MTA vs MTO. Who will win? No one anybody. Work work

In my last note, I talked about how we are trying to put production flows in order using the methods of the theory of constraints. This time I will describe how we implement the MTA (production to ensure availability).

Small input data:

1. The project is closed. Developed for yourself.

2. The development environment does not matter. The algorithms of the theory of constraints are simple mathematics, which means they are implemented by any available programming language.

3. All notes are an attempt to share our practice with the world. Look for a theory on the Internet.

The manager looked at how many products were in stock, and on this basis placed an order for a warehouse in the production plan. But the principle, to do something, while there is free time, has become obsolete. Suppose in stock 10 pcs of a certain product. The manager decides that this is not enough and says the production: "We need to make 50 pieces." While doing 50 pieces managed to ship half. Again, an order for a warehouse. And so in a circle. The drawback of such a scheme of work is obvious. All data from the "directory Fonareva." We decided that the workshop, although a living organism, should work on easily controlled algorithms.

')

The manager selects the position for which the system must follow. Enters the initial data. Only the size of the initial buffer is sufficient and this is the last thing a person does. Next autopilot. The initial buffer (see definition on the Internet) is what the system will push off to enter the automatic mode. We will decide on the size of the initial buffer using the example shown in the screenshot below. The period of 12 months. The average stock is 13,750 pieces. Turnover period ~ 17 days. Ie in 17 days we will sell approximately 14,000 pcs. It is worth noting that these data are taken from the active database and are fresh for each moment in time. From practice, for comfortable work, we need to have a reserve of about 1-1.5 months (depending on the product). It turns out that we need to keep approximately 20,000 pieces in stock. This is the size of the initial buffer. Accuracy is not important here. You can install and 25 000 pieces. The system after a certain period of time itself will adjust the buffer based on the current shipments and arrivals to the warehouse.

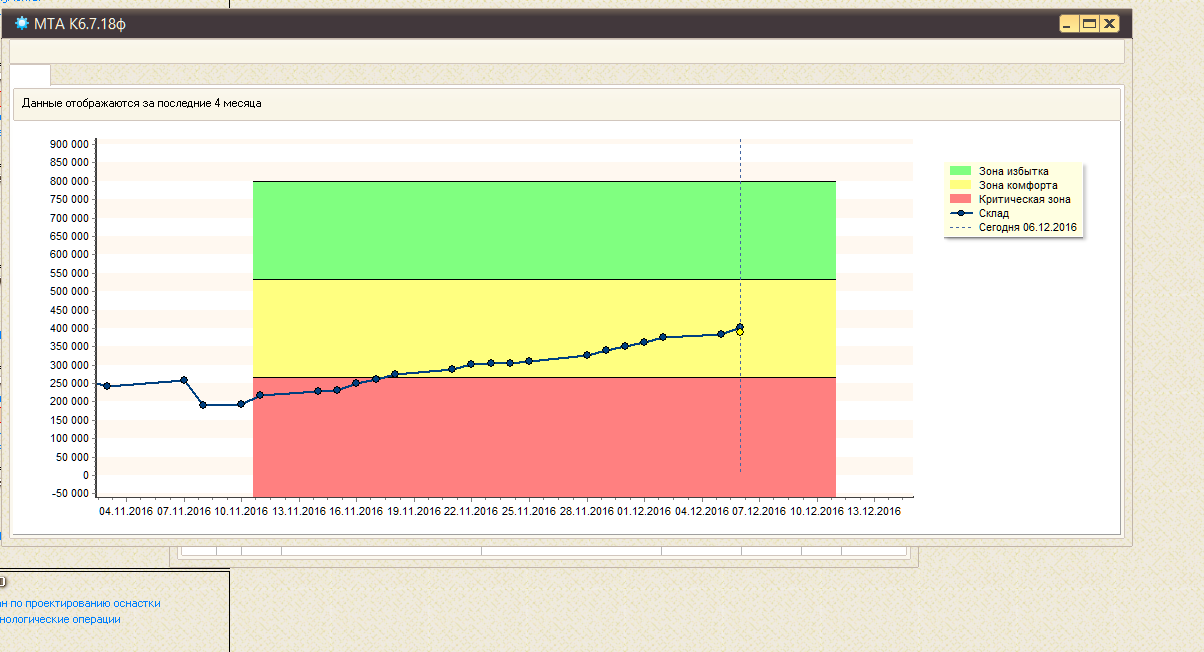

Everything. Next, the system begins to track the positions we have selected and notifies that you need to place in the plan, when the critical points are reached (red zone).

Blue - overproduction. Green - excess. Yellow - comfort. Red - danger. Black hole.

Next time I will tell about our dynamic buffer.

Small input data:

1. The project is closed. Developed for yourself.

2. The development environment does not matter. The algorithms of the theory of constraints are simple mathematics, which means they are implemented by any available programming language.

3. All notes are an attempt to share our practice with the world. Look for a theory on the Internet.

It was

The manager looked at how many products were in stock, and on this basis placed an order for a warehouse in the production plan. But the principle, to do something, while there is free time, has become obsolete. Suppose in stock 10 pcs of a certain product. The manager decides that this is not enough and says the production: "We need to make 50 pieces." While doing 50 pieces managed to ship half. Again, an order for a warehouse. And so in a circle. The drawback of such a scheme of work is obvious. All data from the "directory Fonareva." We decided that the workshop, although a living organism, should work on easily controlled algorithms.

')

It became

The manager selects the position for which the system must follow. Enters the initial data. Only the size of the initial buffer is sufficient and this is the last thing a person does. Next autopilot. The initial buffer (see definition on the Internet) is what the system will push off to enter the automatic mode. We will decide on the size of the initial buffer using the example shown in the screenshot below. The period of 12 months. The average stock is 13,750 pieces. Turnover period ~ 17 days. Ie in 17 days we will sell approximately 14,000 pcs. It is worth noting that these data are taken from the active database and are fresh for each moment in time. From practice, for comfortable work, we need to have a reserve of about 1-1.5 months (depending on the product). It turns out that we need to keep approximately 20,000 pieces in stock. This is the size of the initial buffer. Accuracy is not important here. You can install and 25 000 pieces. The system after a certain period of time itself will adjust the buffer based on the current shipments and arrivals to the warehouse.

Everything. Next, the system begins to track the positions we have selected and notifies that you need to place in the plan, when the critical points are reached (red zone).

Blue - overproduction. Green - excess. Yellow - comfort. Red - danger. Black hole.

Next time I will tell about our dynamic buffer.

Source: https://habr.com/ru/post/316940/

All Articles