Prospects for the evolution of hard drives: advanced technology and implementation challenges

For Western Digital, 2017 was marked by a number of high-profile premieres. On April 6, we announced an updated flagship in the line of specialized drives for video surveillance WD Purple with a capacity of 10 TB, and already on May 19, 10-terabyte models of the WD Red and WD Red Pro series were introduced, focused on personal use and operation in corporate NAS. Autumn also did not remain without fresh releases: WD Gold began selling 12 TB in September, and in October the world saw the first 14 TB hard drives released to the market under the HGST Ultrastar Hs14 brand.

All this was a response to the growing needs of IT enterprises: the business is in dire need of increasing the density of information storage, and every year the appetites of companies only grow. The question is, where is the limit, reaching which we can confidently declare: “The time has come to look for a fundamentally different solution to the problem, the potential of hard drives is completely exhausted.” We will discuss this in today's article.

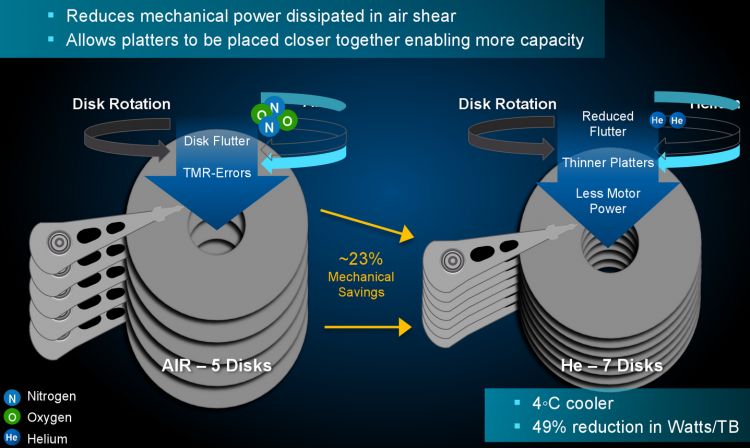

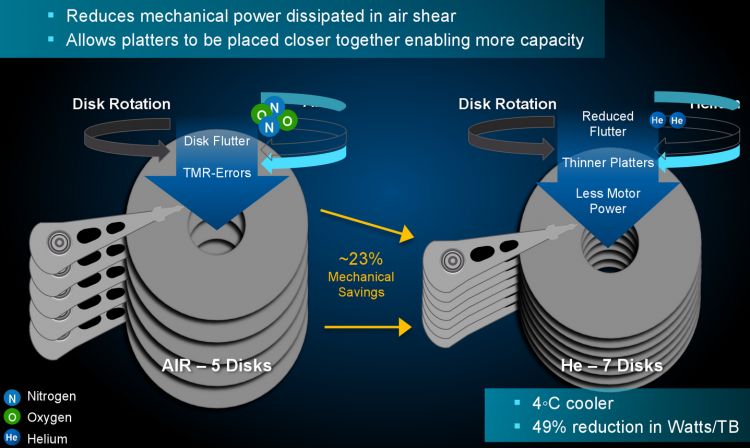

One of the key milestones in the history of our company is the development of the helium platform HelioSeal. Its essence is quite simple: the hard drive case is made completely sealed and filled with helium - a gas that has seven times less density than air. This design provides a number of key benefits:

Advantages of the HelioSeal Platform

')

It is thanks to HelioSeal that the appearance of 6 and 8 terabyte models at the beginning, and then the “heavyweights” of 10, 12 and 14 TB, became possible. But even this did not help to fully meet the demand. The rapid development of the field of information services (especially cloud technologies) has led to an explosive growth in the amount of information processed. While data center volumes increase by approximately 40% each year (as estimated by consulting company International Data Corporation), the HDD capacity for the same period increases by only 20%. In this regard, it is not surprising that if in the first one and a half years of existence HelioSeal Western Digital successfully implemented about 1 million units of hard drives for 6 and 8 TB, then in the third quarter of 2015 alone, a total of 1.1 million were sold. HDD, and already in early October 2016, deliveries crossed the milestone of 10 million drives, the total capacity of which was 76 DL (exabyte).

These statistics leave no reason for doubt: although the new drives and broke world records in their weight, but even 14 TB per device is too little, given the appetites of modern business, which already needs more productive equipment. What are the ways to solve this problem today?

Although the HelioSeal platform helped significantly increase the amount of hard drives, a further increase in the number of magnetic plates is not possible: as practice has shown, adding at least one more device will make it extremely unstable, significantly reducing their reliability. However, the number of “pancakes” is just one of many parameters that determine HDD capacity, and since such characteristics as cell size for storing information units and width of tracks have remained unchanged for many years, there are still prospects for development.

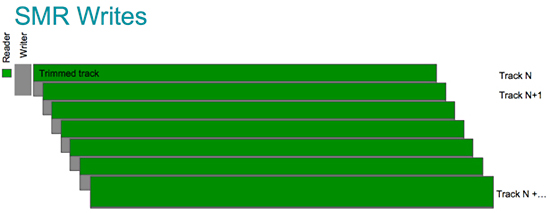

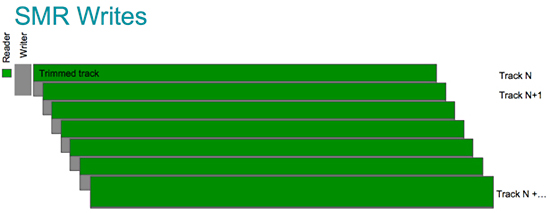

The first thing that comes to mind is the SMR (Shingled Magnetic Recording) technology, which has found application in the new HGST Ultrastar Hs14. The “tiled” method of recording differs from the classical perpendicular method in that each successive track overlaps the previous one: this way it is possible to overcome the threshold of 1 Tbit / inch2 (the maximum that can be squeezed out of PMR). The difference between the two approaches is clearly demonstrated in the diagrams below.

PMR recording: track width well above read area

When we talk about improving PMR recording density due to the high accuracy of head positioning in HelioSeal-based products, we are talking about reducing the gap between tracks (Guard Space in the figure). SMR, in theory, is able to provide volume growth of up to 20% or more.

SMR recording: each new track is layered on the previous one

But, again, only in theory. In practice, there are significant problems with overwriting: since the recording head is wider than the reading area, updating the data not only erases the required fragment, but also subsequent tracks. As a result, each operation has to adjust both the target track and its neighbors. In order to minimize speed losses, tracks are placed in separate groups (“tapes”), which allows fixing the maximum number of tracks requiring rewriting and ensuring stable device performance. However, the need for additional space between the tapes makes SMR no longer so effective in terms of increasing disk capacity.

An alternative to this approach is a combination of PMR and SMR. In fact, HDD is divided into “working” and “archival” zones, in each of which different recording methods are used. The work area plays the role of a kind of cache where files used regularly are stored. Subsequently, they are automatically transferred to the SMR zones without user intervention, which somewhat resembles the “garbage collection” procedure for SSDs.

Another option is to create hybrid models in which, along with the DRAM buffer, either SLC NAND memory or cheaper pLC-based SLC chips will be present. At the output, we get devices that implement three-level caching, which greatly complicates the HDD architecture and requires fundamentally different read / write algorithms that could fully unleash the potential of such a bundle.

But even despite all of the above, SMR will remain a narrowly targeted solution for specific industries - for example, for archiving information and video surveillance (a combination of DRAM + SLC + PMR-zones can provide a sufficiently high sequential recording speed in multi-threaded mode, when one drive serves from 32 to 64 cameras). In the retail segment, this technology is only suitable for the production of compact USB-drives: since such devices are used primarily as portable storage, the difference in performance between SMR and PMR is not so critical. At the same time, tiled recording allows not only increasing the capacity of external HDDs, but also significantly reducing their overall dimensions. For operation as a part of high-performance servers and desktops, such devices, alas, will not work.

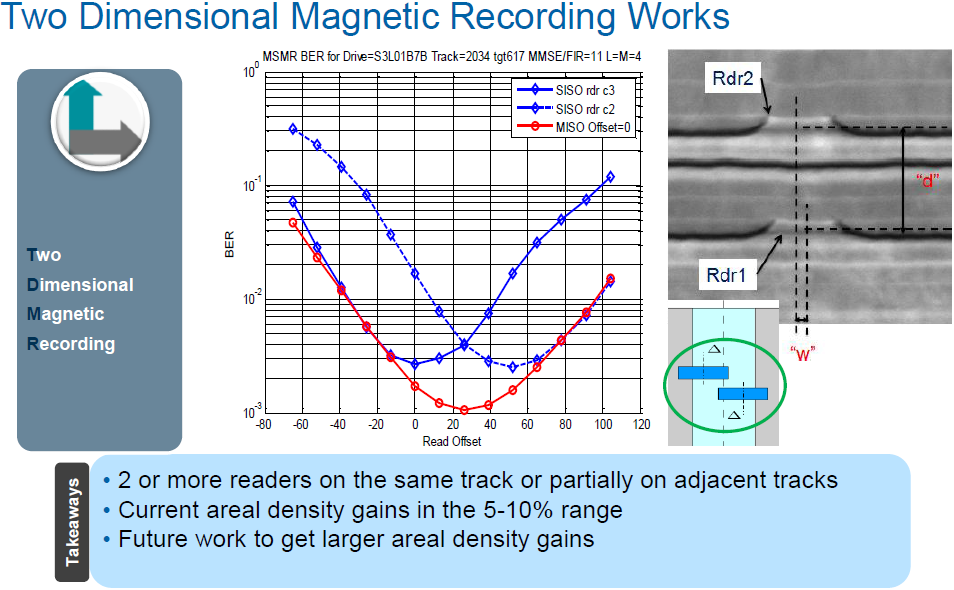

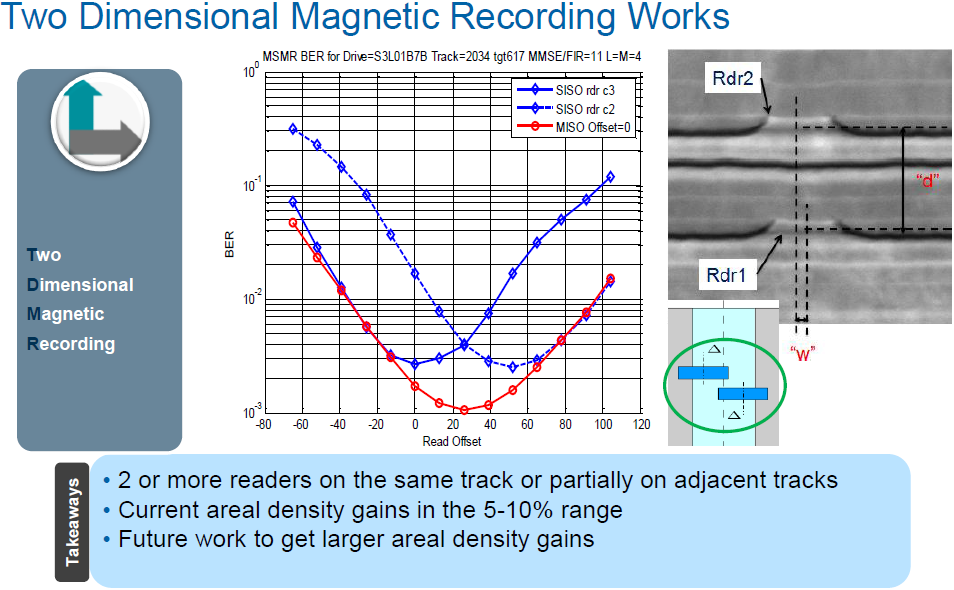

A more interesting technology is a two-dimensional magnetic recording TDMR, capable of providing a stable gain of capacity up to 10% without loss of HDD performance.

TDMR operation and benefits

Its essence lies in the physical reduction of the size of the writing heads, which allows you to position the magnetic tracks more compactly. Here another problem arises - the emergence of ITI (Inter-Track Interference). Simply put, in the process of reading information, the reader will perceive electromagnetic pickups from neighboring tracks, which is fraught with recognition errors. The interference can be defeated by means of additional consecutive calls to one track. As a result, the controller will receive the necessary amount of data to suppress interference, but this approach will significantly increase the delay and will require a significant expansion of the cache.

Another solution is to create an array of read modules that can simultaneously read data from one track. This method allows to reduce the signal-to-noise ratio without the need for additional passes, however, real-time filtering will require more efficient chips, as well as an error control system (however, the latter can be implemented on the basis of the Gallager code). In addition, the use of several readers on one head, if there is an effective ITI suppression system, would help to increase the speed of hard drives by reading several tracks at a time.

Even more interesting prospects are HAMR (Heat-Assisted Magnetic Recording) technology, which can increase recording density up to 2 Tbit / inch2 and even higher. The essence of the thermally-assisted magnetic recording is as follows: the recording head is equipped with a laser with a wavelength of 810 nm and a power of about 20 mW, which locally heats the magnetic plate to 450 ° C. High temperature helps to reduce coercivity (the value of the magnetic field strength required for complete demagnetization), which, in turn, reduces the area required for storing one bit of information, while eliminating the likelihood of a superparamagnetic effect (arbitrary transition of ferromagnetic particles into a single-domain state). that will lead to loss of recorded data).

HAMR operating principle

By tradition, there has not been without pitfalls. The data carrier is heated by means of an optical near-field converter (NFT), which transmits the thermal radiation to the magnetic plate, allowing recording. Due to its excellent optical properties, gold was chosen as the base material for the manufacture of NFT. However, this metal has insufficient mechanical strength and quickly deforms under long-term high-temperature exposure, due to which the optical converter fails too quickly. Therefore, the commercial implementation of this technology rests on the development of a thermally stable alloy.

Another problem is that HAMR indirectly conflicts with HelioSeal. Since the thermal conductivity of helium is greater than that of air, in order to carry out local heating of the magnetic plate, it will be necessary to use a more powerful laser, thereby increasing the requirements for the characteristics of the NFT. The rapid heating of the gaseous medium will lead to an increase in pressure inside the HDD, which means that the force of resistance to rotation of the “pancakes” will also increase, which will inevitably affect energy consumption. In turn, the temperature of the disk housing will increase, and that under no circumstances should exceed 60 ° C, otherwise the costs for upgrading air conditioning systems will increase significantly. All this is a serious obstacle to the mass production of HDD, based on this technology.

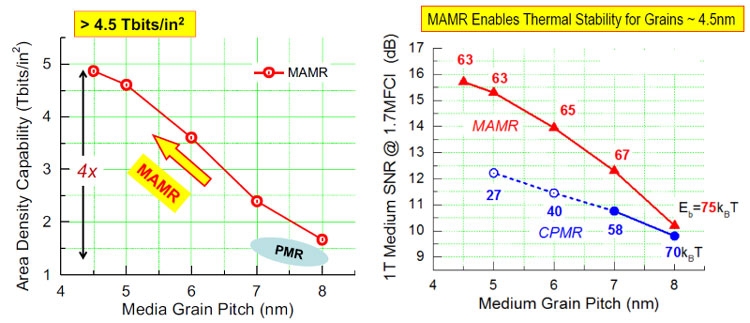

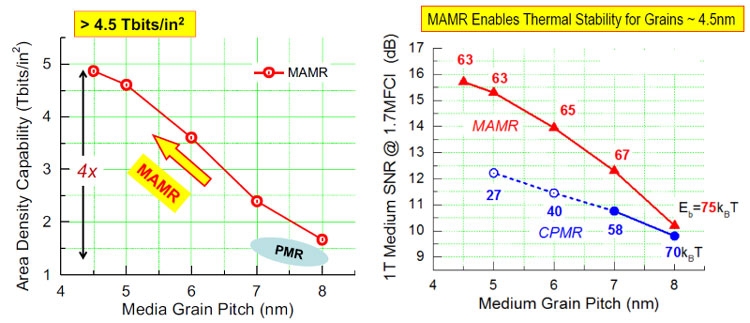

An alternative to the listed technologies is the innovative development Western Digital - MAMR (Microwave Assisted Magnetic Recording - microwave magnetic recording).

MAMR - microwave magnetic recording

The principle of its operation is in many respects similar to HAMR with the only difference being that the generator of the spin moment (STO - Spin Torque Oscillator) is used to excite the magnetic domain in the recording layer. The module is a multi-layer thin-film structure, in the gap of which, under the action of direct current, a high-frequency (20–40 Hz) circular field acts on the magnetic plate, due to which it is possible to significantly reduce the coercivity and, therefore, significantly alter the magnetization vector. MAMR is compatible with classical PMR, while reducing the size of the “grain” (the area required to record one bit of information) from 8–12 nm to a record 4 nm or even less.

Benefits of using MAMR

Thus, we managed to achieve a record recording density of up to 4 Tbit / inch2, which in the future will make it possible to create drives with a capacity of 40 TB and higher in a classic package with a 3.5 ”form factor. The first serial devices are planned to be released on the market as early as 2019. Their use will help to increase the gross data center capacity by 40%, while the operating costs of disk storage remain the same, since, unlike HAMR, new HDDs have low heat generation, and the STO generator is practically not subject to wear. If we talk about the migration from SSD-drives to hard drives based on MAMR, then their implementation will help reduce the cost of storing each gigabyte of information by 10 times.

Speaking about the prospects for further evolution of hard drives, it is necessary to clarify a simple truth: the rules of the game have changed, the industry is slowly but surely heading for a clear segmentation and the creation of highly specialized products, “sharpened” for specific tasks. When it comes to servers and nearline applications, it becomes impractical to sacrifice speed for the sake of greater capacity, and here the helium platform that can provide high performance and impressive capacity remains the best choice.

In the case of network file storage and DAS, SMR capabilities are enough, and for DVRs, a tiled record in tandem with an advanced caching and information processing system based on SLC NAND would be a reasonable choice. TDMR will conquer the consumer market: competent implementation of two-dimensional recording will allow you to create succinct, fast and inexpensive (compared to models based on HelioSeal) solutions that will be quite in demand among professionals and enthusiasts.

Initially focused on the corporate segment, MAMR drives in the future can become the “gold standard” of high-performance data centers and cloud platforms. As for HAMR, there is still no need to talk about the massive introduction of this technology - too many technical and economic problems have yet to be resolved. Considering the appearance of Microwave Assisted Magnetic Recording, it can be said that the thermally-assisted magnetic recording looks like a dead-end branch of development, and HAMR may never be widely used.

All this was a response to the growing needs of IT enterprises: the business is in dire need of increasing the density of information storage, and every year the appetites of companies only grow. The question is, where is the limit, reaching which we can confidently declare: “The time has come to look for a fundamentally different solution to the problem, the potential of hard drives is completely exhausted.” We will discuss this in today's article.

The industry does not keep up with customers

One of the key milestones in the history of our company is the development of the helium platform HelioSeal. Its essence is quite simple: the hard drive case is made completely sealed and filled with helium - a gas that has seven times less density than air. This design provides a number of key benefits:

- significantly less resistance of the gas medium inside the disc allowed the use of thinner magnetic plates, increasing their number from five to seven;

- reduction of turbulence helped to improve positioning accuracy, reduce the gap between the magnetic plates and the recording head, thereby reducing its physical size, achieving higher recording density using the PMR method (perpendicular magnetic recording), and increasing the HDD speed by 21%;

- The reduction in friction force made the discs colder at 4 ° C and almost 49% more economical in terms of capacity (the latter is due to the lower energy consumption for the spindle spin-off).

Advantages of the HelioSeal Platform

')

It is thanks to HelioSeal that the appearance of 6 and 8 terabyte models at the beginning, and then the “heavyweights” of 10, 12 and 14 TB, became possible. But even this did not help to fully meet the demand. The rapid development of the field of information services (especially cloud technologies) has led to an explosive growth in the amount of information processed. While data center volumes increase by approximately 40% each year (as estimated by consulting company International Data Corporation), the HDD capacity for the same period increases by only 20%. In this regard, it is not surprising that if in the first one and a half years of existence HelioSeal Western Digital successfully implemented about 1 million units of hard drives for 6 and 8 TB, then in the third quarter of 2015 alone, a total of 1.1 million were sold. HDD, and already in early October 2016, deliveries crossed the milestone of 10 million drives, the total capacity of which was 76 DL (exabyte).

These statistics leave no reason for doubt: although the new drives and broke world records in their weight, but even 14 TB per device is too little, given the appetites of modern business, which already needs more productive equipment. What are the ways to solve this problem today?

SMR - a promising solution for file storage

Although the HelioSeal platform helped significantly increase the amount of hard drives, a further increase in the number of magnetic plates is not possible: as practice has shown, adding at least one more device will make it extremely unstable, significantly reducing their reliability. However, the number of “pancakes” is just one of many parameters that determine HDD capacity, and since such characteristics as cell size for storing information units and width of tracks have remained unchanged for many years, there are still prospects for development.

The first thing that comes to mind is the SMR (Shingled Magnetic Recording) technology, which has found application in the new HGST Ultrastar Hs14. The “tiled” method of recording differs from the classical perpendicular method in that each successive track overlaps the previous one: this way it is possible to overcome the threshold of 1 Tbit / inch2 (the maximum that can be squeezed out of PMR). The difference between the two approaches is clearly demonstrated in the diagrams below.

PMR recording: track width well above read area

When we talk about improving PMR recording density due to the high accuracy of head positioning in HelioSeal-based products, we are talking about reducing the gap between tracks (Guard Space in the figure). SMR, in theory, is able to provide volume growth of up to 20% or more.

SMR recording: each new track is layered on the previous one

But, again, only in theory. In practice, there are significant problems with overwriting: since the recording head is wider than the reading area, updating the data not only erases the required fragment, but also subsequent tracks. As a result, each operation has to adjust both the target track and its neighbors. In order to minimize speed losses, tracks are placed in separate groups (“tapes”), which allows fixing the maximum number of tracks requiring rewriting and ensuring stable device performance. However, the need for additional space between the tapes makes SMR no longer so effective in terms of increasing disk capacity.

An alternative to this approach is a combination of PMR and SMR. In fact, HDD is divided into “working” and “archival” zones, in each of which different recording methods are used. The work area plays the role of a kind of cache where files used regularly are stored. Subsequently, they are automatically transferred to the SMR zones without user intervention, which somewhat resembles the “garbage collection” procedure for SSDs.

Another option is to create hybrid models in which, along with the DRAM buffer, either SLC NAND memory or cheaper pLC-based SLC chips will be present. At the output, we get devices that implement three-level caching, which greatly complicates the HDD architecture and requires fundamentally different read / write algorithms that could fully unleash the potential of such a bundle.

But even despite all of the above, SMR will remain a narrowly targeted solution for specific industries - for example, for archiving information and video surveillance (a combination of DRAM + SLC + PMR-zones can provide a sufficiently high sequential recording speed in multi-threaded mode, when one drive serves from 32 to 64 cameras). In the retail segment, this technology is only suitable for the production of compact USB-drives: since such devices are used primarily as portable storage, the difference in performance between SMR and PMR is not so critical. At the same time, tiled recording allows not only increasing the capacity of external HDDs, but also significantly reducing their overall dimensions. For operation as a part of high-performance servers and desktops, such devices, alas, will not work.

TDMR, HAMR or MAMR?

A more interesting technology is a two-dimensional magnetic recording TDMR, capable of providing a stable gain of capacity up to 10% without loss of HDD performance.

TDMR operation and benefits

Its essence lies in the physical reduction of the size of the writing heads, which allows you to position the magnetic tracks more compactly. Here another problem arises - the emergence of ITI (Inter-Track Interference). Simply put, in the process of reading information, the reader will perceive electromagnetic pickups from neighboring tracks, which is fraught with recognition errors. The interference can be defeated by means of additional consecutive calls to one track. As a result, the controller will receive the necessary amount of data to suppress interference, but this approach will significantly increase the delay and will require a significant expansion of the cache.

Another solution is to create an array of read modules that can simultaneously read data from one track. This method allows to reduce the signal-to-noise ratio without the need for additional passes, however, real-time filtering will require more efficient chips, as well as an error control system (however, the latter can be implemented on the basis of the Gallager code). In addition, the use of several readers on one head, if there is an effective ITI suppression system, would help to increase the speed of hard drives by reading several tracks at a time.

Even more interesting prospects are HAMR (Heat-Assisted Magnetic Recording) technology, which can increase recording density up to 2 Tbit / inch2 and even higher. The essence of the thermally-assisted magnetic recording is as follows: the recording head is equipped with a laser with a wavelength of 810 nm and a power of about 20 mW, which locally heats the magnetic plate to 450 ° C. High temperature helps to reduce coercivity (the value of the magnetic field strength required for complete demagnetization), which, in turn, reduces the area required for storing one bit of information, while eliminating the likelihood of a superparamagnetic effect (arbitrary transition of ferromagnetic particles into a single-domain state). that will lead to loss of recorded data).

HAMR operating principle

By tradition, there has not been without pitfalls. The data carrier is heated by means of an optical near-field converter (NFT), which transmits the thermal radiation to the magnetic plate, allowing recording. Due to its excellent optical properties, gold was chosen as the base material for the manufacture of NFT. However, this metal has insufficient mechanical strength and quickly deforms under long-term high-temperature exposure, due to which the optical converter fails too quickly. Therefore, the commercial implementation of this technology rests on the development of a thermally stable alloy.

Another problem is that HAMR indirectly conflicts with HelioSeal. Since the thermal conductivity of helium is greater than that of air, in order to carry out local heating of the magnetic plate, it will be necessary to use a more powerful laser, thereby increasing the requirements for the characteristics of the NFT. The rapid heating of the gaseous medium will lead to an increase in pressure inside the HDD, which means that the force of resistance to rotation of the “pancakes” will also increase, which will inevitably affect energy consumption. In turn, the temperature of the disk housing will increase, and that under no circumstances should exceed 60 ° C, otherwise the costs for upgrading air conditioning systems will increase significantly. All this is a serious obstacle to the mass production of HDD, based on this technology.

An alternative to the listed technologies is the innovative development Western Digital - MAMR (Microwave Assisted Magnetic Recording - microwave magnetic recording).

MAMR - microwave magnetic recording

The principle of its operation is in many respects similar to HAMR with the only difference being that the generator of the spin moment (STO - Spin Torque Oscillator) is used to excite the magnetic domain in the recording layer. The module is a multi-layer thin-film structure, in the gap of which, under the action of direct current, a high-frequency (20–40 Hz) circular field acts on the magnetic plate, due to which it is possible to significantly reduce the coercivity and, therefore, significantly alter the magnetization vector. MAMR is compatible with classical PMR, while reducing the size of the “grain” (the area required to record one bit of information) from 8–12 nm to a record 4 nm or even less.

Benefits of using MAMR

Thus, we managed to achieve a record recording density of up to 4 Tbit / inch2, which in the future will make it possible to create drives with a capacity of 40 TB and higher in a classic package with a 3.5 ”form factor. The first serial devices are planned to be released on the market as early as 2019. Their use will help to increase the gross data center capacity by 40%, while the operating costs of disk storage remain the same, since, unlike HAMR, new HDDs have low heat generation, and the STO generator is practically not subject to wear. If we talk about the migration from SSD-drives to hard drives based on MAMR, then their implementation will help reduce the cost of storing each gigabyte of information by 10 times.

The course for highly specialized products

Speaking about the prospects for further evolution of hard drives, it is necessary to clarify a simple truth: the rules of the game have changed, the industry is slowly but surely heading for a clear segmentation and the creation of highly specialized products, “sharpened” for specific tasks. When it comes to servers and nearline applications, it becomes impractical to sacrifice speed for the sake of greater capacity, and here the helium platform that can provide high performance and impressive capacity remains the best choice.

In the case of network file storage and DAS, SMR capabilities are enough, and for DVRs, a tiled record in tandem with an advanced caching and information processing system based on SLC NAND would be a reasonable choice. TDMR will conquer the consumer market: competent implementation of two-dimensional recording will allow you to create succinct, fast and inexpensive (compared to models based on HelioSeal) solutions that will be quite in demand among professionals and enthusiasts.

Initially focused on the corporate segment, MAMR drives in the future can become the “gold standard” of high-performance data centers and cloud platforms. As for HAMR, there is still no need to talk about the massive introduction of this technology - too many technical and economic problems have yet to be resolved. Considering the appearance of Microwave Assisted Magnetic Recording, it can be said that the thermally-assisted magnetic recording looks like a dead-end branch of development, and HAMR may never be widely used.

Source: https://habr.com/ru/post/344252/

All Articles