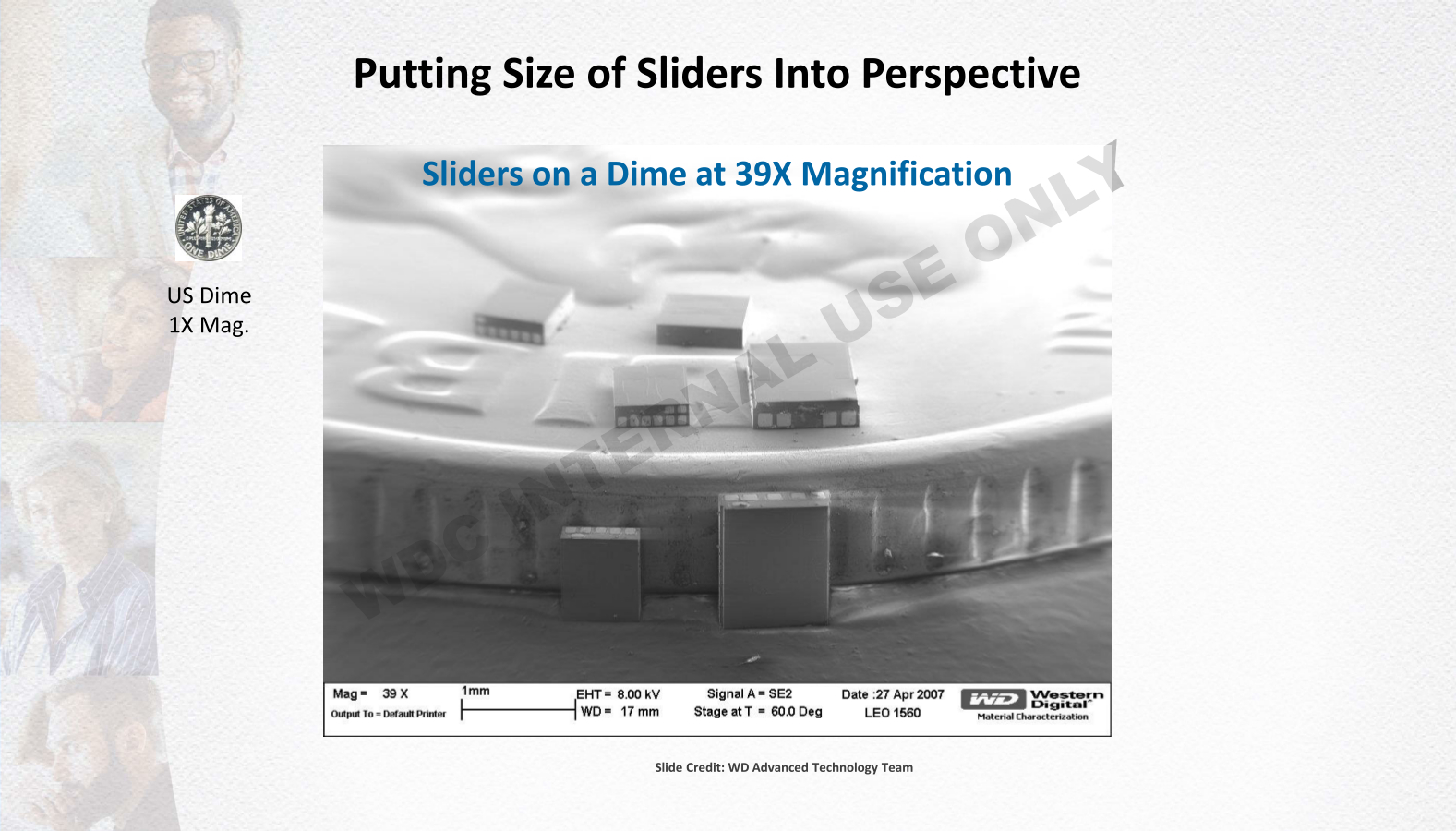

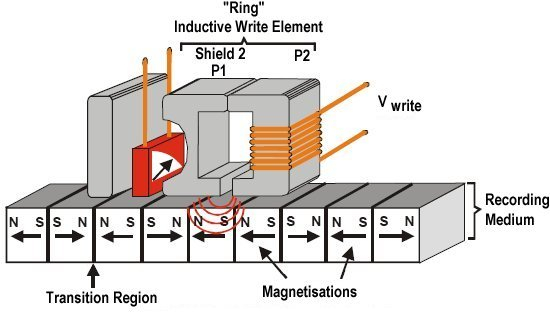

Deliveries of the first drives using PMR (Perpendicular Magnetic Recording) began only in 2006. Until 2005, bits of information were stored in magnetic domains, the vector of which lay parallel to the disk plane. For all its simplicity, this approach had a significant drawback: in order to overcome coercivity (the transition of magnetic particles into a single-domain state), an impressive buffer zone had to be left between tracks, and at some point further increase in recording density became impossible physically.

Method of parallel magnetic recording

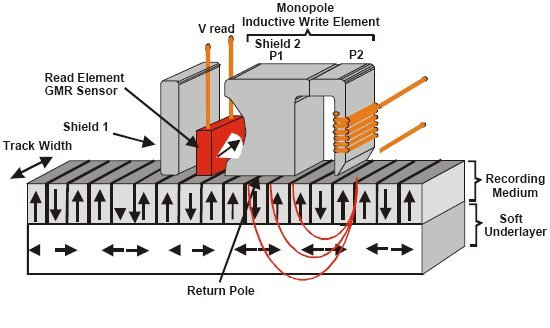

The method of perpendicular recording, known since the 70s of the 20th century, but not used in commercial products due to a more complex implementation, solved this problem due to the fact that the vector of magnetic directivity began to settle at 90 ° relative to the surface of the pancake. This made it possible to reduce the gap between individual tracks and, at the same time, further increase the stability of the magnetic domains. The transition to PMR provided a significant increase in recording density: in the first samples, such an increase increased by more than 30% - up to 400 gigabits per square inch, and modern models reached 1 terabit per square inch.

Perpendicular Magnetic Recording Method

The evolution of hard drives continues: new magnetic recording technologies will soon allow the launch of tens of terabytes of devices on the market, which could not even be dreamed of several years ago. But if the needs of corporate clients have not changed since the times of RAMAC 305, then the interests of the average consumer are no longer limited to dry figures of technical characteristics. In today's reality, almost every device, regardless of the true purpose, becomes an integral part of the personal image. Plain, angular boxes are no longer interesting to people - the buyer wants to get at their disposal not just a convenient and functional tool, but a stylish accessory that will organically fit into the overall concept of the created image.

Anticipating this development, Western Digital has updated the My Passport portable drive line, clearly proving that even such a purely utilitarian item as an external HDD can become a means of self-expression.

The updated line of drives WD My Passport

The visual concept was created in close cooperation with Fuseproject, a world leader in the development of industrial design, which included such famous brands as Microsoft, Disney, BMW, Johnson & Johnson, and many others. Reflecting on the image of My Passport, we tried to do everything possible so that for the end user, the possession of this device turned into a unique, personal perception experience.

We store on external disks photos and videos of major life events, favorite music, books and films - all that is dear to us for one reason or another. And if for a computer, photography is only a collection of zeros and ones, then for a person it is the embodiment of emotions, an integral part of his past, forever imprinted in a static image. It is this thought that more accurately conveys the appearance of My Passport. The body of each HDD is divided into two equal halves by a straight line, symbolizing the border between two realities - the physical (embossed surface with a distinct texture) and digital (symbolized by the laconic glossy part of the device). At the intersection of so different and unlike worlds, there is a portable drive that can help its owner to preserve memories and impressions in the form of a sequence of bits.

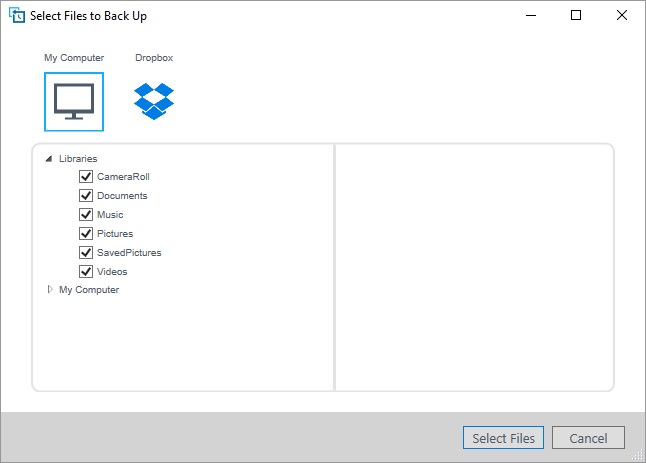

Exquisite, concise case design

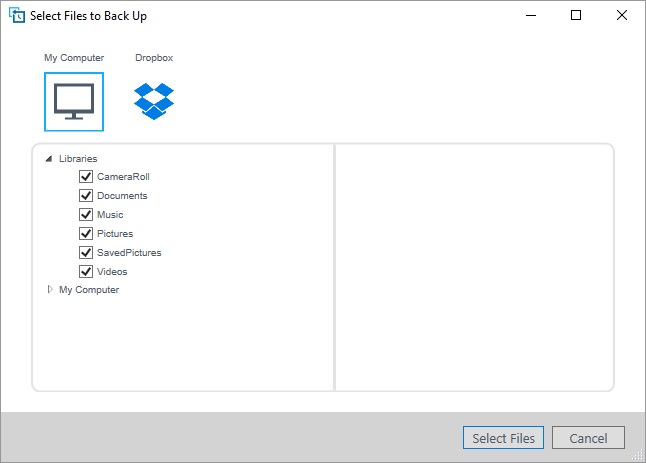

When developing WD My Passport, we didn’t forget about consumer properties - compact and stylish drives are able to satisfy the urgent needs of the pickiest customer. The model range is presented by devices with a capacity from 1 to 4 terabytes. Connecting to a personal computer via the USB 3.0 interface (cable in the color of the package is supplied), while the data transfer rate reaches 110 megabytes per second, which is one of the highest rates among external HDDs. To use the hard disk, you can use the standard tools of the operating system (current versions of Microsoft Windows 7, 8 and 10 are supported) or use the proprietary utility WD Backup. With its help, you can configure scheduled backups, select the folders you want to save, enable automatic synchronization of files if they are edited. You can also connect to the cloud service Dropbox.

Setting up backup using the WD Backup utility

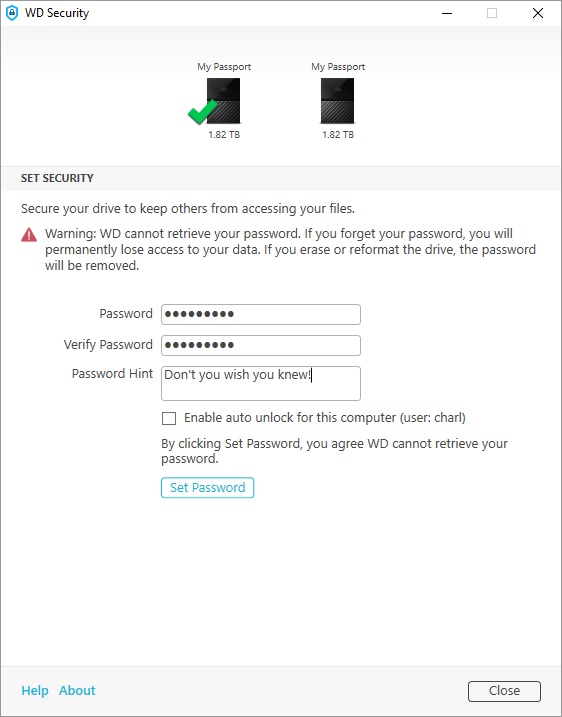

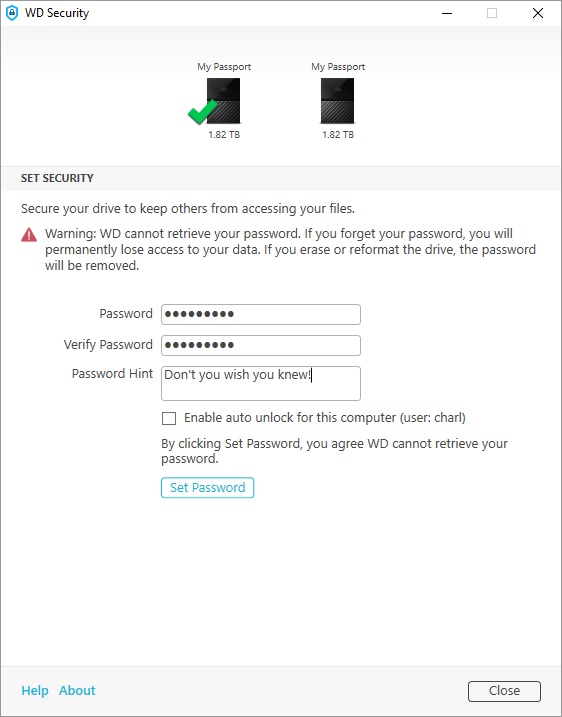

To protect confidential data, the owner of WD My Passport can use the WD Security application - all information will be encrypted, and access to the disk will be possible only with a password. In order not to enter a passphrase every time, you can assign a trusted device status to the computer - in this case, unlocking will be done automatically when connected.

WD My Passport password protection

In addition, we added another very interesting and useful function Return-if-Found (“Return if found”).Behind the telling name is a virtual business card, which will be displayed on the computer screen each time it is connected. Here the user can specify his phone or email, so that in case of loss of the hard drive, the person who found it will be able to contact the owner using the contact details provided. And, of course, all drives in the series support the WD Drive Utilities application, with which you can find out the SMART performance by evaluating the remaining working life of the device.

The updated My Passport portable hard drive line will appeal not only to those who prioritize convenience and functionality, but also to connoisseurs of elegant forms and original design solutions. Combining practicality and stylish look, balanced, fully responsive to modern realities, the devices will appeal to the most demanding audience and can become an excellent gift for the New Year or Christmas.

Comparison of the size of the block of heads and coins of 10 cents

At the same time, magnetic heads soar above the plates at a height of about 12–15 nanometers, which is achieved due to the screen effect: under each of them, as if under a wing of a Boeing on takeoff, an air (or helium, if it comes to solutions on the HelioSeal platform) providing the necessary lifting force. Given such a meager distance, the surface of the pancakes themselves should be perfectly smooth, because the slightest unevenness will lead to irreversible damage to the components of the device. The accuracy of the manufacture of plates is easy to estimate using the following example.

')

If we could increase the 2.5-inch drive about 13 million times so that the gap between the plate and the magnetic head reaches 1 meter, then the latter would overcome a path comparable to the distance between New York and San Francisco (> 4000 kilometers ), and the height difference throughout its length would not exceed 4 centimeters.

The accuracy of the performance of modern HDD in the real world

All the more surprising is the simple fact that the basic principles of HDD construction have not changed for the past 60 years! About what a thorny path has overcome the hard drives from the time of the monstrous RAMAC to the present, we will describe in today's publication.

From RAMAC to Winchester

The first hard drive in the world appeared 15 years before the invention of a floppy disk - in 1956. The progenitor of modern HDD was the brainchild of IBM - Model 305 RAMAC, the name of which is an abbreviation of "Random Access Method of Accounting and Control" ("Method of random access to accounting and control"). The unit had enormous dimensions comparable to the dimensions of an industrial refrigerator, weighed almost a ton (or, to be exact, 970 kilograms) and was a system of 50 aluminum plates coated with a ferromagnet, each with a diameter of 24 inches (61 centimeters).

The progenitor of modern hard drives - IBM RAMAC 305

The speed of rotation of pancakes reached 1200 revolutions per minute, impressive for those times, which provided an access time of about 600 milliseconds and an information transfer rate of 8.8 bytes per second. These figures are averaged. The thing is that the device had only one reader moving between the plates with the help of a stepper motor. This approach caused constant delays in the event that the computer needed to receive data recorded, for example, on the first and fiftieth disks. Another weak point of the RAMAC 305 was the reliability of the system: since the writing head directly touched the surface of the plates, this led to strong heating and rapid mechanical wear of both parts.

Despite these shortcomings and the high cost (the price of the issue was $ 10,000, but customers could get a lease - “just” for $ 3,200 per month), IBM was able to sell about 1,000 products, because the cabinet, capable of saving 5 megabytes, successfully replaced 64,000 punch cards and worked much faster than tape drives, also actively used in the IT industry for archiving data since 1951. By the way, after the acquisition of HGST (the former division of Hitachi), the Western Digital production complex of IBM, located in Live Oaks, was at the disposal of Western Digital - it was here that the first devices of the RAMAC 305 series were developed, several of which have remained operational up to the present.

In 1961, the RAMAC 305 was discontinued - it was replaced by the IBM 1301, which embodied a number of important innovations. The main innovation was the implementation of the Air Bearing technology - a gap of 5 micrometers appeared between the pancakes and the recording head, which made it possible to increase the reliability and durability of the device. The plates themselves were now bilateral, and each of them received its own reader.

On the cutting edge: the IBM 1301 drive

Thanks to these features, the IBM 1301 turned out to be almost 3 times more productive than its predecessor, as well as more capacious: the access time was reduced to 180 milliseconds, the spindle speed increased to 1800 revolutions per minute, and the amount of stored information reached 28 megabytes (i.e. the recording density was 520 bits per square inch). In addition, IBM somewhat adjusted the pricing policy for the new model: now it was possible to rent equipment for $ 2,100, and this at a price of $ 115.5 thousand.

The next very important step was made already in 1962. Modification of 1311 was fundamentally different in that it received replaceable cassettes. Each of them, with a weight of 4.5 kg, had in its composition 6 “compact” (only 14 inches) magnetic disks. Only 10 planes were available for recording (external surfaces were devoid of a ferromagnetic layer) with a total capacity of 2.6 megabytes, which is comparable to 25 thousand punched cards or 1–5 standard coil. Due to the portability of the IBM 1311, it turned out to be less productive: although the recording density increased by 2 times (1025 bits per square inch), the rotational speed had to be reduced to 1500 revolutions per minute, as a result, the average access time to the sector that could hold 100 bytes increased up to 250 milliseconds. Despite this, the model has gained immense popularity in the corporate environment, since the replaceable cartridges have significantly reduced the cost of storing a unit of information.

This is how the cassette replacement for IBM 1311 looked like.

Due to commercial success, IBM 1311 was released over 10 years - until 1975, and although during this period the model range of hard drives was supplemented by improved models 2302, 2305 and 1311, none of them became equally widespread.

But in the history went to the device under the symbol 3340, which was released in 1973. First of all, the existing technologies were brought to mind. Thanks to the efforts of the corporation engineers, the access time to the sector was reduced by 10 times compared to its predecessor, reaching 25 milliseconds, while the data transfer rate reached 885 kilobytes per second. To improve aerodynamics, cassette casings were made completely airtight, which made it possible to level the influence of environmental factors on the magnetic plates, increasing their reliability.

The world's first "hard drive" - drive IBM 3340 30-30

The device itself acquired a microchip, which more accurately calculated the trajectory of the magnetic heads and corrected the spindle rotation speed, which made it possible to improve positioning accuracy, reduce the distance between tracks and, as a result, increase the capacity of each cartridge to 30 MB. In addition, the device has learned to maintain two disk modules - stationary and removable, as indicated by the suffix "30-30". It was thanks to this marking from the light hand of Kenneth E. Houghton, the project manager, that the slang name “Winchester” clung to the device in honor of the world-famous Winchester rifle using 30-30 ammunition. In the original, these figures signified a bullet caliber (0.3 inches) and a powder charge weight (30 grains). Today, the hard drive has become the common name for hard drives of any model.

The introduction of thin film coating technology

An important milestone in the evolution of hard drives is the creation of a thin-film magnetic coating. Although research in this area began as early as the late 1960s based on a research center in Yorktown Heights (New York), iron oxide was used in the production of pancakes until the late 80s. The coating was prepared as follows: a rapidly rotating aluminum billet was poured with a slurry of Fe2O3 powder in a polymer solution. Under the action of centrifugal forces, the composition is evenly distributed over the surface. Then followed the stage of grinding and applying an outer, protective layer characterized by a low coefficient of friction, which was also polished.

The main disadvantage of such a coating is mechanical fragility: in the event of a collision with a head, it easily crumbled, and the disc itself became unusable. However, due to the simplicity of the technology and its cheapness, the oxide coating was safely used in data carriers for almost a quarter of a century.

Consequences of "sticking" of the writing head: the disc received irreversible damage

The transition to a thin-film working layer made possible the emergence of an innovative model of IBM 3370 drives, marketed in 1979. The system, consisting of 7 disks with a diameter of 14 inches, could boast a recording density of up to 7.53 megabits per square inch and already had a volume of 571.3 megabytes. The data transfer rate increased to 1.86 megabytes per second, and the average access time was reduced to a record 20 milliseconds. The price of the device also turned out to be very democratic - the device could be purchased for only $ 35,100, and the rental rate dropped to $ 900 per month. This solution was developed specifically for the IBM System / 38 server platform — up to four hard drives could be connected to each machine, which provided a total storage capacity of 2.28 gigabytes, which at that time could only be dreamed of.

IBM System / 38 Server Platform

All of the above was made possible thanks to the use of thin-film coating. Initially, galvanization was used to create it, which was replaced by a more advanced method of vacuum deposition. The technological process itself is as follows: the used substances and alloys are transferred to a gaseous state in vacuum chambers, then they are deposited on a substrate, in the role of which an aluminum disk acts.

Regardless of the method, in the first stage nickel phosphorus was deposited on the metal surface, followed by a cobalt alloy with magnetic properties, the last was a protective carbon layer comparable in strength to diamond. Due to its presence, it was possible to almost completely eliminate the possibility of damage to the working surface in case of its contact with the recording head (for example, due to a sharp jolt). But the main thing is that the use of a thin-film coating made it possible to significantly reduce the distance between the magnetic head and the pancake, which helped to increase the recording density tenfold. It was thanks to the thin-film coating technology that in 1980 IBM introduced the first hard drive, which overcame a gigabyte boundary. Model 3380 had a capacity of 2.52 gigabytes, while the data transfer rate reached an acceptable 3 megabytes per second.

The beginning of the era of hard drives for personal computers

All the above HDDs were focused exclusively on the corporate sector. And even if you close your eyes to the price, hardly anyone, except for very ideological enthusiasts, would agree to put a wardrobe in their own house of impressive size, even if it contains a huge amount of information. Until the end of the 70s, hard drives remained the prerogative of large commercial and state enterprises. At that time, the PCs were packaged with one or two disk drives for 5.25-inch floppy disks, each of which was capable of storing up to 1200 kilobytes of data, which the average user would have enough.

But the computer revolution was relentless - more and more customers were introduced to information technology, which means that an increasing number of picky customers appeared who were no longer satisfied with the 1.2 megabyte framework. Demand creates supply, but this time IBM was out of work: focusing on the business segment, the company missed the retail market, and a small firm Seagate, founded by Al Shugart and several other employees who had previously left the cozy offices of the world-famous corporation, occupied the empty niche. It was they who created in 1980 the world's first consumer-grade HDD, received the unobtrusive name of the ST-506.

Seagate ST-506 - the world's first HDD for personal computers

The device was intended for installation in a standard 5.25-inch bay (mounted in place of a floppy disk drive) and had a volume of only 5 megabytes, which cannot be compared with industrial models. But the hard drive could boast a good speed, and all thanks to the impressive spindle speed, which reached 3600 revolutions per minute. The price of the drive was $ 1,700 - thus, each megabyte of information cost the owner of the new product $ 340.

As for IBM, the corporation decided not to get involved in the struggle for the mass user, on the contrary - it entered into a strategic agreement with the latter-day competitor. As a result, on March 8, 1983, a modification of the legendary IBM PC, the IBM 5160 or IBM PC / XT (the postfix XT was short for eXtended Technology), appeared on the market. They were equipped with an improved modification of the ST-412 hard drive, which already contained 10 megabytes of data. How successful this decision turned out to be, it is easy to understand from the numbers: by 1988, over 25 million personal computers of this series were sold.

IBM 5160 equipped with a Seagate ST-412 hard drive

The trend for miniaturization was picked up by other enterprises. So, already in 1983, the Scottish firm Rodime introduced a device called RO351. Not only did this drive get two plates of 10 megabytes each, but it also turned out to be much more miniature than its competitors: the HDD was made in the usual 3.5 ”form factor. And the progenitor of modern solutions used in laptops and portable storage media appeared already in 1988 - it was then that PrairieTek began mass production of 2.5-inch disks of 5 and 10 megabytes, designed for use in laptops. It's funny that very few people remember about the enterprise from Longmont (Colorado) considering the Tamba-1 model, released by Toshiba only three years later, as the first miniature hard drive. Perhaps the reason lies in deliberate marketing - a compact drive that can boast a capacity of 63 megabytes and weighed only 200 grams, was served as the cardinal trump card of the owner, which they successfully beat on advertising posters.

Toshiba Tamba-1 - your trump card!

Key milestones that determined the development vector of hard drives

By and large, the further evolution of hard drives is reduced to three simple words - faster, more capacious, more reliable. Anything happened on this path: often the desire to create as productive devices as possible brought to a standstill both small companies and large corporations. A vivid example of the unpromising direction of development can be called the increase in the speed of rotation of the spindle. If in the late 80s such reached the turn of 3600 revolutions per minute, then already in 1992, the Seagate Barracuda 2LP appeared on the market - the first hard drive capable of boasting an indicator of 7200 revolutions per minute.

The first drive with a spindle speed of 7200 revolutions per minute - Seagate Barracuda 2LP

We should stop at this, but the “arms race” dictated its own rules. Following the "Barracuda" followed by "Cheetah", already accelerated to 10,000 rpm. Western Digital also did not lag behind, soon presenting the world with a ten-thousandth codename Raptor. And although the above drives had much more impressive performance, such high speeds significantly increased the final cost of products due to the need for more expensive bearings, and also contributed to a noticeable reduction in time between failures, which for server solutions (namely, the listed models were positioned) was unacceptable. With the onset of the SSD era, the need for “resourceful” HDDs almost completely disappeared, and now the top bar still remains at 7200 revolutions per minute, and the “racing” hard drives are no longer needed by either the IT industry or the enthusiasts.

However, cases similar to those described above are rare - most often the desire to improve hard drives led to surprising scientific discoveries or the emergence of new standards. Consider the most significant events in chronological order.

IDE Interface Development

Initially, expansion cards with an ST-506 or more advanced ST-412 interface were used to connect hard drives to computers, which received support for the buffered search function (this helped reduce access time to 15–30 milliseconds) and the RLL recording method (recording with group coding), which allowed to double the capacity of the same hard drives manufactured by Seagate.

In 1986, Western Digital, together with Compaq, completed the development of a fundamentally new standard called IDE (Integrated Drive Electronics). From this point on, an AT-compatible controller using a 16-bit ISA bus became an integral part of the drive, which favorably affected the cost of the disk subsystem as a whole: although the price of the device increased slightly, the user no longer needed to purchase additional modules. In turn, the channel controller became universal, and the drive controller was already designed for a specific HDD model, which simplified the production process, also opening up virtually unlimited possibilities for vendors with firmware to vendors.

Creating GMR heads

The giant magnetoresistive effect (Giant magnetoresistance, or GMR) was discovered in 1988 by the French physicist Albert Firth and the German scientist Peter Grünberg. They found that when samples of chromium and iron with a clear crystal structure were placed, a sharp increase in the electrical resistance of the material was recorded in a strong electromagnetic field, which is explained by the mismatch of the magnetic field vector and the spin of the electrons of the material. On the contrary, if the direction of rotation of the electrons corresponds to the orientation of the magnetic field, the resistance is significantly less.

The change in electrical resistance under the action of a magnetic field

IBM engineers quickly realized that this phenomenon can be used in practice. The result of their work was the appearance in 1994 of a sensor element (by the way, the thin-film spraying described above was used for its creation), which was based on the GMR effect, and the first commercial hard drives that used this technology were the IBM Deskstar 16GP of 16 gigabytes.

The new generation of magnetic heads was able to pick up much weaker signals generated by the surface of the magnetic plate, which made it possible to increase the recording density several times by reducing the sensor area and, as a result, more compact arrangement of tracks. Already in 1998, IBM announced it was overcoming the line of 11.6 gigabit per square inch, while the upper threshold for classical MR recording was only 3.09 gigabit per square inch (this 2.5-inch drive could boast such a recording density). notebooks IBM Travelstar 8GS volume of 8.1 gigabytes). It is thanks to this discovery in the next four years, the capacity of hard drives increased by almost 5000%, breaking the psychological barrier of 100 gigabytes.

Transition to perpendicular recording method

Deliveries of the first drives using PMR (Perpendicular Magnetic Recording) began only in 2006. Until 2005, bits of information were stored in magnetic domains, the vector of which lay parallel to the disk plane. For all its simplicity, this approach had a significant drawback: in order to overcome coercivity (the transition of magnetic particles into a single-domain state), an impressive buffer zone had to be left between tracks, and at some point further increase in recording density became impossible physically.

Method of parallel magnetic recording

The method of perpendicular recording, known since the 70s of the 20th century, but not used in commercial products due to a more complex implementation, solved this problem due to the fact that the vector of magnetic directivity began to settle at 90 ° relative to the surface of the pancake. This made it possible to reduce the gap between individual tracks and, at the same time, further increase the stability of the magnetic domains. The transition to PMR provided a significant increase in recording density: in the first samples, such an increase increased by more than 30% - up to 400 gigabits per square inch, and modern models reached 1 terabit per square inch.

Perpendicular Magnetic Recording Method

External drives today: appearance matters

The evolution of hard drives continues: new magnetic recording technologies will soon allow the launch of tens of terabytes of devices on the market, which could not even be dreamed of several years ago. But if the needs of corporate clients have not changed since the times of RAMAC 305, then the interests of the average consumer are no longer limited to dry figures of technical characteristics. In today's reality, almost every device, regardless of the true purpose, becomes an integral part of the personal image. Plain, angular boxes are no longer interesting to people - the buyer wants to get at their disposal not just a convenient and functional tool, but a stylish accessory that will organically fit into the overall concept of the created image.

Anticipating this development, Western Digital has updated the My Passport portable drive line, clearly proving that even such a purely utilitarian item as an external HDD can become a means of self-expression.

The updated line of drives WD My Passport

The visual concept was created in close cooperation with Fuseproject, a world leader in the development of industrial design, which included such famous brands as Microsoft, Disney, BMW, Johnson & Johnson, and many others. Reflecting on the image of My Passport, we tried to do everything possible so that for the end user, the possession of this device turned into a unique, personal perception experience.

We store on external disks photos and videos of major life events, favorite music, books and films - all that is dear to us for one reason or another. And if for a computer, photography is only a collection of zeros and ones, then for a person it is the embodiment of emotions, an integral part of his past, forever imprinted in a static image. It is this thought that more accurately conveys the appearance of My Passport. The body of each HDD is divided into two equal halves by a straight line, symbolizing the border between two realities - the physical (embossed surface with a distinct texture) and digital (symbolized by the laconic glossy part of the device). At the intersection of so different and unlike worlds, there is a portable drive that can help its owner to preserve memories and impressions in the form of a sequence of bits.

Exquisite, concise case design

When developing WD My Passport, we didn’t forget about consumer properties - compact and stylish drives are able to satisfy the urgent needs of the pickiest customer. The model range is presented by devices with a capacity from 1 to 4 terabytes. Connecting to a personal computer via the USB 3.0 interface (cable in the color of the package is supplied), while the data transfer rate reaches 110 megabytes per second, which is one of the highest rates among external HDDs. To use the hard disk, you can use the standard tools of the operating system (current versions of Microsoft Windows 7, 8 and 10 are supported) or use the proprietary utility WD Backup. With its help, you can configure scheduled backups, select the folders you want to save, enable automatic synchronization of files if they are edited. You can also connect to the cloud service Dropbox.

Setting up backup using the WD Backup utility

To protect confidential data, the owner of WD My Passport can use the WD Security application - all information will be encrypted, and access to the disk will be possible only with a password. In order not to enter a passphrase every time, you can assign a trusted device status to the computer - in this case, unlocking will be done automatically when connected.

WD My Passport password protection

In addition, we added another very interesting and useful function Return-if-Found (“Return if found”).Behind the telling name is a virtual business card, which will be displayed on the computer screen each time it is connected. Here the user can specify his phone or email, so that in case of loss of the hard drive, the person who found it will be able to contact the owner using the contact details provided. And, of course, all drives in the series support the WD Drive Utilities application, with which you can find out the SMART performance by evaluating the remaining working life of the device.

The updated My Passport portable hard drive line will appeal not only to those who prioritize convenience and functionality, but also to connoisseurs of elegant forms and original design solutions. Combining practicality and stylish look, balanced, fully responsive to modern realities, the devices will appeal to the most demanding audience and can become an excellent gift for the New Year or Christmas.

Source: https://habr.com/ru/post/345112/

All Articles