Digital power industry

"By the way, noble dons, whose helicopter is behind the hut?"

(Strugatsky brothers. "It is difficult to be a god")

We are used to talking about digitalization in relation to communication systems, but with the development of information technology, this process has covered many other industries. The first industrial revolution occurred when, at the end of the 18th century, manual labor began to be widely replaced by machines. The second revolution took place at the beginning of the 20th century, when Henry Ford invented the conveyor. Currently, the world is undergoing a third revolution related to digitalization, and any production will eventually be controlled by computer programs that can be placed somewhere in the "clouds". Although late, this process reached the power industry. Once it was supposed to happen ... This is what I propose to talk about today.

The current problems of the electric power industry are well-known and in some ways are close to the problems that had once been faced in the ICT industry. These include the moral and physical aging of the entire fleet of operating equipment (more than 50% of the assets of the networks of the unified national energy network have an excess period of operation of more than 25 years, and the wear and tear of Russian electric power systems according to various sources ranges from 50 to 70%), the prevalence of imported supplies management and automation of the previous generation (80% of investment goes into the development of foreign technologies and the supply of outdated solutions) and the reduction of the national investment program.

The energy industry needs modernization based on intelligent systems in order to increase efficiency and reduce capital and operating costs. In addition, transformers, power lines and facilities will not save much - according to the laws of physics, the transmitted power requires appropriate "iron". Since N. Tesla’s 100-year-old experiments on wireless power transmission using the Wondercliff tower have not been completed (although interest in them has recently reappeared), the electric power industry hasn’t been so effective in wireless communications.

A little about electricity

Electricity networks are somewhat similar to communication networks - they have main and distribution sections with different operating voltages and a star or ring structure. The network nodes are the substations where the voltage of the transmitted electricity is converted. The most important feature of any electric power system is that the production of electricity, its distribution and transformation into other types of energy are carried out at almost the same point in time. In other words, today the electric power practically does not accumulate anywhere (the projects of creating network electric storage devices are under development), and the whole system works on-line. All elements of the system are interconnected and interact, and the energy produced in the system is always equal to the energy consumed in it. Here you can see that, unlike the ICT industry, which has come a long way, in contrast to postal communication, to be able to have all the information transmitted in the on-line mode, the power industry initially worked in this mode, and the dreams of its specialists are aimed at to teach your network to work off-line.

Another feature is closely connected with a gigantic collection of diverse consumers in a single network, which dramatically increases the relevance of ensuring the reliability of the power system and requires the creation of sufficient power reserve in energy systems in all its elements.

The relative speed of transient processes associated with short circuits, switching on and off, oscillations, stability violations, requires the use of special automatic devices. Such devices, often very fast, must ensure proper adjustment of transients in the system. The right choice and setting up of all these automatic devices, which include overvoltage protection devices, installation of relay protection, automatic regulators, automatic switches, and so on. p., are unthinkable without taking into account the work of the whole system as a whole. All this contributes to the broadest implementation of automation in energy systems and the full automation of individual power plants and substations. And on this automation (in addition to communication systems, of course) depends today the welfare of each developed state.

Control

The above problems are solved by the creation of an automated process control system (APCS). Within its framework, primary information is collected on all parameters of technological processes, the tasks of metrological support are solved, procedures for direct control and remote control of equipment are carried out. This system is a source of information for the upper levels of the management structure (dispatch center, control center) and largely determines the efficiency of management of the entire energy system.

In general, the substation control system integrates the subsystem of relay protection automatics (RZA), anti-emergency automatics (PA), automated information-measuring system of commercial electricity metering (ASKUE), alarm event recorders, power system determining the location of damage (OMP) of the cable, the system for collecting and transmitting operational and non-operational technological information, power quality control systems, engineering and auxiliary systems, etc.

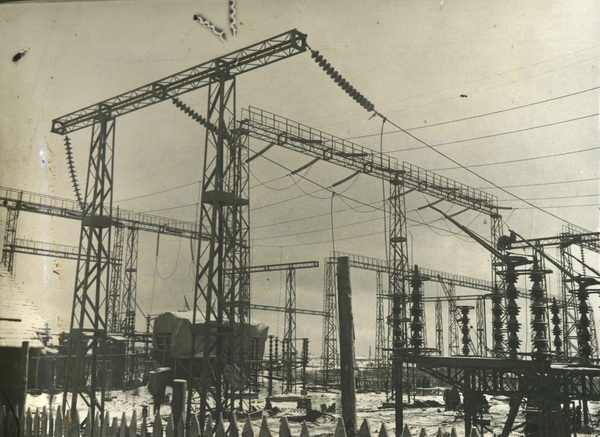

Interestingly, the technologies that have so far been widely used for monitoring and control in the power industry were at the level of telephone communication development in the 1930s: analog channels with copper wires from each of a variety of sensors to an entire army of relays and indicators. In addition, all this material and energy-intensive, which reduces reliability, costly and inflexible in the design, inefficient when scaling and upgrading and, moreover, requires a lot of personnel in the operation. It remains to add that electric power industry, based on outdated principles of monitoring and management, may in itself pose a threat to the state.

Digital ideas

In general, unlike ICT in the power industry, the digitalization process is in its initial stage. Despite the fact that the trend of transition to digital technologies in systems for collecting and processing information, managing and automating substations began more than 15 years ago, the world's first digital substation was launched only in 2006. Nevertheless, today almost all leading companies The producers of the electric power industry are actively working in this direction, given the positive experience of the ICT industry. Moreover, telecommunications are the basis of monitoring and control systems in any other sector of the economy. In addition, digitalization, which finally won in the beginning of the 21st century in ICT, raised to a new height not only the communications industry, but all the industries that managed to take advantage of it.

Innovative development of the power industry today is characterized by the integration of the power grid and information infrastructures in the nodes of the network - digital substations. A digital substation (DSP) is an element of an active-adaptive (intelligent) power grid with a control, protection and control system based on the transfer of information in a digital format. DSP technology makes it possible to reduce the cost of construction of substations, reduce their size, increase reliability and, ultimately, improve the quality of power supply to the consumer without increasing the cost. This, in turn, results in increased noise immunity, reduction in the number of equipment, secondary switching circuits and space savings. DSPs can be built faster and it is easier to work out standard projects for replication. At present, there are hundreds of DSPs installed in China, the USA, Canada and other countries on the planet.

With the advent of the first microprocessor-based relay protection devices, information from them also began to be integrated into the process control systems. Gradually, the number of devices with digital interfaces increased (emergency control automatics, power equipment monitoring systems, DC shield monitoring systems and own needs, etc.). All this information from low-level devices was integrated into the automated process control system via digital interfaces. However, despite the widespread use of digital technologies for building automation systems, such substations are not fully digital, since all the initial information, including the status of the auxiliary contacts, voltages and currents, is transmitted in the form of analog signals from the switchgear to the operational control center where it is digitized separately by each device of the lower level (all this even increases the cost of the substation, since it requires the installation of a large number of ADCs). For example, the same voltage is applied in parallel to all devices of the lower level, which convert it to a digital form and transmit to the automated process control system. At traditional substations, various subsystems use different communication standards (protocols) and information models. For the functions of protection, measurement, accounting, quality control, individual systems of measurement and information interaction are performed, which significantly increases both the complexity of the automation system implementation at the substation and its cost. Well, if we consider that historically the information from all the automation went through separate copper cables, and many thousands of such substations were built, then you can imagine the volume, sorry for the expression, "analog iron".

The transition to a qualitatively new automation and control systems was possible when new standards and DSP technologies emerged, to which, first of all, the specially developed IEC 61850 standard applies. Unlike others, it regulates not only information transfer issues between individual devices, but also issues formalization of the description of circuits - substations, protection, automation and measurement, device configuration. This standard provides for the use of new digital measuring devices (including those with digital optical output) instead of traditional analog meters (current and voltage transformers). For example, digital instrument transformers transmit instantaneous voltages and currents using IEC 61850-9-2 protocol to attachment level devices. As a result, IT allows to move to the automated design of DSPs managed by digital integrated systems, and here there will be analogies with control systems from the ICT industry.

All information links at the DSP are digital and form a single process bus. This opens up opportunities for quick and direct exchange of information between devices, which ultimately eliminates the mass of copper cable ties, individual devices, as well as to achieve a more compact arrangement. So, the main feature of the DSP is that all its secondary circuits are digital data transmission channels that form a single information network (data transmission network).

Thus, the basis of the DSP is a unified telecommunications infrastructure, made on the basis of modern technologies. The main idea behind the ideology of the DSP is to monitor all processes as close as possible to information sources, transfer the received data to all subsystems via fiber-optic communication lines and virtualize most of the functions performed at the substation. Thus, all measuring devices become sources of information, and all embedded intelligent electronic devices become its consumers.

In turn, automation devices are simply transformed into computers with specialized software, and the DSP protection and control system becomes a set of logic software modules with various functions and a new level of security. As a result, the virtualized DSP is located on the server and is assembled from software modules of the RZA, PA, RAS, ASKUE, etc., as a big sandwich or as a matryoshka. The design process also goes into the area of computer programs. The overall result of all this activity is the replacement of multi-functional analog systems with a single server with specialized software, including specialized software modules. In order to increase reliability, the server is manufactured in a protected version and duplicated for the "hot reserve". Thus, it is believed that the DSP allows to increase the level of safety of power facilities, to obtain a significant reduction in metal consumption, to reduce the number of elements in the control and monitoring systems while increasing their efficiency, to increase the level of reliability and observability, and to minimize the costs of engineering and commissioning.

What's next? Further, there will be a logical transition from the hardware platform market to the software market and to cloud solutions. True, they should have adequate protection from both the "fool" and "not a fool", since the possible consequences of the lack of such protection for the country's unified energy system are not difficult to imagine. That is, the introduction of the DSP can pose a kind of threat to the state, but for a century, so are the threats. You can, for example, connect the entire management system of the country's power grids to the Internet, and then heroically fight threats. Here, for example, the military all over the world have long understood that to connect everything to the Internet is not necessary. But in 2014, at the Information Security Conference held at the International Telecommunication Union (ITU) in Geneva, it was heard that a representative of one African country boasted of the national energy management system supplied by one American supplier that can be controlled from anywhere in the world. Mentally, many conference participants wished him success.

At present, there are many projects around the world related to the application of the IEC 61850 standard that have shown the advantages of this technology. However, a number of issues still require additional development. This refers to the reliability of digital systems, to the issues of configuring devices at the substation level and power interconnection, to the creation of publicly available design tools, targeted at different manufacturers.

Benefits

For comparison, the "past" and new technologies can be approximate calculations for the equipment of the "traditional" substation and similar to the tasks of the CPS. In the first case, 150 km of copper cable, 100 automatic control cabinets, 900 m2 of space are required, and the total equipment and installation costs are about 400 million rubles. The second option requires 15 km of fiber-optic cable, three protection and control cabinets (double redundancy of the server itself), 150 m2 of space and total costs - about 160 million rubles. Well, if you consider that with the remote monitoring and all the rest, one operator with a tablet PC can manage in the DSP, it is not difficult to imagine the overall benefits for capital and operational investments. You can make good money on one non-ferrous scrap metal.

Reducing operating costs will be obtained by transferring objects to the category of "unattended", as well as their unification and standardization. In addition, systems will be able to quickly adapt to changing conditions, improve reliability and security by ensuring the transparency of the algorithms used. It is equally easy to imagine the "cloud", from which a whole group of DSPs is managed, or even the entire energy system. That is, there is truly a huge scope for developers and suppliers, which, we note, in general, is not any news for ICT industry specialists.

Little about the problems

Of course, there are problems. First of all, the standards for which the DSPs should be designed and to which the DSPs must meet, have not yet been approved; there is no adequate metrological support, which still contains the “traditional” analogue measurements, and there are no properly trained personnel. There is not even an established definition of DSP.

But how do the experts in the field of RZA, whose instructions are truly “written in blood”, relate to the fact that “some IT people” will have access to the substation? - Suppose, they say, they will understand at least with information security elsewhere on the planet. Obviously, the "new IT specialists" should be properly prepared or even retrained from the "relay". The problem is whether they can be retrained, because many of them have been around for quite a few years. Why are there "relay workers", the rest of the staff, right up to top management, should also "change their heads" and think with new digital realities. That is, the personnel issue in the digital modernization of the electric power industry is by no means the last.

Today, Russia is actively working on the development of the DSP technology, a number of pilot projects have been launched, and leading Russian companies have begun to develop relevant domestic products and solutions. It remains to wish that the leadership of the industry with understanding treated these works and relied on domestic manufacturers (including in the field of software) and pushed the process of digital standardization. But, however, not only the DSP is limited today to the modernization of the electric power industry.

Intelligent network

Intelligent networks are found not only in the ICT industry. If you create a power grid that collects information from all consumers and energy producers and on its basis redistributes power flows, then you can send them to where there is a shortage, and accumulate where there is an excess. In this case, each energy consumer at any time can become its supplier. A similar technology is already being developed and called SmartGrid, and networks based on it are called active-adaptive networks (due to the fact that the network has elements that actively change their parameters depending on the changing consumption mode). As we already know, the most important element of such networks are the DSP.

SmartGrid assumes the creation of a self-regulating electric power system, which, having all the current information about the network status and consumption, will distribute the current energy resources received from both industrial producers and private users. In this case, the excess energy will be accumulated in special storage facilities and used during periods of peak loads. In other words, the energy system of the future can be viewed as a peer-to-peer network very similar to the Internet, in which consumers, like electricity suppliers, will become active participants in the process of electricity distribution and consumption. As on the Internet, increasing the efficiency of the entire system is carried out by decentralizing the functions of generating and managing electricity and information flows in the energy system, as well as reducing the costs of organizing the system of electricity transmission, prompt troubleshooting and the possibility of transmitting electricity and information in two directions.

Today, the SmartGrid concept is seen in many countries as the beginning of a large-scale transition to renewable energy sources (VIZ) in the face of the sun, wind and water, although the approach to this concept may differ somewhat. The widespread accumulation of excess energy can be a driver for the growth of hydrogen energy and electric transport. For example, California intends to 2020. generate 12,000 MW using VIZ at local power plants. According to Pike Research, by this time China will become the regional SmartGrid driver, and the global volume of the relevant market will be over 70 billion US dollars. But, truth, we must also be able to create such batteries and redirect the flow of electricity.

Today, as we all know, we have no choice in the electricity supplier despite the claims of individual "great reformers" that there is a so-called electricity market. But in SmartGrid, the consumer has the opportunity to optimize the schedule of loading their facilities to minimize costs, as well as generate income from their personal power plants. So someday, in addition to the social standards of electricity consumption planned by the Russian government, we may also have multi-tariff electricity meters from different suppliers.

However, not all so simple. The concept of SmartGrid is, of course, beautiful, but to implement all of the above, electric power industry will need to develop new technologies in a variety of areas, which experts include the creation of smart meters (SmartMetering), the development of electrical network components and power flow control devices, the development of energy storage systems ( batteries, hydrogen fuel, supercapacitors, PSP, etc.), the development of distributed energy and the creation of intelligent demand management networks.

Something already appears literally before our eyes. Not so long ago, scientists of the Far Eastern Federal University and the Institute of Automation and Control Processes of the Far Eastern Branch of the Russian Academy of Sciences have created a unique method for diagnosing high-voltage equipment in the on-line mode based on the analysis of the spectra of its own electromagnetic radiation. The invention has a number of undoubted advantages over traditional diagnostic methods. There is no need to turn off the equipment, information about the appearance and development of a defect appears immediately in electromagnetic radiation, there is no need to develop special devices for recording and processing information. And most importantly, the defect is fixed at the earliest stage of its appearance and development. The invention is protected by ten patents and has no world analogues. It remains to add that it is "requested" to the CPS.

Road ahead

To date, the widespread introduction of innovations in the power industry, as usual, is hampered by the imperfection of legislation, insufficient funding and cautious attitude to everything new. Here, for example, in China, it is legislatively stipulated that all new substations should be built only in the form of a central processing unit; in the USA and Europe, a significant number of such facilities are already in pilot operation for gaining experience and transition to this technology. There is no such practice in Russia yet, but, it seems, there are already “conceptual thoughts”. There are also pilot projects of the DSP, which, by the way, by the produced dramatic effect are very similar to the helicopter sown in the middle of the village huts. Someone will be surprised and will go on harness the cart, someone will be interested and come closer, and someone, having crossed, will go back to the hut and climb on the stove. Well, hope, as always, for innovators.

Publication author:

Alexander GOLYSHKO, Systems Analyst, Technoserv Group of Companies

')

Source: https://habr.com/ru/post/342268/

All Articles