Not soon the fence is built, especially a beautiful data center. How we build the data center "Avantage". Part 1

With this post we will begin our story about how Technoserv is building from the open field of a new data center Avantage , which will become one of the largest commercial sites in the Moscow region . The work site is located east of the city of Lytkarino (Moscow Region, Lytkarino), 9 km from Moscow. The data center will be located on an area of 3 hectares, on which a complex of buildings and structures with a total area of 1.08 hectares has already been erected. Attention, there are a lot of photos ahead. I ask under the cat.

Some common words and numbers

DPC "Avantage" is the first commercial platform in Russia of TIER III level with a capacity of over 2,200 racks , owned and invested by LLC Avantage. There are large data centers in Russia with a similar number of racks, but Avantazh will put its own into operation at a time . The design capacity of the data center will be 17 MW design load. Independent high-speed communication channels of the largest telecom operators are brought to the data center. When designing the data center "Avantazh", energy-efficient technologies have been laid down, which make it possible to obtain an average annual PUE ratio not higher than 1.4.

Technical and economic indicators of the data center "Avantage"

| Indicator | Value |

|---|---|

| Total area of the data center building | 24 480 sq.m. |

| IT load power | 11.2 MW |

| PUE | not higher than 1.4 |

| Number of racks | 2240 |

| Diesel rotary ups | 14 pcs. each of 1650 kVA |

| Turbocor Chillers | 9x1600 kW |

| Total area of server rooms | 6 400 sq. M. |

Data Center Concept

So, as planned by the architects, the buildings and the territory of the data center will look at the end of construction.

The layout of the data center "Avantage"

The layout of the data center "Avantage" - another perspective

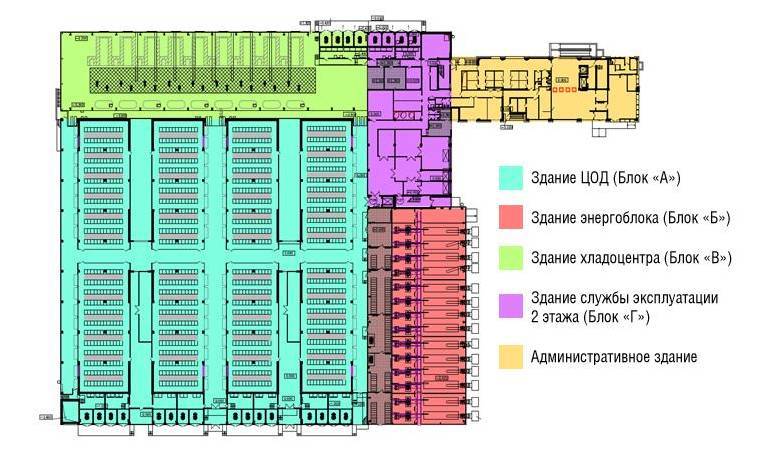

Complex data center "Avantage" in terms of

So, on the areas of 3 hectares are built:

Data center building (Block “A”), 2 floors with a technical underground: dimensions of 72x76.8 m.

There will be 16 server rooms (8 per floor) for the placement of IT equipment (140 racks in each hall, the total number of racks is 2 240 units) and part of the transformer substations of the object. Server rooms are interconnected with the corridor service. In the underground part of Block "A" there is a technical underground underground building (heating, ventilation, air conditioning) for utilities for supplying coolant to air conditioners in server rooms.The building of the power unit (Block "B"), 2 floors with a technical underground: dimensions of 80x18 m.

There will be a machine room for the installation of 14 dynamic diesel uninterruptible power supplies (DDIBP) and premises for the installation of distribution equipment.Cold center building (Block “B”), 1st floor: dimensions 76x22.5 m.

Room for installation of chillers and pumps, expansion tanks, free-cooling heat exchangers, glycol circuit pumps, main circulation pumps, combs, aggregate service areas, equipment for the preparation and supply of refrigerant mixture to Block A on the technical floor. The cooling mixture is traced by pipes in the technical underground of Block “A”.The building service service 2 floors (Block "G").

The first floor is divided into two functional areas: business and control room. The economic zone includes the loading area and equipment reception room, temperature exposure room, unpacking, container storage and a metal workshop. The second floor is divided into two functional areas: the operational technical staff area and the IT equipment preparation area.Administrative building (Block "D"), 4 floors: dimensions of 65x38.5 m.

Designed for the administration of the facility and office space customers.KPP1 and KPP2 for the passage of passenger cars and heavy vehicles, respectively: dimensions 6x9 m.

Fuel storage with a total capacity of 200 cubic meters of fuel.

- Parking for cars for 90 cars.

Construction progress

And it all started like this

So the site looked on February 11, 2015, when the first bucket of soil was “taken out” . No buildings, structures - only cleared and enclosed field for our mega-project. Then it was still difficult to imagine that in a few months everything would “boil and seethe” here, and later a beautiful, large data center would grow.

Development of a cold center pit. The first bucket February 11, 2015

From February to March 2015, we moved closer and closer to the “center of the Earth”. We “bite” into the ground; the excavation of the administrative and residential building (GD blocks) is being developed, the foundation of the refrigeration center is being filled (Block B).

In the photo: development of pits, pouring the foundation of the administrative and residential building (“GD” blocks), cooling center (“B” block). February-March 2015

At the end of July 2015, pits were developed for all the blocks, the foundation works of the refrigeration center and administrative buildings were completed, and 15% of the metal structures of the refrigeration center were installed. Below is a photo of the work process. In total, 75,000 m³ of soil was developed , 13,597 m³ of concrete were adopted .

In the photo: work is underway on all the blocks: the machine hall (“A”), the power center (“B”), the refrigeration center (“C”) and the administrative building (GD), respectively. The metal structures of the refrigeration center are being installed (“B”), the base for the diesel rotary uninterruptible power sources is being prepared for the foundations (Energy Center, Block “B”). June-July 2015

By the end of the summer of 2015. the concreting of the second floor of the administrative building (“GD”) was already being done, the foundation for the dynamic diesel uninterruptible power supply units of the Energy Center (“B”) was being prepared. The site looked like this - the photo below.

In the photo: the Energy Center (“B”) and the bases of the turbine hall (“A”) from a bird's-eye view. August 2015

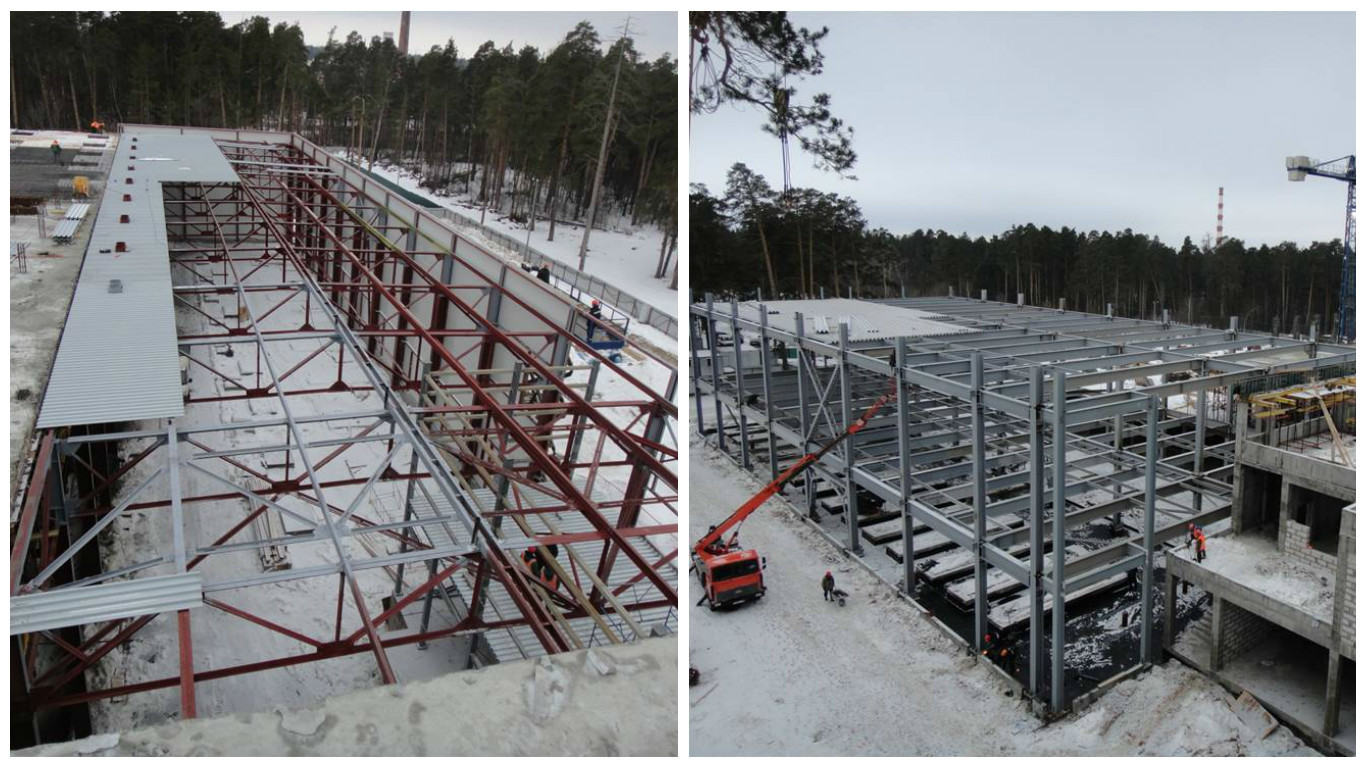

In December 2015 , started the installation of engineering systems. The installation of an individual substation has begun. In February 2016 , the frameworks of all five blocks (“A” - “D”) were completed. The metal structures of the Energy Center (Block “B”) have reached a total weight of 460 tons . The total weight of the metal structures of the Refrigeration Center (Block “B”) was 100 tons .

In the photo: on the left - Cold Center (Block “C”), on the right - Metal structures of the power center (Block “B”). January 2016 - February 2016

In May 2016, all the buildings were “closed” with enclosing structures (in other words, the walls), with the exception of technological openings that were left to supply equipment and materials for the installation of engineering systems. Meanwhile, parallel to the inside was the installation of ventilation boxes in the refrigerating center (“B”) and the installation of technological pipelines in the technical underground of the turbine hall (“A”).

In the photo: on the left - the ventilation box in the refrigerating center (“B”), on the right - technological pipelines in the technical underground of Mashzal (“A”). June 2016

In total, by the summer of 2016, about 724 tons of steel structures were assembled, about 1 760 tons of fittings were used .

In the photo: Mashzal (Block “A”), Energy Center (Block “B”), Cold Center (Block “C”), Administrative Building (Block “D”) - summer 2016.

On June 24, 2016, the first door was installed in Avantage. This event marked the transition to a new stage of construction - interior decoration! Fire doors with an anti-panic system and with a design providing no threshold will be installed in the data center building. All doors in the building are equipped with access control system.

In the photo: the first door installed in the data center "Avantage"

Equipment installation

The first type of equipment , the installation of which began in May 2016 , became Tecofi butterfly valves (France) . The cooling system of the data center involves the use of 18 dry coolers, 9 chillers and 128 precision air conditioners. In the period from June 1 to June 3, 2016, the first batch of main process equipment was delivered to the construction site of the Avantage data center. It consists of 5 sets of diesel-rotary uninterruptible power supplies and 16 ventilation units manufactured by Euroclima , designed for installation in the power center. All equipment was installed immediately on the designated project site. In total, according to the project, installation of 14 diesel-rotary uninterruptible power supplies with a capacity of 1,650 kVA each is provided for in the building of the power center. They are designed to provide uninterrupted power supply of the entire data center complex.

In the photo: top left - the first butterfly valves in the cooling system of the data center, top right and bottom - delivery and installation of diesel-rotor uninterruptible power supplies

In July 2016, 6 plate heat exchangers manufactured by Alfa Laval Potok and 6 refrigerating machines (chillers) manufactured by Cofely (Germany) arrived at the construction site. The devices were installed at the design sites, work was carried out on their piping. A total of 9 plate heat exchangers are installed in the data center, each of which will provide a heat sink of 1600 kW. Plate heat exchangers are used to remove heat in free cooling mode (freecooling). For the cold supply during the summer period, chillers of the internal installation with a liquid cooled condenser with centrifugal compressors Turbocore are used. The total power of the excess heat given off by the data center cooling system will be 11.5 MW.

In the photo: installation of heat exchangers (left) and chillers (right)

Meanwhile, by the end of the summer, outside the data center already looks quite ready, although it can be seen that it is on the “battlefield” (photo below), and inside it is the “cutting” of IT space.

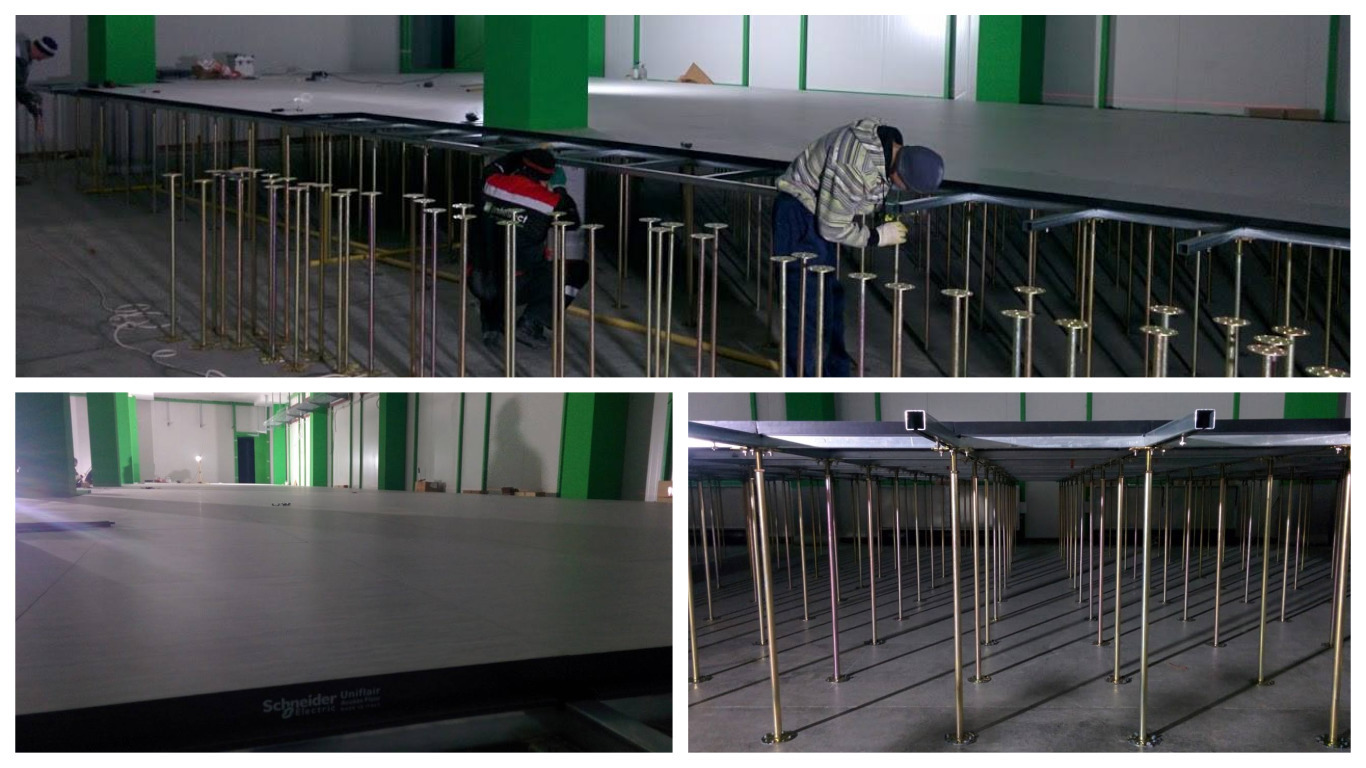

Under the placement of IT equipment in Avantage, 16 server rooms are allocated, located on 2 floors, with 8 server rooms per floor. Each server room has dimensions of 13.1 x 30.2 m (S = 396 sq.m), height (from the floor to the ceiling) 5.0 m and can accommodate 140 server cabinets 800x1200 mm in size. The server rooms will be equipped with a raised floor with a height of 1000 mm to ensure the supply of cooled air. In 13 server rooms of 16 precision air conditioners to prevent service personnel from accessing rooms with IT equipment, they will be installed outside the server rooms in dedicated, technological corridors.

The air conditioning of the server rooms is designed to remove excess heat in the amount of 735 kW to the server room and maintain the temperature of the cooling air at +24 ° C. The power supply of the server rooms will be carried out on 2-line trunk lines of 1600 A. The halls will be equipped with aspiration fire detection and gas fire extinguishing systems.

In the photo: view of the data center "Avantage" outside (top) and inside while cutting IT space by the end of the summer of 2016 (bottom)

In early autumn , delivery and installation of 10 kV switchgear equipment and power transformers manufactured by Siemens (picture below) began on the construction site. In total, the project provides for the installation of 112 10 kV cells combined into 11 sections and the 41st 10 / 0.4 kV power transformer. To create a 10 kV switchgear of the Avantage data center, 10 kV cells of the NXair, Simosec and 8DJH series are used. The power supply system of the data center - 17.3 MW.

In the photo: installation of switchgear equipment and power transformers

In September, we had to perform a difficult operation to lift the first batch of dry coolers produced by Cabero on the roof of the data center building. For this, a 160-ton crane was called to the construction site. Within one day, all 8 dry coolers of the first batch were installed at the project sites. In total, the project provides for the installation of 18 dry coolers. In the project, Cabero dry coolers are used to remove excess heat to the atmosphere. When the outside air temperature is below + 9C, the data center cooling system goes into direct cooling mode, which does not use refrigeration compressors.

In the photo: the rise of the first batch of dry coolers

In the meantime, in October 2016, outside the data center, the front of works on landscaping the data center was opened. In total, 7,800 square meters of driveways will have to be asphalted and 10,500 square meters of lawns will be planted. On the territory will be organized parking for 90 cars. I can not believe it, but there will be a garden city here!

In the photo: landscaping the data center "Avantage"

By November 2016 Technair LV precision air conditioners arrived at the construction site and began to occupy project sites. In total, the project provides for the installation of 128 precision air conditioners in server rooms and 4 in 2 cross rooms. In each of the 16 server rooms installed on 8-m conditioners. Air conditioners have a cooling capacity of 105 kW each and are reserved according to the N + 1 scheme. As a result, each hardware room has the potential of removing excess heat of 735 kW.

At the same time, cable galleries, premises and installed equipment are ready for laying 10 kV switchgear cable lines. Cable lines of 10 kV inside the complex of data center buildings will interconnect 112 cells combined in 11 sections and 41 power transformers, organizing an uninterrupted and guaranteed 18 MW power supply source together with diesel rotary UPSs.

In the photo: precision air conditioners (above) and the future cable gallery (below)

In December 2016, the installation of raised floors began in the data center. Total installed 9300 sq.m. raised floors . 6400 square meters - in the server rooms, the rest - in the corridors and technological rooms. Uniflair spa Schneider Electric, Schneider Electric was chosen as the producer of raised floors. In the server rooms, a raised floor with a height of 1 m is installed, the space under which serves to supply cooled air to the server equipment.

In the photo: installation of raised floors

Well, in the end, this is how we already look from the satellite .

At this point, we’ll interrupt, and the second part, with the remaining work, will be released by the time of the opening of the data center. Plus, perhaps there will be an additional post in which we will highlight more interesting moments for you. I ask questions in the comments.

Here you can find out more details about the project itself.

The material was prepared with the active participation of colleagues from LLC Avantazh.

')

Source: https://habr.com/ru/post/326104/

All Articles