Digital counterparts. Design through reflection

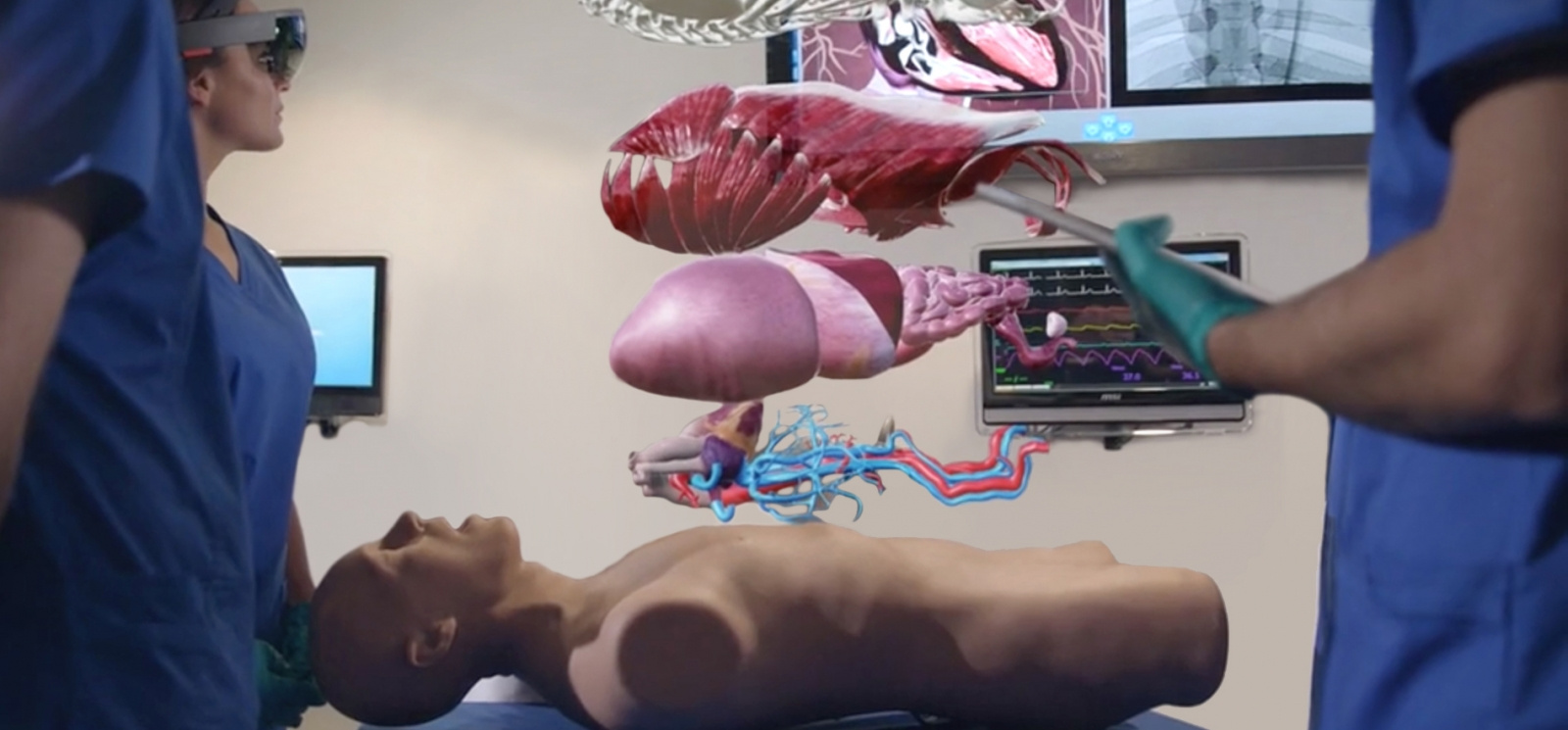

“Their main task is to check every detail, to explain to the surgeon what exactly he should do during the operation. You do not want him to make an incision and ask: “OK, and what should I do next?”. They provide additional capabilities, and the doctor who works with the patient's knee knows exactly what form of implants they will need before the operation begins, ”explains Michael Grieves, describing the use of digital counterparts in health care, a concept he developed more than ten years ago. Despite the fact that for the first time this idea was proposed already in 2003 as a way to reduce the cost of product development using digital models, only now this approach has been widely used. Grives is a professor, researcher and assistant director of the Center for Lifecycle and Innovation Management at the Florida Institute of Technology. In his 2003 article, “Digital Twins: Excellence in Production Based on a Virtual Plant Prototype,” Greaves wrote: “The use of a digital twin occurs throughout the product’s life cycle — to ensure a high level of quality for the consumer and to provide information on how actually uses the product - for the manufacturer. "

The term “Digital Twin” was coined by an engineer with whom Greaves worked at NASA. Regardless of whether the object in question is an artificial knee joint or an aerodynamic engine, Grives believes that using a unified approach can significantly reduce the cost of designing, manufacturing, operating and subsequent maintenance of the product. A number of companies working in the field of computer-aided design (CAD) have approved this idea.

')

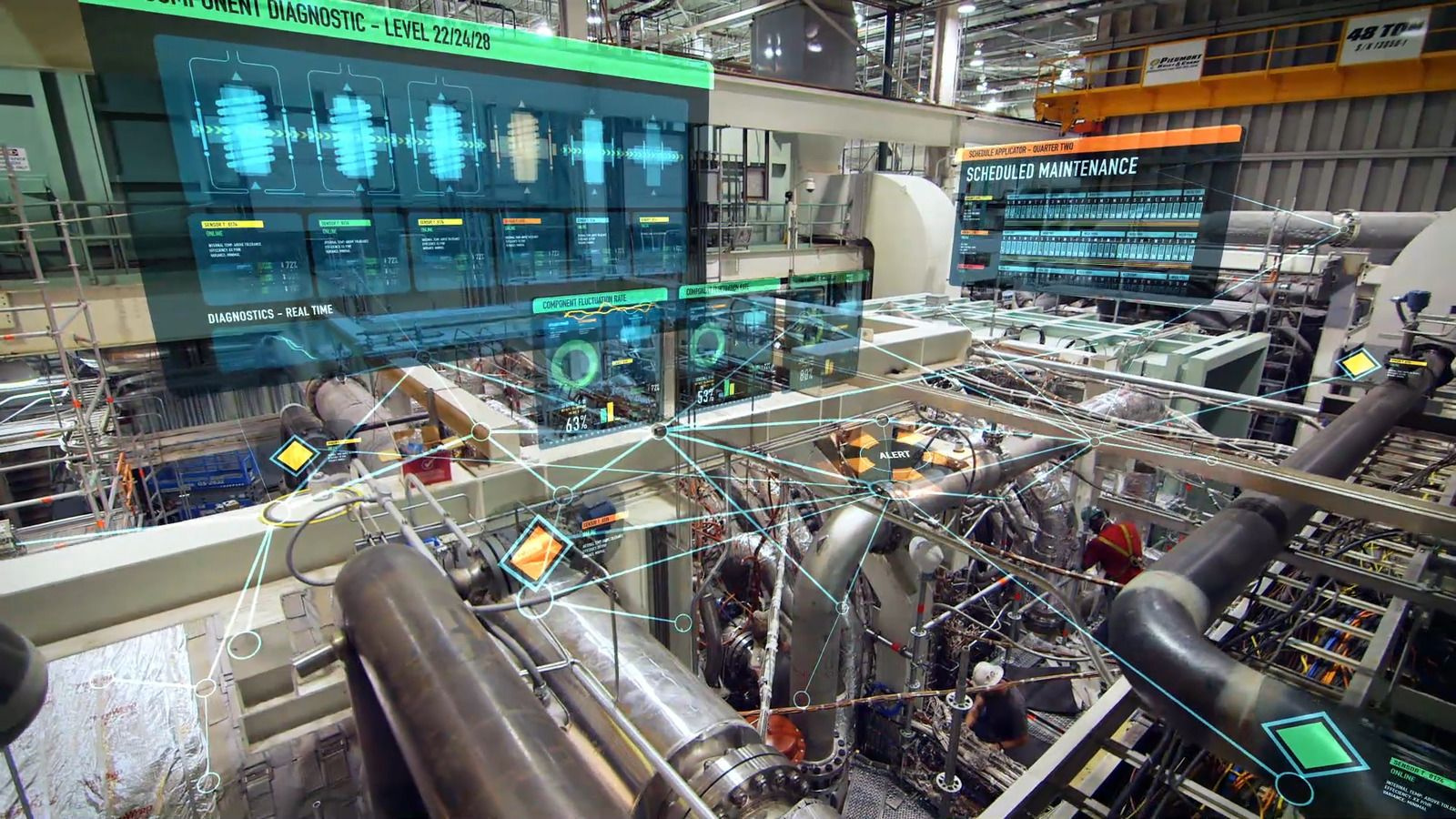

PTC, an industrial software development company, supported the idea of a digital twin of a physical product for both organization and service and support. In conjunction with this, PTC applies virtual reality (VR) and augmented reality (AR) technologies. So, for example, aiming a tablet with a camera, at a machine that needs repair, the software makes a request to the digital twin, and determines what actions the employee needs to perform. “Data from CAD [created during the design] can be used to form“ augmented reality instructions ”, which in parallel use real data coming from a real-life product. Thus, you can find where the failure occurred and even understand the cause of the failure, ”explains Bryan Thompson, vice president of the CAD division of PTC. “This seems to be the most promising industrial use of the technology of the Internet of Things and VR / AR, based on data from the CAD database. Sharing these technologies can have a positive effect. This is very convenient when you, as a service engineer, can get some kind of digital idea of how you need to work with the product further. ” Long before the service engineer gets to the finished product, a virtual twin was created in the form of a CAD model, which then, for several years, was considerably worked out so that it could be considered a digital twin.

Initially, Greaves outlined three basic requirements for a model that could be called a true digital copy. "I proposed three requirements for the virtual double, the first requirement is a check for compliance with appearance, but then I expanded this requirement to match the assessment of perception by all the senses." It is important to note that the main thing in the first requirement is not only the appearance. Virtual visual analysis includes the analysis of the product into parts and a detailed inspection of all its components.

The second requirement of the Greaves - a virtual product must behave realistically when conducting various tests, such as, for example, blowing in a digital wind tunnel or analyzing stresses.

His third requirement is to obtain information from a virtual product using physical expertise, as if the user could check a real product, for example, determining the amount of fuel consumption by an engine.

Greaves notes the growth of industrial opportunities to fulfill his requirements: “Where is the implementation of the digital twin today? When I first started my work, we could not even fulfill the visual requirement - today this is rarely a problem. Today, you can no longer distinguish a photo of a real car from a photographic rendering.

Executive Director of Dassault Systemes EuroNorth Stephen Chadwick fully agrees with this: “Photorealistic rendering of Audi cars has long been used in promotional videos. With the use of our 3D Excite product, the resulting digital videos are difficult to distinguish from a shot. Audi’s promotional videos that you see on television or in movie theaters are produced exclusively using our software platform. What looks like a beautiful and perfect Audi car is actually a visualization based on a CAD model. ”

Digital production

Digital copy, which largely meets the first two requirements of the Greaves, can be used in the work of "virtual production" and be updated, complemented by each "station". It is at these moments that the digital twin receives data on preparation for production and data of computer-aided design (CAE). Each of the factory digital stations where operations are performed on a virtual product: the assembly of the product nodes and the final assembly of the product have already been modeled earlier.

“We can assemble a digital product in a digital factory, thereby verifying that the product is assembled for a given production process,” explains Zvi Feier, executive vice president of software development at Siemens. Siemens can simulate several machines, such as a robot and a conveyor, as well as possible failures and restoration. Feuer explains how the digital double can help companies save money with virtual production technologies. “In the first 10-20 cycles [launch of production of a new product] you are likely to run into problems. The information provided to the supplier was not accurate enough; the supplier used the wrong material or production process. These parts do not fit together, the tolerance is greater than expected; We face it, it happens again and again. Today we have the opportunity to predict the possibility of assembly, to determine the tolerances that have the greatest influence on the process. ” Greves has serious complaints about companies, especially those from the aerospace industry, who cannot provide a virtual product for production simulation. “Boeing and Lockheed Martin require supplier companies to send in their virtual models so that they can be checked. I think this is really important for Boeing and Airbuses, they get virtual information along with physical products. They even choose their suppliers based on the following criterion, “you should be able to provide us with a virtual model,” because this will avoid delays in creating this model in the future. ”

Virtual testing

Once improvements have been made to a virtual product based on its fabrication at a digital factory, there is another area of potential cost savings - quality control simulation. Instead of expensive tools and stands, everything is modeled inside the computer. ” Virtual tests have an advantage over physical in value. When you do one or two tests for the aerospace industry, it’s still expensive, but you can do a lot of testing at almost no additional cost, ”says Greaves. Chadwick adds: “We found that many of our clients use the [Dassault software] platform to be able to perform such checks, and indeed many of them have refused physical testing because this is no longer required for certification. The model based on digital data is fairly accurate. ” Then, after approval and during the operation phase, it is assumed that feedback will be received from the built-in sensors to help improve product performance and take into account shortcomings in future versions of the product. Last year, PTC demonstrated how a virtual product, in their case a bicycle, can be improved using this approach. Thompson explains this as follows: “Customers view the fact that they can track changes in parameters as they are used, as a virtue.

The results we obtained on the example of bicycles will be published in the fall. However, Thompson already sees the difficulty in processing data on all product parameters. “If you have 10,000 unique product models that track 10,000 bicycles in real time, we get a lot of data.” The solution is to highlight key design elements, such as a bicycle fork. He notes that from a business point of view, the entire amount of data may be redundant, and the costs associated with processing it may be unjustified. Instead, highlighting key product parameters, such as bicycle fork wear, reduces data processing costs by providing information about specific product improvements.

Big Data

Solving big data problems is not considered by Grives. “I'm not worried about data structures. We have the necessary tools to solve all such problems, ”he says. He is more concerned that there is a lack of cooperation in the field of information technology, development is happening too quickly, faster than the formation of standards. "The best we can hope for is cooperation, so that all developers play together in the same sandbox, instead of having many of their own data structures, which are then difficult to use together." The stumbling block in this situation is information security. "This is one of the most acute problems," says Greaves. “When we create intelligent products that reflect what they look like, we need to be sure that only authorized users can access this information, not all. I propose to treat this with a high degree of paranoia. It is necessary to determine who requests the information. ”

Information security is also fundamental to another IT direction that supports the concept of a digital twin - the Internet of Things (Internet of Things IoT). According to Thomson, the company's strategy for using IoT is inextricably linked with the virtual product: “It seems strange to me when you say that you have a strategy for the digital twin, but there is no strategy for IoT. You have to have a way to connect these two technologies. ” The IoT approach is already widely used by aircraft engine manufacturers. This is explained by Greaves: “Rolls-Royce works that well. If you ask them, they collect data for each individual engine and each individual flight, so they have the ability to predict a product crash using a giant correlation mechanism. When they see this status and that status, they know that they will have a problem with that component. ” According to Feuer, such a real-time comparison of IoT data can help improve a company's business model, not just product design or repair. He cites the typography business model as an example. “Consider a printing house: why is it smart? Because technologies today allow us to install sensors to collect information by the manufacturer, and now we can offer a new business model, for example, payment for a printed page or payment only for ink. ”

Digital counterparts and PLM

This use of a virtual product is similar to product life cycle management (PLM). This is also due to the fact that the concept of the digital twin is today regarded as part of PLM. The definition of PLM is considered as a process for managing the entire product life cycle: initialization, design and engineering, preparation for production, maintenance and disposal. Like Greves' digital twin, the degree of PLM implementation varies from one industry to another and from one company to another, so are the ideas about the virtual product. Fejer says: “The digital twin is a solution within PLM on its way to the transition to Industry 4.0,” the concept of a digital industrial enterprise.

Thompson sees PLM as a combination of a virtual product and a place where a digital copy will be “created”. He also sees that the twin is what unites data from PLM and areas such as enterprise resource planning (ERP), which he puts out of lifecycle management. “As soon as you move to the product manufacturing stage, the connection with the PLM system ends, and you are in the ERP field or in a similar system that tracks the parameters of the double.” The duplicate effectively collects all the necessary information, company information in the framework of PLM activities and other, such as information from service sensors, complementing the original CAD model. Fejer offers a more extensive look at PLM: “PLM is constantly evolving. If you asked my boss 15 years ago, he would say PLM is CAD data management, and CAD is a collection of some CAE tools. But if you ask him today, he will tell about PLM as a system covering the entire area of an intellectual product, which includes product requirements that are formed before the advent of CAD models, then CAD models, CAE, production, software, life management cycle and integration phase for electronics. " Just as the idea of the Greaves for the digital twin develops in the industry, PLM also does not stand still. As Feuer believes, "we are constantly aware that PLM today is more than what this journey began 35 years ago." The concept of the digital twin of Grives is slowly, but technologically realized. In terms of the application of this technology, the aerospace industry is probably the most advanced. It is clear that in the 13 years that have passed since Greaves and his colleague from NASA formed this idea, the concept was viewed as having advantages over those approaches that were used at that time. And these distinctive advantages in the future will have an even stronger impact, including the impact on changes in business models and services. So what will happen in 35 years?

Source: https://habr.com/ru/post/331562/

All Articles