PLC from manufacturers Aries, Segnetics and Schneider Electric for HVAC

In this article, a brief overview of programmable controllers for HVAC (heating, ventilation and air conditioning) from 3 manufacturers:

Based on personal experience of their use.

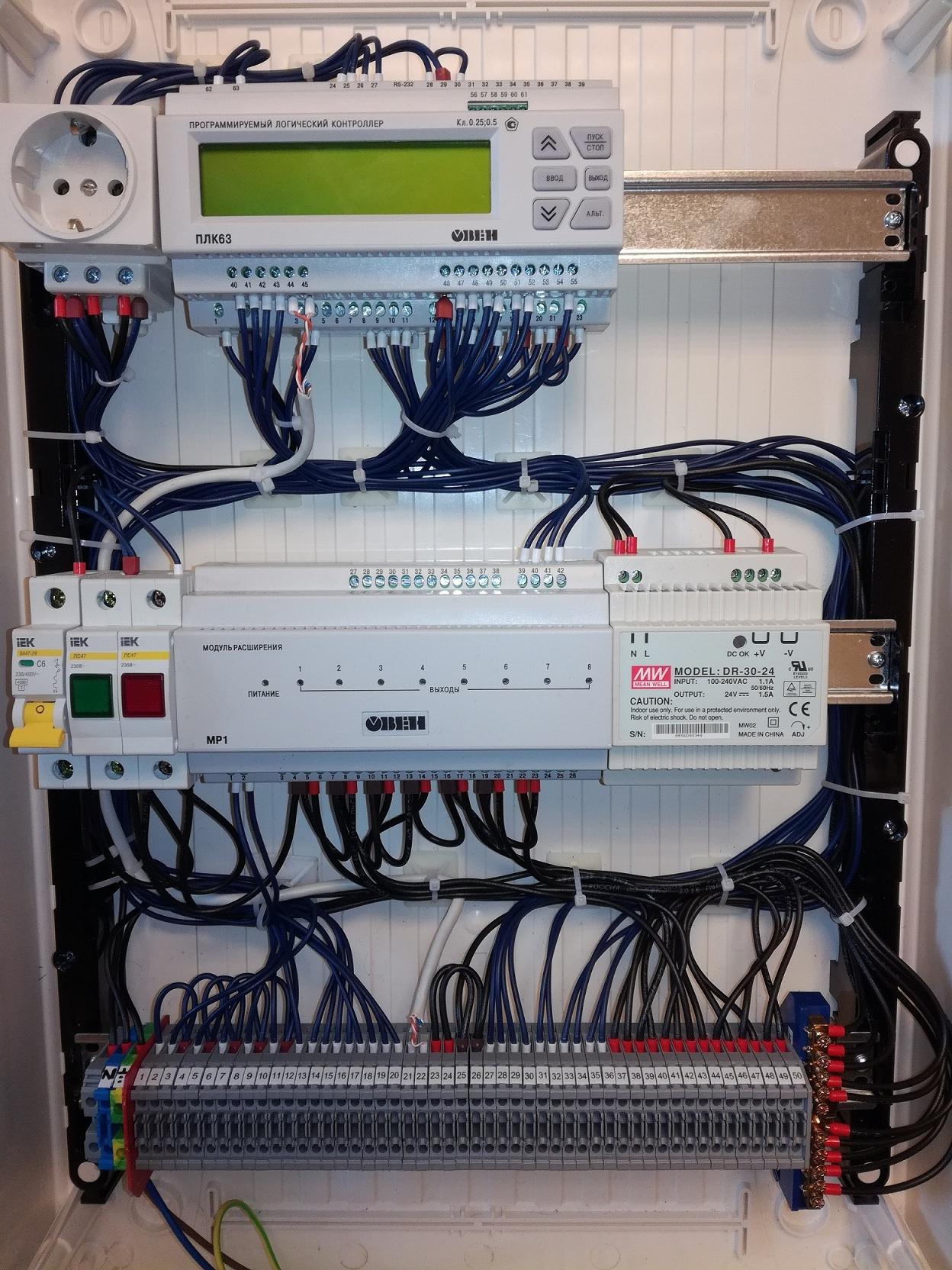

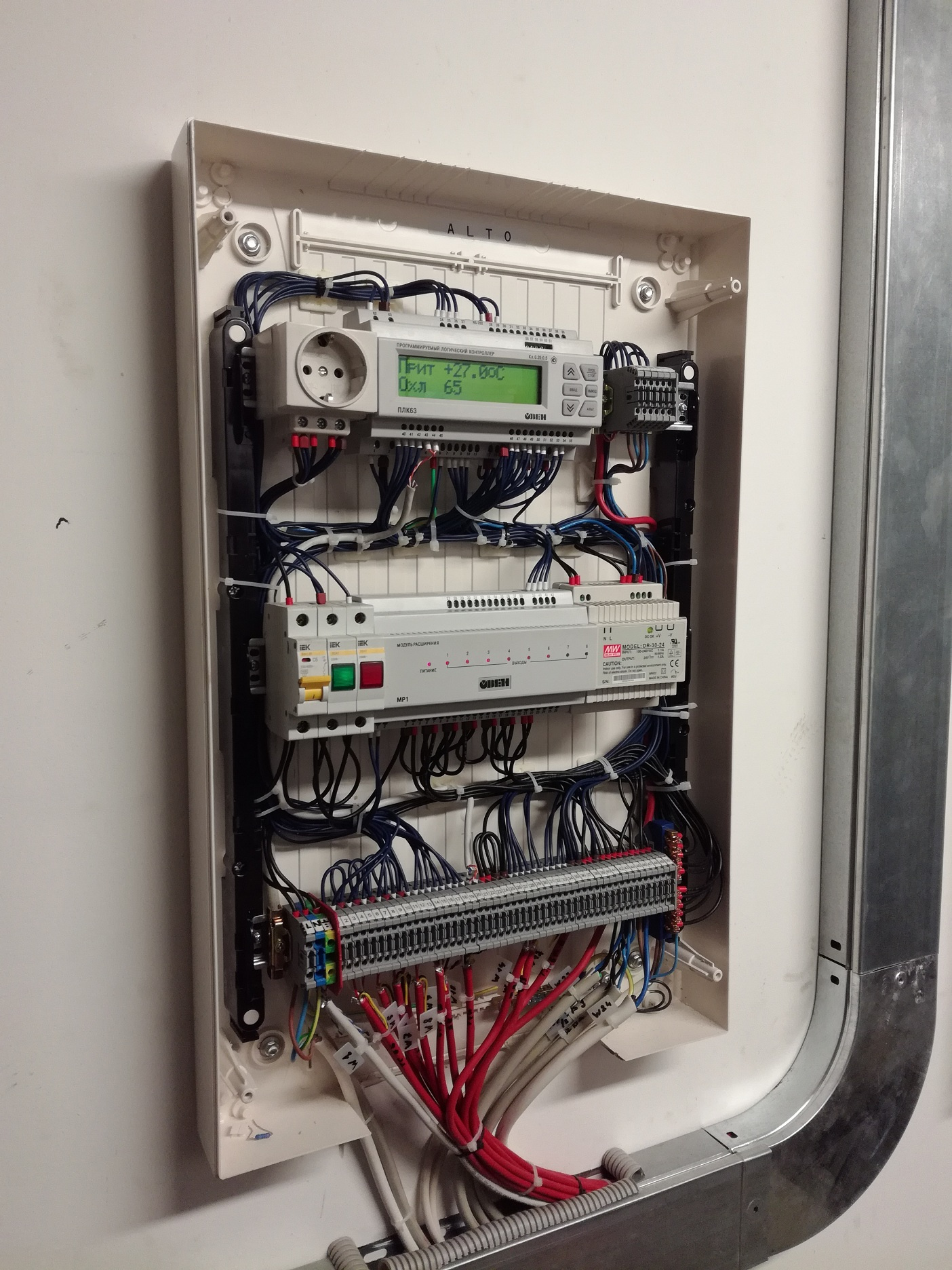

So, two brothers of an acrobat: PLC63 –beatle DIN rail and PLC73 - stubborn fortochnik (for installation you have to mount it in the shield door).

')

With any modification you get - 8 digital inputs, 8 analog inputs. For the tasks of automation of ventilation systems of such a number of sensors is enough.

PLC73 boasts 2 COM ports, if you buy an additional fee PI73. Variations 5pcs. Personally, I think the most interesting PI73-5 is RS-485 * 2pcs. The PLC63 always has RS485 on board.

Another 73rd 4 lines on the display against 2 lines on the PLC63. The battery in the clock and the memory of both models are immediately (but mash for variables less than segnetics). The storage mechanism in the ROM of these PLCs is more fun than Segnetics. As I understand it, in the ROM data is recorded only at the time of power off. The rest of the time, data is written to RAM.

And that and the other model a bunch of variations of outputs, which are called VU (output device). These can be relays, current or voltage DACs, optotransistors or optosimistors. For the manufacturer, variations are not difficult to create, because the main board is one and different WU modules can be soldered into it.

Need more relay outputs? No problem - we buy the MP1 module (8 relays). The module is only this - ARIES does not give us more variations.

For PLC63 - Relay plus 5 pcs WU, which you choose upon purchase. For PLC73 - 4 transistors and 4 WU.

In general, the PLC73 is a controversial model. Most of all people are mad about it - harsh hard buttons. Oh yes ... Buttons will force an inexperienced person to experience the whole range of negative emotions. Well, the analog outputs of the PLC73 less.

After working with both models, I left the PLC63 favorite. Somehow he looks more serious, and the buttons are easier to press. But it is a pity that there is only one RS485.

Well, if you really want to, remember that you have RS232-debug - the port through which we pour the firmware. The truth will have to purchase converter RS232 to RS485.

Codesys 2.3. About her already a lot of things written. And not one ARIES uses it (this is a plus). There are many libraries (note Oscat). The environment is not ours, but German (as surprising, yes?). There are many functionalities, both textual and graphical (extended IEC 61131-3). Read more in the books.

Slave . There are out of the box, immediately gives read input, output, button presses, clock. Addresses of new variables will have to come up separately. All is read without group requests.

But if you really want, you can and group, there are descriptions in the manual. However, the addresses in the manual are given with errors.

Do not worry - one kind person has already found the correct addresses. You can find on the forum AWN or here (already filled, so as not to be lost).

Master mode . There is already more difficult. You will have to apply such a terrible thing as "programming skills" - take the Modbus.lib library (or you will do it yourself) and write the interaction with external devices. It sounds scary, but to some extent it will give more flexibility. For example, you can write a job with a bunch of typical devices (the same frequency converters), and not create a bunch of similar variables

Pros:

Minuses:

Prices from the Aries website (see all the modifications on the website):

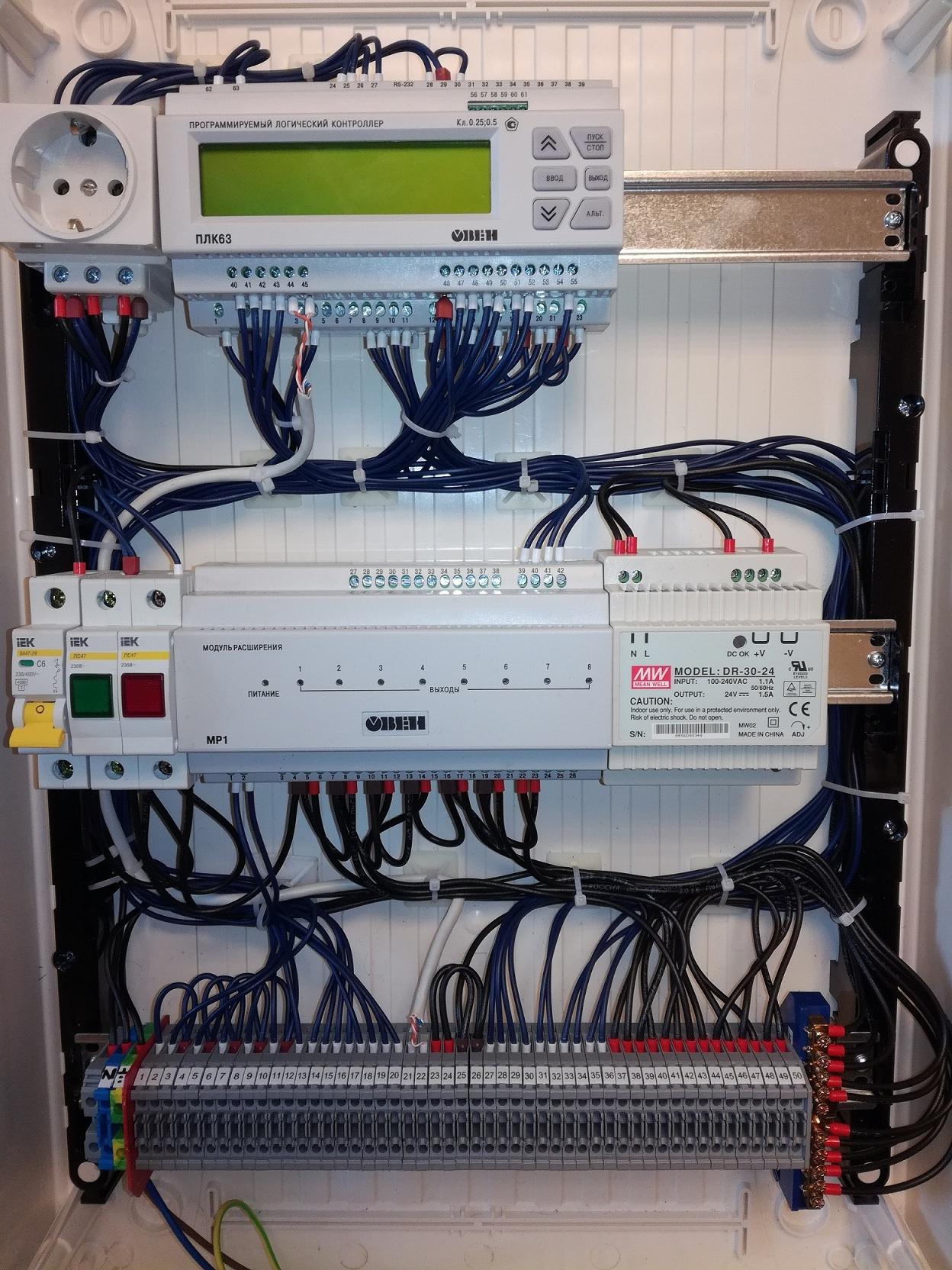

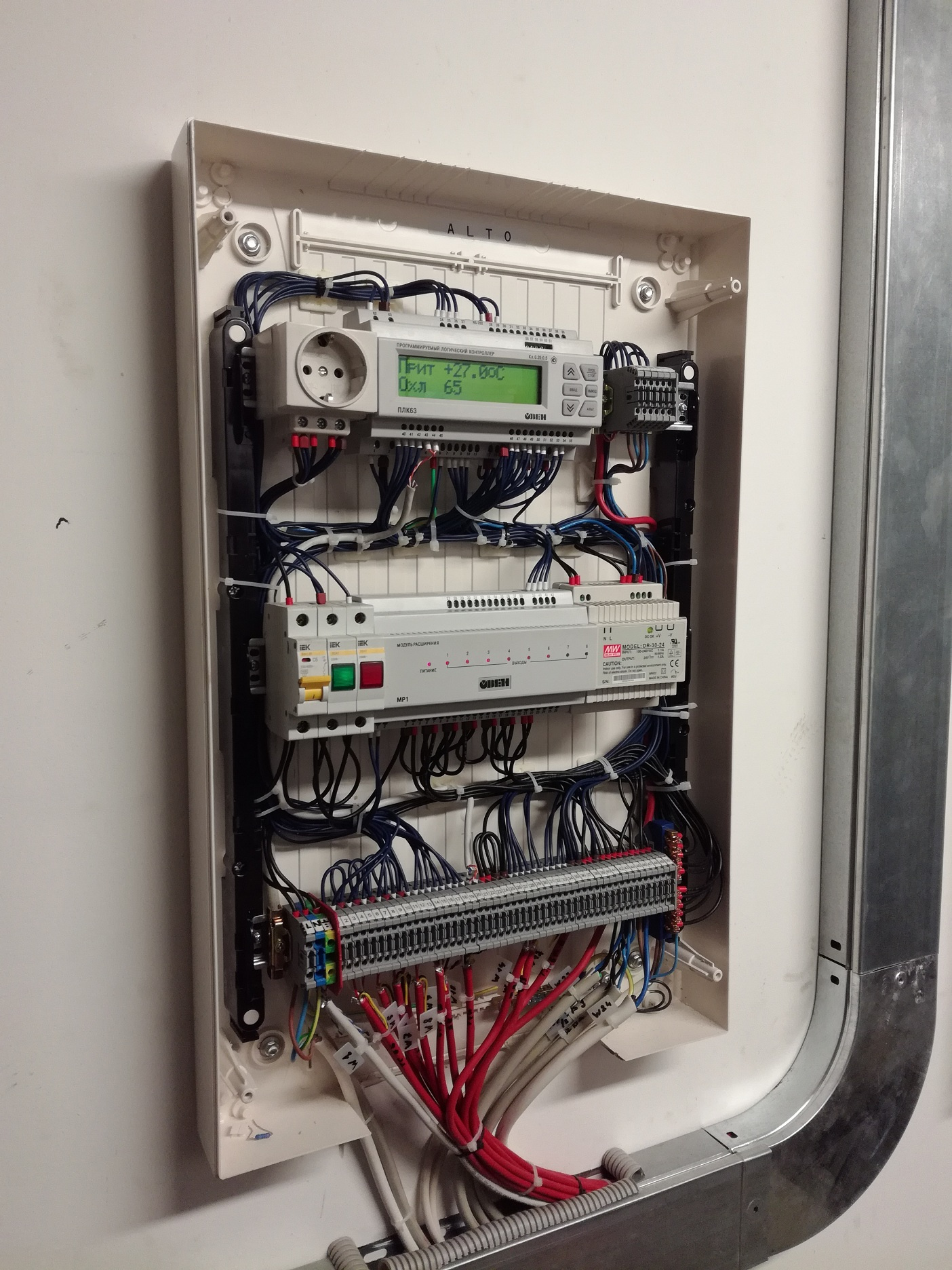

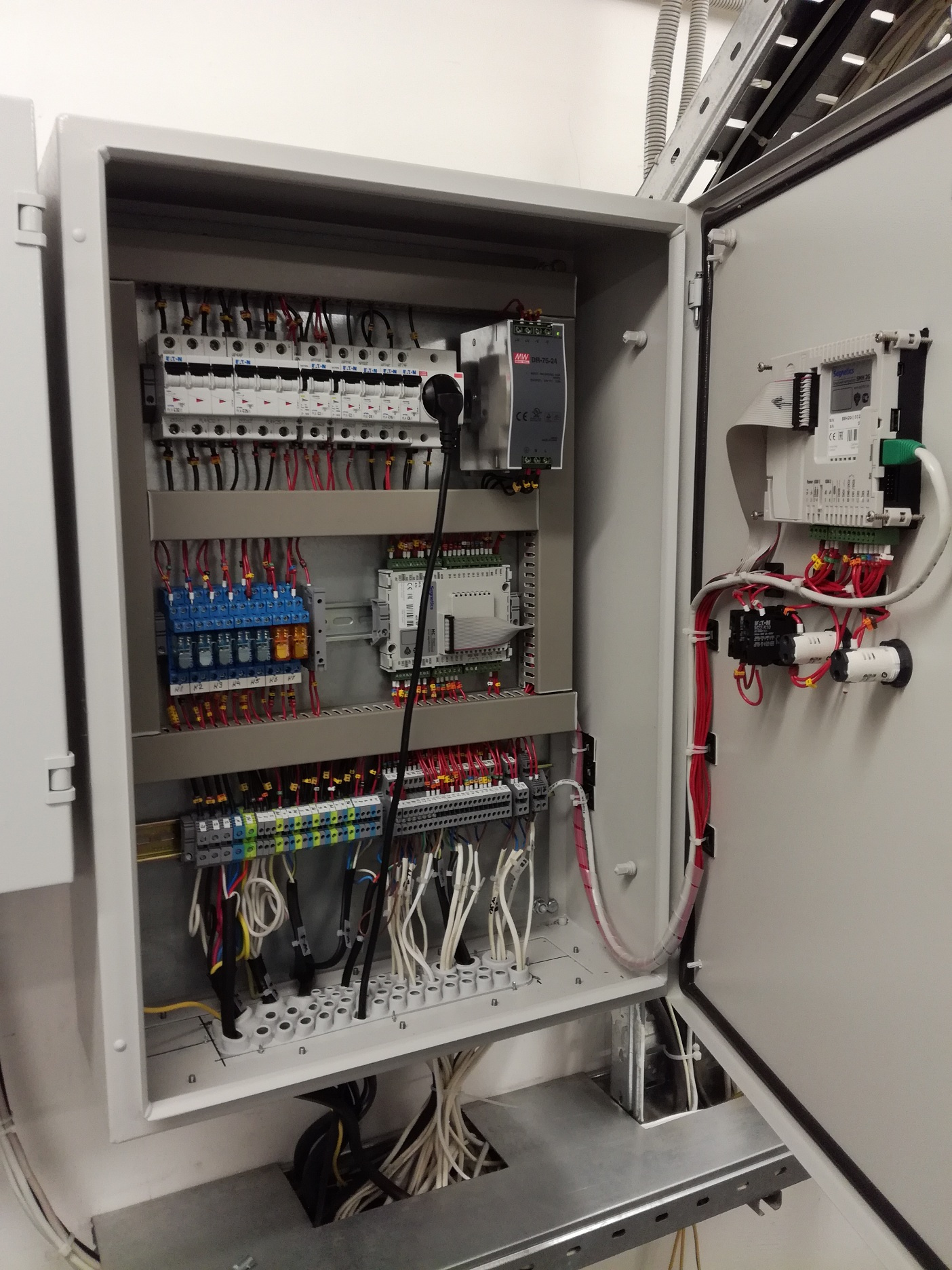

From personal collection:

So, Pixel and his big brother shaper SMH2g. There are SMH2gi with access to linux. It seems to give more opportunities for lovers of the most terrible thing as "programming skills".

Regarding I / O, SMH2g is not particularly interesting without expansion modules (on board 4 DI / 4 DO and 5 DI / 2 DO for SMH2gi). Pixel is doing better (6DI / 3DO / 5AI / 2AO), but you can't always do without modules too.

It is important to note - Pixel galvanic isolation for analog outputs and inputs NO. Of course, Segnetics was confused in terms of extensibility. You can even make Ethernet for Pixel. However, in order for the clock to tick without a glitch, you will need to buy a battery from Segnetics. And this position is separate. Also with memory. Buy separately (if you, for example, need work on a schedule).

Another small pebble in the Segnetics garden is the price of wicked cable for connecting PLCs with expansion modules. In fact - the usual cable with IDC connectors. You can make yourself by buying everything in a store or radio market. Get 5 times cheaper. The main thing is not to confuse with the connection.

In terms of appearance, ease of pressing buttons, the display - everything is fine. For more pathos, Segnetics did not even write a word in Russian on the controller case. Well, we are pleased.

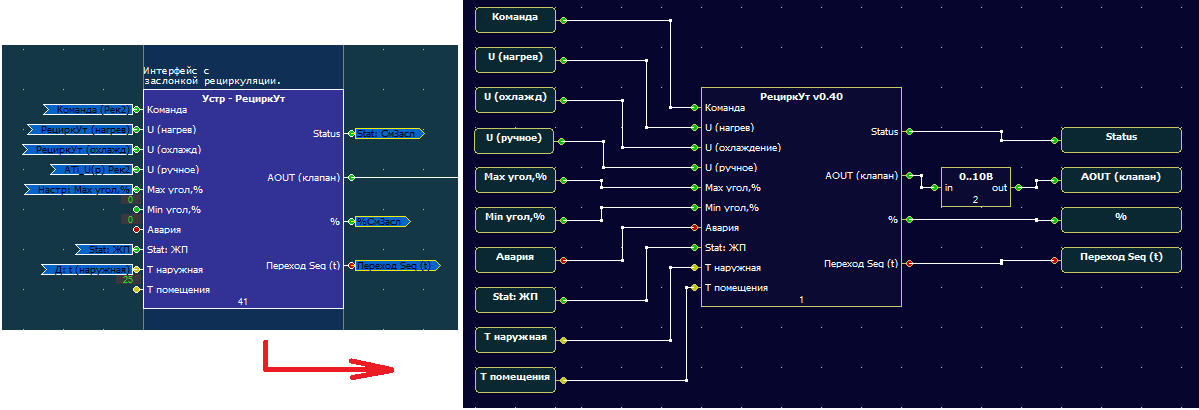

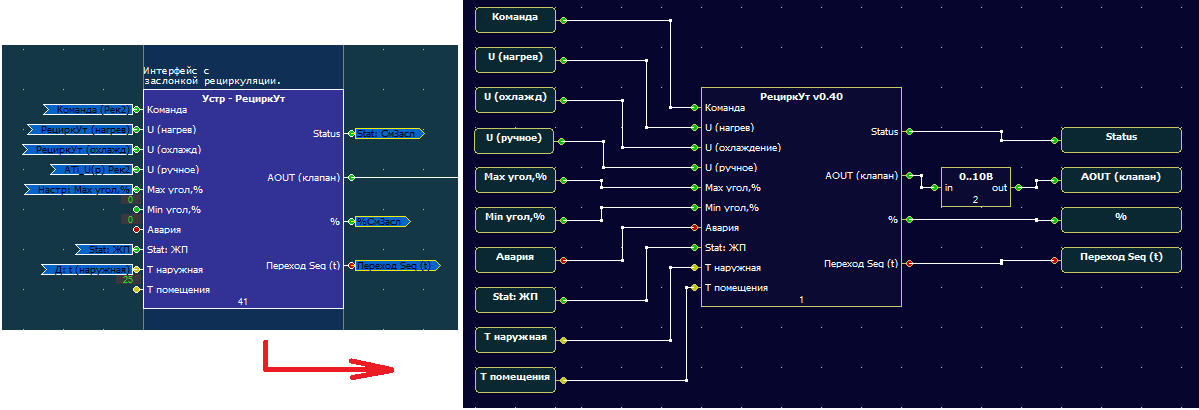

SMLogix. Developed by Segnetics. Graphic language only with all the disadvantages of graphic languages. In order to make it more convenient to make edits in the program, it is desirable to make blocks (they are macros) by the type of nested doll:

So you will not lose external links in the program. Segnetics significantly increased the appeal of its equipment thanks to the SMConstructor configurator, which generates a PLC work program for ventilation systems (now for ITP). It will remain to file it to fit your needs.

However, the same Pixel will not give you full access to the COM port. You do not write the protocol you need. Modbus only.

All is not bad. Each variable you create automatically becomes a Modbus variable. This is how slave mode is implemented.

For the Master, everything is also good. You can load Modbus cards from other Segnetics controllers, or create (and save to a computer) variable maps separately. For most tasks this should suffice

Pros:

Minuses:

Prices are freely available. I will attach a few positions:

From personal collection:

Got acquainted with this lineup for HVAC about a year ago. According to what was read on the forums - the development of the Italian, apparently was bought by Schneider.

The M171 version is simpler and cheaper, so we decided not to waste time on trifles and take the M172. On entrances and exits - a fairy tale. For example, the model TM172PDG42R is 42 I / O. Interfaces - Ethernet (M172), RS485 (there are even 2 of them in the M172), CAN. The screen is not bad, graphic. Add to this a bunch of any expansion modules and get a very interesting solution in terms of hardware.

SoMachine HVAC. And here begins the first fly in the ointment. The environment is not particularly friendly for a beginner. With documentation everything is bad - get ready to search engine wool.

The environment is divided into several separate programs. They even have their own labels. In one you initialize the interfaces and hardware, in the other you draw a screen, in the third you write the program. Youtube will tell you better:

There are graphic and textual languages. There is an ST (there are no Time type variables - you will spin with a DWORD). Also here is a stupid variable initialization system. You can’t just write:

Why so simple? You better create each variable with the mouse through a dialog box. Transferring lessons from other programming environments becomes more complex.

But in general, there are more opportunities here than SMLogix. However, the development is still raw.

Each variable has its own address. Those. Slave will be immediately. With Modbus in this regard, everything is not bad. All, yes, not all. Here you have another 1.5 fly in the ointment:

UPD (August 2018)

More than a year has passed since the writing of the article. Good news has arrived for M172:

The manufacturer has already released several updates to the controller core. So you may not encounter the software ailments listed.

We have, for example, the problem with the loss of communication in Modbus TCP has disappeared. (If someone has a positive experience of use - write, add to the article).

Pros :

Cons :

Prices at the time of purchase:

To controllers it is necessary to buy separately removable terminals.

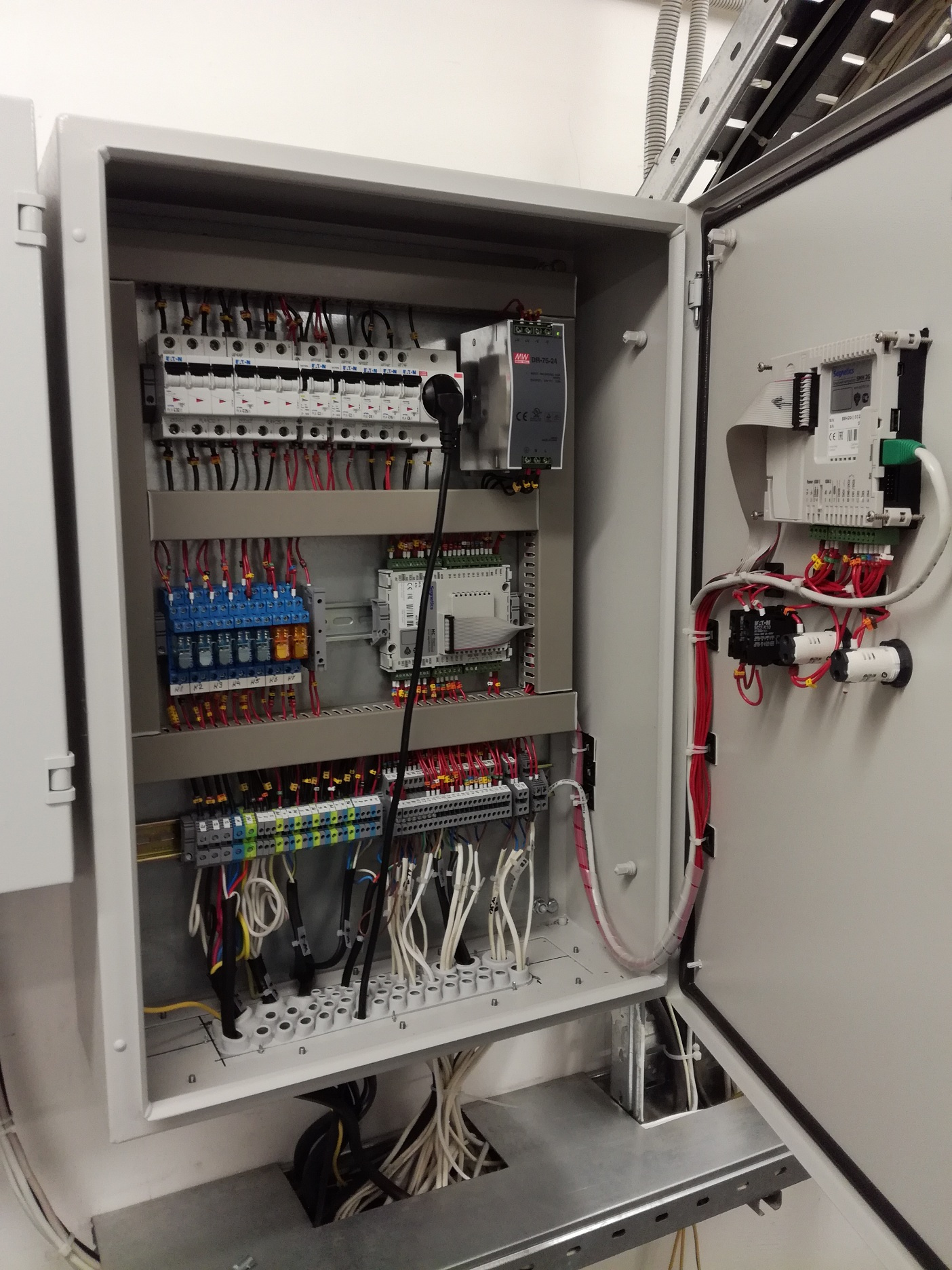

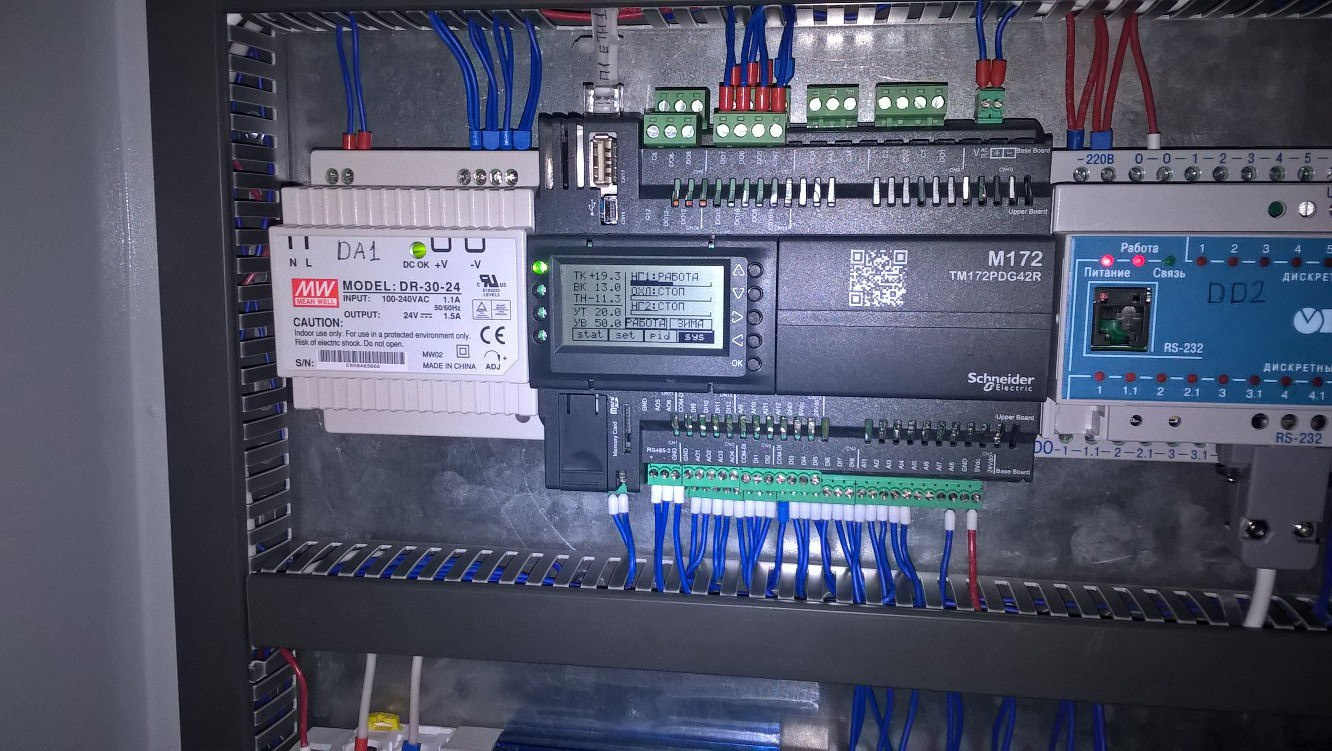

From the personal collection. PLC100 (on the right) just works as a Master instead of M172:

Codesys 2.3. The threshold of entry is higher than that of the Segnetics programming environment, but you can also make things more interesting (even some basic OOP are there). Therefore, it will be difficult to write / draw a program without experience.

If you decide to study Codesys, then I highly recommend starting with ST (Structured Text), Pascal-like language. Text languages have a major advantage - the ability to transfer to other environments that support the language.

The author already had the experience of transferring the program from the PLC63 to the very Schneider M172 with minimal changes.

Graphic languages initially lure you visually. But do not give in - in large programs you get confused, and even lose flexibility (you can’t just comment out a part of the code).

Based on personal experience of their use.

ARIES PLC63 / 73

So, two brothers of an acrobat: PLC63 –beatle DIN rail and PLC73 - stubborn fortochnik (for installation you have to mount it in the shield door).

')

With any modification you get - 8 digital inputs, 8 analog inputs. For the tasks of automation of ventilation systems of such a number of sensors is enough.

PLC73 boasts 2 COM ports, if you buy an additional fee PI73. Variations 5pcs. Personally, I think the most interesting PI73-5 is RS-485 * 2pcs. The PLC63 always has RS485 on board.

Another 73rd 4 lines on the display against 2 lines on the PLC63. The battery in the clock and the memory of both models are immediately (but mash for variables less than segnetics). The storage mechanism in the ROM of these PLCs is more fun than Segnetics. As I understand it, in the ROM data is recorded only at the time of power off. The rest of the time, data is written to RAM.

And that and the other model a bunch of variations of outputs, which are called VU (output device). These can be relays, current or voltage DACs, optotransistors or optosimistors. For the manufacturer, variations are not difficult to create, because the main board is one and different WU modules can be soldered into it.

Need more relay outputs? No problem - we buy the MP1 module (8 relays). The module is only this - ARIES does not give us more variations.

For PLC63 - Relay plus 5 pcs WU, which you choose upon purchase. For PLC73 - 4 transistors and 4 WU.

In general, the PLC73 is a controversial model. Most of all people are mad about it - harsh hard buttons. Oh yes ... Buttons will force an inexperienced person to experience the whole range of negative emotions. Well, the analog outputs of the PLC73 less.

After working with both models, I left the PLC63 favorite. Somehow he looks more serious, and the buttons are easier to press. But it is a pity that there is only one RS485.

I want a second RS485, Karl!

Well, if you really want to, remember that you have RS232-debug - the port through which we pour the firmware. The truth will have to purchase converter RS232 to RS485.

Programming environment

Codesys 2.3. About her already a lot of things written. And not one ARIES uses it (this is a plus). There are many libraries (note Oscat). The environment is not ours, but German (as surprising, yes?). There are many functionalities, both textual and graphical (extended IEC 61131-3). Read more in the books.

And what about Modbus?

Slave . There are out of the box, immediately gives read input, output, button presses, clock. Addresses of new variables will have to come up separately. All is read without group requests.

But if you really want, you can and group, there are descriptions in the manual. However, the addresses in the manual are given with errors.

Do not worry - one kind person has already found the correct addresses. You can find on the forum AWN or here (already filled, so as not to be lost).

Master mode . There is already more difficult. You will have to apply such a terrible thing as "programming skills" - take the Modbus.lib library (or you will do it yourself) and write the interaction with external devices. It sounds scary, but to some extent it will give more flexibility. For example, you can write a job with a bunch of typical devices (the same frequency converters), and not create a bunch of similar variables

Pros:

- programming environment;

- easy to create a menu with settings and settings (Segnetics rests)

- hours and memory is always "with you";

- the ability to work with non-standard protocols on the COM port;

- more PLC inputs and outputs (compared to Pixel);

- "Out of the box" in the PLC menu, you can change the types of sensors, see their readings

- 220V power supply (probably plus, although it is necessary to provide power protection in the form of fuses and circuit breakers - there was already experience with the operation of the internal power protection).

Minuses:

- all versions with power from only 220V;

- PLC buttons 73;

- only one expansion module;

- the text display of the PLC63 is large but stupid - 2 x 16 characters;

- Entering the menu with settings using one “Enter” button. I personally do not like, because complicates the creation of additional menus;

- it is inconvenient to transfer the menu from one PLC model to another (replicate the same type of settings). It is necessary to create anew. Annoying.

Prices from the Aries website (see all the modifications on the website):

- PLC63--L (8DI; 8AI; 3 relays; 3 AO 0-10) - price 14 514 r

- PLC73-KKKKUUUUU-L (8DI; 8AI; 4 transistors, 4 AO 0-10V) - price 14 986 r

- MP1-P (8 relays) - price 3 953 p.

From personal collection:

Segnetics SMH2g and Pixel

So, Pixel and his big brother shaper SMH2g. There are SMH2gi with access to linux. It seems to give more opportunities for lovers of the most terrible thing as "programming skills".

Regarding I / O, SMH2g is not particularly interesting without expansion modules (on board 4 DI / 4 DO and 5 DI / 2 DO for SMH2gi). Pixel is doing better (6DI / 3DO / 5AI / 2AO), but you can't always do without modules too.

It is important to note - Pixel galvanic isolation for analog outputs and inputs NO. Of course, Segnetics was confused in terms of extensibility. You can even make Ethernet for Pixel. However, in order for the clock to tick without a glitch, you will need to buy a battery from Segnetics. And this position is separate. Also with memory. Buy separately (if you, for example, need work on a schedule).

Another small pebble in the Segnetics garden is the price of wicked cable for connecting PLCs with expansion modules. In fact - the usual cable with IDC connectors. You can make yourself by buying everything in a store or radio market. Get 5 times cheaper. The main thing is not to confuse with the connection.

In terms of appearance, ease of pressing buttons, the display - everything is fine. For more pathos, Segnetics did not even write a word in Russian on the controller case. Well, we are pleased.

Programming environment

SMLogix. Developed by Segnetics. Graphic language only with all the disadvantages of graphic languages. In order to make it more convenient to make edits in the program, it is desirable to make blocks (they are macros) by the type of nested doll:

So you will not lose external links in the program. Segnetics significantly increased the appeal of its equipment thanks to the SMConstructor configurator, which generates a PLC work program for ventilation systems (now for ITP). It will remain to file it to fit your needs.

However, the same Pixel will not give you full access to the COM port. You do not write the protocol you need. Modbus only.

And what about Modbus?

All is not bad. Each variable you create automatically becomes a Modbus variable. This is how slave mode is implemented.

For the Master, everything is also good. You can load Modbus cards from other Segnetics controllers, or create (and save to a computer) variable maps separately. For most tasks this should suffice

Pros:

- there is little time to create typical programs for ventilation;

- nice equipment design;

- up to 8 expansion modules;

- you can always get ethernet.

Minuses:

- weak programming language;

- lack of galvanic isolation of analog inputs and outputs (for Pixel);

- "Out of the box" there is no possibility to change the type of analog sensors;

- There is no possibility to work with non-standard protocols on the COM port (something can happen through linux from SMH2gi, but the programming environment itself will not give such an opportunity);

- Pixel spit terminals. Tip type NSVI 1.5-8 will often be pushed out of the terminals when tightening. I recommend longer - NShVI 1,5-12. Otherwise, you risk a lot of foul language during installation.

Prices are freely available. I will attach a few positions:

- Pixel-2511-02-0 - price 11,054 r

- Pixel-MR602-00-0 Expansion Module 6out. (relay 5A), 2 analog. out (0 ... 10) - price 7 206 r

- Pixel-MR120-00-0 12vh expansion module. (NPN / PNP) - price 5 190 r

- SMH 2G-4222-01-2 - price is 12,614 r

- SMH 2Gi-0020-31-2 - price 17,064 r

- MC-0401-01-0 Extension Module for SMH 2G / SMH 2Gi; 9in. (NPN / PNP) / 10out. (5 relays 5A, 5 optorele 400 mA), 8 analog. in (6 universals, 2 voltage / current 0 ... 10V / 4 ... 20mA, 24 bit) / 4 analog. out (0 ... 10) - price 10 582 r

From personal collection:

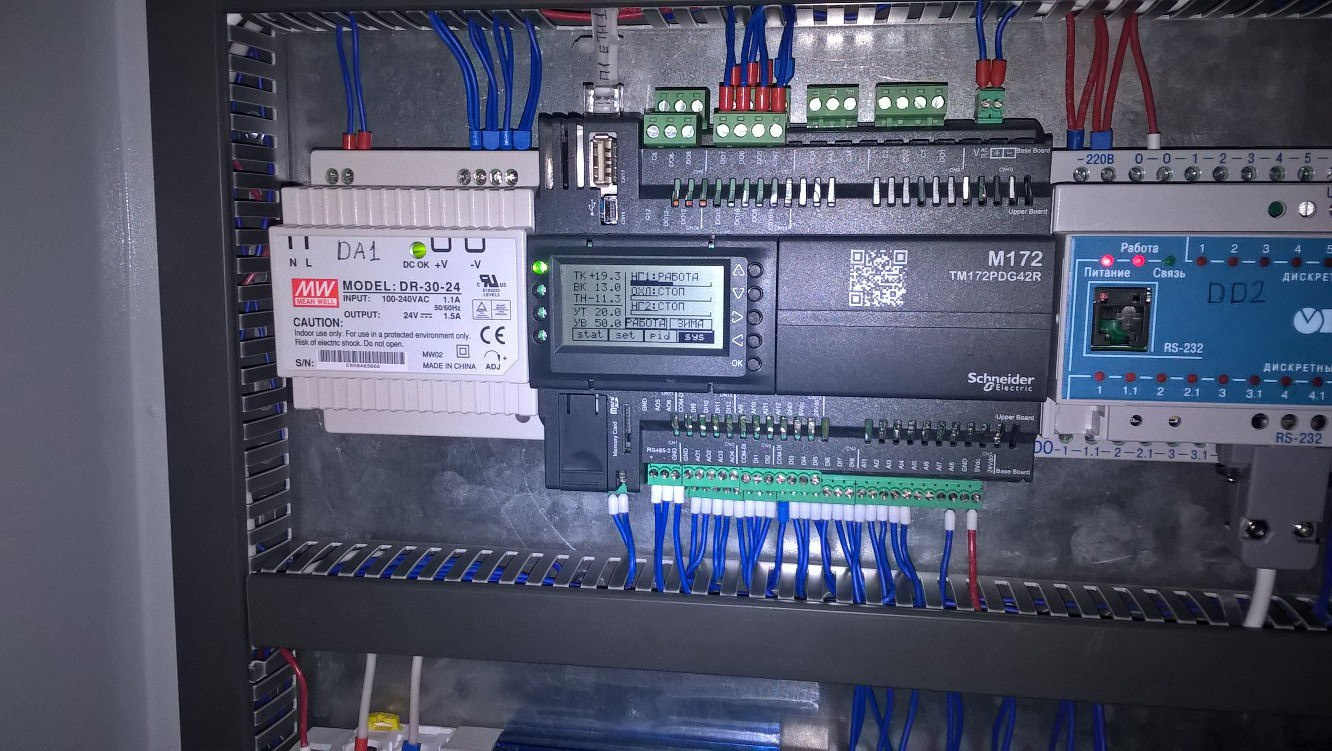

Schneider Electric M171 / 172

Got acquainted with this lineup for HVAC about a year ago. According to what was read on the forums - the development of the Italian, apparently was bought by Schneider.

The M171 version is simpler and cheaper, so we decided not to waste time on trifles and take the M172. On entrances and exits - a fairy tale. For example, the model TM172PDG42R is 42 I / O. Interfaces - Ethernet (M172), RS485 (there are even 2 of them in the M172), CAN. The screen is not bad, graphic. Add to this a bunch of any expansion modules and get a very interesting solution in terms of hardware.

Programming environment

SoMachine HVAC. And here begins the first fly in the ointment. The environment is not particularly friendly for a beginner. With documentation everything is bad - get ready to search engine wool.

The environment is divided into several separate programs. They even have their own labels. In one you initialize the interfaces and hardware, in the other you draw a screen, in the third you write the program. Youtube will tell you better:

There are graphic and textual languages. There is an ST (there are no Time type variables - you will spin with a DWORD). Also here is a stupid variable initialization system. You can’t just write:

Var Var1 : bool; Var2 : bool; End_var Why so simple? You better create each variable with the mouse through a dialog box. Transferring lessons from other programming environments becomes more complex.

But in general, there are more opportunities here than SMLogix. However, the development is still raw.

And what about Modbus?

Each variable has its own address. Those. Slave will be immediately. With Modbus in this regard, everything is not bad. All, yes, not all. Here you have another 1.5 fly in the ointment:

- 1 scoop - Master mode AT ALL does not work.

How much our programmer did not fight, and could not run. Instead, at the output of RS485 we received only the first byte of the package. Those. address of the polled device. So at one site we had to supplement the shield - insert Aries of the PLC100, so that it would perform the role of Master 100th (picture below); - 0.5 spoon - Slave mode on the object, we fell for 12 hours of work. This concerned Modbus TCP. It is treated only with a power failure. And here we don’t already know what to do - try to transfer the survey to the COM port.

UPD (August 2018)

More than a year has passed since the writing of the article. Good news has arrived for M172:

The manufacturer has already released several updates to the controller core. So you may not encounter the software ailments listed.

We have, for example, the problem with the loss of communication in Modbus TCP has disappeared. (If someone has a positive experience of use - write, add to the article).

Pros :

- a large line of equipment, expansion modules;

- many interfaces;

- There are modifications of the PLC with a large number of I / O;

- graphic display (high models);

- there is a remote and wall panel;

- good appearance;

- several programming languages.

Cons :

- raw product (in any case, M172). Applies to both the software and the PLCs themselves;

- unfriendly development environment;

- there is no normal documentation for working in the programming environment;

- no tech support. The distributor was still trying to help something - but he did not really help out;

- long supply of equipment. In the case when everything is “yesterday” - these PLCs are not your choice.

Prices at the time of purchase:

To controllers it is necessary to buy separately removable terminals.

- TM172PDG42R PLC M172, display, 42 I / O, Eth - price 26 991 r

- TM172ASCTB42 Terminal block with 42 I / O screws - price 1,159 r

- TM172PDG28R PLC M172, display, 28 I / O, Eth - price 19,283 p

- TM172ASCTB28 Terminal block with 28 I / O screws - price 989 r

From the personal collection. PLC100 (on the right) just works as a Master instead of M172:

PS A little more about environments

Codesys 2.3. The threshold of entry is higher than that of the Segnetics programming environment, but you can also make things more interesting (even some basic OOP are there). Therefore, it will be difficult to write / draw a program without experience.

If you decide to study Codesys, then I highly recommend starting with ST (Structured Text), Pascal-like language. Text languages have a major advantage - the ability to transfer to other environments that support the language.

The author already had the experience of transferring the program from the PLC63 to the very Schneider M172 with minimal changes.

Graphic languages initially lure you visually. But do not give in - in large programs you get confused, and even lose flexibility (you can’t just comment out a part of the code).

Source: https://habr.com/ru/post/332722/

All Articles