Strike iron: hot hardware startups

Boris Kaganovich, Technical Director of CINEMOOD, opens a series of articles on hardware startups, development, production and product development. In the first article of the cycle - a dictionary of specific terms that will help developers and founders of companies to integrate faster in the hardware environment.

')

Hi, Habr! To begin, introduce ourselves. We are already 4 years old, we are developing rapidly and ... we are not a hardware startup. We have developed and produced a portable cinema, we are passionately engaged in the development of new devices, support their quality, design and innovation, but the devices are those

Google has been teaching us the term “reference device” for many years, releasing a series of products under the brands of Nexus, Pixel, Home and all sorts of Chrome-something-there. Users have learned the value of these products well. It is in high-quality build, balanced specification, always fresh design, and, of course, impeccably optimized software with regular updates and long-term support.

We share the principles laid out by the Mountain View company. CINEMOOD OS is the content platform for which we invented and released the reference device CINEMOOD Storyteller.

In a series of articles devoted to the development and production of "iron", we turn to external sources - including, we decided to supplement our experience of working on the product with the knowledge of Bolt.io professionals to help young hardware startups not to go the distance on the road to success .

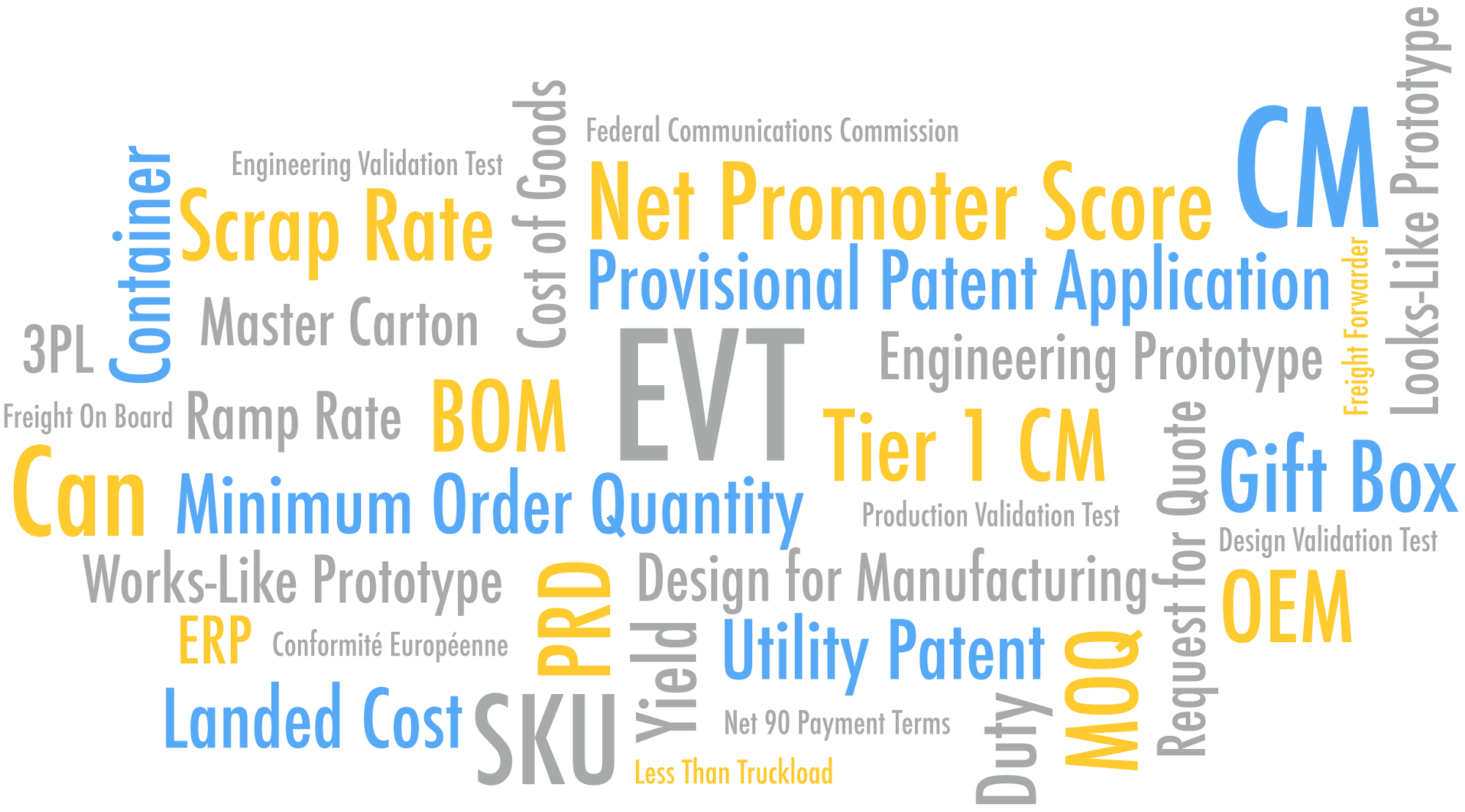

Iron Language Short Course

The first article of the cycle is devoted to specific terminology used in communications within hardware start-ups, as well as with partners in development, production, logistics and distribution. Must have. With your help, this list can be supplemented with important acronyms and abbreviations. We make a reservation in advance that some terms in the professional environment have different interpretations, all of the following are a reflection of our experience.

This list of hardware jargon was compiled by Ben Einstein , managing partner of the Bolt Venture Fund and one of the regular authors of the blog blog.bolt.io. We publish an adapted translation of the squeeze from several articles with our additions.

One of the most discouraging elements of any professional field is an endless list of abbreviations and jargon. Acronyms are sometimes difficult to avoid, but the jargon has a painful side effect: people "not from the plow" feel inferior and unwanted interlocutors, trying to learn about a new field from a pro who is fluent in "bird language."

Funders, their employees, investors and distributors occasionally encounter professional jargon. We decided to help people integrate faster with the growing community of engineers, so we collected in this post the most frequently used terms in the world of hardware companies.

Product development

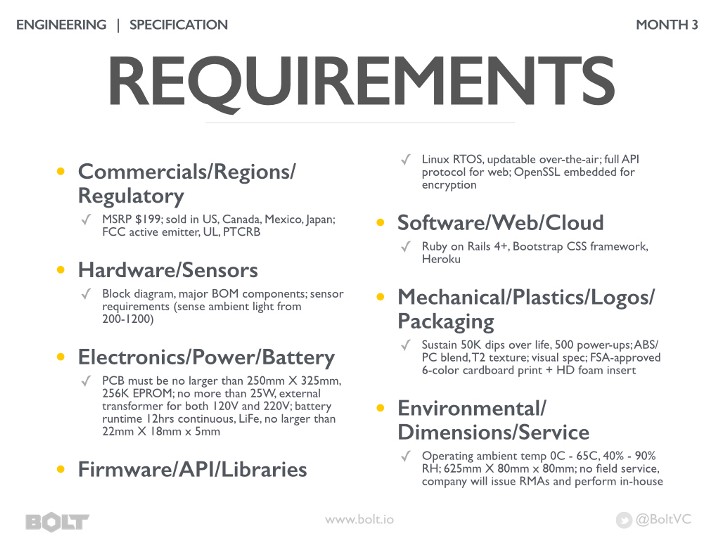

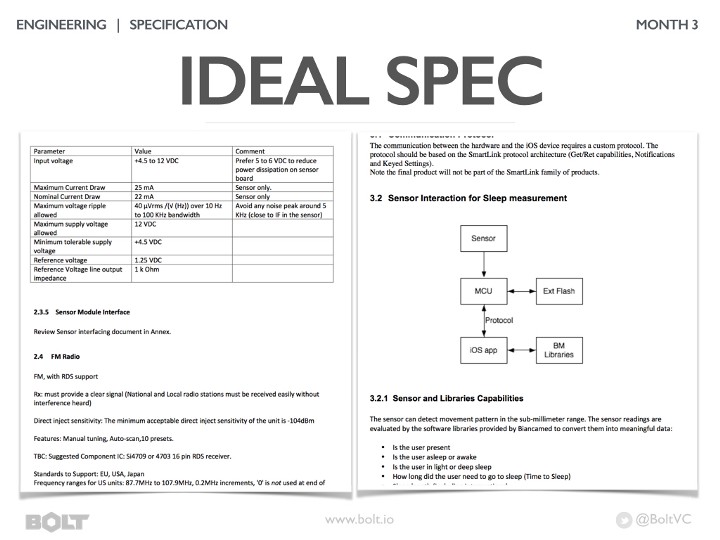

PRS / PRD / Spec (product specification / document describing product requirements) - there are many names and abbreviations for specification documents, but they all boil down to one thing: a document that describes the product in detail. What and how should it do, what it looks like, who needs it, what it is intended for, etc. Companies that do not neglect to write a detailed plan of product requirements, face fewer problems in design and manufacturing. A good specification includes details in at least seven functional areas:

- Commercials and regulatory (commercial information and regulation) - geography of distribution and MSRP (RRP - recommended retail price), regulatory requirements, pricing, product life cycle (EOL - end of life).

- Hardware and sensors (hardware and sensors) - the architecture of the "iron" solutions, a list of key components, requirements for sensors.

- Electronics (electronics) - dimensions and other characteristics of the printed circuit board, memory size, requirements for the processor and wireless modules, dimensions, service life, type, current, voltage and battery capacity.

- Firmware and libraries (firmware and libraries) - the operating system or embedded environment used in the firmware, API specification, requirements for third-party libraries (software modules).

- Software and web (software and web) - software stack and development environment, server infrastructure requirements, software configuration management plans, error conditions.

- Durability and packaging - requirements for durability, impact resistance, water resistance, design, pattern and packaging materials.

- Environmental and service - working temperatures and humidity, descriptions of the health and return process of a faulty product, customer support system and tolerance.

BOM (Bill Of Materials) - a complete list of the components that make up your product. When forming a BOM, it is critically important not to miss a single small detail, not to be mistaken in the P / N (part numbers), description and quantity of one or another component, since BOM is one of the main tools for communicating with your manufacturer. Be sure to include the costs, at least planned, and acceptable delivery times. Update the BOM for any changes, respect versioning.

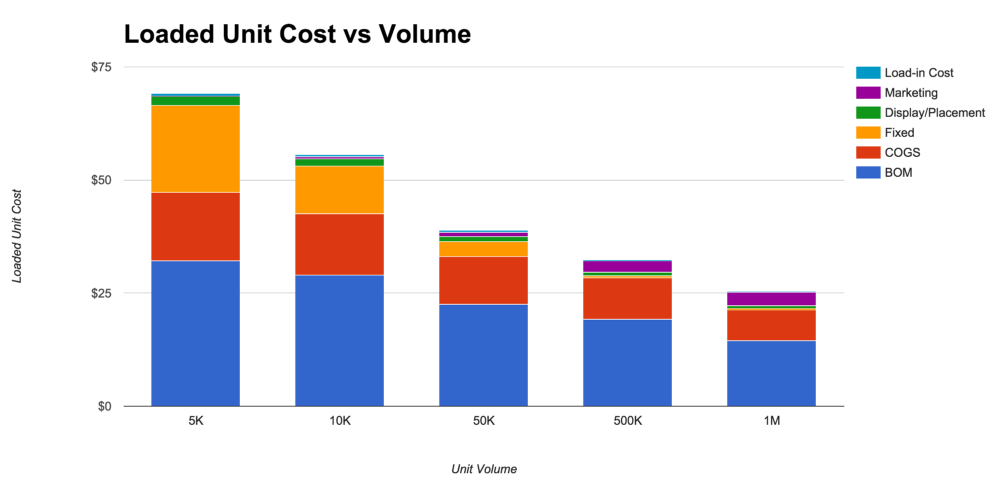

COGS (Cost Of Goods Sold / cost of goods sold or cost of goods sold) - in the language of finance, this is the total cost of production divided by the number of units produced. To simplify, it is recommended to treat COGS as “BOM plus”. COGS includes production costs, logistics, customs, duties and other costs that BOM acquires in the way of the product to the shelf in the store.

NPS (Net Promoter Score) is a widely used system for assessing customer interest in your product. By asking customers, “how much can you recommend our product to a friend?” On a scale from 0 to 10, startups can more or less accurately determine whether a product is appropriate for the market. NPS can be statistically relevant and with small sample sizes (about 30 people), making it an excellent tool for testing hypotheses and customer development. The term is used not only in hardware startups.

DFM (Design for Manufacturability / Manufacturing) is a set of common engineering practices for preparing a product for production, aimed at simplifying the production process, optimizing costs and eliminating potential problems at the design stage. In fact, DFM is a project documentation, in which formats and terms are clear for the manufacturer, the processes for preparing all components and parts of the product for assembly are described, as well as detailed characteristics of materials and parts, which are made specifically for a specific product. Like BOM, DFM requires constant updating throughout the product life cycle.

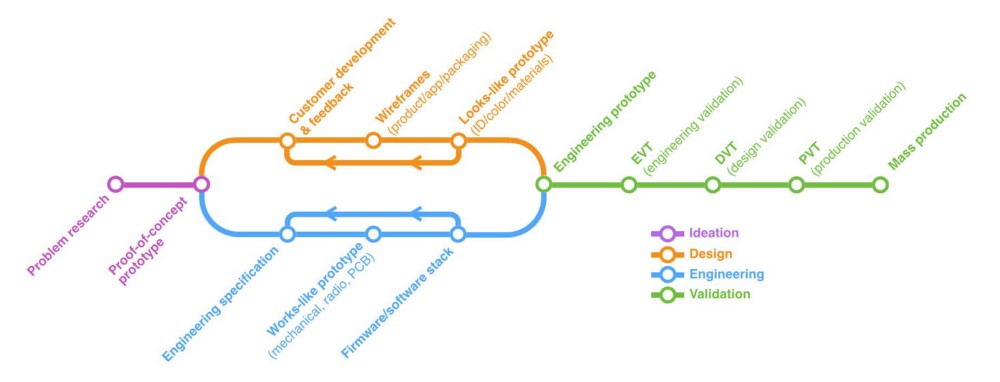

POC (Proof of Concept) - as a rule, the first and made from

Looks-like (Mockup) / Works-like - complementary prototypes that demonstrate the results of customer development - your CA research - and its looks (like) and your progress in the development process (works-like). Mockups or looks-like prototypes may look like real ones, but in most cases they don’t work. It can be as a model of the case, made on a CNC machine, or so-called. "Weight mocap" filled with sand with glue and having a weight like that of the finished product. Unlike mockups, working prototypes (works-like) demonstrate functional design taking into account the requirements of the specification (how the product will work), but rarely reflect the form factor of the product.

EP (Engineering Prototype) is when a

EVT (Engineering Validation Test) is the first of the required steps in the process of preparing a product for mass production. EVT prototypes are designed to test the functional aspects of your product against the requirements specified in the specification. Cases for EVT samples (samples) are usually manufactured industrially, using tulling (molds), but in limited quantities (usually not more than 20 pcs.).

DVT (Design Validation Test) - the second stage of testing the product in preparation for mass production. DVT prototypes are designed to verify the product quality required to start the production process - and for this they pass an expanded set of tests (visual, functional, stress). DVT samples are made in several large volumes (2-5x EVT) and taking into account all planned SKUs (Stock Keeping Units - different configurations of the same product, models for different markets, in different colors or configuration).

PVT (Production Validation Test) - ideally, the final stage of testing a product before launching into mass production. The purpose of this stage is testing for compliance with production metrics: reject percentage, assembly time, clamp / fastener efficiency, packaging speed, etc. The volume of PVT is usually about 10% of the volume of the first batch and is often sold to end users (think they are lucky?).

MP (mass production) is an important development stage when the product at the exit from the conveyor is of high enough quality for delivery to sales channels. Mass production is indirectly dependent on the capacity of the assembly line. For example, the popular model of a passenger airliner is in mass production, but only a couple of dozen units are produced per month.

Batch / Cell Production / Production Lots (mass production) is a characteristic for startups approach to mass production, in which the production process is divided into so-called batches or lots, usually from 1 to 10 thousand units of production, and the order of the new batch follows the previous one. Most contract manufacturers practice this approach when working with young companies, as they are not sure that the demand for start-up products is sufficient to launch a continuous conveyor assembly.

Utility Patent (patent for invention / utility model) is the most common patent for the protection of inventions in almost any country in the world. Pate your model, when you are 90% sure that it will not change, otherwise you will have to pay twice (and the cost in the US often exceeds $ 30 thousand).

NRE (Non-recurring Engineering) is a one-time advance payment for development. NRE usually opens a partnership with your contract manufacturer. This payment includes the most significant costs at the stage of preparing the product for mass production: the manufacture of molds, the production of engineering samples, etc. Less commonly, NRE is a requirement of design houses that take over the development of your product.

MCU / SOC / SOM (Microcontroller Unit / System On Chip / System On Module) - a single component (chip or module) on a printed circuit board that houses a microcontroller or microprocessor, in some cases, wireless interfaces, and the SoM also has memory, I / O control, power management, right down to the physical interfaces for connecting peripherals. Under certain requirements, SOM or SOC can accelerate product development.

The FCC (Federal Communications Commission) is the federal regulatory agency in the United States that controls the use of wireless communications in products manufactured or imported into the United States. If you are to receive an FCC certificate, schedule 2 DVT samples to pass the required tests.

CE (Conformité Européenne) - simplified, CE marking indicates that the product is not harmful to the health of its consumers, and is also harmless to the environment. Mandatory certificate for goods distributed in the EEA (European Economic Area / European Economic Area).

SKU (Stock Keeping Unit) - a code applied to a unique product. Each revision, modification, case color, memory size and other differences of models in your product line should have a unique SKU. Without this, the product simply will not reach the shelves in the store. Remember that too many SKUs

Production

CM (Contract Manufacturer) is a company that manufactures products or components for another company. CM startups provide all the necessary documentation (DFM) to start production of their product. CM receives most of its profits from the use of manual operations and due to a mark-up on components from other suppliers.

OEM (Original Equipment Manufacturer, original equipment or component manufacturer) is a company that independently designs, develops and manufactures products, and has the right to distribute it under its own brand or sell it to third-party companies for distribution under another brand.

ODM (Original Design Manufacturer, original design manufacturer) is a company that, having received design documentation from the customer, assumes not only production, but also product development. Usually in this company there is a R & D department that helps a startup to bring the product design to actual readiness for mass production.

EMS (Electronic Manufacturing Services, electronics manufacturing services) are companies that design, test, manufacture and supply electronic products, as well as provide services for their repair and restoration. The large EMSs are multi-billion dollar companies with a high-level staff. Smaller companies mostly practice the EMS / ODM mixed business model, and often compensate for the lack of their own production facilities with an extensive pool of partners and contractors.

Tier 1/2/3 Contract Manufacturer - the level of the contract manufacturer according to its annual income:

- Level 1: ~ $ 1 Billion + (Foxconn)

- Level 2: ~ $ 200 Million - $ 1 Billion (Earlylight)

- Level 3: ~ $ 10 Million - $ 200 Million (Wynnewood)

Contrary to popular belief, a level 1/2/3 does not mean quality. Often, young startups achieve better results by choosing a contract manufacturer of level 2 or 3 as a partner.

Tier 1/2/3 Supplier (supplier 1/2/3 levels) - types of suppliers according to the position in the supply chain. When Ford assembles a car, it buys ready-made solutions (for example, complete seats) from a level 1 supplier, who in turn buys additional items (electric drives and head restraints) from a level 2 supplier who buys parts and finishing materials (plastic buttons and skin) at the third level suppliers.

MOQ (Minimum Order Quantity / Minimum Order Quantity) - the minimum number of units of products that the manufacturer considers sufficient to take the order to work. Most CMs really care about the total cost of the order, not the quantity of devices produced.

RFQ (Request For Quote) is a formal process used when choosing a supplier or contract manufacturer. Startups often misinterpret the RFQ process and simply email a CAD drawing, counting on a response with a price. Building a good relationship with CM is a much more complex and delicate process, akin from the first date to creating a family and producing

MSA / PA (Manufacturing Service Agreement / Purchase Agreement) - an agreement between a start-up and a manufacturer. MSA covers the most critical parameters of cooperation: terms, penalties, responsibility for marriage, terms of payment, forecasts, etc. It is recommended for both parties to include in the contract and agree all the parameters of cooperation before the start of production, but in practice this happens rarely.

Tooling (technological equipment) - most often, it is a metal mold for the production of body parts by molding from plastic or by stamping from metal.

PCBA (Printed Circuit Board Assembly, printed circuit board assembly) - a printed circuit board (PCB) with components soldered to it. PCBA is one of the most significant nodes in electronic products. Normally PCBAs are manufactured by your CM, third-party EMS, or PCB factory.

SMT (Surface Mount Technology, Surface Mount Technology) is the way most modern electronic components solder to a printed circuit board.

Ramp up (“building”) - a term to describe the rate of growth of production volumes. Often it looks like a series of S-shaped curves in time, showing slow growth at the beginning, maximum acceleration in the middle and stabilization before the beginning of the next production cycle.

Yield (output) is the percentage of devices produced that meet quality requirements and can be sold to customers. A good factory produces at least 98% of products suitable for sale. In the yield may fall products that need to be finalized before selling.

Scrap or Defect Rate is the percentage of devices produced that should be disposed of due to defects found. This coefficient is the inverse of Yield, but is often mistakenly used to designate products that need to be worked out before they go on sale.

Payment Terms - the payment terms that the manufacturer puts forward. This is usually the number of days until full payment for the volume of products that are transferred to the startup. Most beginners should not rely on the flexibility of the manufacturer in this place; 50% of the lot is paid when placing an order, and another 50% - before shipment. Experienced startups who have managed to build a trusting relationship with their CM, can qualify for a delay of 30 or 90 days after the cargo leaves the factory.

Supply Chain and Logistics

Gift box (“gift box”) - packaging in which the user receives the product. Most often, this is the main box developed by product creators, but the term is also appropriate for additional protective packaging, in which Amazon and some other retailers deliver goods from their stores.

Case / Master Carton - a large cardboard box for transporting a lot of product over long distances. Depending on the form factor and the size of the product packaging, 5 to 50 product units are placed in the Master Carton, after which a large cardboard box is loaded onto pallets (Palletes) for subsequent transportation.

FOB (Free / Freight On Board) - the moment of transfer of ownership of products from the manufacturer to the customer. If you produce a product in another country, this moment in most cases occurs at the port of export when the carrier (Forwarder) of the contract manufacturer (CM) unloads the goods (Goods) for subsequent loading onto the ship or aircraft. FOB is just one of the many options for the transfer of ownership of goods from the manufacturer to the customer. The code of such rules is called Incoterms, and sufficiently detailed information about them can be found on Wikipedia.

Duties / Customs (fees and charges) - fees paid for the export of goods into and out of the country. Make up to 10% of the cost, depending on the product. Unpaid customs duties can be a source of significant delivery delays.

Freight Forwarder (carrier / forwarder) is a company that helps move goods between a factory and a distributor warehouse. The freight forwarder reserves space for freight transport (trucks, trains, ships, airplanes). The carrier’s earnings depend on the bulk and weight parameters of the cargo, so it is difficult for young startups to provide good prices for small lots.

Landed Cost (cost price) - the total cost of production and delivery of one unit. Includes COGS plus shipping, storage, maintenance, insurance, currency conversion and banking fees.

ERP (Enterprise Resource Planning, company resource planning) - software used to manage business operations. For hardware startups, the most important aspect of the ERP system is the planning and management of supply chains and inventory control. With the growth of the company, ERP begins to cover accounting, sales, purchases, production management, human resources, etc.

Marketing and Distribution

Crowdfunding is a method of raising funds through online platforms used for preliminary sales of a product (often before their full design and production), demand validation, collection and analysis of user preferences before the official start of sales. Crowdfunding is a great way to launch for certain categories of consumer goods.

PO (Purchase Order, Purchase Order) - a formal agreement between a customer and a supplier to purchase a batch of a product. Key terms include quantity, cost, time from payment to shipment and date of payment. PO is used to order a product from CM or components to produce a product.

Distributor is a company in the supply chain that buys products from manufacturers and resells them with a substantial (yes, we know) mark-up to another business in the supply chain that already sells it to end users (usually retail). Distributors store the product in their warehouse and take over the sale of your product to large retail chains. Retailers often trust distributors more than a young startup "from the street."

CAC (Customer Acquisition Cost, cost of customer acquisition) - the cost of attracting one user of your product. Calculated by dividing the marketing budget by the number of units sold.

Channel (this is a channel, oddly enough) is the path by which the end user comes in to buy the product. These can be direct sales on your website, e-tail (online stores), specialty stores (electronic retail chains, carrier retail, etc.), or hypermarkets with a wide assortment matrix.Startups should choose sales channels depending on the preferences of the target audience and product positioning.

MSRP / List Price (manufacturer's suggested retail price) is the highest price you think the end customer is willing to pay for your product. Retail will try to sell your product at a cheaper MSRP in order to use the price as a competitive advantage and increase turnover. Your task is to support MSRP in all channels.

GM (Gross margin, gross margin)- the difference between the price per unit of output and COGS, expressed as a percentage. If the margin is indicated in monetary terms, it is called gross profit. For example, if COGS is equal to $ 33, and the product is sold for $ 100, then the gross margin is 67%, including retail network mark-up and your profit.

Sell-in (sales to retailer) - the number of units of products that the retailer agrees to purchase from a startup or distributor. In most cases, the retailer pays for the purchased goods after they are sold to the final consumer, which indicates the obvious benefit of working with retail through a distributor.

Sell-through and Sell-out (sales to the end user)- the moment when the seller sells the unit to the final consumer, as well as the volume of units sold. Startups consider the goods sold only at this moment, and based on this, they calculate the revenue. In the reporting, as a rule, is indicated as a percentage of Sell-in.

Lift (growth) - an increase in product sales as a result of a marketing campaign. Most often indicated in percentage terms.

Backstock (inventory) - the number of units needed by the retailer to maintain inventory. Most retailers include in the order of 20-50% of the order as a backstock.

EOL (End Of Life, end of life cycle) - the end of the production of a product or model. Most consumer electronics have a life cycle of 12 to 18 months.

MRR / ARR (Monthly / Annual Recurring Revenue) is the regular revenue from services that a user of a product receives after purchasing it. In the eyes of investors, regular income increases the company's valuation by 5-10 times compared to the iron sales business model.

Attach Rate - the percentage of users who subscribe to additional services after purchasing a product. Successful "hardware" companies earn 30-35% of revenue through the provision of additional services.

LTV / CLV (Lifetime Value of a Customer)- the total income from the client for the entire period of "life" or use of the product. This indicator includes income from the sale of equipment, subscription to services, sales of accessories, etc. Calculating LTV requires knowledge of% churn, changes in product margins over time, and user retention costs.

In the next article we will discuss the nuances of development and production in large and small hardware companies: what are the key differences, and what should a hardware startup pay attention to?

In order not to miss the following articles from the cycle, as well as other useful content for IT and hardware startups and announcements of business development and technology events - subscribe to the IIDF Friday newsletter !

Source: https://habr.com/ru/post/344214/

All Articles