Dynamic UPS: the story of an engineering upgrade is very much in the spirit of the times

Now I will tell about the evolution of the device, originally intended to provide power to military data centers around the world. Here is this:

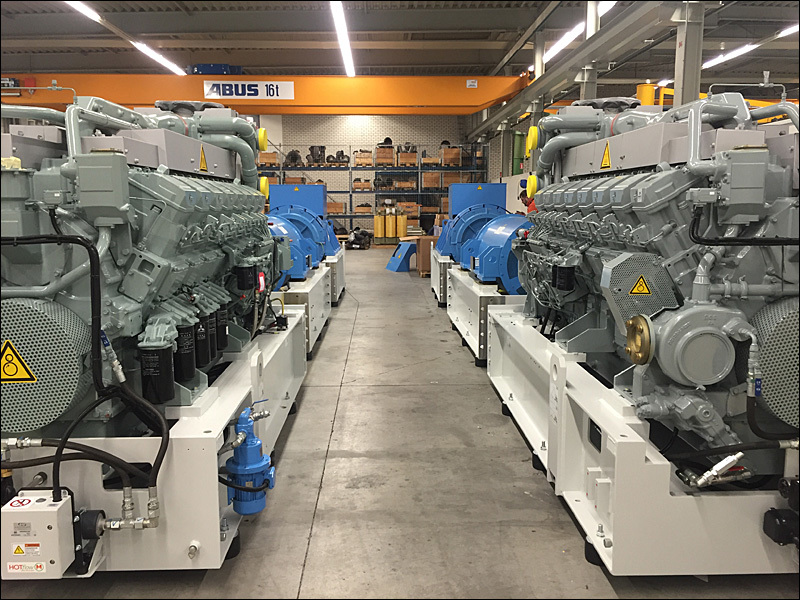

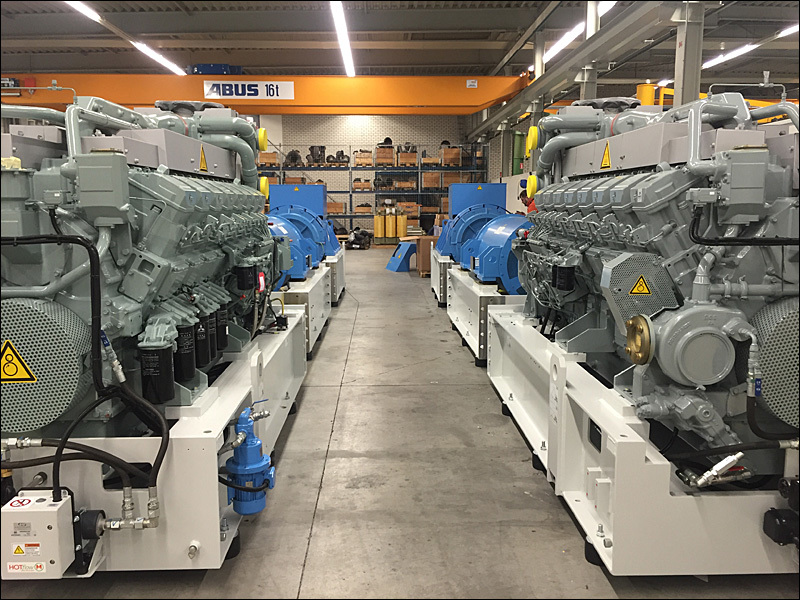

The new generation, "armored train" in the jargon. On the right, our old dream is a grid so that rats do not suck.

The technology was born around the same period as the nuclear bomb, so it is simple and straightforward, like a Kalashnikov assault rifle. We take a huge iron top, spin the electric motor. After overcoming the inertia of rest, the heavy piece of iron turns almost without friction. The power is cut off - the piece of iron starts to turn the electric motor itself, which started it, and thereby converts its kinetic energy into electrical energy for some time, until it stops. During this time, the diesel has time to start.

')

The old Soviet DDIBP, which stood on Baikonur, are not fundamentally different from their modern counterparts. The same top, the same diesel engines. But there are lots of useful nuances. We'll talk about them and how such “cool” iron evolves at all.

Previous generation

DDBP consists of three main parts:

The history of DDIBP began with small capacities. Over the years, capacities grew, dimensions increased, difficulties with transportation appeared. The manufacturer began to work out the technology of transporting DDIBP, and the machines began to be divided into modules.

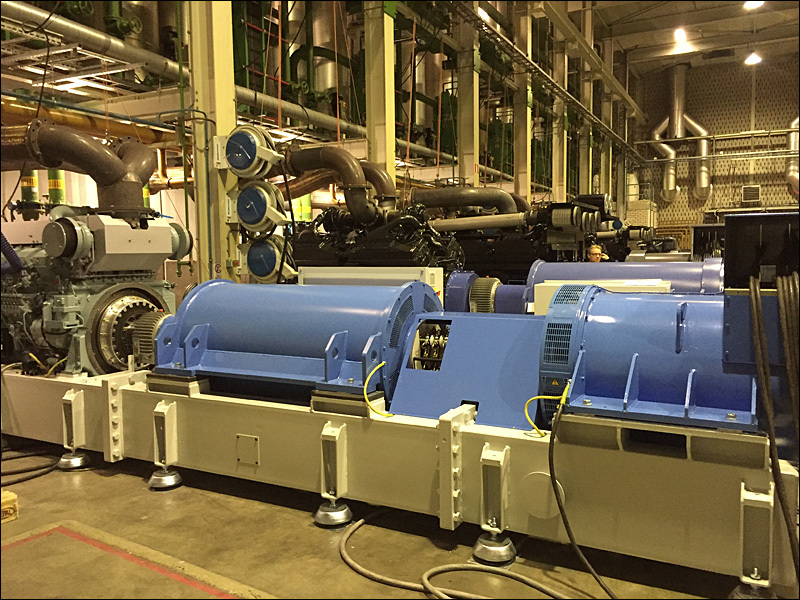

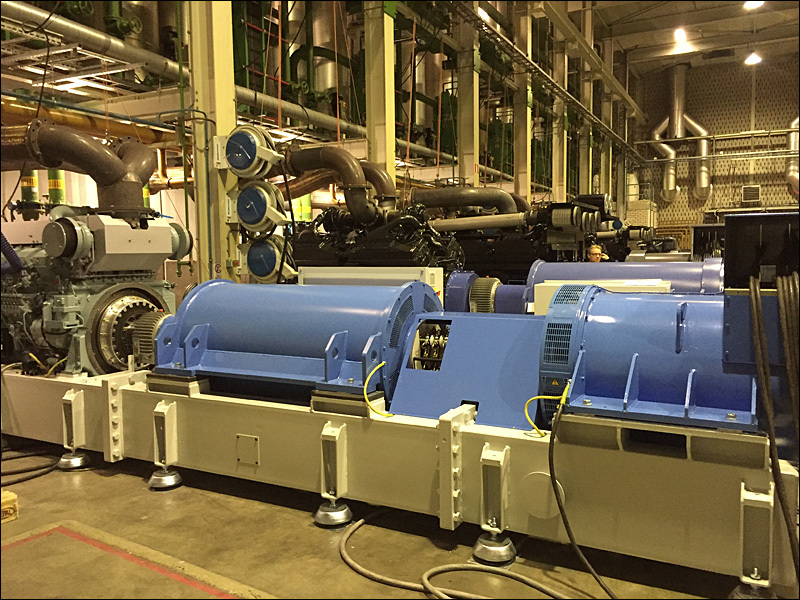

This is how the modern architecture of the three modules connected via couplings appeared, which greatly simplified their delivery. Depending on the wishes of the customer, the number of connections between modules varies.

The piece of iron has a number of completely unrelated improvements to the technology. And these improvements somewhat change the device usage profile.

I'll start with the most important thing. The biggest hemorrhoids of these systems was that regular maintenance and replacement of bearings required a module with a flywheel, since it is most susceptible to mechanical wear due to constant movement. This module, to our great regret, was located in the middle of the device. The impression was that our Dutch friends on most of the objects, apparently, DDIBP are placed in rooms like hangars and quietly buzzing in the corner. And if they need to pull out the middle module, they fit the crane and pull it out like a carrot from the garden bed.

In the case of Russia, the arrangement is sophisticated: it is always some kind of hole - a very big one, but in fact a hole. So you need a beam crane or some other device.

The drive is not repaired at all on the spot, for this you need additional equipment. Usually they bring and install a new one, and the one that was brought to the factory. And there already with him poking around seriously. The difficulty lies in the fact that before you pull out, the module must be disconnected from both sides. From the generator and from the engine. It takes about 4–5 hours. And then, after the repair, you need to mount everything back, and this is also not easy. When assembling, you need to adjust the position of each block relative to each other.

Sometimes everything is even more fun if the diesel-dynamic source is placed in a room where a crane cannot reach ...

For the last car, the engineers thought out an architecture in which the flywheel was in the extreme module, and not on average. This will greatly affect maintenance and reduce the complexity of work.

At one of our installations, the customer did not carry out maintenance for nearly two years. In particular, he did not lubricate the device at the points of rotation. Logically, it should have failed in a few months, but it worked much longer than we would like. Why? Because if it stopped right away, we would simply smear and carry out minor preventive measures. But no, the piece of iron proved that words about military use are not an empty sound. And with the "crunch and creaks" worked another half year without lubrication. Brushes, too, did not change, they erased just to the meat, to the very iron base. Only then did the generator stop.

I must say that the indication of the lack of lubrication and the lack of maintenance in the past generation looks like a little red light on the dashboard.

In the new generation of self-diagnosis system displays a generalized result directly to the casing:

See the highlight? It is here not only for design, but also works as a system for indicating the results of self-diagnostics. If she blinked red all the time, the customer would probably notice that something was wrong with the car.

This, by the way, is a general tendency - to make the indication clear without special knowledge. But in this case, the need for design was very important to the Dutch guys, too, and so the casing is so interesting in appearance. The fact is that for customers in Europe (and the USA), a presentable type of car is important. I will tell our story to make it clearer what this is about.

Mounted to the customer two cars (main and reserve), delivery, acceptance, beauty, everything is signed. They looked like this:

The customer at the end comes up and says:

- Guys, is it possible to glue the LED tape here and here?

We him:

- What for?

- Well, so much money has been raised. Tomorrow journalists will come, officials. They won't believe that these boxes are worth so much. Let's glue the LEDs so that the cars look cosmically.

We, of course, stuck. Both LEDs and photon reflectors. But, as it is easy to guess, cosmically they didn’t look like that. Rather, like a casino. Officials looked like it.

But the new high-tech “armored train” immediately impressive.

Returning to the history of lack of service. As it turned out, this is an important issue not only here, but also in Europe, so the automatic lubrication has now been made in new cars. Yes, and now serve the least of all: brushes excluded.

Earlier, the cables were stuck in several dozens of different places on the case and all had different connectors. Now everything is one sideways in one point, very easy and pleasant. As a result, the assembly became like a lego: everything is worked out at the factory, just a click-click is in place - and assembled.

In Europe, it is very important to be environmentally friendly and economical. Accordingly, it may be a political move by the engineers, but definitely very thoughtful. They reworked the cooling system: in the past, the mechanical impeller consumed power constantly, regardless of the load. Now the cooling is done by an electric drive so that the power can be changed in accordance with the temperature conditions and the load. If it is cold outside and the device is in a container outside the building, the DDIBP will no longer be turned in vain by a fan.

Many small alterations in the engine. The choke was “turned over”, it was wound in another section. Engines are also very economical now. Everything is simple: the manufacturer DDIBP buys engines from those who make them. And the engines are constantly put in conditions that it is necessary to improve environmental friendliness.

System:

For about the thirtieth year of operation, Dutch engineers learned that there might be midges in the air in other countries, quite a lot of dust and other unpleasant things. In Europe, there is simply not as much dirt as we have after sprinkling roads with salt and sand. Now, accordingly, there are filters in the ventilation system.

Filters of the incoming diesel engine were on the machines for a long time, but we still put separate separators on each installation. Our native diesel fuel is usually not inferior in quality to a foreign one, but Dutch engineers still do not know how to easily grab a piece of water due to the fact that maintenance personnel or the supplier will save 3 kopecks. Therefore, the paradoxical question of whether some kind of leftist will be poured in there is already decided by us.

Naturally, the casing. It is more aesthetic than functional, but also reduces noise.

And of course, the safety grille on the end. They certainly have some important aesthetic function and protect the hands of the staff. Here she solved one very important and long-standing task: now the incoming air flow does not create a rat dispersion inside the machine.

I already have more than 5 years of experience in operating such machines, and I can say that both the old and the new Hi-techs are very well repaired, and often even without replacing the modules. Everything is thought out, reliable, with a good margin of strength. The latter was a surprise, because we are used to the fact that if a uninterrupted work period is declared on a European piece of iron, the incident happens next week after the end of this period.

In our office, at the 4 such DDIBP themselves for several years, they just delivered and installed. But we mounted them on another city object with great interest. They had to be transferred to the site by crane, and everything was closed near the construction site. As a result, one crane hooked the device from the board, passed it to the second construction one, and he already gave it to our third one, which was installed. The drivers waited for unloading due to all approvals for a very long time, and we fed them pizza and carried heaters.

If you need a normal power supply without jumps and interruptions - from 1 MW DDBP have no equal. Usually they are placed on data centers, often in industry, in critical industries, in situational and emergency centers.

In general, everything that has high requirements for continuity of power. If your iron is experiencing a half-second gap without shaking or for 20–30 seconds without power, nothing terrible will happen, then you don’t need to pay so much for DDIBP - it’s easier to do a regular diesel generator set in this range.

The new generation, "armored train" in the jargon. On the right, our old dream is a grid so that rats do not suck.

The technology was born around the same period as the nuclear bomb, so it is simple and straightforward, like a Kalashnikov assault rifle. We take a huge iron top, spin the electric motor. After overcoming the inertia of rest, the heavy piece of iron turns almost without friction. The power is cut off - the piece of iron starts to turn the electric motor itself, which started it, and thereby converts its kinetic energy into electrical energy for some time, until it stops. During this time, the diesel has time to start.

')

The old Soviet DDIBP, which stood on Baikonur, are not fundamentally different from their modern counterparts. The same top, the same diesel engines. But there are lots of useful nuances. We'll talk about them and how such “cool” iron evolves at all.

Previous generation

Flywheel

DDBP consists of three main parts:

- Heavy flywheel - energy storage, rotating on exactly aligned axis. The electric motor spins it and supports rotation.

- A synchronous generator, which rotates either from the top (constantly evenly), or from the mains (in this case, it becomes a motor), or from the operation of a diesel engine, which starts immediately after turning off the city power supply and after 2-4 seconds "picks up" the rotation.

- Diesel engine.

The history of DDIBP began with small capacities. Over the years, capacities grew, dimensions increased, difficulties with transportation appeared. The manufacturer began to work out the technology of transporting DDIBP, and the machines began to be divided into modules.

This is how the modern architecture of the three modules connected via couplings appeared, which greatly simplified their delivery. Depending on the wishes of the customer, the number of connections between modules varies.

The piece of iron has a number of completely unrelated improvements to the technology. And these improvements somewhat change the device usage profile.

Rebuild

I'll start with the most important thing. The biggest hemorrhoids of these systems was that regular maintenance and replacement of bearings required a module with a flywheel, since it is most susceptible to mechanical wear due to constant movement. This module, to our great regret, was located in the middle of the device. The impression was that our Dutch friends on most of the objects, apparently, DDIBP are placed in rooms like hangars and quietly buzzing in the corner. And if they need to pull out the middle module, they fit the crane and pull it out like a carrot from the garden bed.

In the case of Russia, the arrangement is sophisticated: it is always some kind of hole - a very big one, but in fact a hole. So you need a beam crane or some other device.

The drive is not repaired at all on the spot, for this you need additional equipment. Usually they bring and install a new one, and the one that was brought to the factory. And there already with him poking around seriously. The difficulty lies in the fact that before you pull out, the module must be disconnected from both sides. From the generator and from the engine. It takes about 4–5 hours. And then, after the repair, you need to mount everything back, and this is also not easy. When assembling, you need to adjust the position of each block relative to each other.

Sometimes everything is even more fun if the diesel-dynamic source is placed in a room where a crane cannot reach ...

For the last car, the engineers thought out an architecture in which the flywheel was in the extreme module, and not on average. This will greatly affect maintenance and reduce the complexity of work.

Service

At one of our installations, the customer did not carry out maintenance for nearly two years. In particular, he did not lubricate the device at the points of rotation. Logically, it should have failed in a few months, but it worked much longer than we would like. Why? Because if it stopped right away, we would simply smear and carry out minor preventive measures. But no, the piece of iron proved that words about military use are not an empty sound. And with the "crunch and creaks" worked another half year without lubrication. Brushes, too, did not change, they erased just to the meat, to the very iron base. Only then did the generator stop.

I must say that the indication of the lack of lubrication and the lack of maintenance in the past generation looks like a little red light on the dashboard.

In the new generation of self-diagnosis system displays a generalized result directly to the casing:

See the highlight? It is here not only for design, but also works as a system for indicating the results of self-diagnostics. If she blinked red all the time, the customer would probably notice that something was wrong with the car.

This, by the way, is a general tendency - to make the indication clear without special knowledge. But in this case, the need for design was very important to the Dutch guys, too, and so the casing is so interesting in appearance. The fact is that for customers in Europe (and the USA), a presentable type of car is important. I will tell our story to make it clearer what this is about.

Mounted to the customer two cars (main and reserve), delivery, acceptance, beauty, everything is signed. They looked like this:

The customer at the end comes up and says:

- Guys, is it possible to glue the LED tape here and here?

We him:

- What for?

- Well, so much money has been raised. Tomorrow journalists will come, officials. They won't believe that these boxes are worth so much. Let's glue the LEDs so that the cars look cosmically.

We, of course, stuck. Both LEDs and photon reflectors. But, as it is easy to guess, cosmically they didn’t look like that. Rather, like a casino. Officials looked like it.

But the new high-tech “armored train” immediately impressive.

Returning to the history of lack of service. As it turned out, this is an important issue not only here, but also in Europe, so the automatic lubrication has now been made in new cars. Yes, and now serve the least of all: brushes excluded.

Earlier, the cables were stuck in several dozens of different places on the case and all had different connectors. Now everything is one sideways in one point, very easy and pleasant. As a result, the assembly became like a lego: everything is worked out at the factory, just a click-click is in place - and assembled.

Environmental friendliness

In Europe, it is very important to be environmentally friendly and economical. Accordingly, it may be a political move by the engineers, but definitely very thoughtful. They reworked the cooling system: in the past, the mechanical impeller consumed power constantly, regardless of the load. Now the cooling is done by an electric drive so that the power can be changed in accordance with the temperature conditions and the load. If it is cold outside and the device is in a container outside the building, the DDIBP will no longer be turned in vain by a fan.

Many small alterations in the engine. The choke was “turned over”, it was wound in another section. Engines are also very economical now. Everything is simple: the manufacturer DDIBP buys engines from those who make them. And the engines are constantly put in conditions that it is necessary to improve environmental friendliness.

Ambient conditions

System:

Efficiency up to 97%

Class A interference level (EN 55.011)

IP21 or higher protection

Working height <150 m above sea level

External temperature 5–40 ◦C (41–104 F)

For about the thirtieth year of operation, Dutch engineers learned that there might be midges in the air in other countries, quite a lot of dust and other unpleasant things. In Europe, there is simply not as much dirt as we have after sprinkling roads with salt and sand. Now, accordingly, there are filters in the ventilation system.

Filters of the incoming diesel engine were on the machines for a long time, but we still put separate separators on each installation. Our native diesel fuel is usually not inferior in quality to a foreign one, but Dutch engineers still do not know how to easily grab a piece of water due to the fact that maintenance personnel or the supplier will save 3 kopecks. Therefore, the paradoxical question of whether some kind of leftist will be poured in there is already decided by us.

Naturally, the casing. It is more aesthetic than functional, but also reduces noise.

And of course, the safety grille on the end. They certainly have some important aesthetic function and protect the hands of the staff. Here she solved one very important and long-standing task: now the incoming air flow does not create a rat dispersion inside the machine.

Repairs

I already have more than 5 years of experience in operating such machines, and I can say that both the old and the new Hi-techs are very well repaired, and often even without replacing the modules. Everything is thought out, reliable, with a good margin of strength. The latter was a surprise, because we are used to the fact that if a uninterrupted work period is declared on a European piece of iron, the incident happens next week after the end of this period.

In our office, at the 4 such DDIBP themselves for several years, they just delivered and installed. But we mounted them on another city object with great interest. They had to be transferred to the site by crane, and everything was closed near the construction site. As a result, one crane hooked the device from the board, passed it to the second construction one, and he already gave it to our third one, which was installed. The drivers waited for unloading due to all approvals for a very long time, and we fed them pizza and carried heaters.

Total

If you need a normal power supply without jumps and interruptions - from 1 MW DDBP have no equal. Usually they are placed on data centers, often in industry, in critical industries, in situational and emergency centers.

In general, everything that has high requirements for continuity of power. If your iron is experiencing a half-second gap without shaking or for 20–30 seconds without power, nothing terrible will happen, then you don’t need to pay so much for DDIBP - it’s easier to do a regular diesel generator set in this range.

This is how it looks: switching

Links

Source: https://habr.com/ru/post/318184/

All Articles