About my LIR2032 and CR2032 tester, the batteries themselves and accumulated experience

In this article, I publish in free access my tester and meter 8pcs of watch batteries, tablets of the form factor CR2032. I hope it will come in handy for those who make portable electronics and various IoTs. In the article I will describe the scheme of my tester and tell you how it works. I will give the results of measurement of batteries LIR2032. And check out eight CR2032 from different manufacturers. I will also share a wealth of experience: which batteries are better not to take, and which ones are good. I will sign the dangerous moments with a bonus: and how not to suffer and not burn the house yourself, as Kreosan likes to do.

Table of contents:

For what?

Key parameters and verification algorithm

Work indication and log

Microcontroller and how to flash it

Whole scheme

Power scheme

Diagram of one of eight channels LIR2032 / CR2032

Pro charging and charge controller

Pay

Battery Results LIR2032

Test results for 8 different CR2032 batteries

Results and about battery quality

About safety

Conclusion and link to my github project

For what?

In order to be self-employed and as a hobby, we are making wrist devices with another circuit designer, which operate in two modes: active and standby. In the active mode, a beautiful, smooth and responsive interface is required, so the consumption is within 10-15 mA. In standby mode, only the watch works, consumption - units of microamps. The device has data synchronization via USB, therefore, it should be able to charge. Therefore, we use rechargeable tablet batteries in the form factor CR2032, they are called LIR2032.

The devices are sold to Europe. These customers are more demanding on quality than domestic consumers, and therefore it is important that all devices work for a long time and approximately the same time. And the biggest problem is the quality control of batteries. Quickly they did not check, and the volume has grown so much that I had to make this tester. What I will discuss further.

Main settings

- Powered by USB 5V, 400mA.

- Type of batteries and batteries LIR2032, CR2032 (with restrictions)

- The number of at the same time checked accumulators: 8 pieces

- Individual two color indication of the status of each battery

- Monochrome general status LED.

- Per second text log for each battery.

- Measuring instruments: voltages and rates of its change, time, capacity in µA / h.

- Discharge load: 250 Ohm (~ 10mA).

- Charging current: 30mA

- Test cycle time: 4-6 hours.

Check algorithm

The difference between LIR2032 and CR2032 is that CR2032 batteries and LIR rechargeable batteries. And they have a higher operating voltage range, but almost 10 times less capacity.

CR2032: voltage range of 2000–3300 mV, capacity 200+ mA / h.

LIR2032: voltage range 3300-4200 mV, capacity 35 - 45 mA / h.

- Primary charging , ending - charger signal #STAT in Z. Maximum 3 hours.

- Discharge, up to 3300 mV , time: minimum 2 hours, maximum 5 hours.

- Final full charge , ending - charger #STAT signal in Z. Maximum 3 hours.

A battery is considered valid if all these time limits are respected.

The voltage should not sink below 3000 mV or exceed 4300 mV - i.e. those limits at which batteries quickly deteriorate or are considered unusable.

Indication

Individually for each battery holder:

- flashing green frequently - Primary charge

- blinking red frequently - Discharge

- flashing green slowly - Final charge

- green constantly on - Test is over, battery is valid

- always lit red - test over, battery not good

Common to USB port:

- Lit - check in the course of work, at least one is being tested.

- Goes off - verification is over, all 8 batteries are checked.

Log of work

Output to UART. If you solder the CP2103, it can be read, otherwise you will have to connect a third-party UART to USB converter.

The device stores in the free flash memory (about 50kb) the parameters of all previously measured batteries and outputs them with each reboot.

After the reboot and initialization begins to be issued every second:

- Time in seconds

- Debug charger statuses and so on, three groups of characters of 8 pcs.

- Voltage on batteries in millivolts, accuracy 30mV, 8pcs

- Time passed in ticks (~ 8 million)

- Analog power voltage (convenient for checking and debugging power)

- The rate of change of power in microvolts per second, 8 pcs. Accuracy 5 µV / sec.

After all the batteries have been checked, the measured values are given for all the batteries.

- Capacity in mka / h (norm from 25 and above)

- Time in sec., Voltage in mV beginning and voltage in mV of the end of the period.

- Three periods: primary charge, discharge, final charge.

example:

LIR_1 capacity 40943 uAh LIR_1 #0 Charge_A 2203 4078 4217 LIR_1 #1 Load_250 9755 4172 3297 LIR_1 #2 Charge_B 6542 3470 4220 Microcontroller and how to flash it

For the battery tester, I chose the STM32F100R8 microcontroller to be the ARM Cortex M3.

A large 64-pin package was selected, since There were not enough conclusions for all 8 channels, but I did not want to do crutches with expandable GPIO and registers. MK operates from an internal generator without using PLL and dividers, i.e. at 8 MHz.

The firmware is made in gcc and makefile in the Eclipse Kepler environment and in the CDT plugin.

No setup required. Enough to flash and can already be used.

You can flash the external UART programmer, for this, the signals RX TX BOOT0 RST and ground are output to a separate PLS.

You can flash with my built-in USB-UART programmer about which I spoke earlier , but for this you will have to install a CP2103 for each copy.

Whole scheme

functional level:

wiring diagram (increase on click):

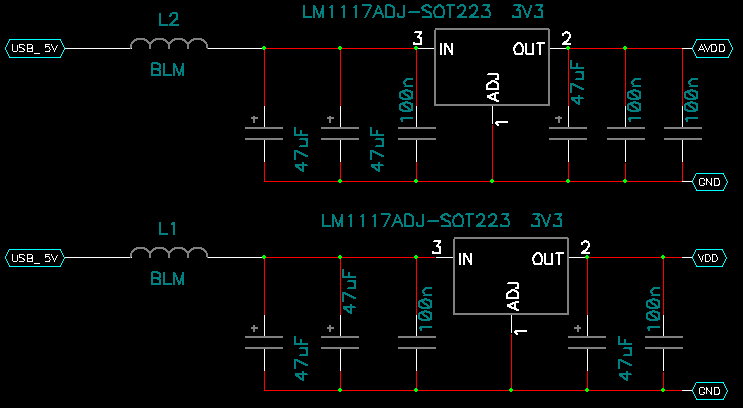

Power scheme

Two power lines on two LM1117 linear stabilizers from 5 to 3.3V.

Separate power supply for digital and analog parts.

With protection from mutual interference coils - inductors at the input of each stabilizer.

ATTENTION there is an error in the board : you forgot to install and dilute the common electrolyte in USB power, solder in parallel with USB at least 4000 microfarad x 6V. Otherwise, when you turn on one charger, the rest is reset due to a strong power drawdown.

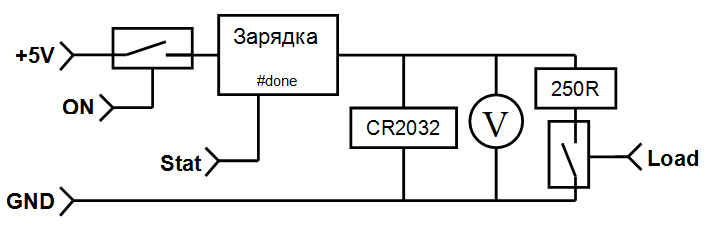

Diagram of one of eight channels LIR2032 / CR2032

functional level:

electrical circuit:

From left to right:

- Charge controller power on key (ON1 circuit)

- Charge controller (microcircuit MCP73831T)

- Charging status display: during charging = GND or completed = Z (chain STAT1)

- Vertical battery holder

- Voltage divider by 2 and voltage sensor on the op-amp (circuit ADC1)

- Load 250 ohms, which is switched on by a field effect transistor (LOAD1)

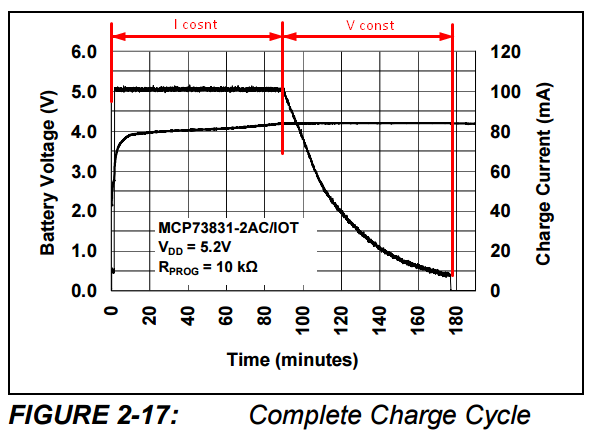

Pro charging and charge controller

Li-ion batteries need to be charged in two modes:

- fast charge in constant current mode;

- further charging in constant voltage mode.

For this purpose, a ready-made charge controller is used that can do all this - MCP73831T. It is used both in the power tester and in the target device.

Its characteristic charge over time:

There are also two additional findings:

- Conclusion #STAT - indication that the charge in the process, while charging there GND, at the end it turns into high impedance. Usually, the cathode of the LED is connected to it.

- Conclusion #Prog - sets the current limit, for versatility and depends on a simple formula:

Ireg = 1000V / Rprog;

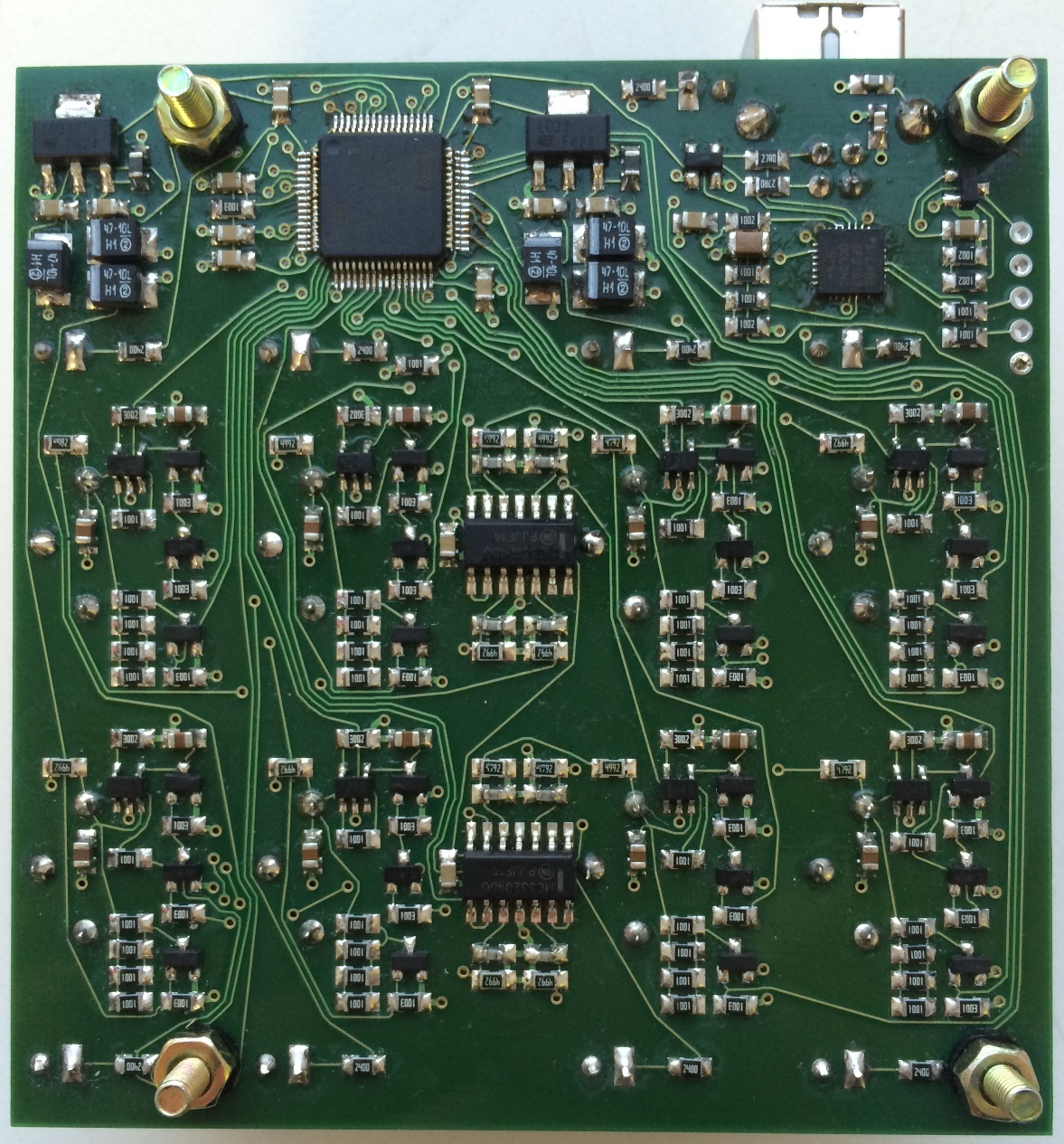

Pay

Four-layer, middle layers: ground and power, external top and bottom - signal.

Clearances and track thickness of 0.2mm. All 0805 resistors are recommended to be set with 1% accuracy.

Click increase

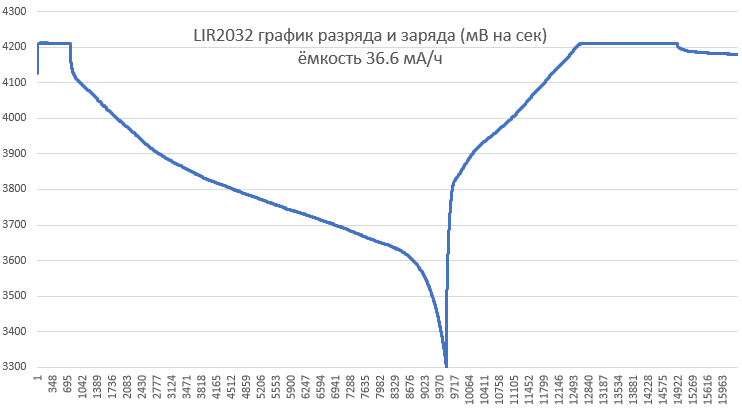

Battery Results LIR2032

Here is a graph of charge and discharge, built on the tester logs

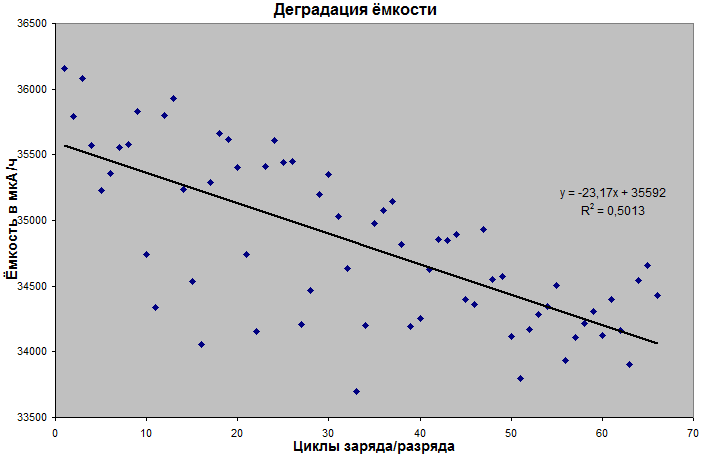

Within 64 cycles I discharged and charged 8 pcs of batteries and plotted how the average capacity of 8 batteries changes as cycles accumulate and "wear".

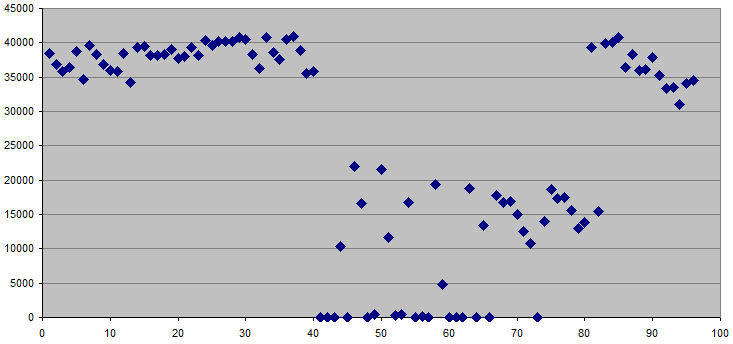

Further, it became interesting whether there is a relationship between the measured capacity and the charging time or the discharge time. For this, I took the accumulated statistics from 500+ working and suitable batteries:

It turned out that yes, there is a dependency, but only on the time of discharge to the load.

By the time of charge is too indirect. And with small capacities in the range of 25-30mA, a timeout of the minimum charge time can be seen at the charger chip - mountains formed. shelf.

Two groups of batteries are also noticeable: one is the new branded EEMB with a capacity of 34-40 mA / h, the others are also EEMB, but of the 13th year of release with a capacity of 25-30 mA / h. I accidentally found the second group among my stocks while I was doing an article and decided to also drive out and give it to the assembly fit.

Made the animation of the first 65 measurements of different batteries:

the upper graph is the voltage in mV, the horizontal time scale is 16000 seconds wide

the lower graph is the rate of change of the upper graph in µV / s.

Test results for 8 different CR2032 batteries

Immediately I warn you that the battery tester is not designed for CR2032 . They are designed for discharge by micro amperes and units of milliamperes, besides, the load less than 1 kΩ is not recommended to be connected. But I have cheap Chinese products where it is broken, for example, toys for children and cats with LEDs. And I remember that it was in this case that the branded batteries showed themselves the worst, and the cheap consumer goods did well.

If desired, you can drop out three of the four single-kilohm resistors - for this, the load is done on the board. Or solder another resistor in general more, for example 10k. If the community is interested, I can do it, but the results will not be very soon.

The results are made in the form of a table on threshold slices, ranging from 2000 mV to 2900 mV in increments of 100 mV.

Those. The capacity in milliamer-hours is measured as if they were discharged to 2000 mV, or 2100 mV, and so on to 2.9 V. The higher the threshold, the smaller the capacity.

Unit of mA / h.

The green-red gradient is individual for each column and independent of adjacent columns.

Yes, indeed, simple and cheap batteries such as ERA, megamag and Trophy, better in this situation. That confirmed my previous experience of using them.

But I repeat once again - the batteries are not required to issue such a current!

Often, CR2032 batteries are attached using miniature magnets, for example, in a misfit shine fitness bracelet, and therefore must be able to magnet well. And yes, indeed all 8 batteries are attracted by a magnet perfectly.

Results and about battery quality

I personally liked the tester, it is very convenient to use. And at 4 o'clock the cycle fits well with personal life - in the morning I set it - at lunch I changed the next one, after work I changed all 8 pieces again, and for the night another 8 pieces. They do not require much time, especially if you do not connect to the terminal and do not log.

The battery problem has been resolved.

We previously bought the Chinese "nouneym" batteries, but they turned out to be almost 100% rejected.

The company EEMB branded themselves better than others - they have stable parameters and a marriage of 2-3%. And in some of the 50-40 pieces of pallets, not a single defective one. They are also well experienced long-term storage for 3-4 years, but the percentage of marriage rises to 10%.

For comparison, the screenshot of the first 100 pieces, where EEMB and where ordered for aliexpress, I think will be clearly visible immediately.

there are three batches: the first 40pcs are the new EEMBs, the second is the fresh "nouneym" of China, the last 15 pieces are the EEMBs that have been left for three years without use. It is noticeable that even a little degraded 15 pieces of EEMB are better than Chinese ones.

About safety

- Remember that when a short circuit and the batteries and batteries noticeably warm. Yes, even such small, low-powered and low-capacity ones. Especially if you work with a large number, then it’s not the best idea even to discard defective ones in one pile. If you are certainly not Kreosan .

- The batteries are flat, and I want to take them in a pile, but even in a discharged battery, the voltage is 3-4V, and in the stack it can reach dangerous 50-70V. Stack them can not be folded, even defective. Unless, of course, you want to be another proof of Darwin's theory.

- Chinese batteries often swell and flow unpleasant to the smell of liquid, from which a headache and itchy fingers. If you deal with Chinese consumer goods, then gloves and well-ventilated non-residential premises are necessary.

Conclusion and link to my github project

I did not want to write an article, because I thought that since the IoT theme is popular in Habré, there are definitely reviews about such batteries, but I haven’t.

By the way, I am looking for a job and at the moment I also accept one-time orders for development or production.

Link to github project:

https://github.com/Mirn/LIR2032_tester/

MIT license, use on health!

I also do not mind talking about the experience of use. And help with advice.

')

Source: https://habr.com/ru/post/315110/

All Articles