Cockroaches and Keys: What can break in modern trading scales

The more difficult the equipment becomes, the more opportunities appear for its breakdowns. Trade scales are no exception. We tell from our own experience how the cockroaches, improper care and careless handling lead them to disrepair.

In trade scales, as in any other complex devices, almost the entire component base to some extent breaks. Usually the number and nature of breakdowns are directly related to the quality of the equipment itself and the reliability of its components. However, there are a number of common factors that affect almost all modern trade scales.

')

Breakdown # 1: Strain gauge

More often than not, strain gauges that convert strain values into a convenient measurement signal (usually electrical) fail in trading scales. As a result, the devices begin to incorrectly show the weight of the goods - it becomes jumping or it turns out to be more / less valid.

Most often, the strain gauge fails for two reasons:

- or the weight limit that the scale can withstand has been exceeded;

- or the scales dropped weight close to the limit. In this case, the load on the weighing platform and, as a consequence, the load cell is just as significant as in the first case.

Sometimes this problem is solved by calibrating the strain gauge, but often it is necessary to resort to repairing it, and more often to replacing it.

Our practice shows that usually failure of strain gauges can be due to two reasons:

- manufacturers began to use lower-quality components;

- errors of logistics companies (delivery of spare parts and equipment is often made with violations due to the fault of transport carriers).

Most often, this is a problem of inexpensive weights of Eastern manufacturers, which, including, come to the Pilot service department .

Breakdown # 2: Motherboard, ports and power supplies

Today trade scales are practically full-fledged computers with their own components peculiar to this category. One of them is the motherboard, which often stops working.

Manufacturers of weights place on the motherboard a different number of elements: some are many, some are few. The second, on which, for example, there is only a control element and memory, breaks, as a rule, less often. But motherboards, where "caring" manufacturers have placed Wi-Fi, display, keyboard controls, interfaces, fail much more often.

Often, motherboards suffer from the waste products of cockroaches living inside the scales. For this reason, and also because liquids penetrate the device, a short circuit occurs on the motherboard. To prevent this from happening, some retailers prefer scales with a high class of protection against dust and moisture.

Unlike cash registers, which are connected to an uninterruptible power supply, the scales operate from the usual unprotected store electrical network. In their power supplies, there is no serious protection, so the motherboard, as the most sensitive electronics, as a result of voltage drops, is out of order first. The same problem leads to breakage and strain gauges.

A similar situation arises with the ports: what is Ethernet, what is COM, what specific ports often become unusable. Usually, if they are placed on a separate board, then it is easier to replace them. If the ports are hidden deep in the scales and inaccessible to customers and store employees, then they serve longer.

The power supply can be tied to the motherboard or placed separately. And, alas, the reliability of the scales directly depends on its quality - there are cases when, when it fails, almost the entire stuffing of the device has to be changed.

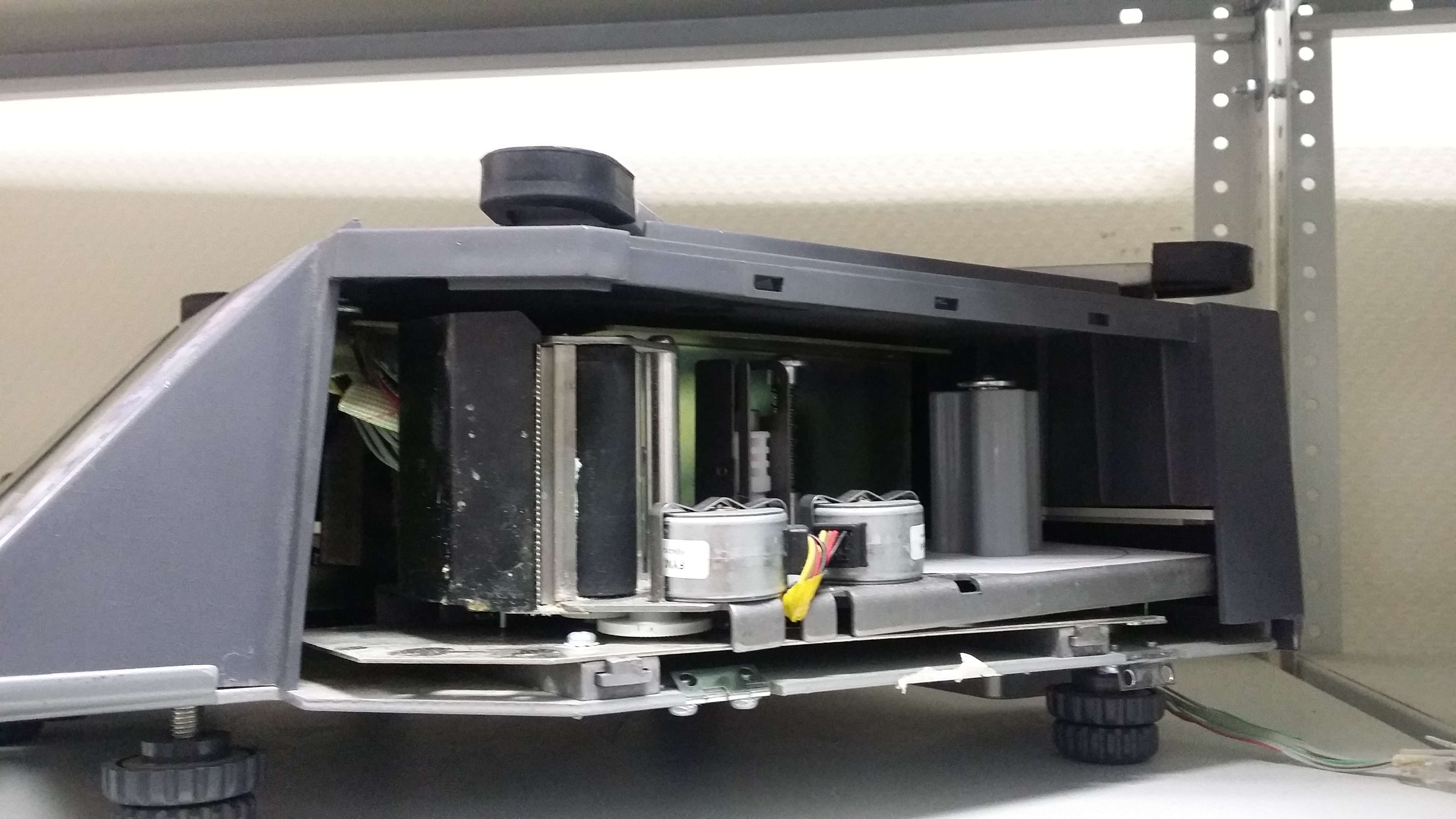

Breakdown # 3: Checkbooking mechanism

The problem with check printing scales is check printing. Unlike the motherboard, it has its own lifespan, including physical. In addition to repair, the check printing mechanism requires regular prophylaxis. It is often clogged, this is especially true if retailers use substandard consumables. As a result, the claimed service life of the check printing mechanism is reduced by several times. The only way to deal with this is to regularly carry out prevention. The mechanism of check printing at good foreign scales has a resource of 150 km of check tape. Scales are simpler (especially domestic production) have a smaller work resource - 50 kilometers of printing tape. But if the weights do not carry out the prevention of the check printing mechanism at least once a month (that is, on a periodic basis, do not clean the tape drive mechanism and do not remove the remnants of labels on the print head), then its lifespan is sometimes reduced by almost 50%.

Mechanical breaks in the compartments for replacing the ribbon of labels are also connected with the check printing elements. In the old models of scales, designed for self-service in small European grocery chains, did not provide for frequent replacement of the tape. The latches on the lids of the compartments, which were not designed for such frequent opening and closing, were made of soft plastic. Therefore, they often break.

Breakdown # 4: Inadequate Care

Cockroaches - the scourge of commercial equipment. When our specialists open trade scales for repairs, insects and their livelihoods are found extremely often. As a result, dies electronics components of the scales. Of course, sometimes you can find more exotic things in them - for example, disposable rubber gloves in which sellers weigh goods. Especially often it is possible to see them in portion scales in the event that the block for a label is under a cover and has the big sizes.

By the way, the scales with a high class of dust and moisture protection are protected from such surprises - usually they have difficulty accessing the internal element base.

On average, if you do not carry out regular preventive maintenance of scales, they can get into the risk zone of breakage in just one year after purchase.

Breakdown # 5: Buttons and Touch Screens

A common illness of push-button scales is the breakdown of keyboards. The stores that use self-service push-button scales most often have a sufficient number of spare parts, and either the company’s employees themselves or the technical service center (TEC) specialists quickly change the failed buttons. It would not seem at first glance, repair push-button scales - not the easiest task. Even if only one button is out of order, the store will have to purchase at least ten of them - in order to get to the minimum lot, since the buttons are not sold for one piece.

If the panel of scales is equipped with a polarizing film, then another trouble arises: the film breaks due to inaccurate treatment - sellers often try to poke it with nails and pens. In this case, you have to completely change the film. This is an actual problem for small stores, where there are only one scale. The life cycle of a polarizing film does not exceed two years, and often you have to change it at all annually.

Susceptible to breakage and scales with touch screens. They may break as a result of strong mechanical impact. The difficulty of repairing here is that if the store and buttons are able to change the store employees, then in the case of sensory scales, they will definitely have to be taken to a service center. This problem is solved by signing a service contract specifying the repair time - the contractor usually keeps a replacement fund for a specific client and returns the scales fairly quickly.

Breakdown # 6: Checkout scanner scales

Screens of the checkout weigher scales remain the weak link of these devices, although they are made of durable and wear-resistant glass, and some are impact-resistant and make them with a ruby coating. Over time, the glass is erased and scans worse, because the number of goods passing through them every day is simply tremendous. But most often they break down due to poor screen fixing. But this applies only to the scanner. The scales themselves, if their trains are well placed, turn out to be almost eternal.

Most often, the checkout scanner weights break down in the event that they were installed in an artisanal way - they are simply embedded into the surface of the cashier's desk. Then dirt, liquids and even parts of products that can penetrate into the device itself, which leads to its failure, get into the slots.

Breakdown # 7: Lifetime

Any device has a lifetime. And if it is exceeded, the equipment simply fails. Alas, often Russian retailers are not in a hurry to change the fleet of equipment: therefore, instead of, for example, 7 years, the scales serve 10. They are transferred from one store to another, returned after numerous repairs. And this is followed only by all new breakdowns.

The lifetime of the scales is significantly reduced due to the battery on the motherboard, which is responsible for maintaining the operational status of the memory modules. It lasts for 5-7 years of permanent work (it does not recharge). If the battery fails, when the scales are turned off from the electricity network, they are completely zeroed and go to the factory state (all settings set by the store employees are reset). As a result, any information on the display also ceases to appear.

Source: https://habr.com/ru/post/341442/

All Articles