Why do board games cost so much - or do it yourself

Cutting cards. The dust is interesting: on papermaking it covers everything very quickly.

I have already been asked many times how a box of cut cardboard can cost 1500 rubles. What is in it?

The price of any product can be calculated in three ways:

')

- From the chain of formation, that is, starting from the costs of development and production - this is the lower limiter.

- From the economy - how many people are willing to pay, and what price can be set until competitors devour (this is the upper limiter, it also shows the cost of production we must fit).

- And from the cost of analogue substitutes. In our case, handicraft production. That is making a board game with your own hands.

You will be terribly surprised when you come to the printing house with the models and ask them to print. We have three copies of the game for the exhibition are obtained for 20 thousand. I'll explain why.

Let's start with the box

The size of the box is usually determined by the size of the game field (and most often - folded in half or four times).

- We make handicraft ourselves. Of course, you can take a box for shoes or the Russian Post, but it will be scary and not about the game. The cost of mail boxes here . As you can see, we are suitable for those that are for 90 and 120 rubles, but it is possible to keep within 70 rubles (in practice they get even cheaper - if without a logo).

- We do to the exhibition. In our case, however, the preparation of a game that has not yet been released for the exhibition requires full-sized taping of the box. We do this manually in our production using the existing cutting, by ordering the printing of liners in a digital printing house, that is, on the basis of one of the typical production boxes. The cost, including manual work, is about 1000 rubles.

- We do in the printing house as a pre-release master layout. This is a beta box, on which you need to check how the inscriptions look, if there are any problems with the image on the corners and so on, twist in your hands, put in our special cabinet in the office with games (like in a store) and evaluate the visibility from a distance. For this beta, the printing house prints a sheet of cardboard on which is the bottom and a sheet with a lid. Further, all this is cut with ordinary scissors and glued together with tape. It is immediately clear whether it is necessary to edit something in the layout or give it to the circulation. The cost of such work is about 700 rubles. The box is perfect for the presentation of the project to the publisher, but not for permanent use - it will be unstuck and tear very quickly, and its quality is far from “glossy.”

- We do in circulation. Normal industrial boxes have a cost price of 5–10 thousand pieces, about 40–70 rubles per piece. And this is only the cost of production for excluding logistics and other things. The box for your phone is so durable, beautiful - most likely, in the cost price, 150-250 rubles. Box for hair dryer (ugly) - cheaper than hundreds. For example, our standard box of the “Jackal: Treasure Island” format with dimensions of 257x257x74 mm, mouthguard thickness (binding cardboard) 1.25 mm, plain coated paper for pasting, printing and varnish for a circulation of 3000 pieces costs 68 rubles (hereinafter prices ordering by the external author of the game as part of the production of his circulation). But we, of course, print much larger circulation, and it turns out much cheaper.

I poked pictures from the presentation of our production, they are very well suited to explain, here:

The only point: the photo itself is not the compound itself, but the application of glue before the compound.

To understand why a box can cost so much, you need to start from afar - namely, with the general issue of box production. Beautiful large boxes in Russia at reasonable prices can do 4 factories, and one of them is ours in Podolsk. The rest (not from these factories) are transported from China or other countries. The problem is in the technical process, for example, cover-bottom boxes (self-assembly is cheaper, but much worse for large games):

- First you need to take a sheet of cardboard and draw a cutting on it.

- Then cut down the future designer for the box (more precisely, two for the cover and the bottom separately). This is done with a bang on the crucible press and is nothing complicated.

- Fold the boxes. This is already more difficult, because if the boxes are of different sizes (and, in general, you need at least 4 different sizes), then it is quite difficult to automate. Therefore, it is done by hand.

- Folded cardboard need to paste over paper (kashirovat) - on this paper will be printed pictures and all sorts of inscriptions. It is impossible to print on the cardboard itself, because the paint is completely absorbed into it (the offset printing machine on the tray does not work). Want beautiful - hold the paper. This is also done in most cases with hands on special machines.

Pasting, by the way, is done not only outside, but often inside the box, especially on the covers, like this:

Are all boxes made by hand? Far from it, but a fully automatic line is extremely rare for Russia. We, for example, have our own, but the adventures with this fucking creation of a Chinese engineering genius are being pulled to a whole post, where little children should not be allowed. On the third day of commissioning, for example, it turned out that the power relay is exactly under the tank for boiling glue. And this very glue boils, splashes and splashes closes the contacts tightly. Then the machine gets up, and all the glue hardens inside in thin tubes. We made the first upgrade with a children's bucket for the sandbox - we protected the relay. Since then there have been many more upgrades of the same level, only slightly more technological. Now, pah-pah, it works fine.

Printing any sheet is also not a trivial story. To print a drawing on the box liner, you must first prepare an offset film and do the make-up. It costs at least 15 thousand rubles: first, color separation is done. What it is for: a printing machine is a block the size of a KAMAZ, in which four colors are applied to the sheet in turn. The first block is the first color, the second block is the second, the third is the third, the fourth is the fourth. In mixing, the desired shade of CMYK is obtained - from blue, violet, yellow and black. We still have the fifth compartment - this is for additional processing of our material, for example, varnish or printing with a fixed pantone color. So, you need to prepare and calculate everything so that they are applied correctly - this is the color separation and make-up.

Then the offset film is made. From the film image is transferred to the aluminum form. These forms need to be loaded into the car - also not five seconds (and, for a second, there could be printed at this time newspapers or leaflets of some candidate - that is, idle time is paid). Then the make-up begins. To run a circulation, you need to spend about 200-300 sheets on circulation up to 5,000 pieces. With large runs, there may be several make-ups, and conditionally, every hour the make-up is corrected, because it is gradually lost. The make-up is the accuracy of hitting the color, the accuracy of combining the face and the circulation, and so on. At the time of fitting the printer runs around the machine and slightly tightens the leaf stops, or moves them, slightly adds ink to the sections and so on. We print on the exhibition of the game with a circulation of 50 pieces and a digit, and an offset - yes, they are cheaper to make a digit, but there will be no quality for the show. The figure does not allow you to accurately face the turn, constantly jumping up to 2 millimeters regardless of make-up, digital machines (except extremely expensive) do not know how to precisely position the sheet. In general, solid random, disappointment and rather poor-quality color (not least because of this randomness). Large format printing (also a digit, but different) - quality is worse there, but they can print. The price of the inclusion of the machine - 300 rubles (this is even for one sheet). Standard sheet B3, that is, it does not fit there as much as we would like. There are also features of paper - for example, a coated layer should be applied to the cardboard. This is done for each sheet of the box, for maps, fields and other components. And this is another simple case when there is no pantone or varnishing.

Cutting the box is also a surprise. In general, this is a stamp on the liner cover, a stamp on the liner bottom and 2 stamps on the cardboard for these boxes. There are curly exceptions. A crucible stamp is plywood in which the desired pattern is laser burned, and then knives of a certain configuration are inserted into this pattern, then the knives are glued on both sides with rubber bands of a certain stiffness (for different types of cutting, different stiffness). If the rubber bands are not set, then after a couple of blows all the knives will be bent - you need to soften the blow, giving such a load on the knife, which will allow you to cut through the product, but not deform the knife. Also make-up and stamp production.

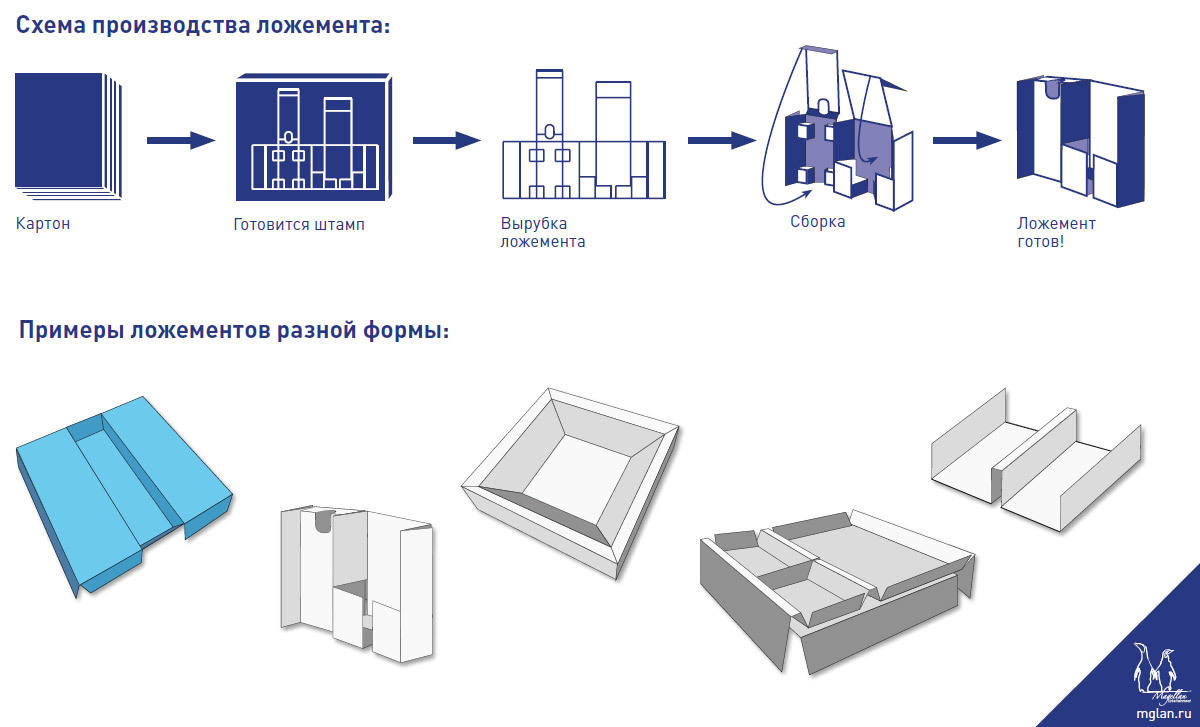

Do you think everything is with the box? But no. Now you need a lodgement. This is such a thing that keeps the components of the game in place - with grooves for maps and so on. You can make a simple and a bit scary cardboard (it will move away from the walls, small chips will wake up under it, but for games from the field and cards it fits). And you can - inflate the form of plastic.

It is done like this:

- Handy. We take the cardboard and just knock it as it will. It turns out, as a rule, not so much, but, in general, it doesn’t really hinder, if we consider that our box is not a game anymore.

- In circulation. Need a form and a special machine. The scheme for the production of a plastic lodgement is not very different from the scheme for the production of a plastic bottle (only bottles are riveted in millions, and lodgments in thousands). The cost of plastic - rubles 80-90 rubles. In our handicraft case for the three prototypes are made cardboard. Arithmetic is also simple. Process: drawing development, creating a 3D model, then preparing the manufacture of a die stamp, frame and punch for mechanical drawing (if necessary), color matching and cutting of the material being processed is the process of vacuum thermoforming of lodgements. The cost of equipment on average from 50 to 100 thousand rubles. Total in the minimum circulation of 1000 pieces the price for the lodgement is about 80-90 rubles. Another question is that if you make 5000 lodgements (as we do), then the price may drop to 30-40 rubles.

- To the exhibition. For a prototype, you can make equipment not from aluminum, but from MDF, it costs 15 thousand rubles. 10 pieces maximum, and the cradle will turn out a little different in shape. Still need fixing. Polymer takes about 30 rubles for each lodgement.

- In the print shop. In the case of a “household order” in a printing house, a cardboard bed in the spirit of “brr”, made with manual labor by cutting out a sketch, is 200–300 rubles per unit. If it is done correctly - 5,000 rubles per stamp, 2 rubles per hit (1 punch = 1 lodgement).

Cards

Cards most often in a box from 50 to 100 pieces.

- Handy. You can take protectors for cards (200 rubles), a regular deck in their size (70-100 rubles) and put pieces of paper on top of ordinary cards in protectors - this way you can mix cards, and so usually we bring prototypes. Or buy prototyping cardboard cards and write by hand on them - this is how we test the games in alpha.

- For the exhibition you need to make more or less beautiful cards. To do this, we print them on an exact color printer, take them to a specialized production such as ours or a printing press with a tunnel press as in the picture at the top of the post (or, in extreme cases, with manual rounding corners). Could and to the production, but to printing house is cheaper, we in Podolsk. Then first we cut the sheets with printed cards into rectangles, and then we cut and round the corners on the press. Such a deck of 100 cards will cost from 3 to 3.5 thousand rubles. It looks good, although there are facial displacements relative to the turnover due to the inaccuracy of the digit printing.

- For a prototype to play or demonstrate to the publisher, you can not bother. Simply print the cards in the printing house and ask them, or independently cut the sheets into rectangles with scissors. Cost 100 cards will be about 2 thousand rubles.

- In drawing - a deck of 100 cards in size 63 x 89, printed on cardboard 260 grams, 4 + 4, dv-varnish, and a different turn will cost approximately 70 kopecks per card with a circulation of 3000 pieces. A maximum of 100 cards will fall on two sheets. 101 cards - no longer fit into the sheet - also plus make-up and all the consequences. Plus a separate corrugation for packaging and installation work. If you watched the film “War dogs” about 100 million rounds of Kalashnikov cartridges, you should understand how important this is.

"Stupid Casual" ordered cards for Imaginarium from us - or rather, began to order after a series of "hairy" around the edges at another production

Plastic cards will be even more expensive. On the draw still emerges the need to accurately fall into the color of the shirts (this immediately means a very accurate pantone fit). Plus, there are often non-format cards, for example, very small ones - these are new forms. Again, in our case, the printing house cuts by hand, the production still needs to be customized machine - this is quite a long time.

That's all - if the stamp is standard. We have several dozen of them, and some of them are repeated - to avoid downtime when stamps leave for grinding. The stamp on the non-standard, taking into account the delivery, will be released at about 20,000 and takes 2 weeks. There is only one factory in the country that manufactures tunnel stamps. They make tunnel presses, and they have to sharpen these stamps.

Field

The field is made on the same principle as the box - from several layers of material. Fortunately, it is necessary to bend it a little, and there is no bulk pasting there. Therefore, everything is relatively simple.

- Handy. We take a large sheet of cardboard and draw everything on it, or paste on it a printout. 50 rubles for a sheet and 20 rubles for a printout.

- It is better to do this to the exhibition : we print on the liner an image with a digit or wide format. We go to the printing house, where they know how to lash (glue) the binding cardboard with liners. We make our liner from our face, and with beautiful white or black paper. Let our folding field has a size of 500 * 250 mm, shirka + cardboard - then the price is 550 rubles.

- For a presentation to a publisher, it is easier as with a box to print the box on a regular cardboard - this will be enough for the correct impression of the game. Issue price - 350 rubles.

- With a circulation of 3000 pieces, our field of 500x250 mm will cost approximately 56 rubles per unit.

Box masking is also often done with margins.

rules

- Handy - a pack of printouts, say, 10 rubles per sheet (this is the price of printing services at the metro, on your own printer is cheaper - but do not forget about the price of the printer).

- In a printing house or exhibition : 200 * 200, 12 pages 4 + 4, clip = 650 p. Very expensive due to the unit circulation.

- In circulation - 25 rubles apiece per 1000 pieces.

Chips

Figures are made difficult. Here is an approximate technical process:

The final step is the casting in polymer form, in which the metal turns into a figure.

- Handy: take chips from another game.

- For the exhibition: you can make figures on an industrial high-precision 3D-printer or cast individual metal products is not just expensive, but horse-like. Model, shape - or model and normal printer. You can take and standard wood for the prototype, of course.

- In circulation from 10 thousand pieces on model. In metal, the most difficult thing is a master copy (made of silver, it is necessary for making a casting mold). Usually the cost of a 3D model and the production of a master copy is very high. Then the casting circulation, which does not make sense on the circulation up to 10 thousand pieces. There is a cast "in silicone", there is a figure in the cost of the factory from 20 to 100 rubles, depending on the complexity and size.

- Less than 10 thousand pieces. There is rational use of wood. In the tree there is nothing more complicated coloring. There is generally a magical story. The painting machine (so that the paint would fall without drops, would not flow, would not change color, and then the figures would not paint the table when pressed) costs 20 thousand euros. We traveled several German manufactures, looking second-hand. Did not find cheap. Then they complained to "Kuzmich" - a local engineer, lying half a day under the products of the AZLK plant. He thought and said that he would do if we bring home appliances to him for analysis. As a result, he bungled a monster from Frankenstein from the parts of the refrigerator and washing machine, piles of plywood and pipes. Then, after a year and a half, the Austrians came to us to watch how everything works. They were very surprised by the quality of coloring, which in some places is even higher than German. There wasn’t enough foreigners there, the second in a day. The first happened when they saw the industrial zone with the men before the payday.

Crumbly

Cardboard markers, tiles and composite fields are made like this:

Everything else is purchased. Cubes, hourglasses, markers - this is China. In our case - our warehouse stock. An hourglass, for example, is made only for medicine in Russia (terrible and large). With the rest, about the same. Wooden cubes have learned to do here, before it was necessary to 3 countries in the process. Short-run backbellite production (this is an artificial polymer stone, it is made of escalator steps and poker-type chips, only heavier) went bankrupt two years ago. We are going to make cubes right now. Something like this.

That is why a self-made game of the same quality as a replica copy costs 5-10 thousand per unit (this is when we bring it to the exhibition). If all the stamps are new, then the price would be higher by another 15-20 thousand.

The same is true in the typography “hands” somewhere 2000-2500 (without stamps).

Or the same for 1200-1500 in retail on the shelf.

Pricing for the economy

Taking into account the cost of production, this factor has almost no effect. More precisely, it influences the choice of materials: most often it is necessary to replace plastic cards with paper ones and to invent something else with figures. How much people are willing to pay for board games is not determined by production, but by the price of other gifts. The maximum price for normal demand for Moscow is 2000-2500 rubles for a large box with a lot of everything, for other cities - 1000-1500 rubles. Therefore, all interesting things should fit up to 2000 rubles iron.

Industrial pricing

There is one more thing besides production. Development. It is necessary to draw illustrations (this is 50-70 thousand minimum), make everything up, make proofreading, perform prepress work (including color correction and optimally expand everything on the sheet), make a bunch of logistics, have intermediate and final warehouses for components and finished things, a workshop for drying boxes, a workshop for assembling components inside a box, carry out quality control and much more. Plus a license if the game is foreign or royalty to a domestic author (5-10% of the wholesale price). This part is described in more detail here .

Phew Everything, I hope, I answered this question.

Source: https://habr.com/ru/post/316010/

All Articles