In-line cooling in the data center: myths and realities

In-line cooling systems have been used in data centers for more than 10 years, but even specialists have a number of misconceptions regarding their work. Below we look at common misconceptions, and in the meantime we will explain how heated air is discharged and what are the basic design principles that make these systems as efficient as possible.

The space of server rooms in data centers, as a rule, is divided into zones. A zone (pod in English terminology) is a group of cabinets united by a common power and cooling infrastructure. Most often, one zone consists of two rows of cabinets, between which a “hot” corridor is formed.

')

In-line cooling involves the installation of air conditioners directly in a row of racks. At the same time, such air conditioners, as well as other types of air conditioners, are often considered as a “cold air supply” system (IT equipment). Because of this, many delusions arise. In reality, the main thing is to ensure “heated air discharge” from IT equipment without mixing with indoor air.

Below are three common misconceptions about the functioning of row cooling systems.

The effect of in-line air conditioning is limited to the zone limits. Many believe that in-line air conditioners are able to serve the load only within their zones, and increasing the cooling system power in one of the zones does not help the removal of heat from the others.

Before we begin to debunk the myths, let's talk about the general principles of operation and design of data center cooling systems. The main objective of any such system is the removal of heat generated by IT equipment. A measure of the efficiency of collecting hot air in such systems (or supplying cold air) is called the coefficient of isolation of exhaust air (KIOV). This coefficient is calculated by post, based on the air flow diagram. High values correspond to better performance of the cooling system.

KIOV is defined as the proportion of exhaust air (heated by IT equipment) that flows directly to the heat exchangers of in-line air conditioners in the same area. This is a basic metric for evaluating the effectiveness of in-line cooling.

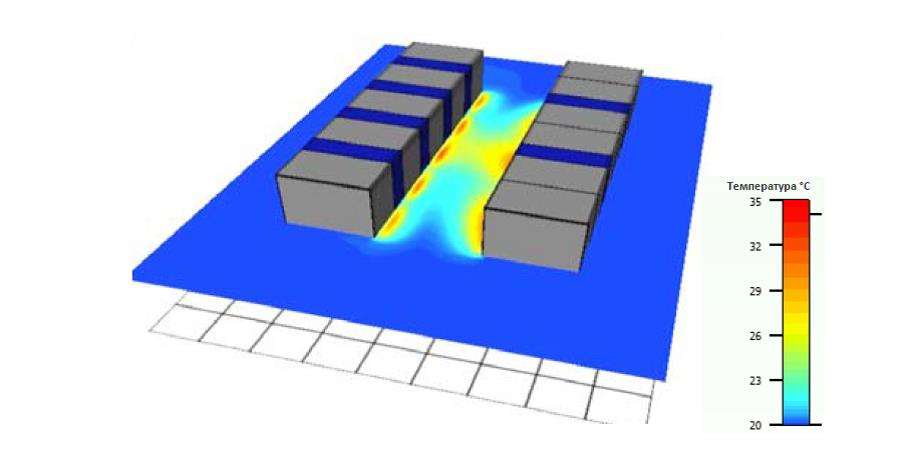

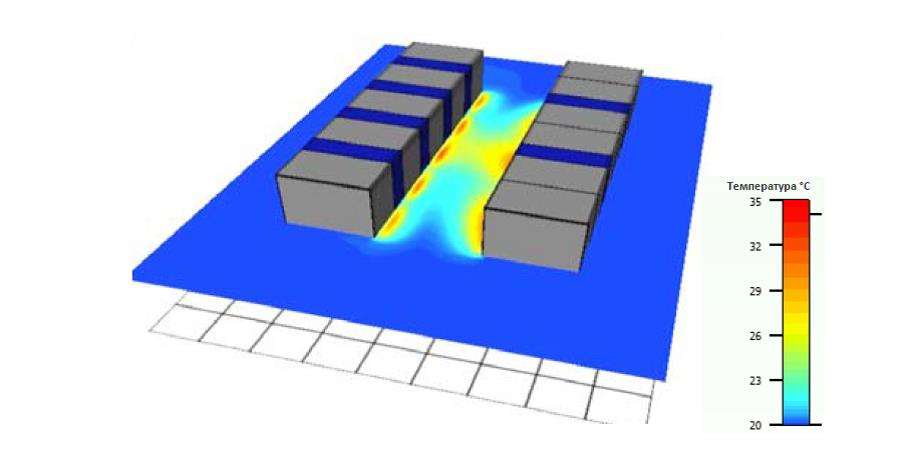

Results of aerodynamic modeling of the process of collecting exhaust air (the central passage serves as a “hot” corridor; inline air conditioners are marked blue).

Ideally, it is desirable that all the heated air is directed to the heat exchangers of the cooling devices, without raising the temperature in the room. In this case, the Kirov will be equal to 100%. To achieve the level of 90% and exceed it helps the following design techniques.

Air conditioners in-line usually take air from the back and throw it through the front. They are consistent in size with cabinets for IT equipment (they have the same or half width). The maximum distance between the air intakes of the air conditioner and the ventilation holes of the IT equipment usually should not exceed 3 m. When the exhaust of the rack is “out of reach” of the nearest air conditioner in its row, most of it goes to the air conditioner from the opposite row.

In-line conditioner with a vertical line of fans, "drive" air from the rear panel to the front

If all the heated air in the zone is neutralized by air conditioners located in it (i.e., KIOV = 100%), then local overheating zones cannot arise by definition.

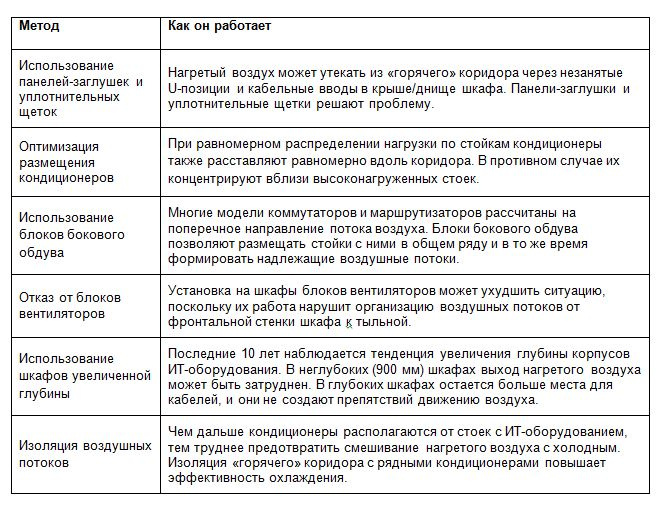

Example of placement of air conditioners. Their number and location are determined based on the energy consumption of the racks and the length of the corridor

Modern in-line air conditioners are equipped with electronically switched fans, which allows you to control the speed of rotation of the blades, and therefore the intensity of the air flow and cooling capacity in accordance with the thermal load. To control the operation of such devices, an automatic temperature measurement is performed on the air intakes of devices in nearby racks or throughout the room.

Now, armed with knowledge of the principles of operation and design of in-line cooling systems, proceeding to dispelling myths.

Myth 1: In-line air conditioners need special tools to create a directional air flow.

If 100% of the exhausted (hot) air is isolated to the hot corridors, then the rest of the room in the data center server room becomes a reservoir of cold air. Therefore, it does not matter which way it comes from the in-line conditioner. The main thing is that the air heated (by IT equipment) is fully collected and neutralized.

Various deflectors and reflectors are used by some manufacturers to direct cold air to the next rack. But, rather, it speaks of a lack of understanding of the principles of collecting the exhaust air. Installing reflectors not only increases costs, but also creates difficulties with the organization of air flow. The directional flow of air from the air conditioner has a higher speed than the air flow entering the nearby racks and is perpendicular to it. It can create rarefaction zones in front of the racks, disrupting the calculated flows.

Powerful air jets formed by reflectors can block air intakes and create significant uneven cooling conditions from rack to rack. The use of rotary reflectors is associated with the creation of a significant pressure drop, which requires additional energy consumption for the operation of the fans.

Myth 2. Inline air conditioners must be installed in each row.

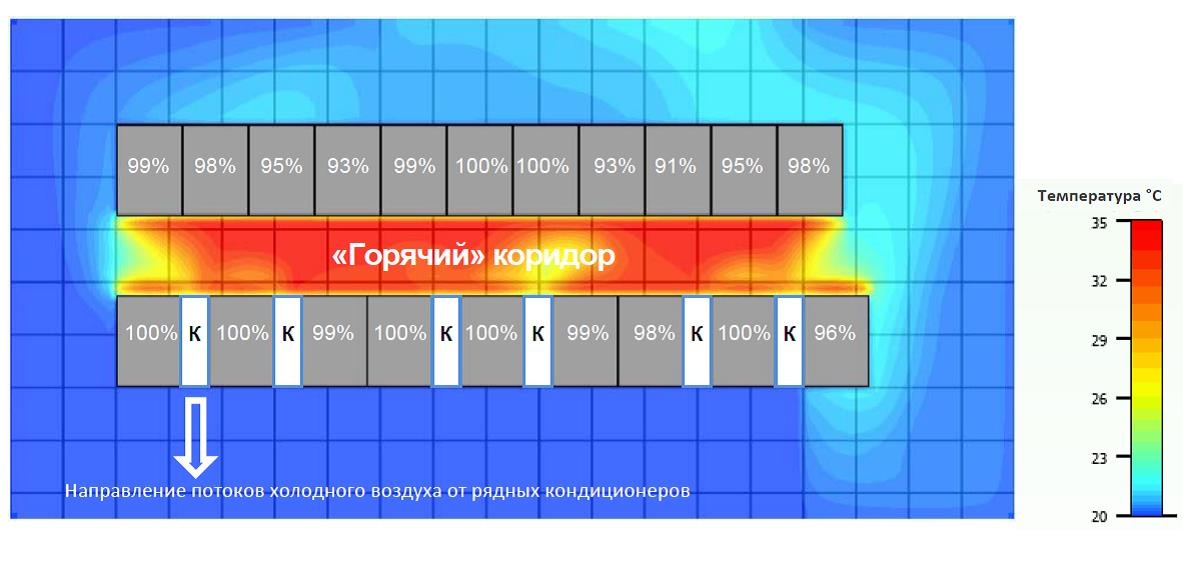

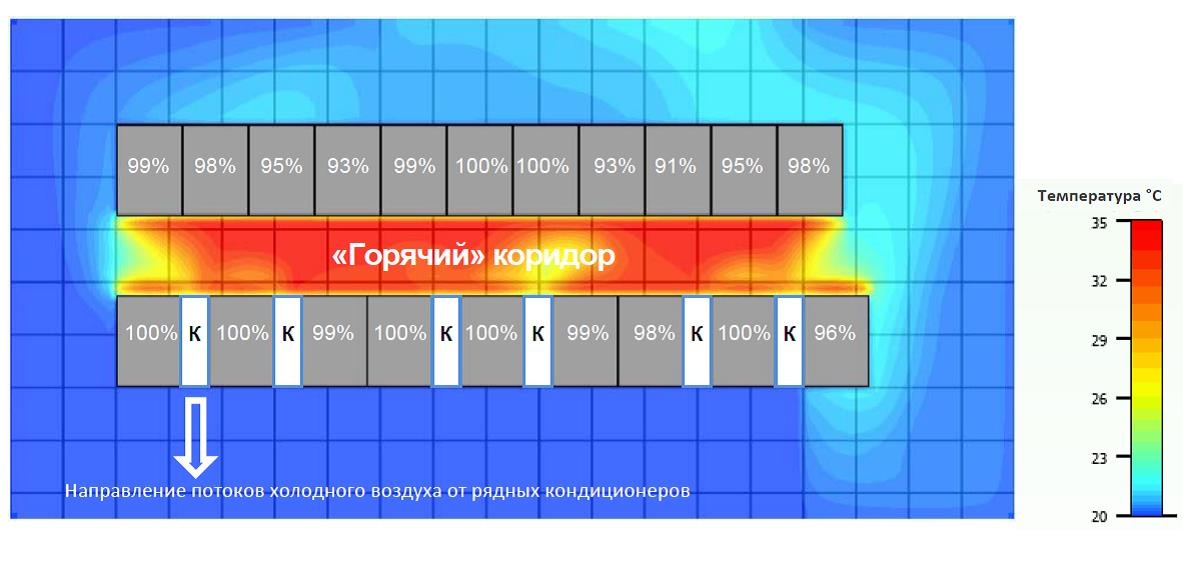

It follows from the design principles described that if it is possible to ensure high values of Kirov, then it does not matter how air conditioners are distributed between the rows of the zone. Numerical simulation and examples from practice show that air conditioners located in one of the rows of the zone effectively provide cooling equipment in both.

The result of airflow modeling in the server room when in-line air conditioners are installed in only one row of racks

Myth 3. In-line conditioner is limited to the area where it is installed.

According to this myth, inline air conditioners are intended solely for local cooling of selected areas, not suitable for cooling racks in other zones, as well as for stand-alone equipment (for example, tape drives) located along the perimeter of the room.

The most predictable way to cool stand-alone IT equipment is to place an air conditioner next to it and create a mini-zone with high Kiow. And what if with separate equipment there is no dedicated in-line air conditioner? Will the hot corridor insulation have a negative effect on the cooling of such equipment?

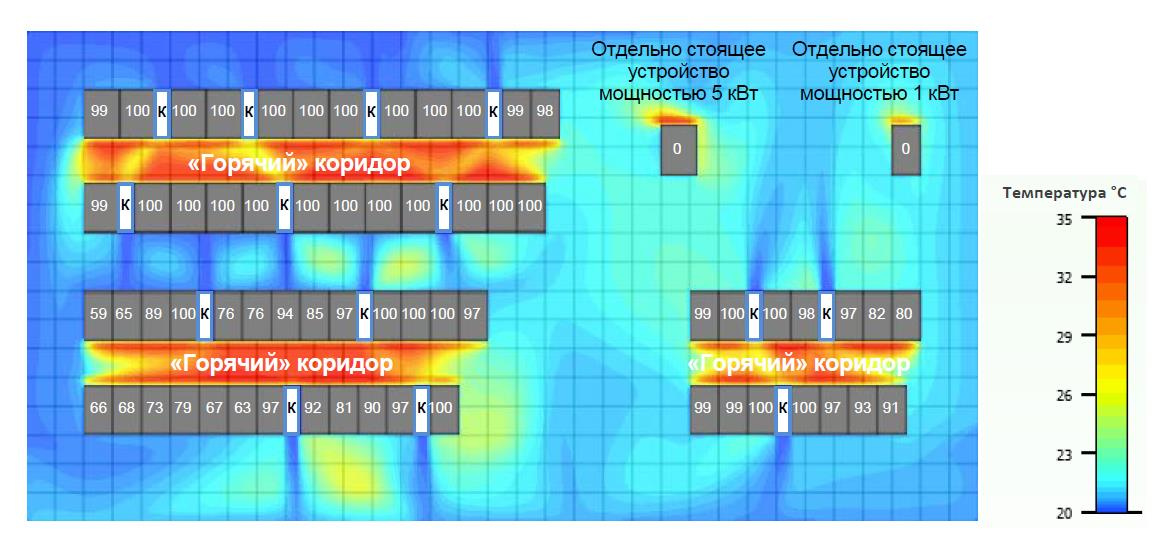

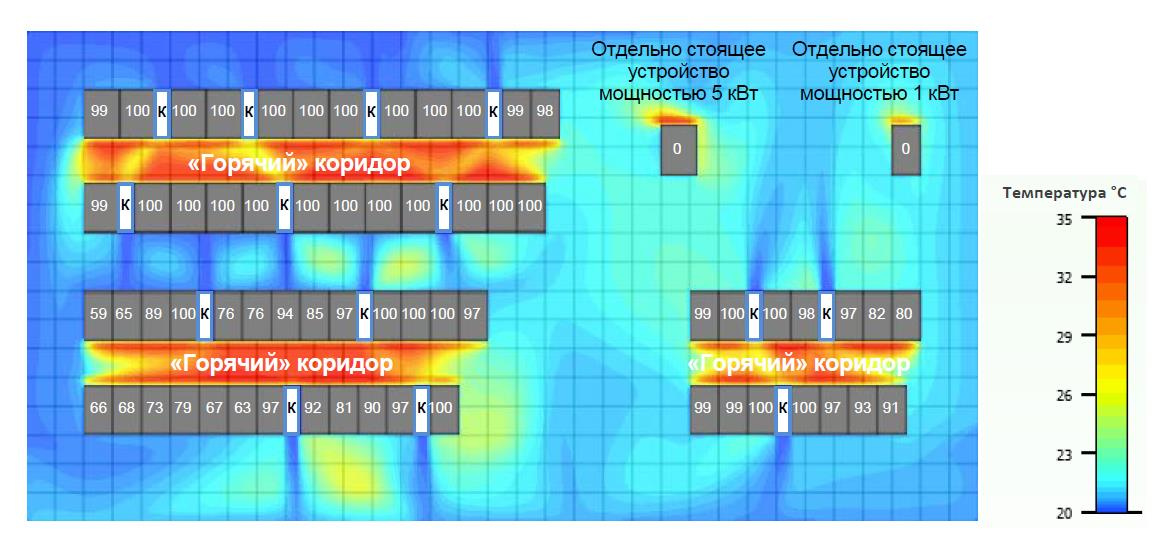

To answer these questions, let's consider two identical server rooms (each has 65 racks, 235 kW of IT load, two separate IT devices), but in one the “hot” corridor was insulated, in the other - not.

Below are the results of calculations of the temperature in the halls using 14 air conditioners, evenly distributed over them. Each counter is listed KIOV. In the absence of insulation of hot corridors, the average temperature at the air intakes of freestanding equipment is 22˚C.

The result of modeling a data center with in-line air conditioners without insulation of hot corridors. The total load of 235 kW. A total of 65 racks: wide - 5 kW per rack, narrow - 3 kW per rack.

With the isolation of “hot” corridors for most racks, Kiovs are 100%. The average temperature at the air intakes of both detached devices is 21˚C.

The result of modeling data center with in-line air conditioners and insulation of hot corridors. The total load of 235 kW. A total of 65 racks: wide - 5 kW per rack, narrow - 3 kW per rack.

When installing stand-alone equipment, the room temperature first rises. Then the next air conditioners detect this and increase their cooling capacity. After reaching a new state of equilibrium, all indicators further remain at a constant level.

Such a process of “picking up a new auxiliary load” also takes place in the presence of insulation systems of “hot” corridors. In any case, it should be borne in mind that stand-alone IT equipment will operate at higher temperatures (as compared to equipment installed in air conditioner racks), and the further the equipment is located from air conditioners, the higher the temperature at its air intakes will be. But with proper design, this temperature will be acceptable for its reliable operation.

At one time, Schneider Electric pioneered the development of inline cooling systems for IT rooms. Today, such systems have become the industry standard, but the company maintains primacy in this area. In its portfolio of solutions - "intracavity", working as a chilled water (InRow Chilled Water), and freon systems (InRow Direct Expansion). The customer can choose air conditioners with a width of 30 or 60 cm and use the most convenient in a particular project scheme for supplying pipes (top or bottom). InRow devices are equipped with temperature and humidity sensors to automate procedures for regulating operation. They are compatible with Hot Aisle Containment and Rack Air Containment insulation systems, which increase the efficiency of cooling systems.

InRow systems are installed and successfully operated in many Russian data centers, both in corporate and commercial centers. It is an effective and economical solution for creating the optimal climate for the operation of IT equipment.

The space of server rooms in data centers, as a rule, is divided into zones. A zone (pod in English terminology) is a group of cabinets united by a common power and cooling infrastructure. Most often, one zone consists of two rows of cabinets, between which a “hot” corridor is formed.

')

In-line cooling involves the installation of air conditioners directly in a row of racks. At the same time, such air conditioners, as well as other types of air conditioners, are often considered as a “cold air supply” system (IT equipment). Because of this, many delusions arise. In reality, the main thing is to ensure “heated air discharge” from IT equipment without mixing with indoor air.

Below are three common misconceptions about the functioning of row cooling systems.

The effect of in-line air conditioning is limited to the zone limits. Many believe that in-line air conditioners are able to serve the load only within their zones, and increasing the cooling system power in one of the zones does not help the removal of heat from the others.

Before we begin to debunk the myths, let's talk about the general principles of operation and design of data center cooling systems. The main objective of any such system is the removal of heat generated by IT equipment. A measure of the efficiency of collecting hot air in such systems (or supplying cold air) is called the coefficient of isolation of exhaust air (KIOV). This coefficient is calculated by post, based on the air flow diagram. High values correspond to better performance of the cooling system.

KIOV is defined as the proportion of exhaust air (heated by IT equipment) that flows directly to the heat exchangers of in-line air conditioners in the same area. This is a basic metric for evaluating the effectiveness of in-line cooling.

Results of aerodynamic modeling of the process of collecting exhaust air (the central passage serves as a “hot” corridor; inline air conditioners are marked blue).

Ideally, it is desirable that all the heated air is directed to the heat exchangers of the cooling devices, without raising the temperature in the room. In this case, the Kirov will be equal to 100%. To achieve the level of 90% and exceed it helps the following design techniques.

Air conditioners in-line usually take air from the back and throw it through the front. They are consistent in size with cabinets for IT equipment (they have the same or half width). The maximum distance between the air intakes of the air conditioner and the ventilation holes of the IT equipment usually should not exceed 3 m. When the exhaust of the rack is “out of reach” of the nearest air conditioner in its row, most of it goes to the air conditioner from the opposite row.

In-line conditioner with a vertical line of fans, "drive" air from the rear panel to the front

If all the heated air in the zone is neutralized by air conditioners located in it (i.e., KIOV = 100%), then local overheating zones cannot arise by definition.

Example of placement of air conditioners. Their number and location are determined based on the energy consumption of the racks and the length of the corridor

Modern in-line air conditioners are equipped with electronically switched fans, which allows you to control the speed of rotation of the blades, and therefore the intensity of the air flow and cooling capacity in accordance with the thermal load. To control the operation of such devices, an automatic temperature measurement is performed on the air intakes of devices in nearby racks or throughout the room.

Now, armed with knowledge of the principles of operation and design of in-line cooling systems, proceeding to dispelling myths.

Myth 1: In-line air conditioners need special tools to create a directional air flow.

If 100% of the exhausted (hot) air is isolated to the hot corridors, then the rest of the room in the data center server room becomes a reservoir of cold air. Therefore, it does not matter which way it comes from the in-line conditioner. The main thing is that the air heated (by IT equipment) is fully collected and neutralized.

Various deflectors and reflectors are used by some manufacturers to direct cold air to the next rack. But, rather, it speaks of a lack of understanding of the principles of collecting the exhaust air. Installing reflectors not only increases costs, but also creates difficulties with the organization of air flow. The directional flow of air from the air conditioner has a higher speed than the air flow entering the nearby racks and is perpendicular to it. It can create rarefaction zones in front of the racks, disrupting the calculated flows.

Powerful air jets formed by reflectors can block air intakes and create significant uneven cooling conditions from rack to rack. The use of rotary reflectors is associated with the creation of a significant pressure drop, which requires additional energy consumption for the operation of the fans.

Myth 2. Inline air conditioners must be installed in each row.

It follows from the design principles described that if it is possible to ensure high values of Kirov, then it does not matter how air conditioners are distributed between the rows of the zone. Numerical simulation and examples from practice show that air conditioners located in one of the rows of the zone effectively provide cooling equipment in both.

The result of airflow modeling in the server room when in-line air conditioners are installed in only one row of racks

Myth 3. In-line conditioner is limited to the area where it is installed.

According to this myth, inline air conditioners are intended solely for local cooling of selected areas, not suitable for cooling racks in other zones, as well as for stand-alone equipment (for example, tape drives) located along the perimeter of the room.

The most predictable way to cool stand-alone IT equipment is to place an air conditioner next to it and create a mini-zone with high Kiow. And what if with separate equipment there is no dedicated in-line air conditioner? Will the hot corridor insulation have a negative effect on the cooling of such equipment?

To answer these questions, let's consider two identical server rooms (each has 65 racks, 235 kW of IT load, two separate IT devices), but in one the “hot” corridor was insulated, in the other - not.

Below are the results of calculations of the temperature in the halls using 14 air conditioners, evenly distributed over them. Each counter is listed KIOV. In the absence of insulation of hot corridors, the average temperature at the air intakes of freestanding equipment is 22˚C.

The result of modeling a data center with in-line air conditioners without insulation of hot corridors. The total load of 235 kW. A total of 65 racks: wide - 5 kW per rack, narrow - 3 kW per rack.

With the isolation of “hot” corridors for most racks, Kiovs are 100%. The average temperature at the air intakes of both detached devices is 21˚C.

The result of modeling data center with in-line air conditioners and insulation of hot corridors. The total load of 235 kW. A total of 65 racks: wide - 5 kW per rack, narrow - 3 kW per rack.

When installing stand-alone equipment, the room temperature first rises. Then the next air conditioners detect this and increase their cooling capacity. After reaching a new state of equilibrium, all indicators further remain at a constant level.

Such a process of “picking up a new auxiliary load” also takes place in the presence of insulation systems of “hot” corridors. In any case, it should be borne in mind that stand-alone IT equipment will operate at higher temperatures (as compared to equipment installed in air conditioner racks), and the further the equipment is located from air conditioners, the higher the temperature at its air intakes will be. But with proper design, this temperature will be acceptable for its reliable operation.

At one time, Schneider Electric pioneered the development of inline cooling systems for IT rooms. Today, such systems have become the industry standard, but the company maintains primacy in this area. In its portfolio of solutions - "intracavity", working as a chilled water (InRow Chilled Water), and freon systems (InRow Direct Expansion). The customer can choose air conditioners with a width of 30 or 60 cm and use the most convenient in a particular project scheme for supplying pipes (top or bottom). InRow devices are equipped with temperature and humidity sensors to automate procedures for regulating operation. They are compatible with Hot Aisle Containment and Rack Air Containment insulation systems, which increase the efficiency of cooling systems.

InRow systems are installed and successfully operated in many Russian data centers, both in corporate and commercial centers. It is an effective and economical solution for creating the optimal climate for the operation of IT equipment.

Source: https://habr.com/ru/post/336404/

All Articles