Muda marriage

(Muda - loss of enterprise resources without value creation)

Equipment control

What is being done at an ordinary production plant, having discovered that the line produces damaged products? Suspend production, and it is more than reasonable. However, quite often it is not possible to detect a defect immediately and high-speed equipment during mass production can produce a large amount of defective products. It happens earlier than experts notice the abnormal situation and will be able to do something.

Failure of welding equipment.

- All high-speed machines and mechanisms must be under the constant control of the staff. That is, there should be controllers who will always be nearby and check the products, stop the line in case of a malfunction. Of course, such a measure will affect the additional costs of staff, but in the end, they will be justified, because the marriage rate will be reduced.

- Equipment must be equipped with automatic shutdown devices when a defect or breakdown occurs on the line. This is as an alternative or addition to the previous item. There are machines that produce a huge amount of products in a matter of seconds and, the more progressive the equipment, the more urgent the automatic line shutdown systems.

Cumulative effect of product value

From my publication, we take the technological process of production of the wire PG. It has the following operations:

')

The first semi-finished product "MM 1.8" contains the costs of direct and auxiliary materials, the salary of a worker, the cost of non-returnable waste, electricity for equipment and much more. If you made a marriage, the company bears these costs, conditionally called X1 rubles.

If a marriage was made after the second “Dragging” operation, then it contains the costs of the current operation and the previous X1 + X2.

As you understand, the production of marriage in the last operation “Twist” contains costs X1 + X2 + X3 + X4 + X5 + X6 + X7. In some cases, it is possible to compensate for the marriage by processing it (additional costs), but still a significant part of the costs in the form of wages and electricity remains the loss of the enterprise.

- The qualifications of employees and the quality of equipment in multi-production in the final stages should be extremely high. This unwanted release takes a significant portion of the profits. Do not allow marriage in the final stages of production.

- Defective products should not be accepted and transferred to the next stage. It should be placed in the isolation ward with the explanation of the causes of education. Finding a marriage should be handled by an independent quality control officer or technologist. In addition to the necessary impartiality, he does not distract the production worker from the piece-work piece. The result of the investigation is the last to deprive employees, as this increases the level of negligence in the following installments.

Atmosphere

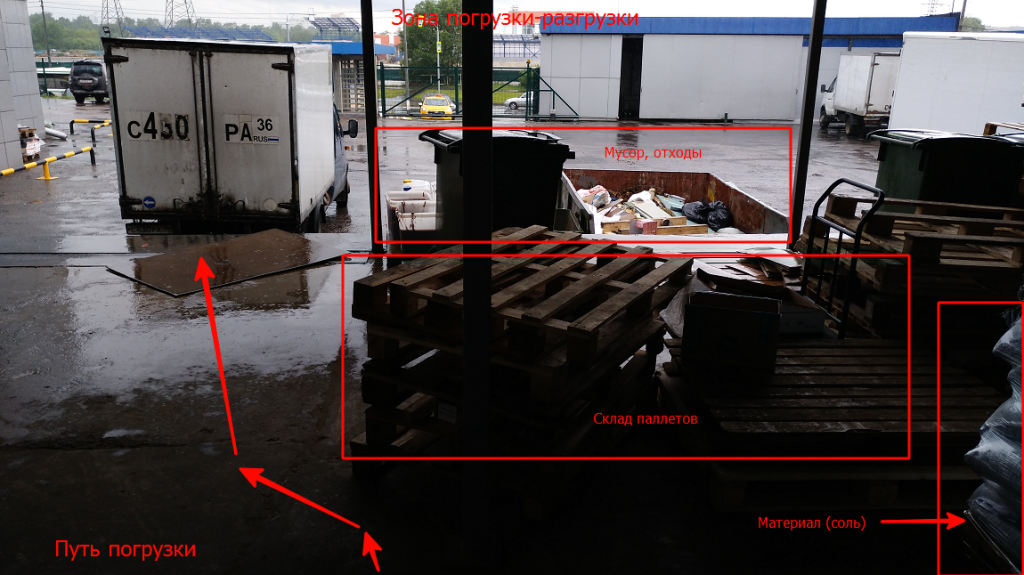

A little higher, I wrote "do not allow marriage in the final stages of production ." At the majority of enterprises, after production, there are warehousing and loading and unloading operations. They also add product cost. Allowing damage, loss, theft, shipping errors at this stage is an unaffordable luxury. Consider a real example of the loading and unloading zone of a food enterprise of a well-known brand.

From the point of view of the organization of production and logistics, everything is done here in order to reduce its own profit: break (it is in glass), mix up batches or products, injure workers, interfere with each other. I repeat - this is the area where the products collected all the production and storage costs.

Organize a favorable atmosphere in the enterprise throughout the production and storage circuit.

Quality system

Today, aviation has unprecedented safety in the world. The majestic technology and all-Russian negligence does not speak about air crashes in the USA.

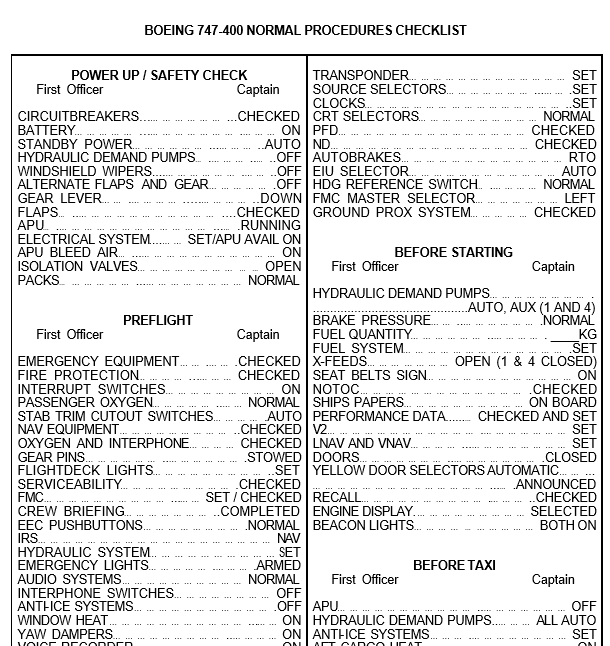

Each element of this industry is reliably controlled and duplicated. Whether it is an aircraft control system, where apart from electronics there is pneumatics, mechanics and hydraulics as a control loop, be it a take-off control procedure that is pronounced out loud by one pilot and checked by another.

Extract from B-747 pilot checklist:

The full text of the checklist is available here .

Why don't you use this method in your own production? Implement quality systems and, at a minimum, use checklists and accompanying passports.

Excessive distraction to marriage

The general director, the director of production, the master shift, the quality control controller, the workers ... are hanging around the produced marriage ... This is an unscheduled meeting. And the meeting is already bad. A unplanned, and with the working staff - a very undesirable event. For example, an hour-long trial of listed employees costs 5-10 working man-hours (5-10 employees x 1 hour) [in addition to the costs of marriage]. If the presence of the director and deputy director does not affect the costs of the product, then attracting workers is highly undesirable in the process of the proceedings. They create value, and the rest parasitize on them. As if it did not sound harsh, but it is.

Do not be distracted by marriage and do not distract others. Do not beat down the production schedule. Minimally solve the problem without meetings.

Negligence

I consider negligence one of the main scourges of the economic backwardness of our country. Negligence creates low productivity. Once I bought a new weight measuring equipment of domestic production "Tenzo-M". See how it came.

I can still cite dozens of examples from my own experience, but I think everyone has come across this.

With psychoanalysis and cause-and-effect relationships, give yourself the answers:

- Why should an employee produce quality products? (The first and most incorrect answer - because you pay him a salary - skip)

- What happens if a worker releases a marriage?

- What happens if the worker DOES NOT release the marriage?

- What quality standards have you implemented in the enterprise? Check lists? Accompanying passports?

- What are the motivational and depremal schemes in your arsenal?

- What measures are taken to eliminate negligence in your factory?

Source: https://habr.com/ru/post/333466/

All Articles