The organization of the switching field of high-density SCS

The volume and density of the switching field of the SCS are directly proportional to the chaos on it and inversely proportional to the possibility of its elimination. The problem of designing and building a new SCS comes down to the arrangement of workplaces, cable routes and switching nodes. Nobody thinks about technical solutions designed to ensure the effective operation of the system after its delivery.

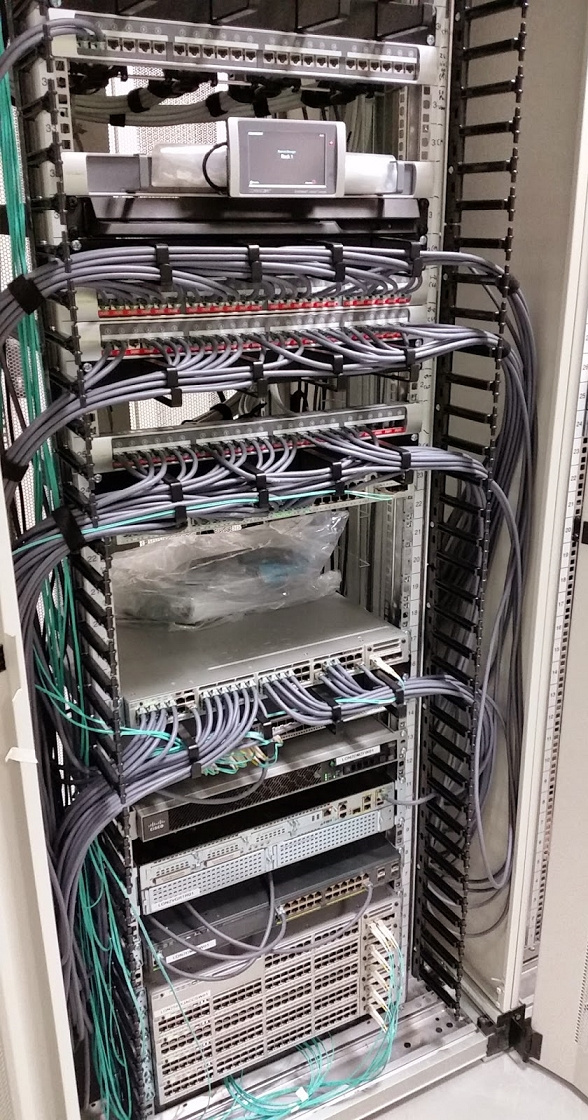

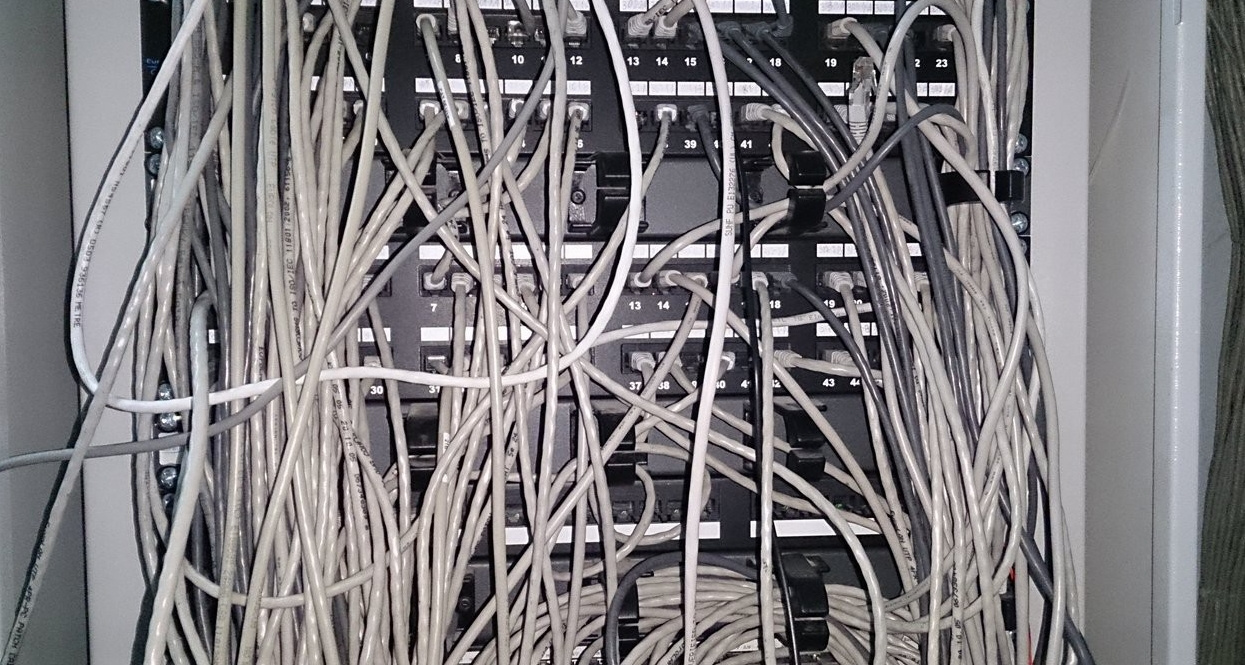

By operation, I primarily mean working with a switching field. For the organization of the switching node, the installer is usually limited to a set: a cabinet, patch panels, horizontal organizers. Regardless of the number of "ports". Everything. The customer, taking the SCS, sees the idealistic picture, without the "web" of patch cords and awareness of the inevitability of chaos:

')

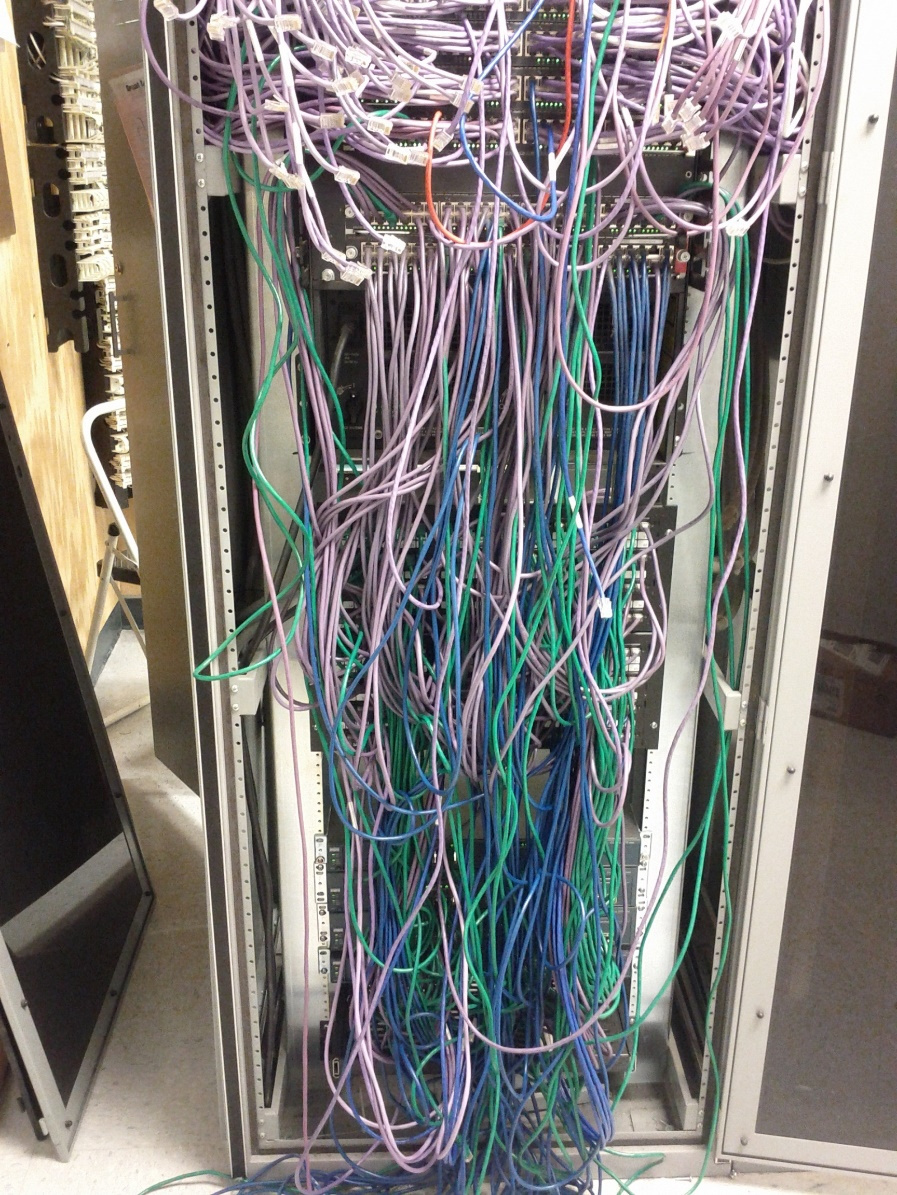

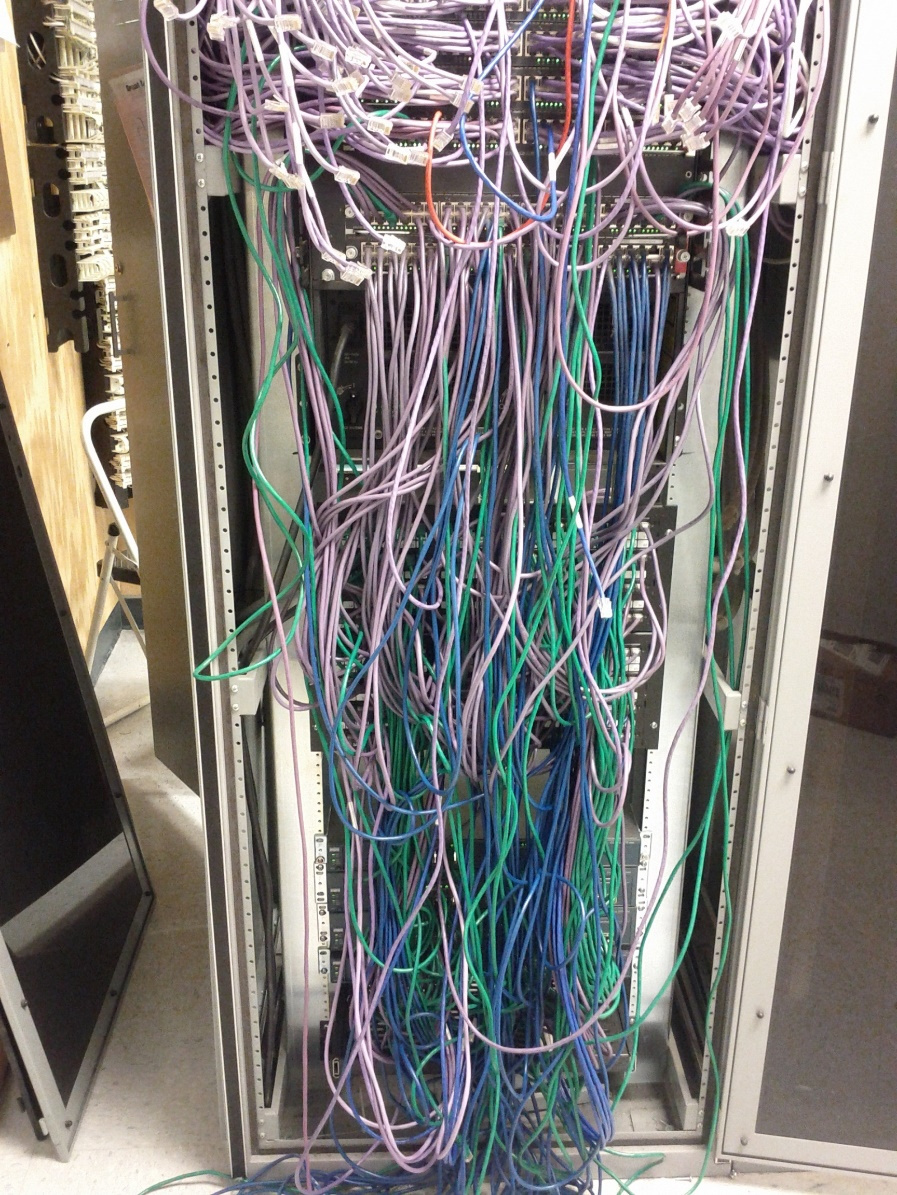

After 2-3 years, everything will change. Do you think the customer would accept such trash?

And it is inevitable. Wardrobe only 600mm wide, all organizers are horizontal. No chance.

Someone will argue that the fault is lazy administrators who do not keep order. This is true, but only in part. If people do not have normal tools, if they are framed, when it is impossible to ensure the effective organization of cables, then everyone will give up.

To avoid this, you need to follow only 3 simple principles:

Principle number 1

The minimum width of the switching cabinet is 750mm. The minimum distance between racks with row arrangement is 200 mm.

Argumentation: all surplus patch cords should be placed in a vertical , not horizontal plane. If there is no vertical space, like in 600-mm cabinets, all the surplus will be clogged up with horizontal organizers or just hang snot on the facade of the cross. The patch cord must leave the patch panel port or switch left or right along the shortest path. All the excess is placed outside the front of the cross.

The minimum distance between racks with row arrangement is 200 mm.

The minimum width of the switching cabinet is 750mm.

Principle number 2

Use vertical cable organizers. Stop using horizontal organizers. At all.

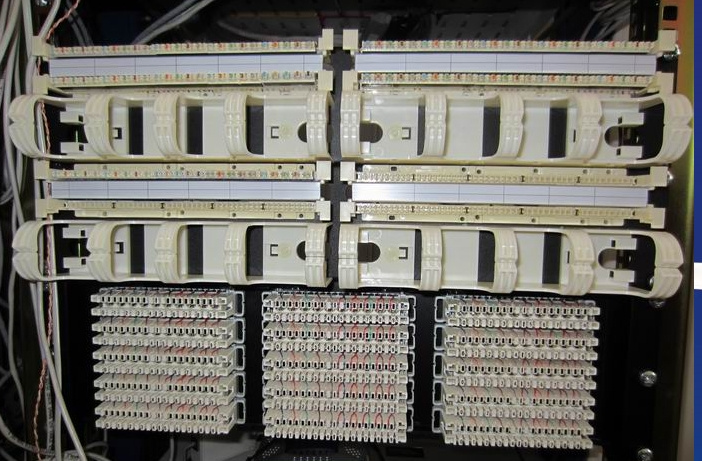

Introduction: horizontal organizers are anochronism, inherited by inertia from 110 cross-panels. Recall that the 110 cross-panel is the ancestor of the current patch panels, where on the front side, instead of the usual RJ45 split connector (8P8C), 110 type connectors were used. Patch cords were thin and light (unshielded, no higher than category 5 / 5e).

Panel 110 type forcibly completed horizontal organizer. And although the excess cords here should also have been retracted to the vertical plane, the horizontal organizer eventually became so entrenched in everyone’s consciousness that its absence in the modern SCS could even cause hysteria for IT professionals who consider themselves to be professionals.

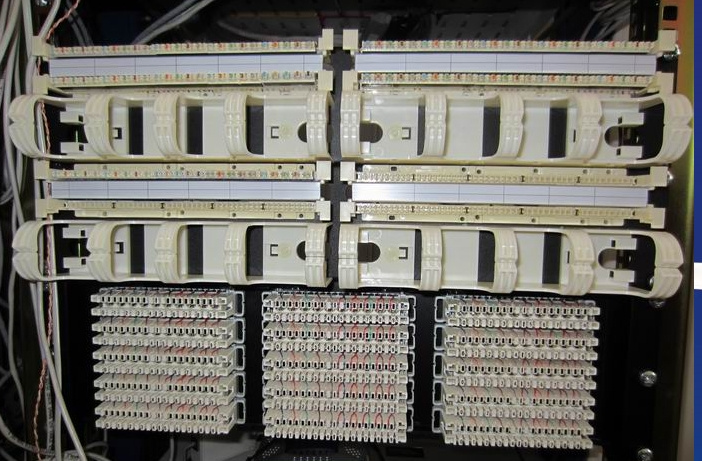

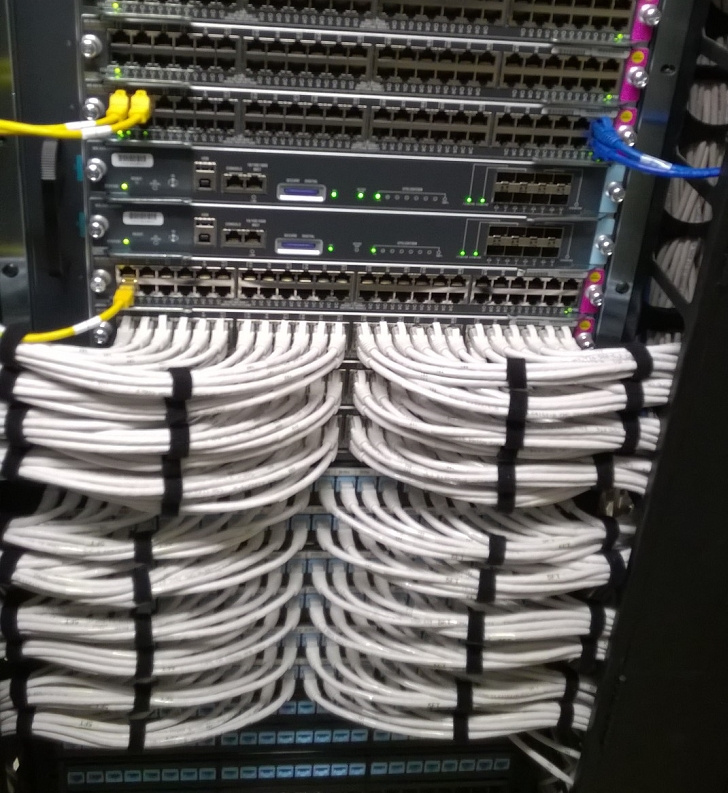

As a result, in the ideal case it turns out something like this:

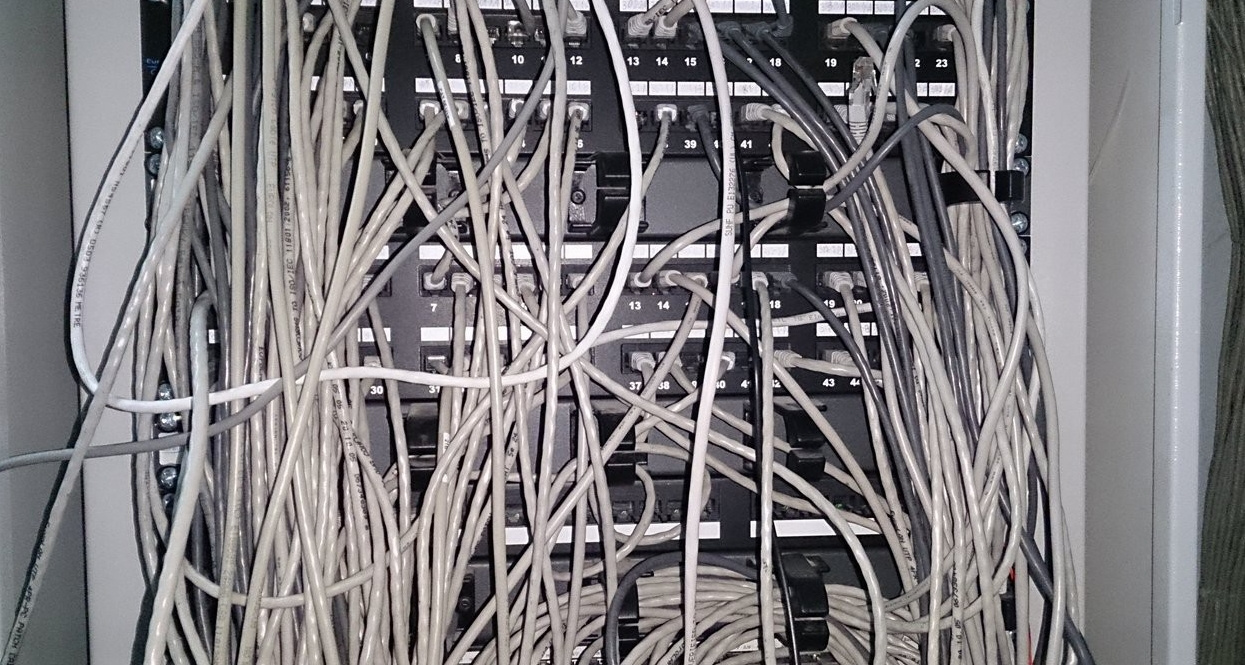

Even with this seemingly “beautiful” state, the readability of the labeling is zero. To look for the necessary patch cord, to take it out through all these rings, to get out of the bundle and to lay it again is a task for a person who is completely devoid of emotions. Below is an example of a cabinet with installed horizontal organizers, the meaning of the installation of which was initially absent. What is actually colorful and confirmed.

There are organizers. There is no order, and there will not be. And the reason here is not the administrator. He initially slipped, let's say, a rotten version.

Question : What to do?

Answer : Use vertical / lateral cable organizers in the cabinet and racks. If possible, use specialized constructs for organizing a high-density switching field. About horizontal organizers forget.

The argument will be mostly visual.

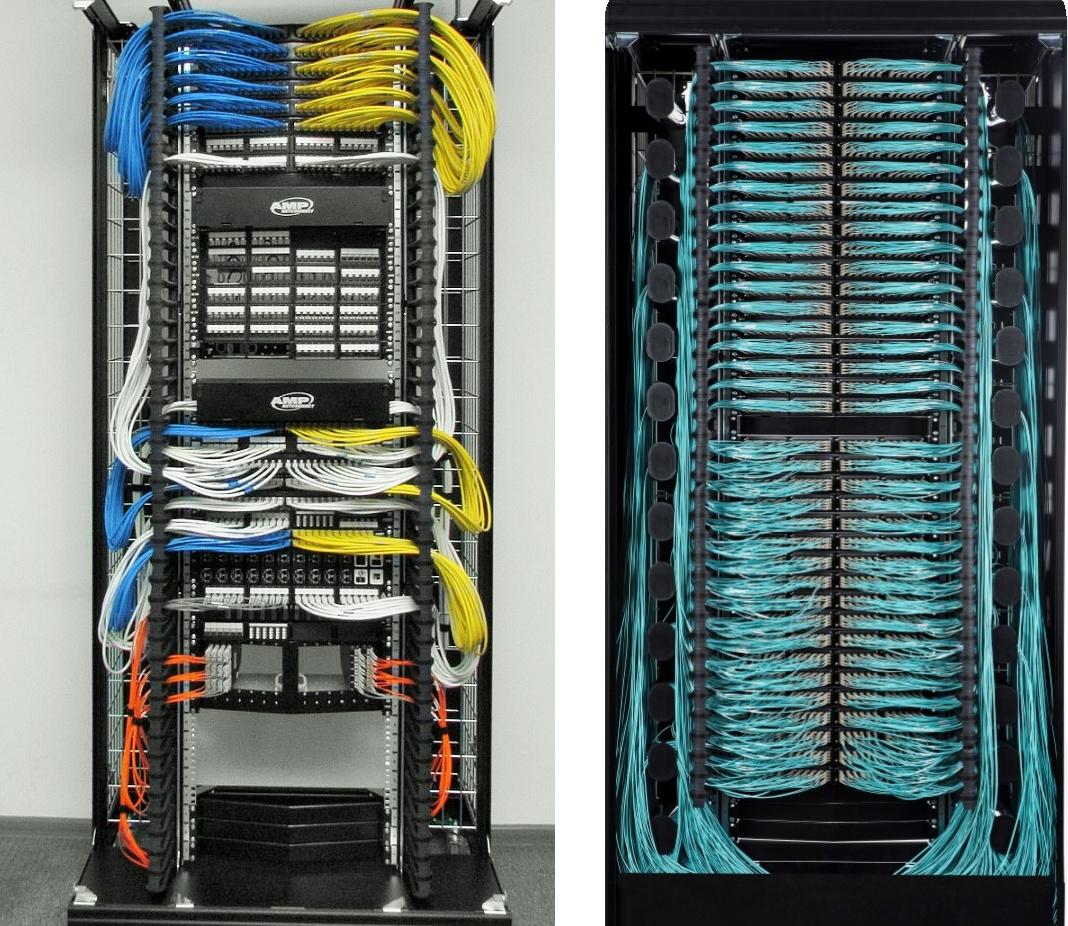

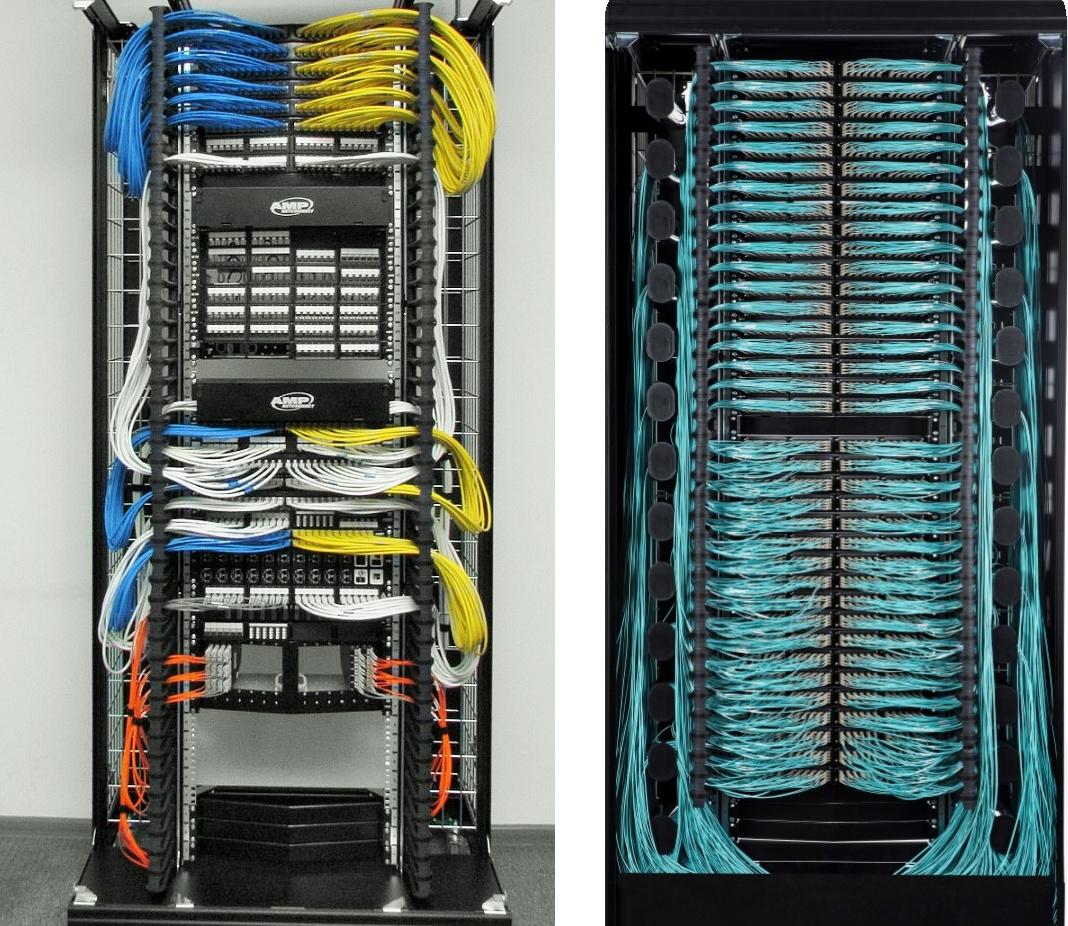

Example №1 Cable organizers AMP NETCONNECT NEW Hi-D

Copper example, with a density of 48 ports per 1U:

An example with optics, with a density of 48xLC Duplex at 1U:

They are in conjunction with a specialized solution AMP NETCONNECT Netpodium:

The pictures are of course marketing, not entirely from real life, but they demonstrate the advantage of vertical organizers over horizontal ones. There is no chaos with the cobwebs, marking switching panels readable, extra units under the organizers are not involved.

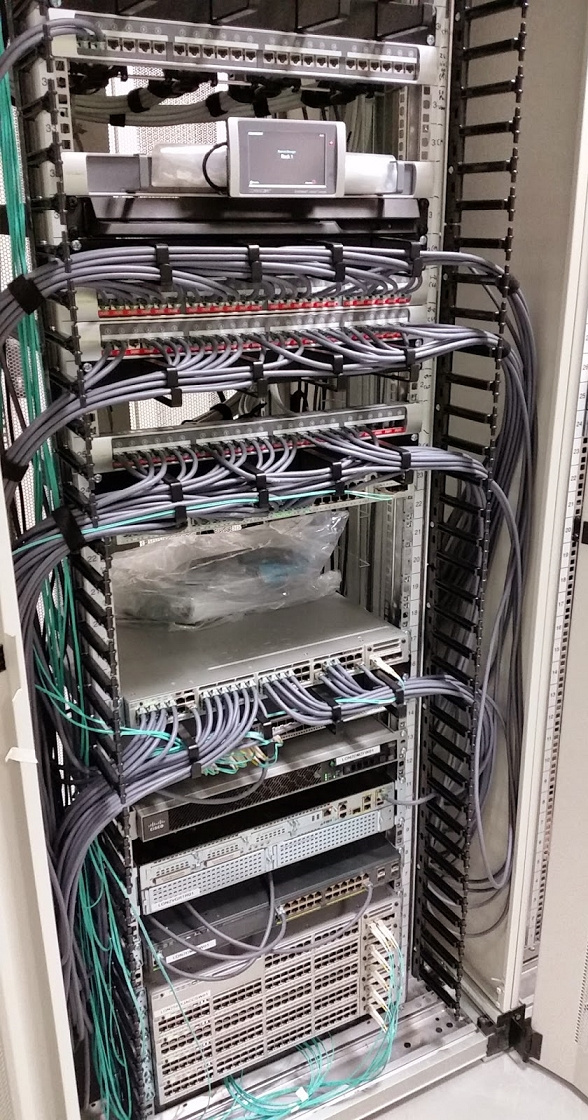

Here is the option of the organizers from the APC in the APC cabinet:

Here are more examples of organizers from other manufacturers (unfortunately, not identified):

The last picture has horizontal organizers, but believe me, they are not needed. You will understand this by familiarizing yourself with principle number 3.

Some solutions (the same Hi-D from AMP Netconnect) allow the organization to be provided only in dedicated units. It all depends on the model: for 1U, 2U, 4U, etc. Those. No need to overpay for a 42U kit.

Since we have already touched upon the subject of specialized switching racks, it is worth saying a few words about them. I have already given an example of the constructive - AMP NETCONNECT Netpodium. This solution was designed from the ground up and specifically for high-density port switching nodes.

Similar solutions from other manufacturers are based on the use of standard open racks, with vertical cable organizers. They lose a little Netpodium, but still much better than regular cabinets. And they all profess the principle of maximum withdrawal from the use of horizontal organizers. In order to save space and more efficient cable management.

Systimax Solution:

Panduit Solution:

Chatsworth solution:

Horizontal organizers, if used, are mainly used as transit channels, for switching cords from one side of the rack to the other.

Principle number 3

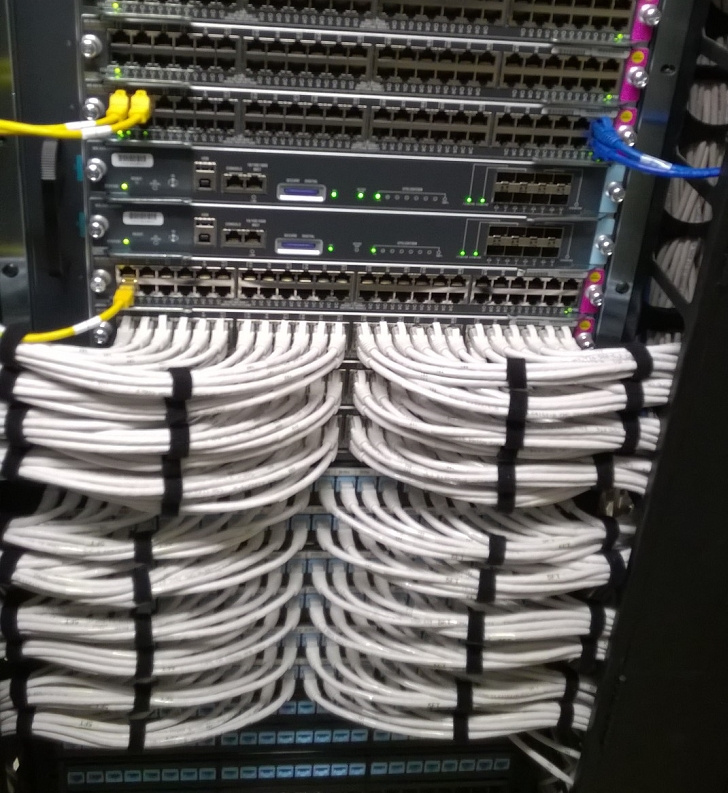

Flame and lay patch cords using Velcro velcro fasteners. This will ensure a beautiful appearance and readability of the labeling of the patch panel. And also protects the cords from interlacing in the bundle.

Practice shows that undoing and fastening Velcro on a neat harness is easier and faster than pulling out the patch cord from the rings of the horizontal organizer, where patch cords are usually intertwined.

Summing up, I will once again recall 3 principles of proper organization of your switching node:

1. Cabinet width from 750mm. In the case of racks, the distance between them is at least 200mm.

2. Priority use of vertical cable organizers. Ideally, in combination with open racks or specialized constructions, such as Netpodium from AMP NETCONNECT.

3. Active use for the organization of the patch cords of Velcro velcro tape fasteners.

By operation, I primarily mean working with a switching field. For the organization of the switching node, the installer is usually limited to a set: a cabinet, patch panels, horizontal organizers. Regardless of the number of "ports". Everything. The customer, taking the SCS, sees the idealistic picture, without the "web" of patch cords and awareness of the inevitability of chaos:

')

After 2-3 years, everything will change. Do you think the customer would accept such trash?

And it is inevitable. Wardrobe only 600mm wide, all organizers are horizontal. No chance.

Someone will argue that the fault is lazy administrators who do not keep order. This is true, but only in part. If people do not have normal tools, if they are framed, when it is impossible to ensure the effective organization of cables, then everyone will give up.

To avoid this, you need to follow only 3 simple principles:

Principle number 1

The minimum width of the switching cabinet is 750mm. The minimum distance between racks with row arrangement is 200 mm.

Argumentation: all surplus patch cords should be placed in a vertical , not horizontal plane. If there is no vertical space, like in 600-mm cabinets, all the surplus will be clogged up with horizontal organizers or just hang snot on the facade of the cross. The patch cord must leave the patch panel port or switch left or right along the shortest path. All the excess is placed outside the front of the cross.

The minimum distance between racks with row arrangement is 200 mm.

The minimum width of the switching cabinet is 750mm.

Principle number 2

Use vertical cable organizers. Stop using horizontal organizers. At all.

Introduction: horizontal organizers are anochronism, inherited by inertia from 110 cross-panels. Recall that the 110 cross-panel is the ancestor of the current patch panels, where on the front side, instead of the usual RJ45 split connector (8P8C), 110 type connectors were used. Patch cords were thin and light (unshielded, no higher than category 5 / 5e).

Panel 110 type forcibly completed horizontal organizer. And although the excess cords here should also have been retracted to the vertical plane, the horizontal organizer eventually became so entrenched in everyone’s consciousness that its absence in the modern SCS could even cause hysteria for IT professionals who consider themselves to be professionals.

As a result, in the ideal case it turns out something like this:

Even with this seemingly “beautiful” state, the readability of the labeling is zero. To look for the necessary patch cord, to take it out through all these rings, to get out of the bundle and to lay it again is a task for a person who is completely devoid of emotions. Below is an example of a cabinet with installed horizontal organizers, the meaning of the installation of which was initially absent. What is actually colorful and confirmed.

There are organizers. There is no order, and there will not be. And the reason here is not the administrator. He initially slipped, let's say, a rotten version.

Question : What to do?

Answer : Use vertical / lateral cable organizers in the cabinet and racks. If possible, use specialized constructs for organizing a high-density switching field. About horizontal organizers forget.

The argument will be mostly visual.

Example №1 Cable organizers AMP NETCONNECT NEW Hi-D

Copper example, with a density of 48 ports per 1U:

An example with optics, with a density of 48xLC Duplex at 1U:

They are in conjunction with a specialized solution AMP NETCONNECT Netpodium:

The pictures are of course marketing, not entirely from real life, but they demonstrate the advantage of vertical organizers over horizontal ones. There is no chaos with the cobwebs, marking switching panels readable, extra units under the organizers are not involved.

Here is the option of the organizers from the APC in the APC cabinet:

Here are more examples of organizers from other manufacturers (unfortunately, not identified):

The last picture has horizontal organizers, but believe me, they are not needed. You will understand this by familiarizing yourself with principle number 3.

Some solutions (the same Hi-D from AMP Netconnect) allow the organization to be provided only in dedicated units. It all depends on the model: for 1U, 2U, 4U, etc. Those. No need to overpay for a 42U kit.

Since we have already touched upon the subject of specialized switching racks, it is worth saying a few words about them. I have already given an example of the constructive - AMP NETCONNECT Netpodium. This solution was designed from the ground up and specifically for high-density port switching nodes.

Similar solutions from other manufacturers are based on the use of standard open racks, with vertical cable organizers. They lose a little Netpodium, but still much better than regular cabinets. And they all profess the principle of maximum withdrawal from the use of horizontal organizers. In order to save space and more efficient cable management.

Systimax Solution:

Panduit Solution:

Chatsworth solution:

Horizontal organizers, if used, are mainly used as transit channels, for switching cords from one side of the rack to the other.

Principle number 3

Flame and lay patch cords using Velcro velcro fasteners. This will ensure a beautiful appearance and readability of the labeling of the patch panel. And also protects the cords from interlacing in the bundle.

Practice shows that undoing and fastening Velcro on a neat harness is easier and faster than pulling out the patch cord from the rings of the horizontal organizer, where patch cords are usually intertwined.

Summing up, I will once again recall 3 principles of proper organization of your switching node:

1. Cabinet width from 750mm. In the case of racks, the distance between them is at least 200mm.

2. Priority use of vertical cable organizers. Ideally, in combination with open racks or specialized constructions, such as Netpodium from AMP NETCONNECT.

3. Active use for the organization of the patch cords of Velcro velcro tape fasteners.

Source: https://habr.com/ru/post/331394/

All Articles