Kanban in engineering product management

On the Internet, a huge amount of information on project management in the IT-sphere and much less information about the practice of applying the design approach to the development of products in mechanical engineering.

This article will be of interest to specialists who are engaged in managing the development of new products in the field of mechanical engineering and metalworking. The tool that I propose to use is kanban on the foundation of priorities.

When I first came to the company to work as a project manager (and this happened almost a year and a half ago), the director and the chief engineer sat me at the big negotiating table and said: we have many projects and a lot of preparatory work has been done on them; as they say:

- Pour, yes drink!

')

The director is a high-flying person, so all projects were given high priority. A high priority involves, of course, take on everything at once. But this does not happen in conditions of limited resources. For about a year, the projects were brought to life: yes, all for a little bit. As a result, only one big and good product appeared during the year.

And so I began to dig, what tasks need to be solved before in order to effectively manage projects.

The first important problem is the lack of stated goals. If there are no goals, then further planning can not even deal with.

Any activity begins with goal setting. Any company must have a goal. Based on the goals, the priorities of the projects are set. The development vector, and accordingly the company's goals, is formulated by the company's management. The first thing that needed to be done was to set the director and the chief engineer at the negotiating table in order to determine the goals. And here I, the director and the chief engineer for a couple of meetings prioritized projects.

At the end of February, work was completed on a project roadmap, in which each project was given importance. The importance is indicated by a number from 1 to 100. The larger the number, the more priority the project. This roadmap guides each team member in their daily activities. If there is a choice to do a task with the importance of 95 or with the importance of 89, then the task with the importance of 95 is executed first. Everything is quite transparent and understandable.

After that, it became possible to start launching projects based on priorities, rather than blindly.

The second important problem is limited resources.

In our company, about 30 projects of varying complexity (from typical with standard solutions to non-trivial, requiring the search for non-standard solutions) are permanently in development. The project team consists of two design engineers, a technologist, a supplier, a designer, a marketing specialist, machine tool operators, a production manager, a technical writer (8-9 people in total). Thus, naturally there is a conflict of resources both within projects, and between projects and operational activities. It is worth noting that the production of serial products (the so-called production) has the highest priority, since it is he who brings money to the company.

I analyzed the solutions: how to manage the resources? Almost all the material on the Internet referred to the experience of IT-companies in the field of project management. Having studied the information about agile, scrum, kanban, the classic method of project management and the experience of manufacturing companies that was openly available, for me the realities of our production seemed to be the most appropriate kanban (hereinafter referred to as "kanban"). Soon, a magnetic board measuring 1.8 mx 1 m was acquired, which turned into a kanban board. In addition, the kanban board also solved the task of visualizing project activities.

The third important issue is visualization and visibility.

By the time we started introducing kanban principles, we already used a powerful planning tool - this is Elma's business process management system. However, unfortunately, everything is not so clear in it and the overall picture of the projects is not visible. The kanban board is a very convenient tool in its visualization.

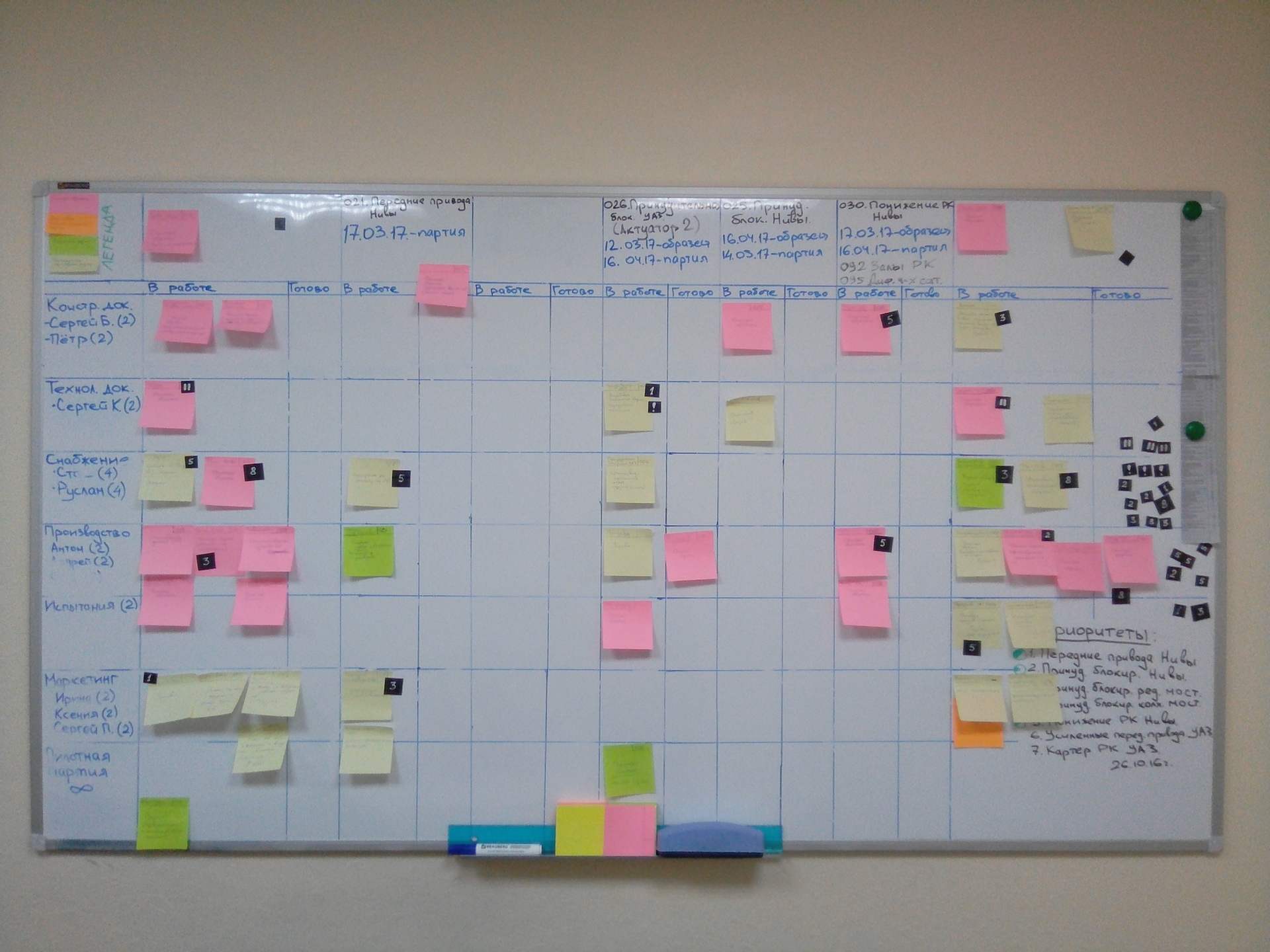

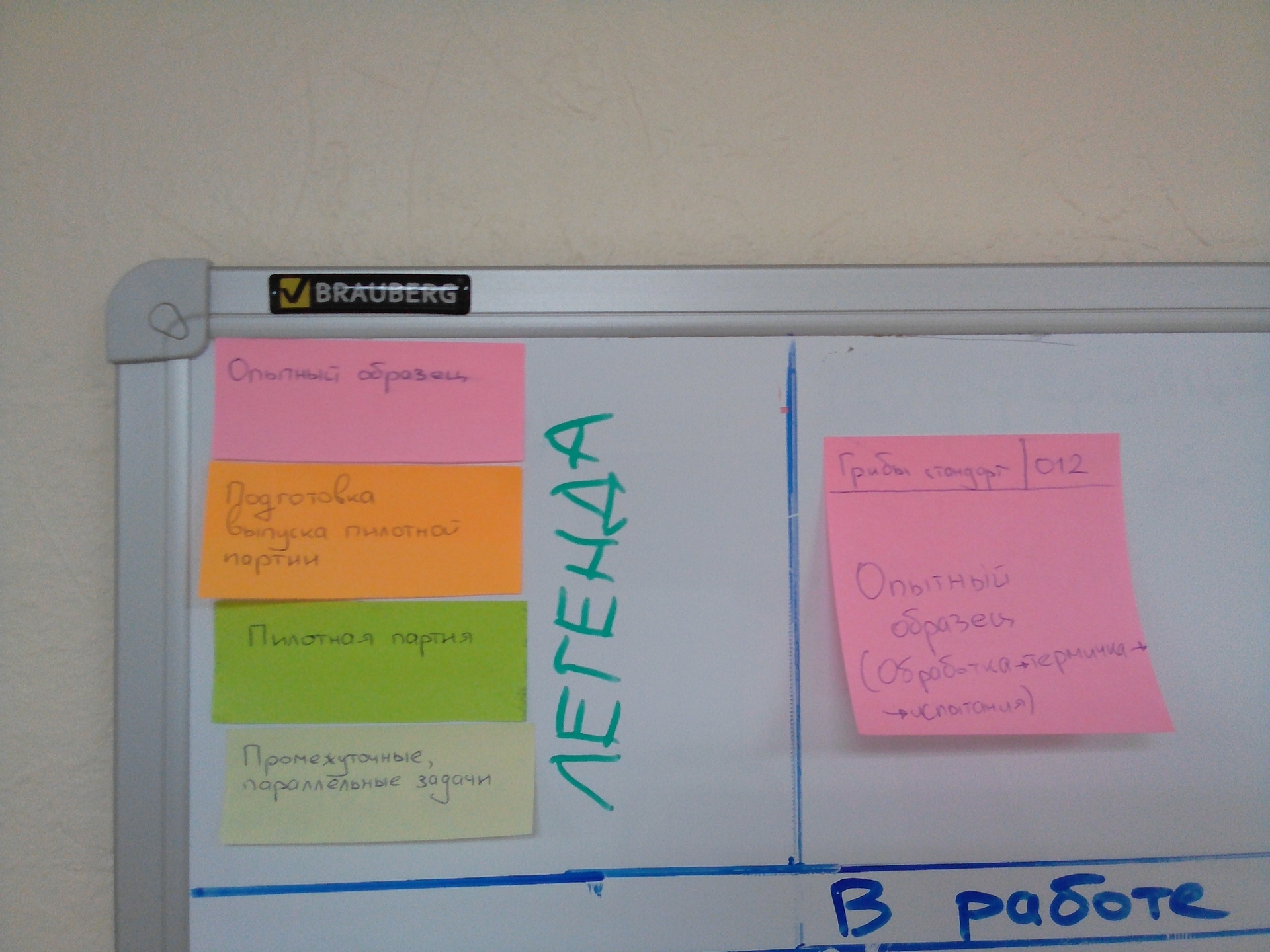

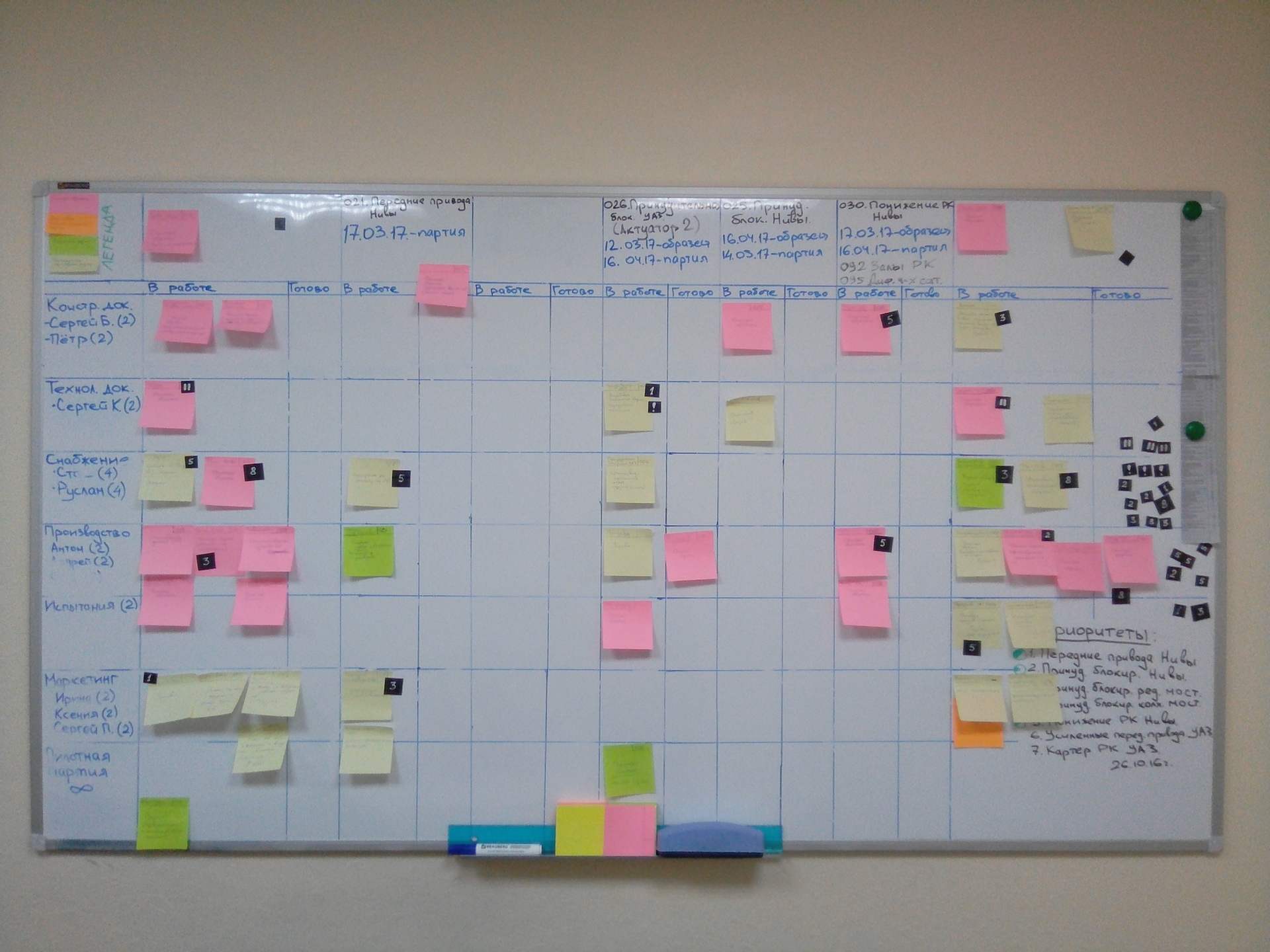

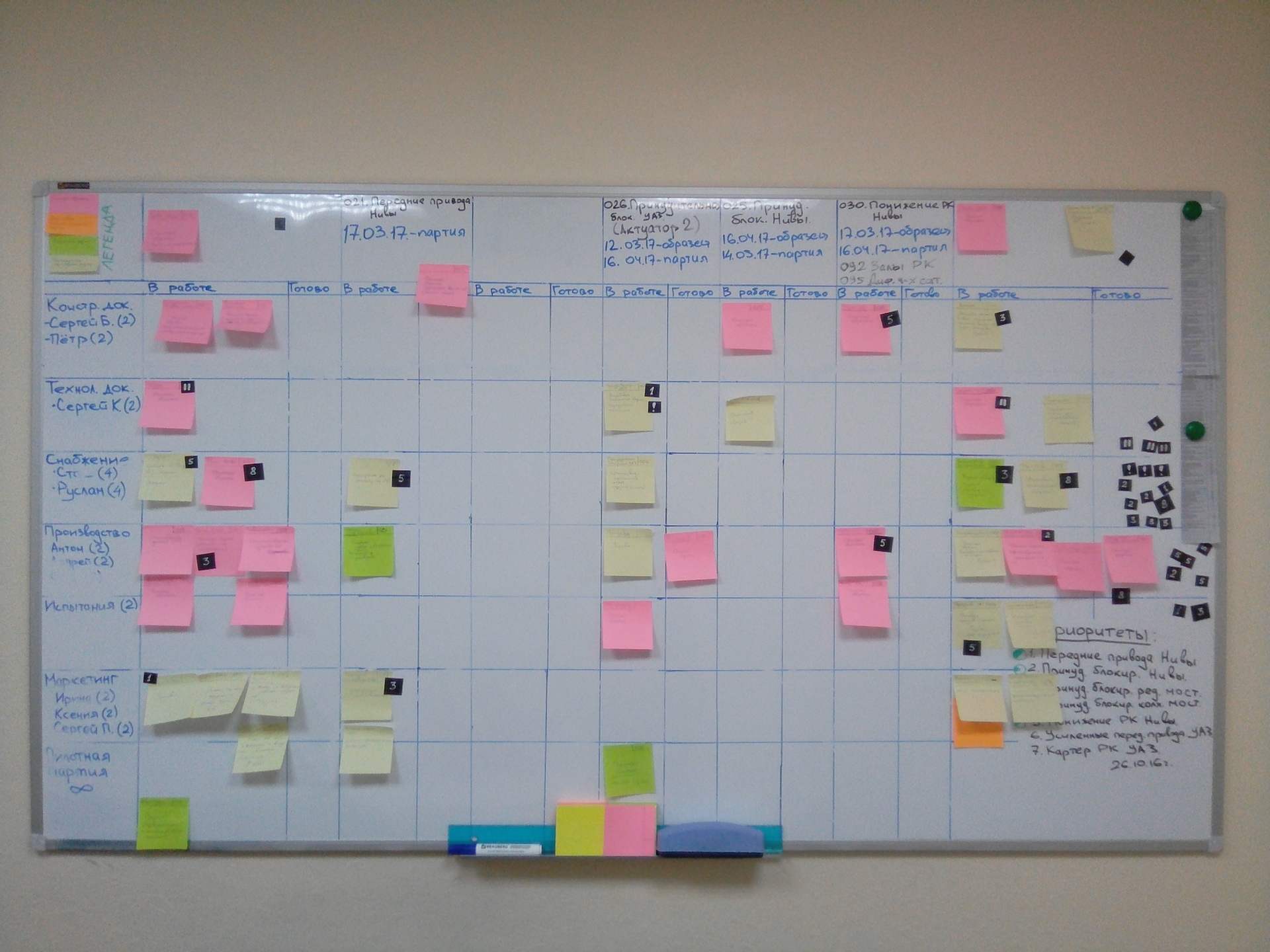

Below is a brief summary of how the work with the kanban board is organized in our enterprise.

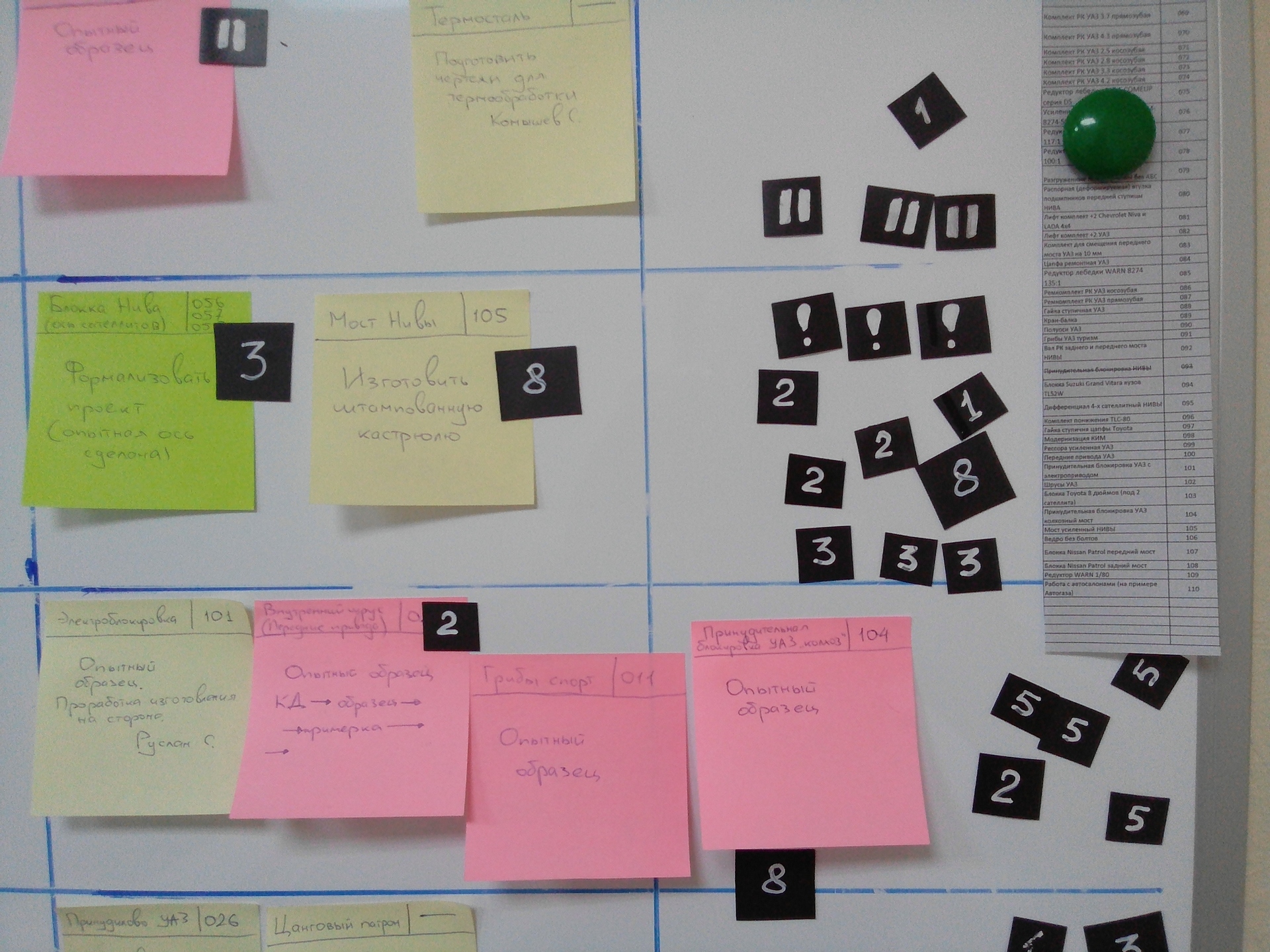

Board lined horizontally by resources. The number in brackets opposite the name indicates the number of tasks that can be simultaneously performed by one person (resource). Vertical columns highlighted the main projects. There is also a general column for projects of lower priority at this stage.

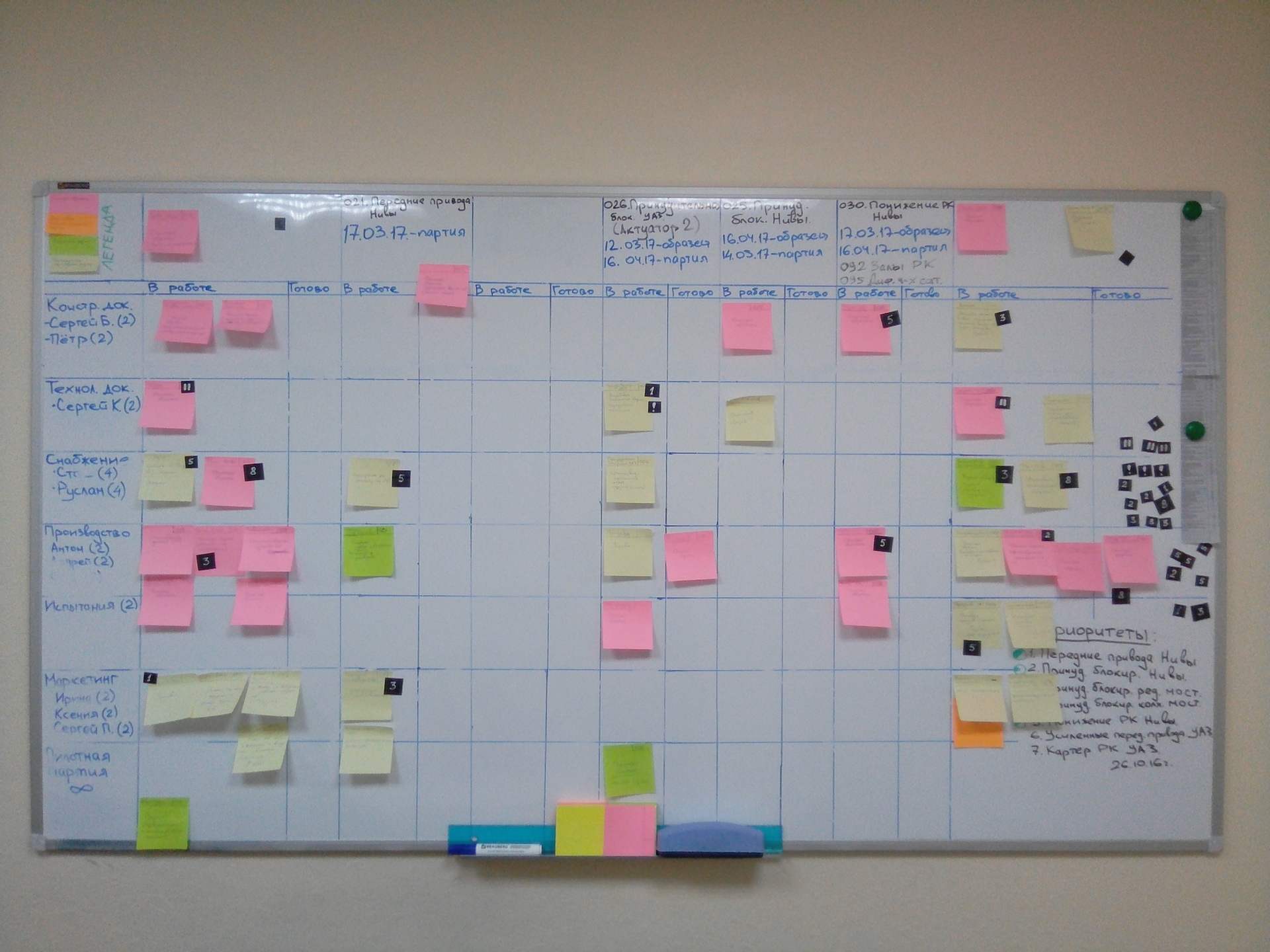

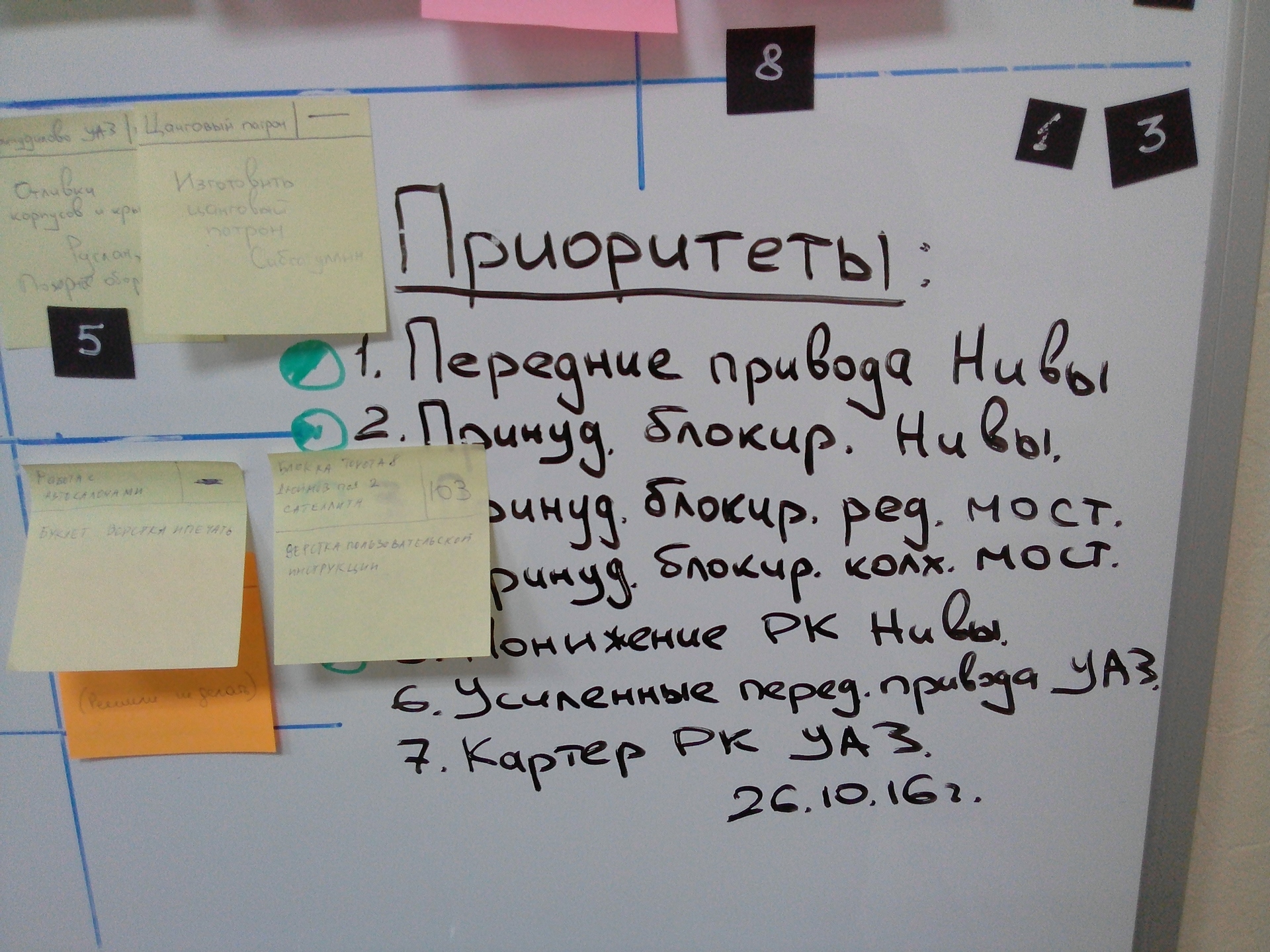

In the lower right corner priority projects are written from the highest to the lowest:

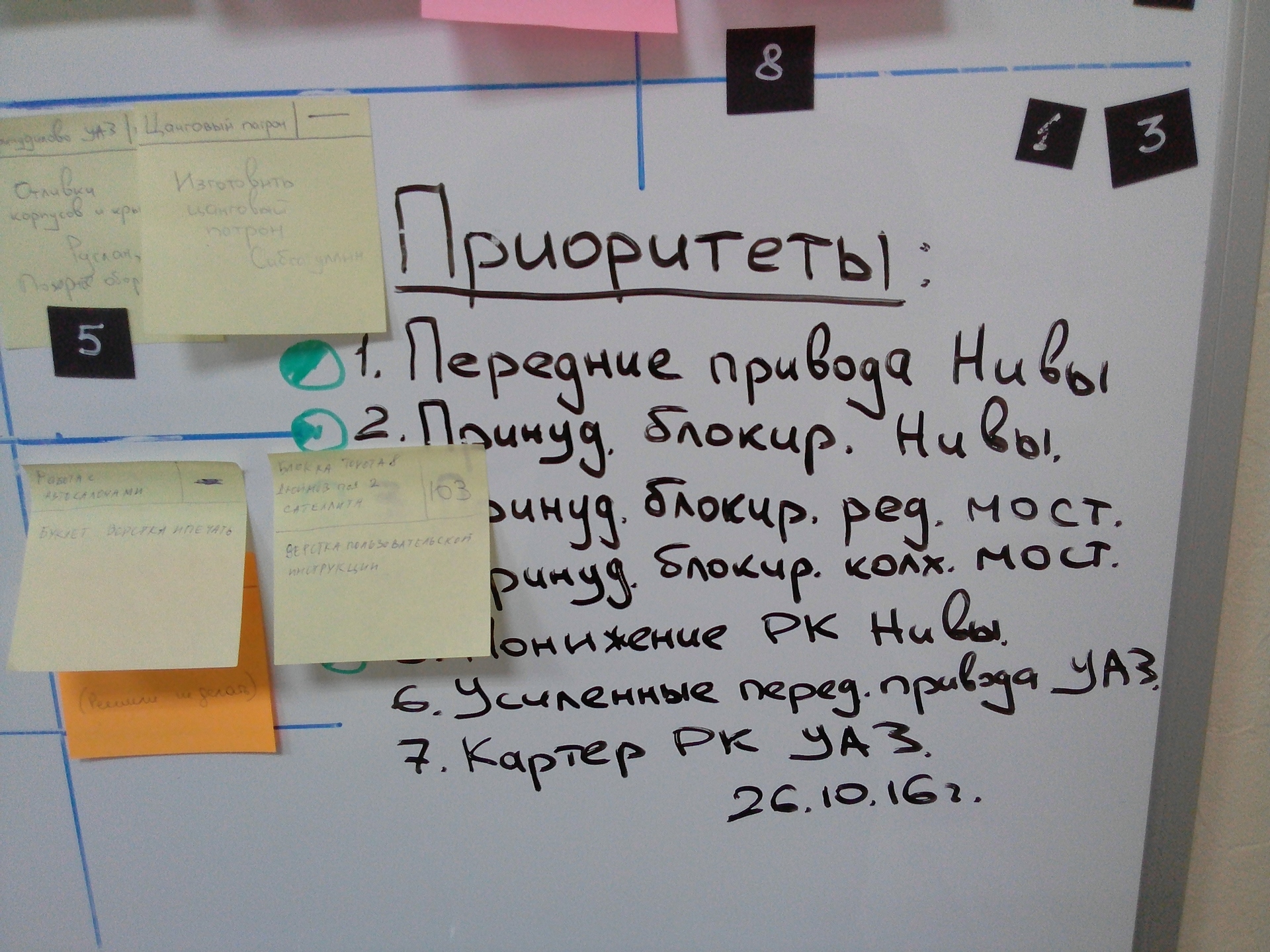

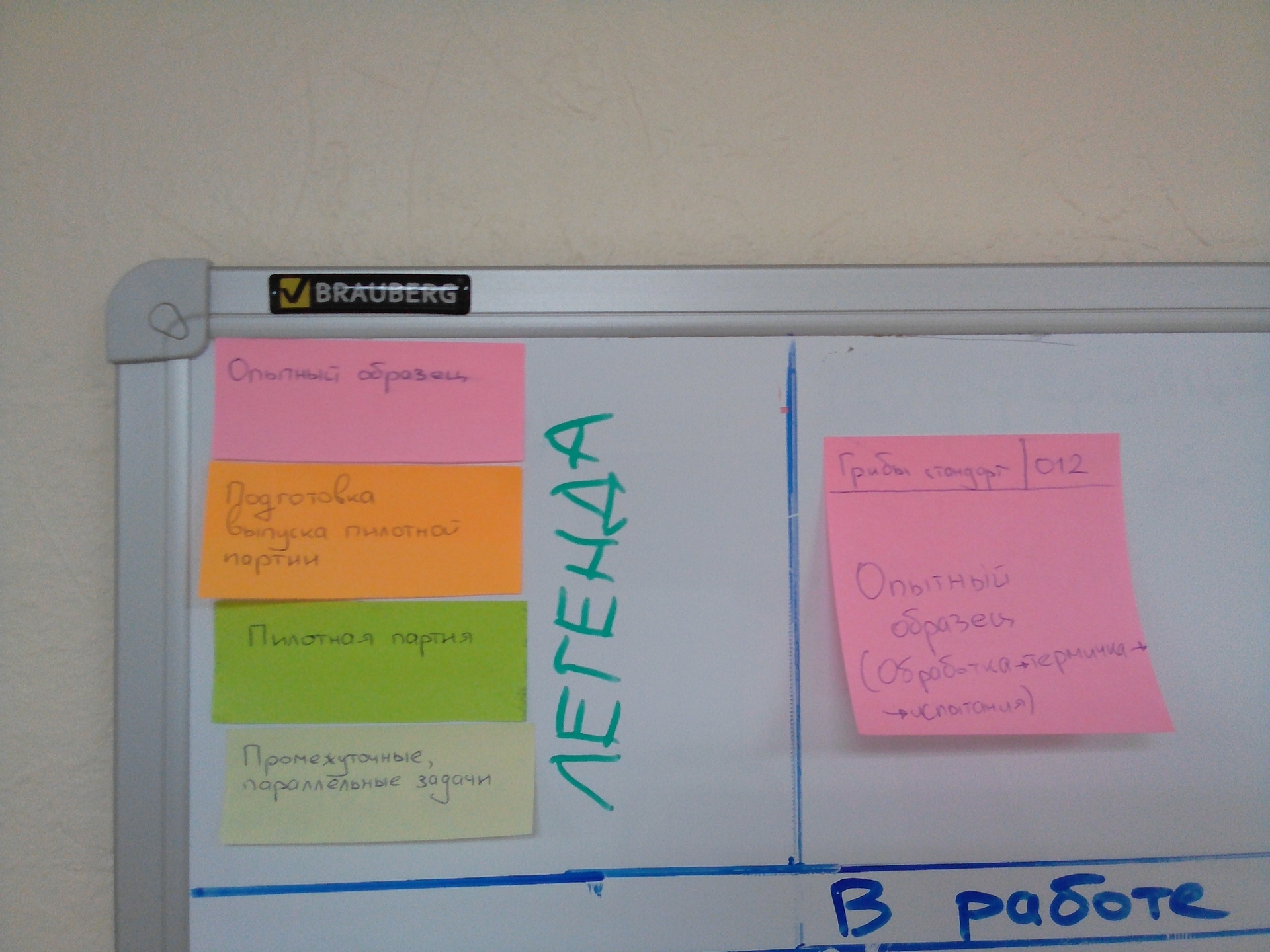

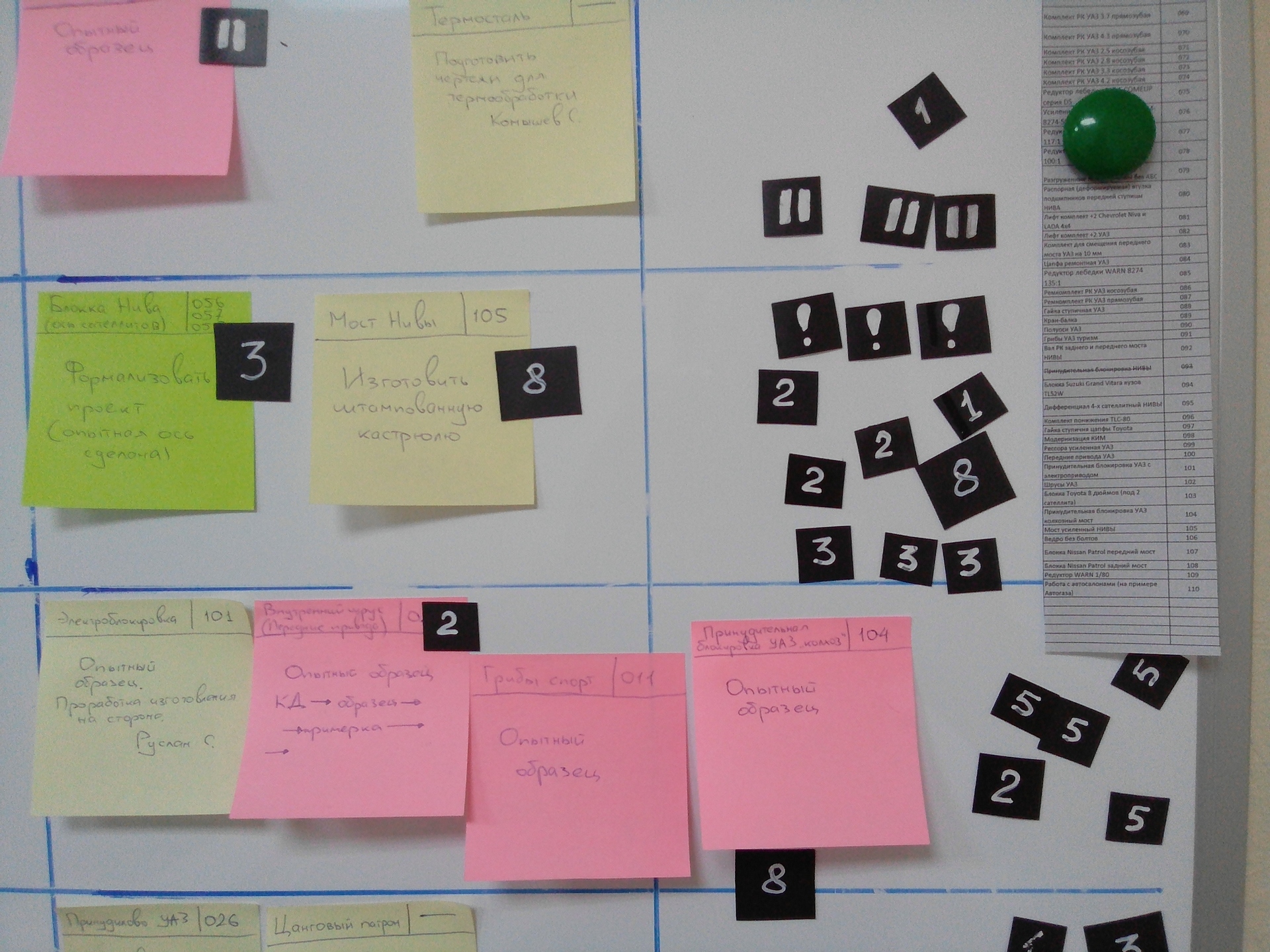

At the first stage of the implementation of the kanban board, the tasks were indicated only by stickers with color differentiation. Our projects are divided into three stages (checkpoints):

- the release of a prototype (pink sticker);

- preparation of the pilot batch release (orange sticker);

- release of a pilot batch and completion of the project (green sticker).

Also, pale yellow highlights intermediate tasks for which additional control is required.

The legend is displayed in the upper left corner of the board:

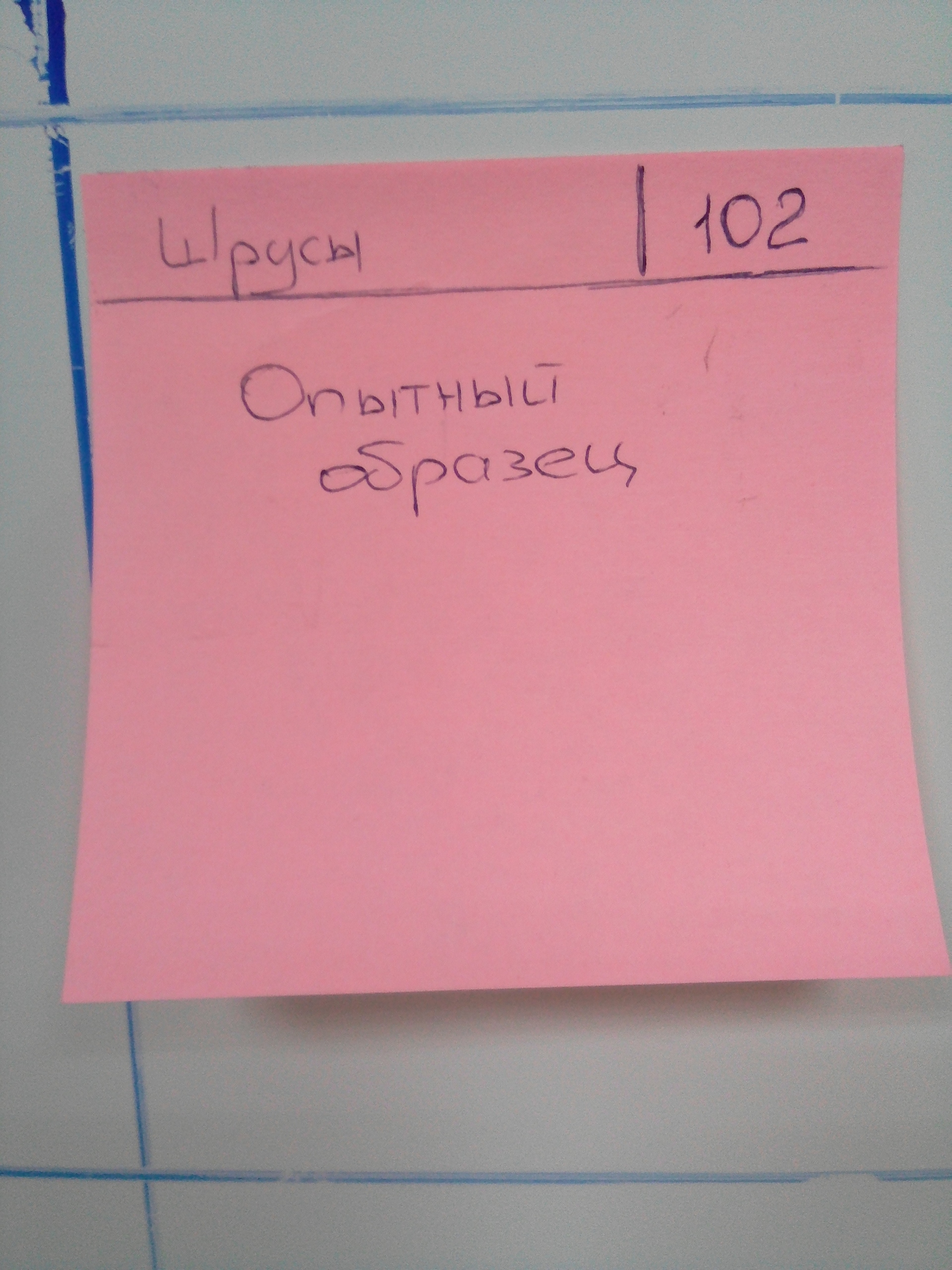

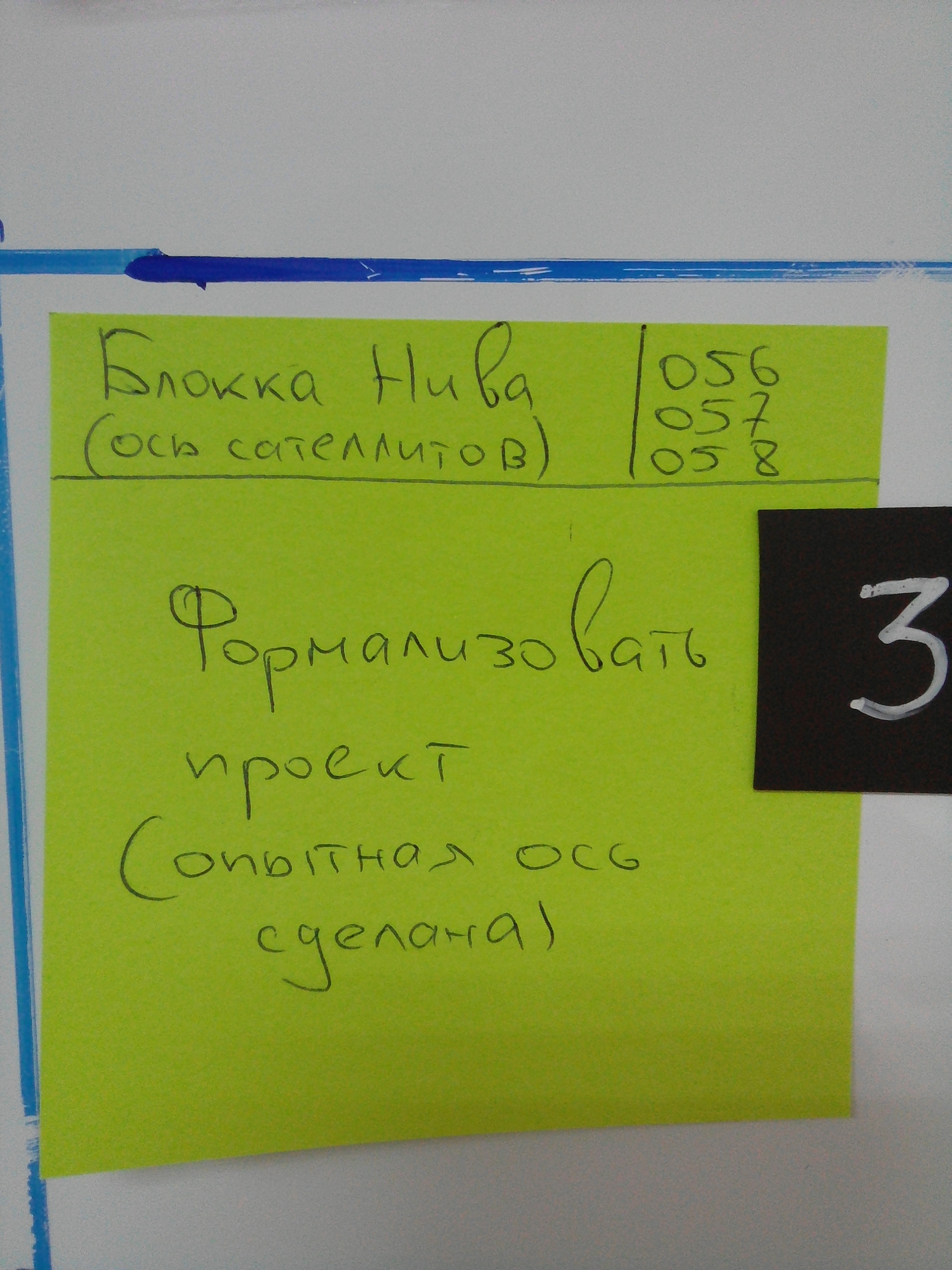

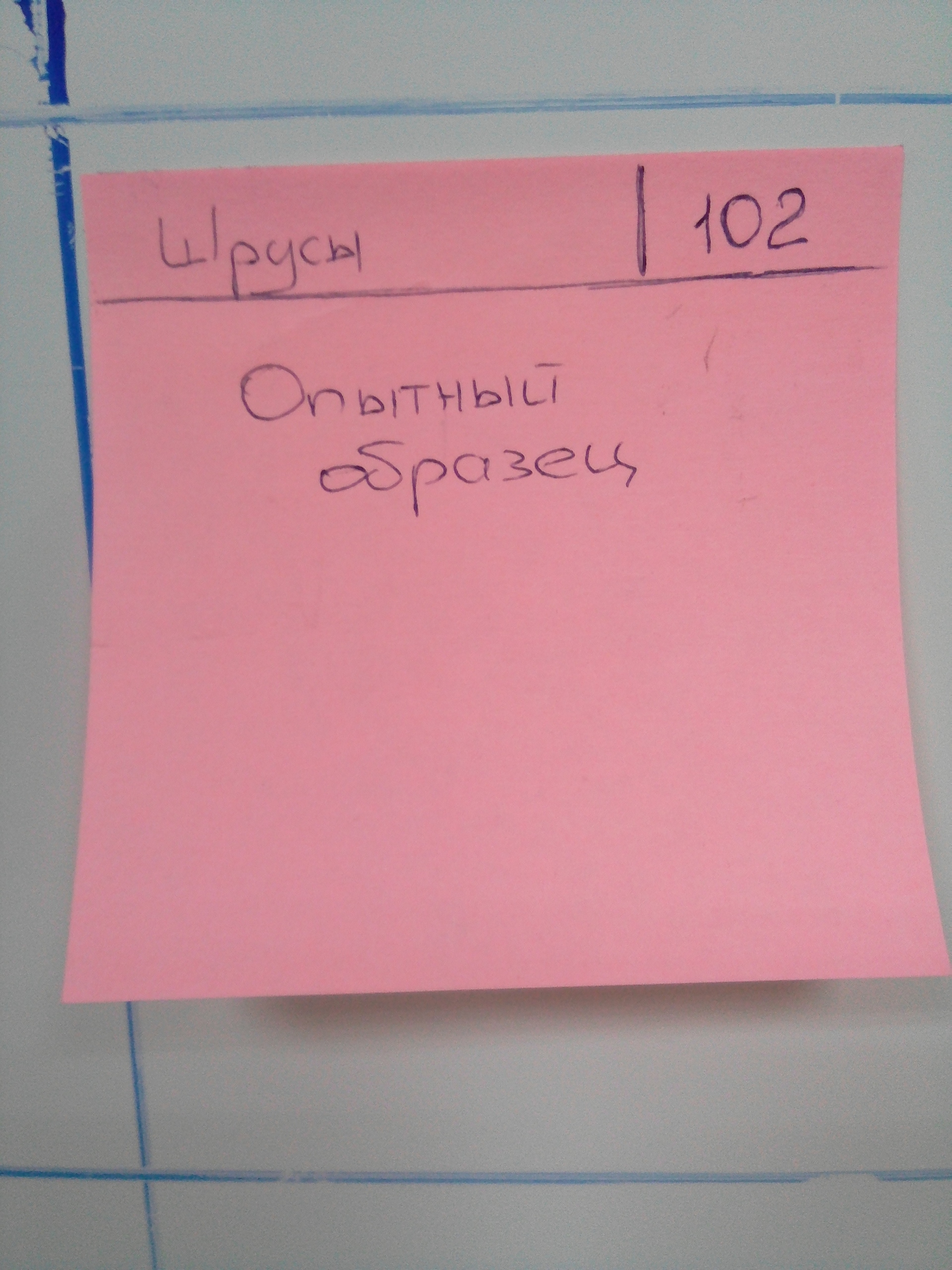

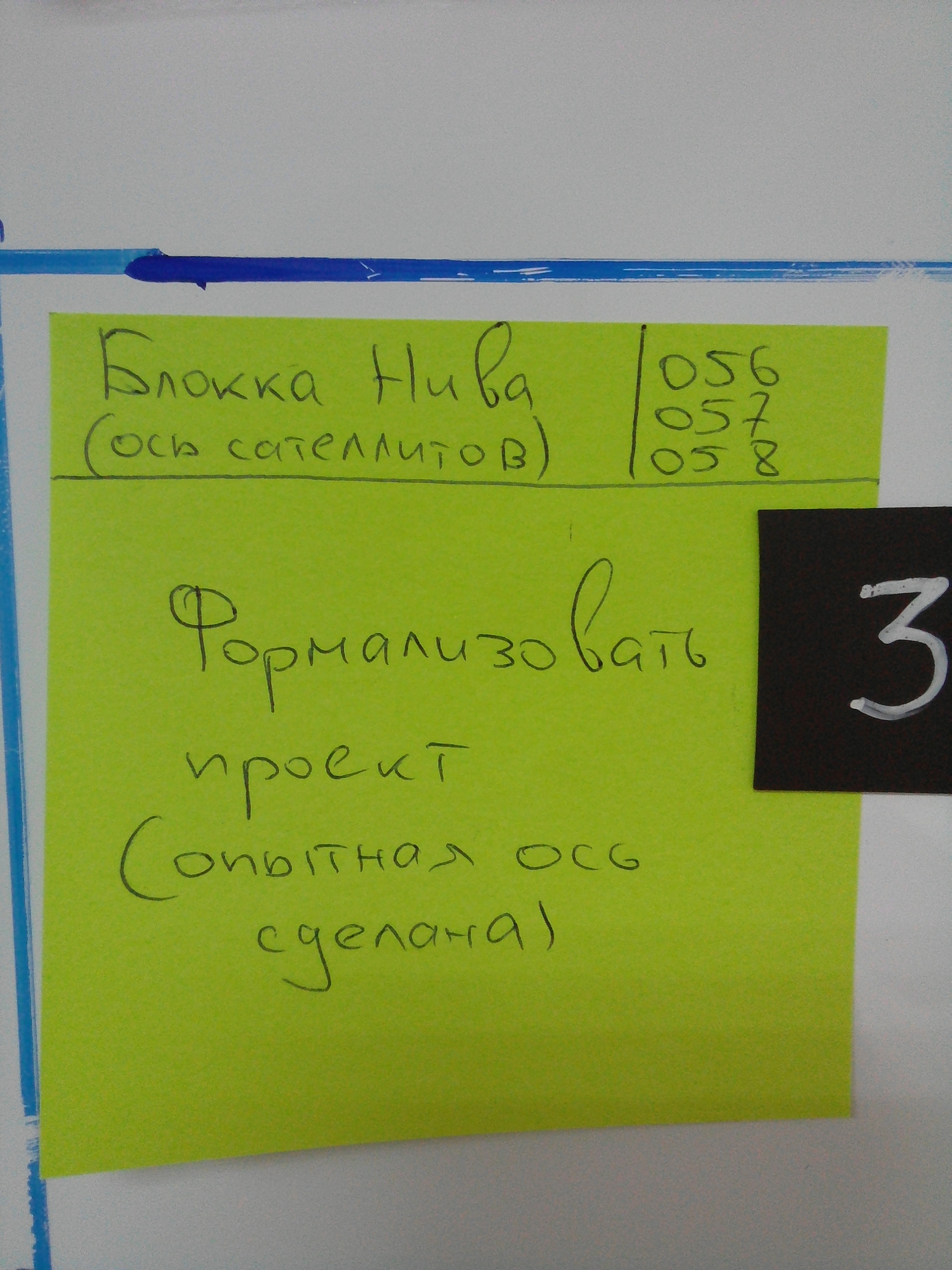

The sticker also has its own structure. The sticker displays the short name of the project, its number and a brief summary of the task. The content also, if necessary, specify the deadlines for completing the task and the most important information:

Compliance with the project number posted on the right of the board.

Every working day at 10.00, we and the team gather at the bat at the kanban board, where everyone answers three questions:

- What has been done for the last day?

- What problems have arisen?

- What is planned for the coming day?

On the fly, solutions to problems and problems are not discussed, but only voiced problems; discuss the problem is proposed separately after the fly or in working order. Thus, firstly, the team is synchronized and it is always clear to everyone what is happening on the projects, and secondly, the human brain wakes up and turns on the work. In general, I even noticed on myself that my activity after the flyers is increasing. At the same time, fly is a tool for quick response and flexibility.

This model was borrowed from scrum:

For issues that require lengthy and thorough discussion, we allocate a separate time at the project meetings; it passes every Wednesday.

At some point it became clear that there are still a lot of stickers for quick orientation. I suggested each sticker to be numbered 1, 2, 3, 5, 8 (Fibonacci numbers, which are also often used to estimate the complexity and / or duration of a task in a project activity). Each number indicates the number of days it will take to complete a task. The status of the figures is updated directly by the executor of the task. Thus, at the flyers, you can quickly assess what tasks you need to ask today from the performer. If this number is 5 or 8, then the task is still in the work and it is not required to discuss it at the moment. If it is 1 or 2, then I ask the team member to tell about the status of the task, since according to the plan it is necessary to close it and pass on to the next stage.

The numbers are marked with a white corrective pencil on a flexible magnet. There are also magnets with the symbol "!" (attention, urgent, important, pay attention) and "||" (pause, task suspended):

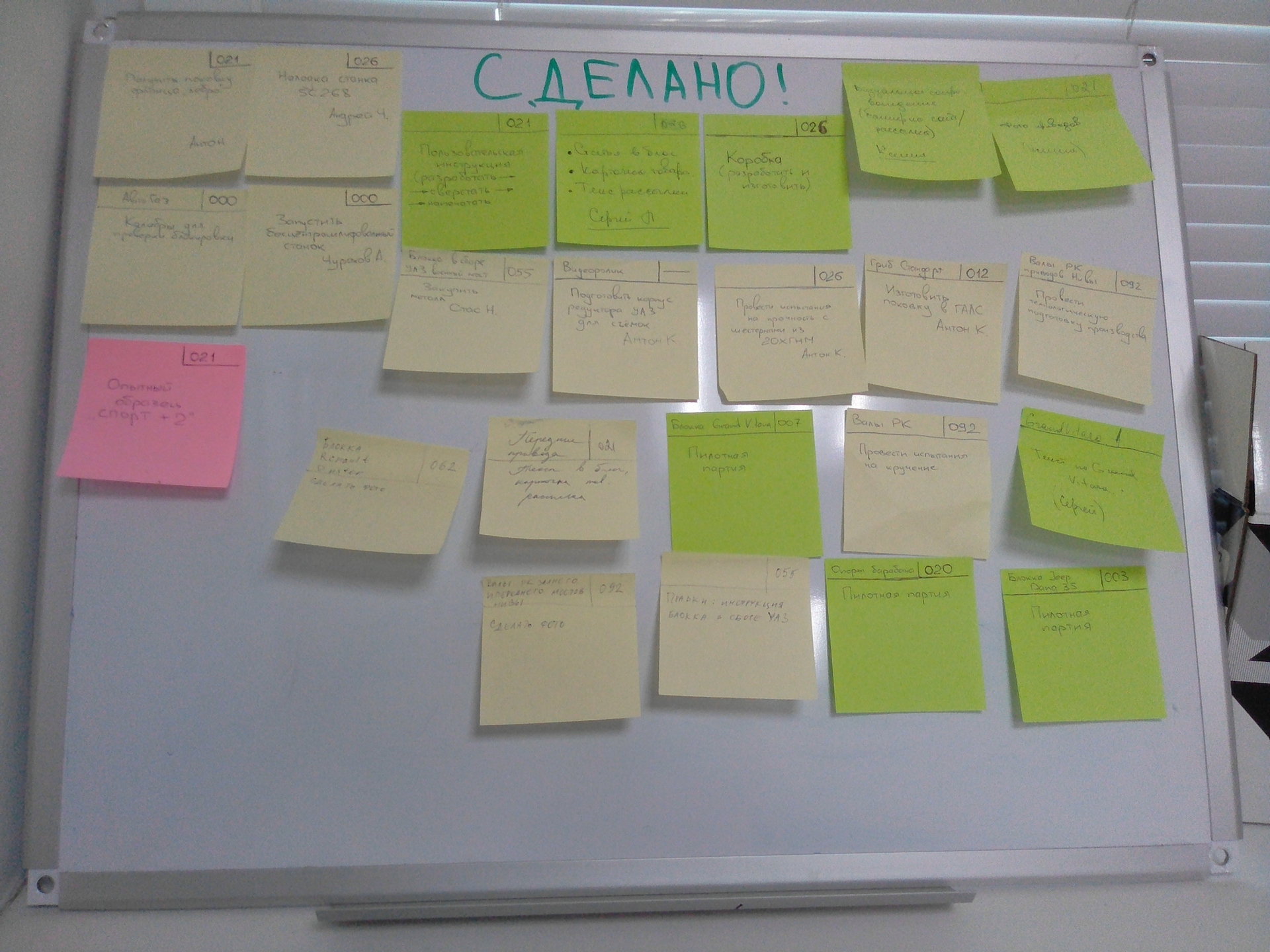

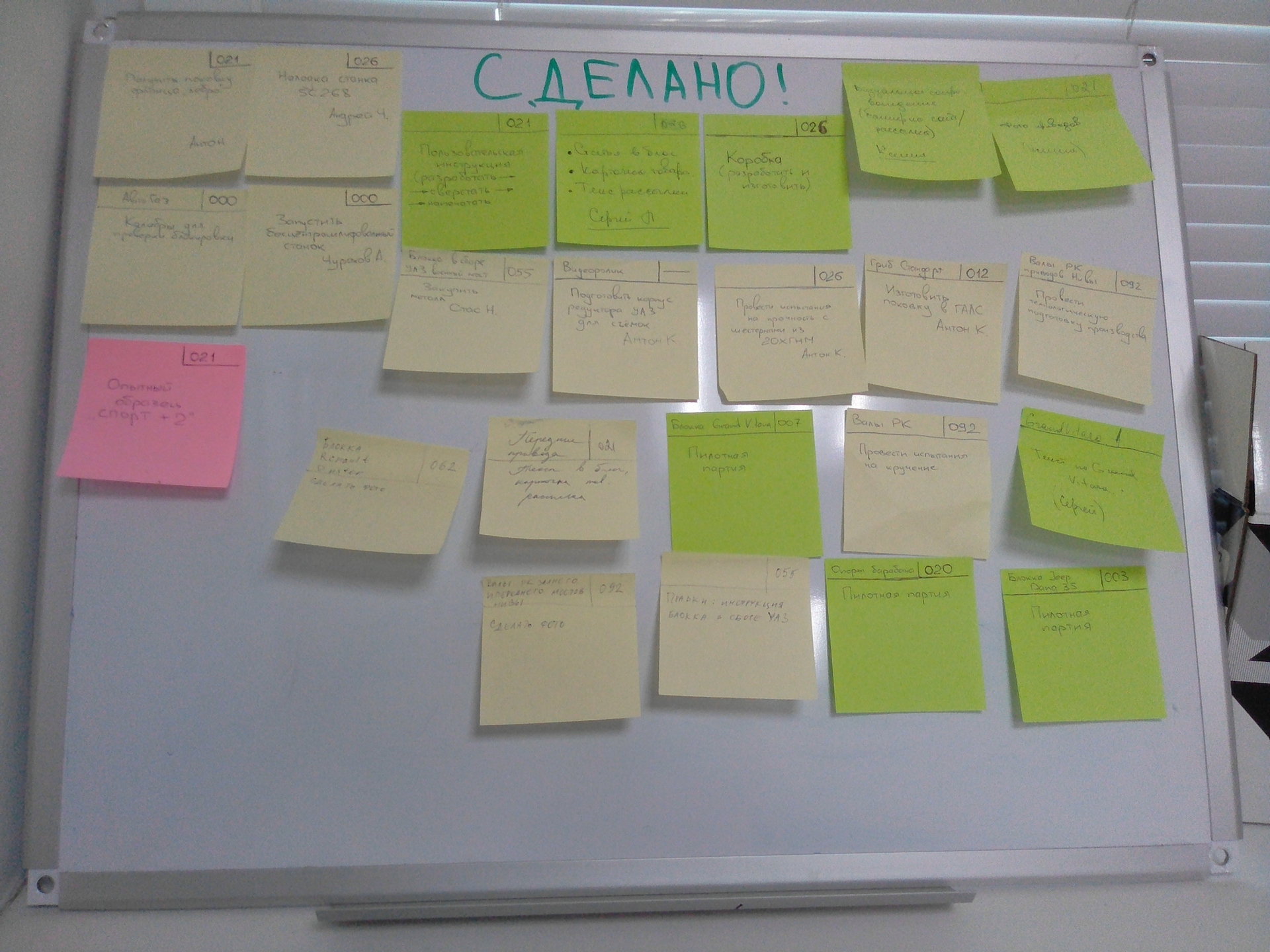

Sticker with the completed task is moved to the column is ready. This means that the task can be transferred to the next performer.

Completed tasks are moved from the kanban board to a small window board so that you can always track the progress of the team.

Speaking about the effectiveness of this approach, it can be noted that in the first quarter of 2017, two large and complex projects and several small model projects were closed.

As they say at Toyota, Kanban is a tweaking tool. So here we are setting up continuously and more improvements will be made for convenient and efficient work.

This article will be of interest to specialists who are engaged in managing the development of new products in the field of mechanical engineering and metalworking. The tool that I propose to use is kanban on the foundation of priorities.

When I first came to the company to work as a project manager (and this happened almost a year and a half ago), the director and the chief engineer sat me at the big negotiating table and said: we have many projects and a lot of preparatory work has been done on them; as they say:

- Pour, yes drink!

')

The director is a high-flying person, so all projects were given high priority. A high priority involves, of course, take on everything at once. But this does not happen in conditions of limited resources. For about a year, the projects were brought to life: yes, all for a little bit. As a result, only one big and good product appeared during the year.

And so I began to dig, what tasks need to be solved before in order to effectively manage projects.

Problem number 1: Formulate goals

The first important problem is the lack of stated goals. If there are no goals, then further planning can not even deal with.

Any activity begins with goal setting. Any company must have a goal. Based on the goals, the priorities of the projects are set. The development vector, and accordingly the company's goals, is formulated by the company's management. The first thing that needed to be done was to set the director and the chief engineer at the negotiating table in order to determine the goals. And here I, the director and the chief engineer for a couple of meetings prioritized projects.

At the end of February, work was completed on a project roadmap, in which each project was given importance. The importance is indicated by a number from 1 to 100. The larger the number, the more priority the project. This roadmap guides each team member in their daily activities. If there is a choice to do a task with the importance of 95 or with the importance of 89, then the task with the importance of 95 is executed first. Everything is quite transparent and understandable.

After that, it became possible to start launching projects based on priorities, rather than blindly.

Task 2: Manage Limited Resources

The second important problem is limited resources.

In our company, about 30 projects of varying complexity (from typical with standard solutions to non-trivial, requiring the search for non-standard solutions) are permanently in development. The project team consists of two design engineers, a technologist, a supplier, a designer, a marketing specialist, machine tool operators, a production manager, a technical writer (8-9 people in total). Thus, naturally there is a conflict of resources both within projects, and between projects and operational activities. It is worth noting that the production of serial products (the so-called production) has the highest priority, since it is he who brings money to the company.

I analyzed the solutions: how to manage the resources? Almost all the material on the Internet referred to the experience of IT-companies in the field of project management. Having studied the information about agile, scrum, kanban, the classic method of project management and the experience of manufacturing companies that was openly available, for me the realities of our production seemed to be the most appropriate kanban (hereinafter referred to as "kanban"). Soon, a magnetic board measuring 1.8 mx 1 m was acquired, which turned into a kanban board. In addition, the kanban board also solved the task of visualizing project activities.

Task number 3: Visualize project activities

The third important issue is visualization and visibility.

By the time we started introducing kanban principles, we already used a powerful planning tool - this is Elma's business process management system. However, unfortunately, everything is not so clear in it and the overall picture of the projects is not visible. The kanban board is a very convenient tool in its visualization.

How is the kanban board implemented?

Below is a brief summary of how the work with the kanban board is organized in our enterprise.

Board lined horizontally by resources. The number in brackets opposite the name indicates the number of tasks that can be simultaneously performed by one person (resource). Vertical columns highlighted the main projects. There is also a general column for projects of lower priority at this stage.

In the lower right corner priority projects are written from the highest to the lowest:

At the first stage of the implementation of the kanban board, the tasks were indicated only by stickers with color differentiation. Our projects are divided into three stages (checkpoints):

- the release of a prototype (pink sticker);

- preparation of the pilot batch release (orange sticker);

- release of a pilot batch and completion of the project (green sticker).

Also, pale yellow highlights intermediate tasks for which additional control is required.

The legend is displayed in the upper left corner of the board:

The sticker also has its own structure. The sticker displays the short name of the project, its number and a brief summary of the task. The content also, if necessary, specify the deadlines for completing the task and the most important information:

Compliance with the project number posted on the right of the board.

Every working day at 10.00, we and the team gather at the bat at the kanban board, where everyone answers three questions:

- What has been done for the last day?

- What problems have arisen?

- What is planned for the coming day?

On the fly, solutions to problems and problems are not discussed, but only voiced problems; discuss the problem is proposed separately after the fly or in working order. Thus, firstly, the team is synchronized and it is always clear to everyone what is happening on the projects, and secondly, the human brain wakes up and turns on the work. In general, I even noticed on myself that my activity after the flyers is increasing. At the same time, fly is a tool for quick response and flexibility.

This model was borrowed from scrum:

For issues that require lengthy and thorough discussion, we allocate a separate time at the project meetings; it passes every Wednesday.

At some point it became clear that there are still a lot of stickers for quick orientation. I suggested each sticker to be numbered 1, 2, 3, 5, 8 (Fibonacci numbers, which are also often used to estimate the complexity and / or duration of a task in a project activity). Each number indicates the number of days it will take to complete a task. The status of the figures is updated directly by the executor of the task. Thus, at the flyers, you can quickly assess what tasks you need to ask today from the performer. If this number is 5 or 8, then the task is still in the work and it is not required to discuss it at the moment. If it is 1 or 2, then I ask the team member to tell about the status of the task, since according to the plan it is necessary to close it and pass on to the next stage.

The numbers are marked with a white corrective pencil on a flexible magnet. There are also magnets with the symbol "!" (attention, urgent, important, pay attention) and "||" (pause, task suspended):

Sticker with the completed task is moved to the column is ready. This means that the task can be transferred to the next performer.

Completed tasks are moved from the kanban board to a small window board so that you can always track the progress of the team.

Speaking about the effectiveness of this approach, it can be noted that in the first quarter of 2017, two large and complex projects and several small model projects were closed.

As they say at Toyota, Kanban is a tweaking tool. So here we are setting up continuously and more improvements will be made for convenient and efficient work.

Source: https://habr.com/ru/post/323940/

All Articles