Looks like I'm not an entrepreneur

In order to understand this, it took me four million rubles (half of which are mine) and four years.

I launched and headed a cool robot startup that I managed to bring to the first sales. As far as I know, we have advanced further than any other similar Russian project, but, about two months ago, I left it, transferring control to the team, and now I have nothing to do with it.

In this article, I would like to

')

- share the findings

- recommend a project if you want to join it as a developer / investor

- lay out technical documentation if you want to fork

For a start - a little about what we did.

The aim of the project was to create a cheap universal robot that has capabilities comparable to the human hand. Similar speed, load capacity, accuracy - and at a price ten times lower than that of modern industrial robots.

Now there are two main areas in which robotic manipulators are developing.

The first is robots that have small sizes, 3-4 degrees of freedom, low accuracy, large backlashes and many other restrictions that make it impossible to use them to replace human labor. Their purpose is geek toy or research projects. Their manufacturers are forced to balance between the technical complexity of the design, sufficient to satisfy the curiosity of customers, and its price.

The second direction is industrial robotics, which is widely used, for example, in automotive manufacturing for assembling, welding and painting parts. These are robots that have absolutely amazing characteristics (for example, repeatability - 0.05 mm ) that are absolutely inaccessible to humans. Such robots can be used to perform operations with speed and accuracy, which in principle can not be achieved using manual labor. Also, at the expense of a long time of life and on condition of a small number of interruptions in work, they can be cheaper than a person performing similar functions.

Between these two groups there is a gap in price by two orders of magnitude (10k-1m RUB) and, less impressive, but still significant, a gap in characteristics. It was in the niche located between these two groups that we were aiming.

There are huge markets in which manual labor is used, and the only reason for this is that people are cheaper than a group of industrial robots with similar functions. An example would be cooking in fast foods. This activity, which is easy to prescribe as an algorithm, does not need high accuracy or speed. If a robot with a cost equal to several monthly salaries of an unskilled worker, and the ability to perform at least half of his work, will be in the market, he will be in demand.

Based on these prerequisites, we determined the target technical characteristics and then chose solutions that allow them to be achieved at the lowest price. We needed a robot with six degrees of freedom (the minimum number in order to be able to transmit any movement), a load capacity of 3 to 5 kilograms, repetitive movements (under load and without) in the region of 1-2 millimeters, physical size and speed comparable to the arm person Target cost - about 150k RUB.

In short, we have achieved these goals. With some reservations and in a limited number of situations, but we had results that allowed us to say that we are on the right track.

The robot was tested in real conditions - in the summer, for about three months, he worked at the Ball of Robots exhibition, collecting a burger mock-up on the stand.

Then, on the basis of the data, we corrected errors, carried out upgrades and recently the robot returned to the exhibition, where it is now doing the same.

We also proved that there is a demand for a robot - a landing page with minimal advertising made it possible to receive a lot of calls and several purchase requests per week, which is quite enough to start sales.

And, nevertheless, I decided to leave the project.

It was a difficult decision, taking into account the effort and clarity of the result, but I realized that the way that I had to go, almost never brought me pleasure. Each next step was given as hard as the previous one, and the longer the path was, the longer the future seemed.

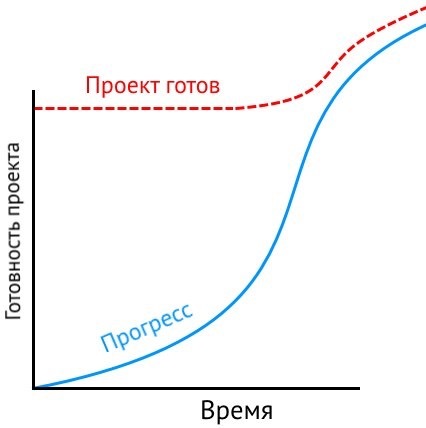

There were several reasons for exit, which can be depicted in one picture.

But if to detail, then:

- The terms are delayed. It is widely known how to estimate the timeframe for the implementation of a technically complex project that you are doing for the first time: take the most negative assessment of the time, which includes all possible problems. And then multiply it by three. Unfortunately it's true.

- The vision is changing. The idea of what customers need is significantly different at the beginning of development and at the end. The point is not only that a potential customer can formulate certain requirements only after seeing a working prototype, but meeting these requirements often requires significant changes. Some technical aspects (for example, reliability) begin to come to the fore only after the prototype is ready and its tests begin in real conditions.

- That stage, which previously seemed to be a sales launch stage, now looks like an intermediate step. In a sense, this is a continuation of the previous paragraph. It is not enough to get a prototype that works as it should. Problems of the same reliability require significant modifications to the design, which do not affect the functional characteristics, but take a lot of time, money and lead to higher prices for products. And almost never there is any certainty that some problem is solved once and for all - often this can be understood only by the statistics of failures, which is better to recruit on a friendly nearby site, which greatly narrows the range of potential customers and, as a result, postpones the deadlines.

- A significant acceleration of work can only be achieved by increasing funding. In this case, the date of self-sufficiency shifted farther into the future.

All the listed problems can be caused by different reasons, for example:

1. Errors in project management (Partially. But those that I see now were not fatal to the project)

2. Unsuccessfully selected team (Definitely not)

3. Insufficient flexibility (Partially. We started to develop an additional direction too late (production of gearboxes), which allows the project to survive somewhere on the limit of self-sufficiency)

4. Discrepancy between the scale of the project and the resources allocated to it (I believe that the main)

Conclusions that I made during the project:

- Take care of really stable financing or try to stop depending on it as soon as possible. If you are doing a project for the first time, whatever the budget - you do not fit into it. In our case, the source of the money was the salaries received by the co-founders at the main place of work. This allowed the project to develop without regard to external factors.

- Deadlines are important. Unambiguously identify the purpose and penalties in case of its non-achievement, it will stimulate to more effective work. The severity of sanctions should not kill after the first actuation, but the sequence of broken deadlines is a serious sign that something is wrong with setting goals or monitoring their implementation.

- The team is more important than the goal. Even with erroneous initial assumptions, the flexibility given by a strong team allows you to see alternatives and change direction without serious negative consequences.

Despite my exit from the project, I feel a sense of responsibility for the work done, and I want the work done by our engineers to help as many people as possible. In coordination with the people left in the project, I post technical documentation that can help you form your own opinion about it.

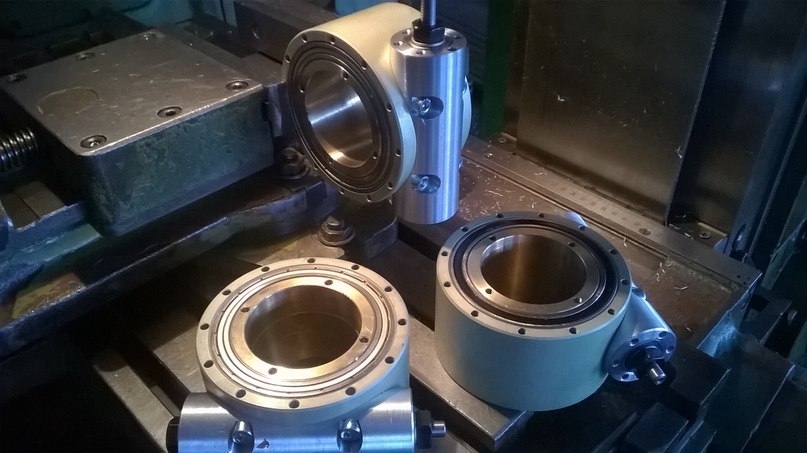

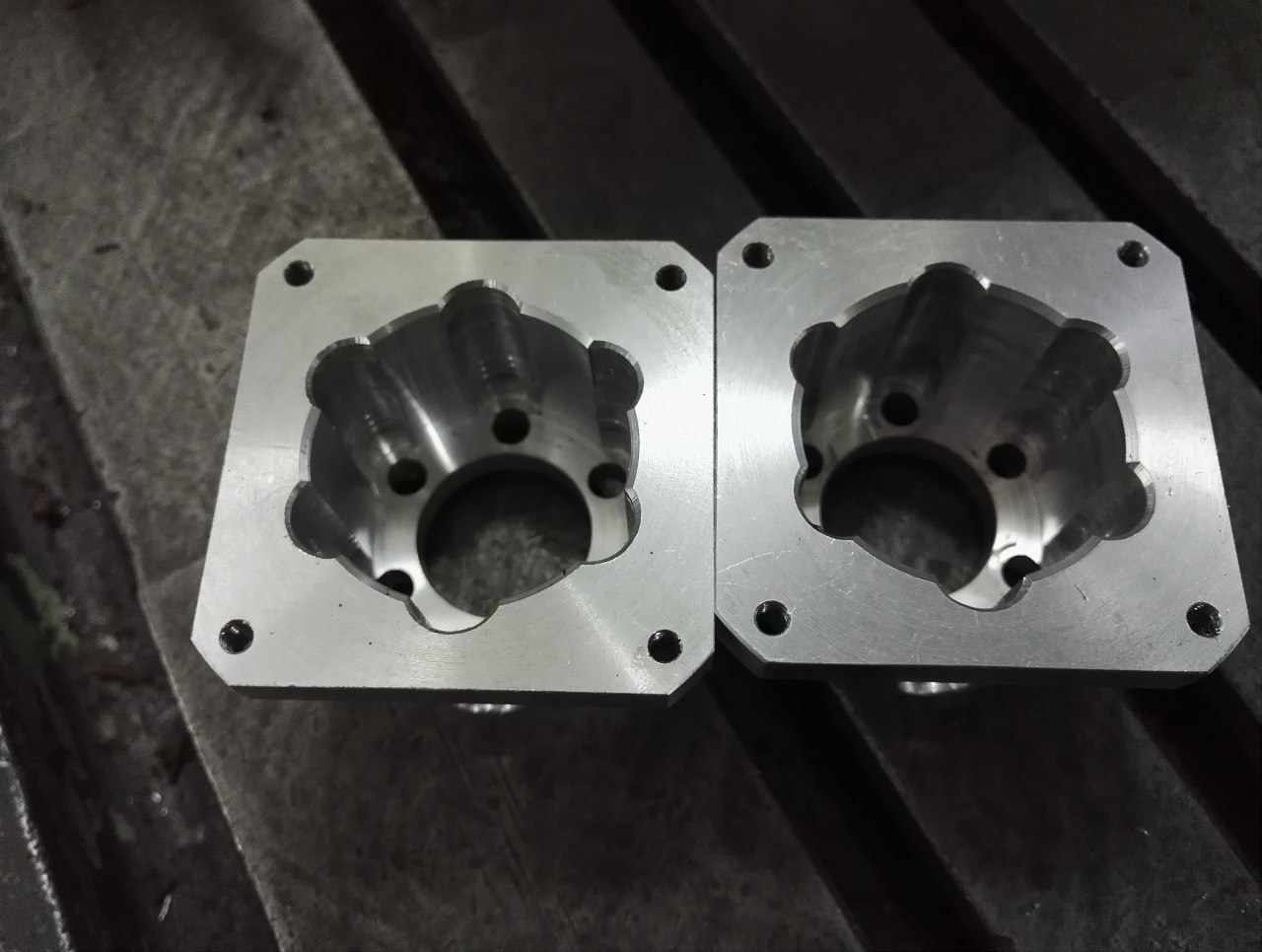

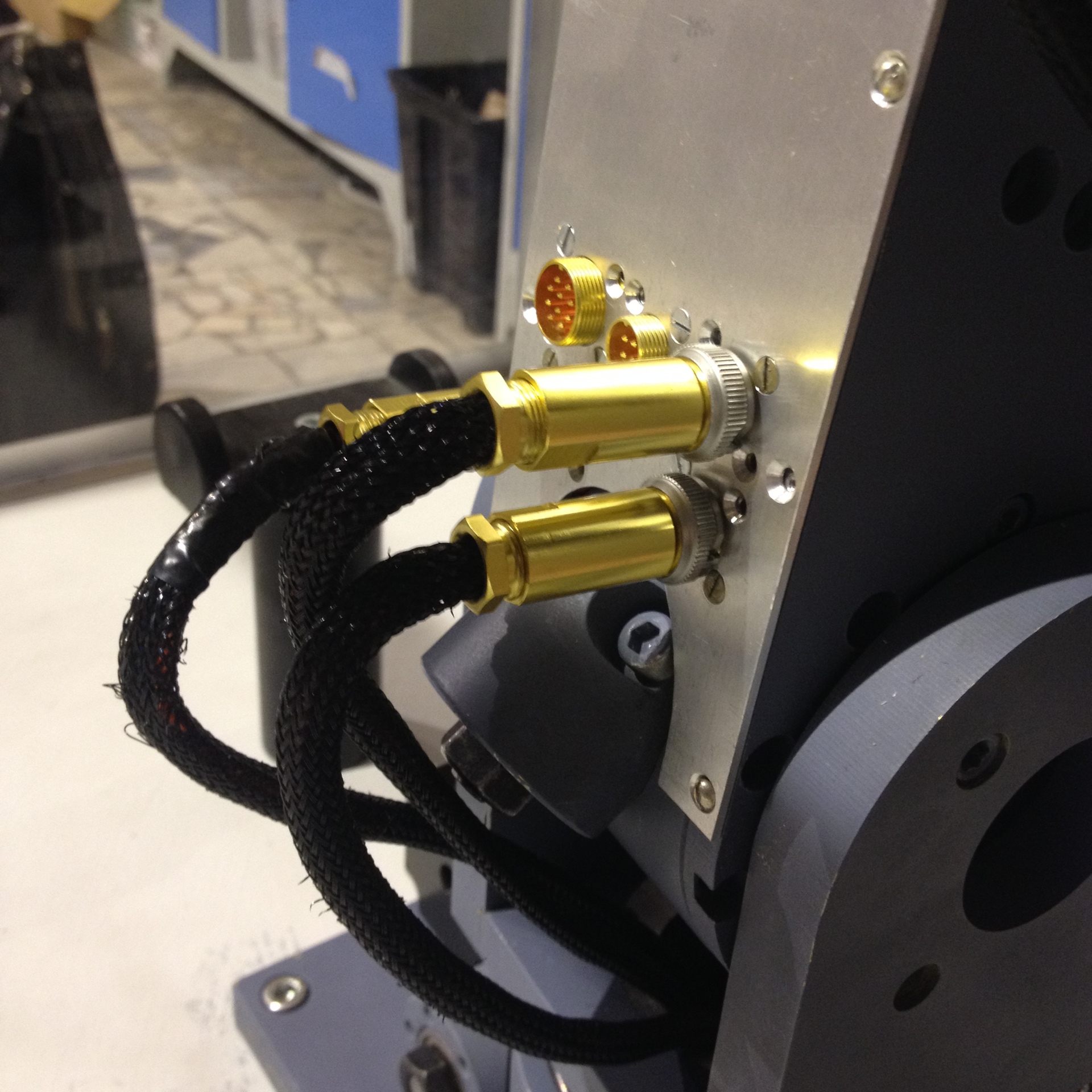

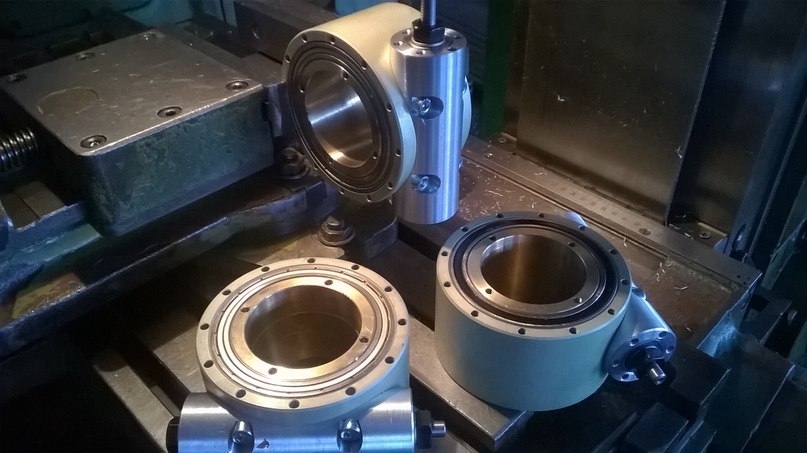

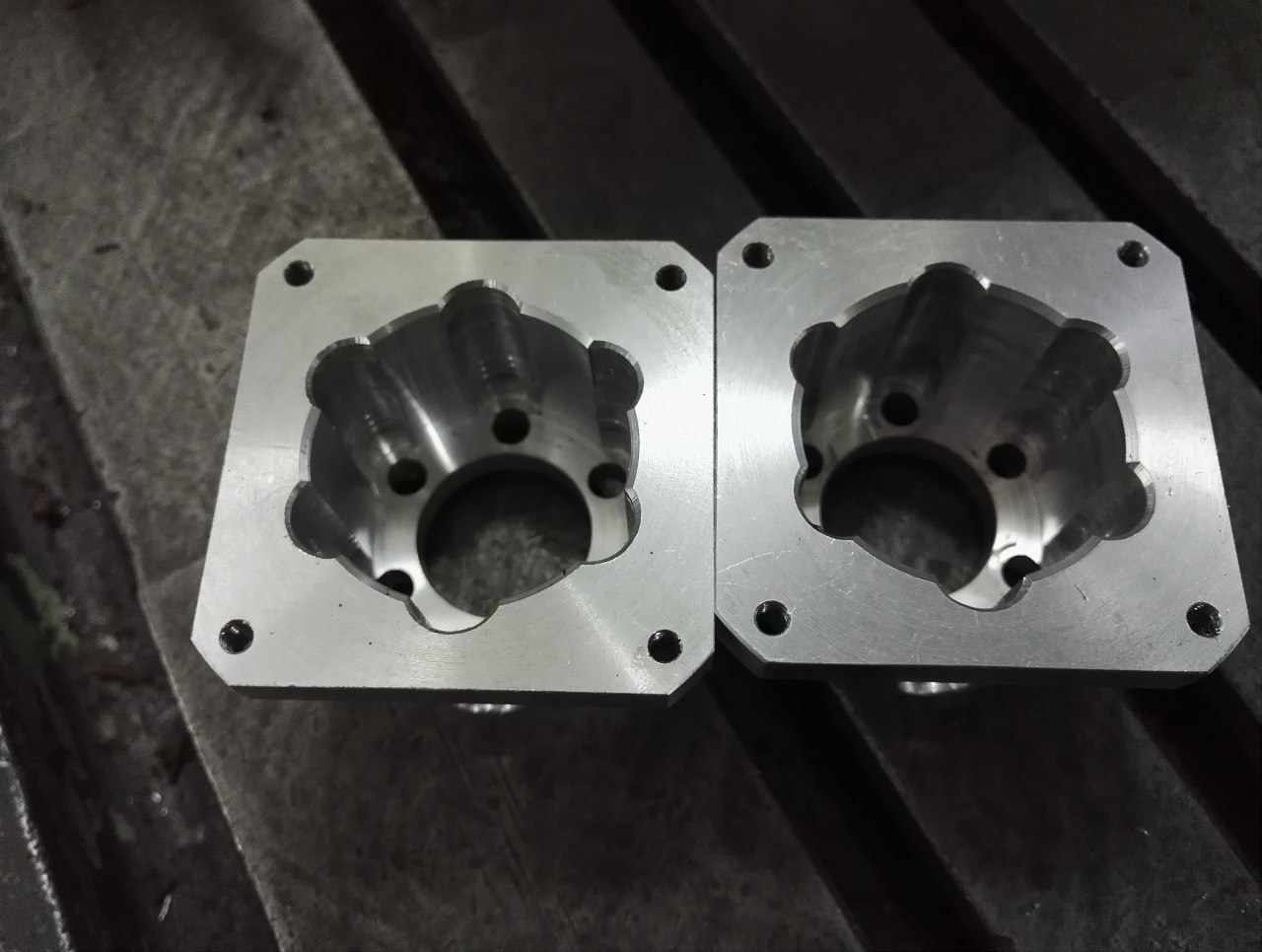

All mechanical parts of the robot were designed and manufactured by us independently. This allowed to experiment with the design, but significantly increased development time.

There were at least three features not characteristic of other robotic projects:

1. Stepper motors instead of servo drives

2. Worm gearboxes instead of planetary-landed or wave gears

3. Almost complete lack of feedback

Used together, these modifications have significantly reduced the cost of construction.

Worm gearboxes are traditionally considered to be insufficiently accurate for robotics, but in the case of manufacturing on good equipment and using some tricks (such as sampling the backlash by approaching the axes), they allow us to obtain characteristics that are sufficient for our purposes. However, worm gearboxes are very cheap. In the case of mass production, they are almost an order of magnitude cheaper than the gearboxes used traditionally in robotics. In addition, they have one extremely useful property - even significant loads on the output axis do not lead to scrolling of the input axis. This eliminates the problem of shock loads - they are not transmitted to the motor axis, and when the power is turned off, the robot is guaranteed to remain stationary.

Stepper motors allow you to opt out of expensive encoders. At each time, the robot "does not know" where it is located. It has only end sensors - which allows you to automatically go to the extreme positions along each of the axes. However, knowing the starting position and the number of steps taken, you can accurately calculate the current position. The disadvantage of this approach is the problem of untraceable skip steps, characteristic of stepper motors. However, if you observe the load, smoothly accelerate / brake the engine, problems can be practically avoided. Those omissions of steps that still arise are usually not significant in one cycle. Returning to the initial position (until the end sensors are triggered) at the end of each work cycle avoids the accumulation of errors.

Under the link you can find a 3D model of the robot, drawings and photos / videos, revealing the history of development. I will be glad if you decide to join the project (the contacts of the team are in the attached files) or if you want to develop your branch of the same design.

Participation in a hardware project is an exciting experience, which, despite my decision, I recommend repeating to everyone. Try to take something that you believe in and try to turn it into a business. It was very interesting for me and I hope it will be just as interesting for you.

I launched and headed a cool robot startup that I managed to bring to the first sales. As far as I know, we have advanced further than any other similar Russian project, but, about two months ago, I left it, transferring control to the team, and now I have nothing to do with it.

In this article, I would like to

')

- share the findings

- recommend a project if you want to join it as a developer / investor

- lay out technical documentation if you want to fork

For a start - a little about what we did.

The aim of the project was to create a cheap universal robot that has capabilities comparable to the human hand. Similar speed, load capacity, accuracy - and at a price ten times lower than that of modern industrial robots.

Now there are two main areas in which robotic manipulators are developing.

The first is robots that have small sizes, 3-4 degrees of freedom, low accuracy, large backlashes and many other restrictions that make it impossible to use them to replace human labor. Their purpose is geek toy or research projects. Their manufacturers are forced to balance between the technical complexity of the design, sufficient to satisfy the curiosity of customers, and its price.

The second direction is industrial robotics, which is widely used, for example, in automotive manufacturing for assembling, welding and painting parts. These are robots that have absolutely amazing characteristics (for example, repeatability - 0.05 mm ) that are absolutely inaccessible to humans. Such robots can be used to perform operations with speed and accuracy, which in principle can not be achieved using manual labor. Also, at the expense of a long time of life and on condition of a small number of interruptions in work, they can be cheaper than a person performing similar functions.

Between these two groups there is a gap in price by two orders of magnitude (10k-1m RUB) and, less impressive, but still significant, a gap in characteristics. It was in the niche located between these two groups that we were aiming.

There are huge markets in which manual labor is used, and the only reason for this is that people are cheaper than a group of industrial robots with similar functions. An example would be cooking in fast foods. This activity, which is easy to prescribe as an algorithm, does not need high accuracy or speed. If a robot with a cost equal to several monthly salaries of an unskilled worker, and the ability to perform at least half of his work, will be in the market, he will be in demand.

Based on these prerequisites, we determined the target technical characteristics and then chose solutions that allow them to be achieved at the lowest price. We needed a robot with six degrees of freedom (the minimum number in order to be able to transmit any movement), a load capacity of 3 to 5 kilograms, repetitive movements (under load and without) in the region of 1-2 millimeters, physical size and speed comparable to the arm person Target cost - about 150k RUB.

In short, we have achieved these goals. With some reservations and in a limited number of situations, but we had results that allowed us to say that we are on the right track.

The robot was tested in real conditions - in the summer, for about three months, he worked at the Ball of Robots exhibition, collecting a burger mock-up on the stand.

Then, on the basis of the data, we corrected errors, carried out upgrades and recently the robot returned to the exhibition, where it is now doing the same.

We also proved that there is a demand for a robot - a landing page with minimal advertising made it possible to receive a lot of calls and several purchase requests per week, which is quite enough to start sales.

And, nevertheless, I decided to leave the project.

It was a difficult decision, taking into account the effort and clarity of the result, but I realized that the way that I had to go, almost never brought me pleasure. Each next step was given as hard as the previous one, and the longer the path was, the longer the future seemed.

There were several reasons for exit, which can be depicted in one picture.

But if to detail, then:

- The terms are delayed. It is widely known how to estimate the timeframe for the implementation of a technically complex project that you are doing for the first time: take the most negative assessment of the time, which includes all possible problems. And then multiply it by three. Unfortunately it's true.

- The vision is changing. The idea of what customers need is significantly different at the beginning of development and at the end. The point is not only that a potential customer can formulate certain requirements only after seeing a working prototype, but meeting these requirements often requires significant changes. Some technical aspects (for example, reliability) begin to come to the fore only after the prototype is ready and its tests begin in real conditions.

- That stage, which previously seemed to be a sales launch stage, now looks like an intermediate step. In a sense, this is a continuation of the previous paragraph. It is not enough to get a prototype that works as it should. Problems of the same reliability require significant modifications to the design, which do not affect the functional characteristics, but take a lot of time, money and lead to higher prices for products. And almost never there is any certainty that some problem is solved once and for all - often this can be understood only by the statistics of failures, which is better to recruit on a friendly nearby site, which greatly narrows the range of potential customers and, as a result, postpones the deadlines.

- A significant acceleration of work can only be achieved by increasing funding. In this case, the date of self-sufficiency shifted farther into the future.

All the listed problems can be caused by different reasons, for example:

1. Errors in project management (Partially. But those that I see now were not fatal to the project)

2. Unsuccessfully selected team (Definitely not)

3. Insufficient flexibility (Partially. We started to develop an additional direction too late (production of gearboxes), which allows the project to survive somewhere on the limit of self-sufficiency)

4. Discrepancy between the scale of the project and the resources allocated to it (I believe that the main)

Conclusions that I made during the project:

- Take care of really stable financing or try to stop depending on it as soon as possible. If you are doing a project for the first time, whatever the budget - you do not fit into it. In our case, the source of the money was the salaries received by the co-founders at the main place of work. This allowed the project to develop without regard to external factors.

- Deadlines are important. Unambiguously identify the purpose and penalties in case of its non-achievement, it will stimulate to more effective work. The severity of sanctions should not kill after the first actuation, but the sequence of broken deadlines is a serious sign that something is wrong with setting goals or monitoring their implementation.

- The team is more important than the goal. Even with erroneous initial assumptions, the flexibility given by a strong team allows you to see alternatives and change direction without serious negative consequences.

Despite my exit from the project, I feel a sense of responsibility for the work done, and I want the work done by our engineers to help as many people as possible. In coordination with the people left in the project, I post technical documentation that can help you form your own opinion about it.

All mechanical parts of the robot were designed and manufactured by us independently. This allowed to experiment with the design, but significantly increased development time.

There were at least three features not characteristic of other robotic projects:

1. Stepper motors instead of servo drives

2. Worm gearboxes instead of planetary-landed or wave gears

3. Almost complete lack of feedback

Used together, these modifications have significantly reduced the cost of construction.

Worm gearboxes are traditionally considered to be insufficiently accurate for robotics, but in the case of manufacturing on good equipment and using some tricks (such as sampling the backlash by approaching the axes), they allow us to obtain characteristics that are sufficient for our purposes. However, worm gearboxes are very cheap. In the case of mass production, they are almost an order of magnitude cheaper than the gearboxes used traditionally in robotics. In addition, they have one extremely useful property - even significant loads on the output axis do not lead to scrolling of the input axis. This eliminates the problem of shock loads - they are not transmitted to the motor axis, and when the power is turned off, the robot is guaranteed to remain stationary.

Stepper motors allow you to opt out of expensive encoders. At each time, the robot "does not know" where it is located. It has only end sensors - which allows you to automatically go to the extreme positions along each of the axes. However, knowing the starting position and the number of steps taken, you can accurately calculate the current position. The disadvantage of this approach is the problem of untraceable skip steps, characteristic of stepper motors. However, if you observe the load, smoothly accelerate / brake the engine, problems can be practically avoided. Those omissions of steps that still arise are usually not significant in one cycle. Returning to the initial position (until the end sensors are triggered) at the end of each work cycle avoids the accumulation of errors.

Under the link you can find a 3D model of the robot, drawings and photos / videos, revealing the history of development. I will be glad if you decide to join the project (the contacts of the team are in the attached files) or if you want to develop your branch of the same design.

Participation in a hardware project is an exciting experience, which, despite my decision, I recommend repeating to everyone. Try to take something that you believe in and try to turn it into a business. It was very interesting for me and I hope it will be just as interesting for you.

Source: https://habr.com/ru/post/326014/

All Articles