How to increase production efficiency with augmented reality?

Experienced business leaders are familiar with the formula for productivity growth. The role of innovation in this process is obvious to everyone. However, not everyone can recognize in time the technologies that can help to increase productivity, especially in such a conservative and not prone to investing in innovation market, as the Russian industry. In their time, Autodesk and Consistent Software made their way to the designers and designers for quite a long time - they did not understand why they would lay out millions for the work that was done with the help of pencils and drawing paper. As a result, a part of enterprises that did not adopt new technologies in time left the market.

In this article, we would like to draw your attention and talk about the new technology that has already been successfully used in industry and manufacturing around the world.

Paul Milgram and Fumio Kishino in 1994 described augmented reality as a kind of space between reality and virtuality. Augmented reality technology projects any digital information (images, video, text, graphics, etc.) over the screen of any devices.

If you watched the film “Iron Man”, then just all the graphic indicators that were displayed on the helmet's screen and refer to the concept of augmented reality (“augmented reality”).

')

Perhaps it sounds and looks more than fantastic, but such solutions are already being successfully used in many industrial and manufacturing companies, including Russian ones.

Today, among the devices of augmented reality can be identified portable devices, stationary and projection systems, glasses and augmented reality lenses.

Portable devices are the most budget-friendly way to get in touch with augmented reality. These include mobile phones and tablet computers. The main requirement for the device is the availability of high-quality camera with high resolution.

Stationary systems are widescreen screens equipped with high resolution cameras that are located in one place. Such systems are not very convenient in mobile work, but they demonstrate more realistic visualization.

Unlike stationary systems of augmented reality, projection systems superimpose an image on any surface, and their work does not require a separate screen.

The most widely used augmented reality glasses, wearing which a person sees virtual objects superimposed on the surrounding reality. The most famous devices in Russia include Google Glass ($ 1600), as well as Epson's Moverio ($ 799.99).

Lenses for augmented reality are still the subject of research by technology giants, including Samsung, Google and Microsoft. The idea is to turn ordinary lenses into a transparent electronic screen containing a control system, a miniature camera, antenna, LEDs and other optoelectronic components. In particular, Samsung has already filed a patent for “smart” contact lenses, so we have every reason to expect the device to enter the market in the next 5-10 years.

Existing solutions already cover many areas: tools for automating processes and increasing productivity, training employees, reducing production waste, improving the efficiency of logistics processes, and ensuring occupational safety.

For example, with the help of augmented reality, workers can quickly access instructions and manuals for any detail. They receive information in the form of visual three-dimensional animation, video, audio, photographs, pictures or graphics. This approach allows to reduce the requirements for the qualification of specialists, and reduce the time for studying and viewing work instructions. Moreover, the system itself is able to recognize the shape of the part and its number and promptly tell if the technician has taken erroneous actions to install it.

Issues of the effectiveness of the introduction of augmented reality are covered in great detail in the case study “The effectiveness of augmented reality in the manufacturing industry” (“ Augmented Reality Efficiency in Manufacturing Industry ”), sponsored by Juha Sääski, Tapio Salonen and several other authors (Tapio Salonen) .

A narrower study is “Assessing the benefits of augmented reality for the task of localizing the maintenance of an armored personnel carrier turret” (“ Evaluating the Armored Carrier Turret ”). Its authors are Columbia University staff members Stephen Henderson (Steven J. Henderson) and Stephen Feiner (Steven Feiner). The study will be useful for familiarizing the top managers of industrial and industrial enterprises in order to make a decision on the effectiveness of investing in a new technology.

Both studies are freely available on the Internet.

Consider a few more impressive examples of the use of augmented and virtual reality in industrial and industrial companies.

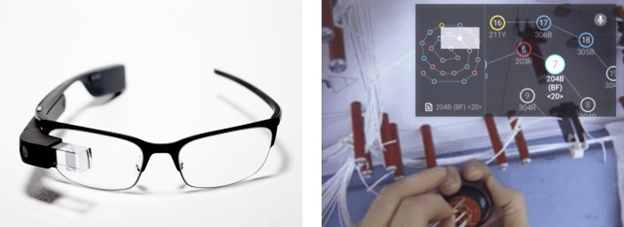

Boeing is one of the largest aerospace companies on the planet that builds airplanes for 150 countries. In the onboard systems of the aircraft contains many components interconnected by a system of wires. The cables are laid and connected according to a special template, after which they are fastened into bundles, and connectors are installed on the ends of the cables. The work process takes a long time and requires special attention and responsibility. For the past 20 years, Boeing has been looking for a system that can shorten production time and eliminate errors. In early 2014, the company introduced the solution of augmented reality on the platform of glasses Google Glass. Using the application, the operator gives a voice command: “Ok, Skylight. Start creating a harness. Scan order 0447 ”and see in augmented reality glasses a visual roadmap for assembling harness No. 0447.

According to data from the report of the Boeing company on the project, "the use of Google Glass has reduced the production time by one quarter and reduced the number of errors by half."

Another example is Lockheed Martin, where NGRAIN was involved in implementing the project. Plant engineers use augmented reality to get a visual hint on the assembly of an F-35 aircraft. The company uses Epson Moverio BT-200 augmented reality glasses, equipped with special motion and depth sensors, as the main platform. When a technician mounts a brake part on the chassis, with augmented reality glasses, he sees all the data about where and in what order to assemble and connect the cables. As a result, the whole process of work resembles the assembly of the LEGO designer, when the worker is only required to take a suitable part and place it in the right place.

According to the company NGRAIN , "software allows engineers to work 30 percent faster with an accuracy of up to 96 percent."

Car models are available in various trim levels and colors. Therefore, automakers often seek to find a balance between mass production and individual consumer preferences. Of course, in the days of Henry Ford, everything was much simpler. The organization of such production is often accompanied by complex work instructions that can provoke downtime, errors and reduced productivity.

Concern Fiat Chrysler Automobiles (FCA) has applied in its work a projection system of augmented reality OPS Solutions. Now, at each stage of the assembly process, workers receive visual information about their next step.

After the introduction of innovation was organized experiment. Operators were tasked with assembling gears and chains. The whole process took place in ten consecutive steps. Employees had to choose the right parts, install and make sure everything was done correctly. Some of the operators performed the task using paper instructions, while others used augmented reality tools. The results of the experiment you can evaluate in the table below.

80% error reduction

38% cycle time reduction

82% increase in throughput

Volkswagen concern became another car company which adopted the technology of augmented reality. At its plant in Wolfsburg, Volkswagen uses Google Glasses augmented reality glasses when picking orders. Workers automatically receive all the information they need about storage locations or part numbers.

The first Russian application of augmented reality was released by VR CORP for electrical production. The management of the Energy Saving Technologies of Siberia company faced a staff turnover, as a result of which a lot of money and efforts were spent on training newly arrived employees. An office application was created for office personnel, with the help of which any employee could point a smartphone at an electrical circuit and examine in detail the 3D model of the finished product, including all its components. Especially this application is important for young professionals without experience. The introductory specialty course was reduced to a simple scheme: he took a smartphone, launched an application, turned on an electrical circuit and reviewed all the details about the product in its finished form.

A similar application in functionality was developed for the assembly workshop workers. Instead of the wiring diagram, a specialist receives information on the placement of parts and cables in a future product, and highlighting every detail warns in time if the wrong components are used.

For its development, VR CORP received a diploma of the City Technologies Forum from the Department of Industry, Innovation and Entrepreneurship of the Novosibirsk City Hall.

Augmented reality technology offers a new interesting look at solving tasks for staff turnover, training, production errors and downtime. It is not always clear what to start with, what costs it will require and how soon the investment will return.

Start small. There are not so many companies working with augmented reality for production and industry in the Russian market, and yet there is a choice. Here are our recommendations:

1. Contact the developer’s representatives and tell in detail about the tasks you are facing.

2. Create a working group together for detailed analysis and solution development.

3. Do not strive to immediately grasp the immensity. Choose one of the small stages of the production process and develop a test solution for it. According to the estimates of the Russian developer of solutions for augmented reality of the company VR CORP, the cost of such a solution ranges from 50,000 to 100,000 rubles.

4. Compare the performance indicators of workers using augmented reality and those who work in the old manner.

5. Based on the indicators, evaluate the investment attractiveness of the complex project.

6. If project indicators please you, agree on its budget and implementation stages.

7. Start to work.

In competition, many enterprises offer identical goods and therefore strive to win mainly due to lower prices. Such a competitive strategy creates difficult conditions in which the profit on transactions ranges from 3 to 7%.

Augmented reality can serve not only for the needs of our own production, but also to create a product with unique properties. Many products require some effort from the user in order to understand and use it. For example, electrical panels, generators, cars and furniture from IKEA. With the help of augmented reality, the manufacturer can add online help for the user, which he can use with his tablet or phone. This help will clearly show how to use the product, eliminate many errors and generally improve customer satisfaction.

BMW has already launched a similar solution for the maintenance and repair of their cars. Immediately after launch, many media outlets announced the end of the era of service stations, because now it has become possible for everyone to detect and fix a malfunction in a car. Using the application, the user sees a sequential instruction that step by step shows how to diagnose and fix any part and what tools are required for this.

Many manufacturers are aware of the harsh conditions of competitive bidding, where they have to greatly reduce their profits. If you convince the customer to include requirements for the availability of such online help in augmented reality of the supplied goods, the manufacturer will receive a direct competitive advantage and a guarantee of victory.

In any case, until such time as augmented reality turns into a mass phenomenon.

In this article, we would like to draw your attention and talk about the new technology that has already been successfully used in industry and manufacturing around the world.

What is augmented reality?

Paul Milgram and Fumio Kishino in 1994 described augmented reality as a kind of space between reality and virtuality. Augmented reality technology projects any digital information (images, video, text, graphics, etc.) over the screen of any devices.

If you watched the film “Iron Man”, then just all the graphic indicators that were displayed on the helmet's screen and refer to the concept of augmented reality (“augmented reality”).

')

Perhaps it sounds and looks more than fantastic, but such solutions are already being successfully used in many industrial and manufacturing companies, including Russian ones.

Overview of augmented reality devices

Today, among the devices of augmented reality can be identified portable devices, stationary and projection systems, glasses and augmented reality lenses.

Portable devices are the most budget-friendly way to get in touch with augmented reality. These include mobile phones and tablet computers. The main requirement for the device is the availability of high-quality camera with high resolution.

Stationary systems are widescreen screens equipped with high resolution cameras that are located in one place. Such systems are not very convenient in mobile work, but they demonstrate more realistic visualization.

Unlike stationary systems of augmented reality, projection systems superimpose an image on any surface, and their work does not require a separate screen.

The most widely used augmented reality glasses, wearing which a person sees virtual objects superimposed on the surrounding reality. The most famous devices in Russia include Google Glass ($ 1600), as well as Epson's Moverio ($ 799.99).

Lenses for augmented reality are still the subject of research by technology giants, including Samsung, Google and Microsoft. The idea is to turn ordinary lenses into a transparent electronic screen containing a control system, a miniature camera, antenna, LEDs and other optoelectronic components. In particular, Samsung has already filed a patent for “smart” contact lenses, so we have every reason to expect the device to enter the market in the next 5-10 years.

Where is the use of augmented reality?

Existing solutions already cover many areas: tools for automating processes and increasing productivity, training employees, reducing production waste, improving the efficiency of logistics processes, and ensuring occupational safety.

For example, with the help of augmented reality, workers can quickly access instructions and manuals for any detail. They receive information in the form of visual three-dimensional animation, video, audio, photographs, pictures or graphics. This approach allows to reduce the requirements for the qualification of specialists, and reduce the time for studying and viewing work instructions. Moreover, the system itself is able to recognize the shape of the part and its number and promptly tell if the technician has taken erroneous actions to install it.

Issues of the effectiveness of the introduction of augmented reality are covered in great detail in the case study “The effectiveness of augmented reality in the manufacturing industry” (“ Augmented Reality Efficiency in Manufacturing Industry ”), sponsored by Juha Sääski, Tapio Salonen and several other authors (Tapio Salonen) .

A narrower study is “Assessing the benefits of augmented reality for the task of localizing the maintenance of an armored personnel carrier turret” (“ Evaluating the Armored Carrier Turret ”). Its authors are Columbia University staff members Stephen Henderson (Steven J. Henderson) and Stephen Feiner (Steven Feiner). The study will be useful for familiarizing the top managers of industrial and industrial enterprises in order to make a decision on the effectiveness of investing in a new technology.

Both studies are freely available on the Internet.

Consider a few more impressive examples of the use of augmented and virtual reality in industrial and industrial companies.

Aviation industry

Boeing is one of the largest aerospace companies on the planet that builds airplanes for 150 countries. In the onboard systems of the aircraft contains many components interconnected by a system of wires. The cables are laid and connected according to a special template, after which they are fastened into bundles, and connectors are installed on the ends of the cables. The work process takes a long time and requires special attention and responsibility. For the past 20 years, Boeing has been looking for a system that can shorten production time and eliminate errors. In early 2014, the company introduced the solution of augmented reality on the platform of glasses Google Glass. Using the application, the operator gives a voice command: “Ok, Skylight. Start creating a harness. Scan order 0447 ”and see in augmented reality glasses a visual roadmap for assembling harness No. 0447.

According to data from the report of the Boeing company on the project, "the use of Google Glass has reduced the production time by one quarter and reduced the number of errors by half."

Another example is Lockheed Martin, where NGRAIN was involved in implementing the project. Plant engineers use augmented reality to get a visual hint on the assembly of an F-35 aircraft. The company uses Epson Moverio BT-200 augmented reality glasses, equipped with special motion and depth sensors, as the main platform. When a technician mounts a brake part on the chassis, with augmented reality glasses, he sees all the data about where and in what order to assemble and connect the cables. As a result, the whole process of work resembles the assembly of the LEGO designer, when the worker is only required to take a suitable part and place it in the right place.

According to the company NGRAIN , "software allows engineers to work 30 percent faster with an accuracy of up to 96 percent."

Automotive production

Car models are available in various trim levels and colors. Therefore, automakers often seek to find a balance between mass production and individual consumer preferences. Of course, in the days of Henry Ford, everything was much simpler. The organization of such production is often accompanied by complex work instructions that can provoke downtime, errors and reduced productivity.

Concern Fiat Chrysler Automobiles (FCA) has applied in its work a projection system of augmented reality OPS Solutions. Now, at each stage of the assembly process, workers receive visual information about their next step.

After the introduction of innovation was organized experiment. Operators were tasked with assembling gears and chains. The whole process took place in ten consecutive steps. Employees had to choose the right parts, install and make sure everything was done correctly. Some of the operators performed the task using paper instructions, while others used augmented reality tools. The results of the experiment you can evaluate in the table below.

80% error reduction

38% cycle time reduction

82% increase in throughput

Volkswagen concern became another car company which adopted the technology of augmented reality. At its plant in Wolfsburg, Volkswagen uses Google Glasses augmented reality glasses when picking orders. Workers automatically receive all the information they need about storage locations or part numbers.

Assembly electrical production

The first Russian application of augmented reality was released by VR CORP for electrical production. The management of the Energy Saving Technologies of Siberia company faced a staff turnover, as a result of which a lot of money and efforts were spent on training newly arrived employees. An office application was created for office personnel, with the help of which any employee could point a smartphone at an electrical circuit and examine in detail the 3D model of the finished product, including all its components. Especially this application is important for young professionals without experience. The introductory specialty course was reduced to a simple scheme: he took a smartphone, launched an application, turned on an electrical circuit and reviewed all the details about the product in its finished form.

A similar application in functionality was developed for the assembly workshop workers. Instead of the wiring diagram, a specialist receives information on the placement of parts and cables in a future product, and highlighting every detail warns in time if the wrong components are used.

For its development, VR CORP received a diploma of the City Technologies Forum from the Department of Industry, Innovation and Entrepreneurship of the Novosibirsk City Hall.

The introduction of augmented reality in their own company

Augmented reality technology offers a new interesting look at solving tasks for staff turnover, training, production errors and downtime. It is not always clear what to start with, what costs it will require and how soon the investment will return.

Start small. There are not so many companies working with augmented reality for production and industry in the Russian market, and yet there is a choice. Here are our recommendations:

1. Contact the developer’s representatives and tell in detail about the tasks you are facing.

2. Create a working group together for detailed analysis and solution development.

3. Do not strive to immediately grasp the immensity. Choose one of the small stages of the production process and develop a test solution for it. According to the estimates of the Russian developer of solutions for augmented reality of the company VR CORP, the cost of such a solution ranges from 50,000 to 100,000 rubles.

4. Compare the performance indicators of workers using augmented reality and those who work in the old manner.

5. Based on the indicators, evaluate the investment attractiveness of the complex project.

6. If project indicators please you, agree on its budget and implementation stages.

7. Start to work.

Commercial opportunities

In competition, many enterprises offer identical goods and therefore strive to win mainly due to lower prices. Such a competitive strategy creates difficult conditions in which the profit on transactions ranges from 3 to 7%.

Augmented reality can serve not only for the needs of our own production, but also to create a product with unique properties. Many products require some effort from the user in order to understand and use it. For example, electrical panels, generators, cars and furniture from IKEA. With the help of augmented reality, the manufacturer can add online help for the user, which he can use with his tablet or phone. This help will clearly show how to use the product, eliminate many errors and generally improve customer satisfaction.

BMW has already launched a similar solution for the maintenance and repair of their cars. Immediately after launch, many media outlets announced the end of the era of service stations, because now it has become possible for everyone to detect and fix a malfunction in a car. Using the application, the user sees a sequential instruction that step by step shows how to diagnose and fix any part and what tools are required for this.

Many manufacturers are aware of the harsh conditions of competitive bidding, where they have to greatly reduce their profits. If you convince the customer to include requirements for the availability of such online help in augmented reality of the supplied goods, the manufacturer will receive a direct competitive advantage and a guarantee of victory.

In any case, until such time as augmented reality turns into a mass phenomenon.

Source: https://habr.com/ru/post/324150/

All Articles