The infrastructure of the communication center from the kettle, or the next construction of server - part 2

Hello!

Thanks to those who read the first part to the end and could understand me. In this part, I will try to set out the principles for the selection and placement of equipment so that you can spend less time searching for options that I think are right. And I am writing on this topic in order to read the alternative opinion in the comments.

Let me remind you that the articles for those who have to work are faced with the need to solve completely different problems in the construction and maintenance of small server / avtozalov. It will also be useful to read the blogs of CROC and Dataline on the topic of data center infrastructure.

(maybe someone else is there, did not see, sorry) .

So, it is necessary to summarize the first part. You have a room that will satisfy the following points:

This is the minimum set to start. If you have a communication center, you need to follow the regulatory documentation quite clearly. Suppose now that small telecom operators can hand over their nodes using a simplified system, without projects for everything and everyone (with the exception of the project for the required type of communications center, in which it still mentions power supply, fire extinguishing, lighting, and other infrastructure of the gates, but projects for many separate engineering systems are no longer needed).

In the last article, I mentioned why we need cabinets, i.e. racks with external walls and doors that close.

I myself do not have much experience with different brands. At the exhibition, svyazexpo used to present many brands and everyone has everything beautiful and a set of accessories usually satisfies any need ... But all this is very expensive! When we were looking for suitable cabinets for ourselves - everything was against us: starting from the exchange rate, ending with the fact that all stores selling Hyperline (which were simply cheaper than the rest and there is a feeling that these Chinese want to keep their brand at the right level) seems purchased at the same warehouse, where, as we were told, there were 10 racks at that time and all of them were reserved by some of the stores for the project. As a result, we bought something "under the license of a company from the USA made in China." After finishing a bit (namely, by welding the base instead of the bent legs and tightly linking the cabinets with each other over the roofs with a metal plate), we got cabinets that suit us by physical parameters.

In terms of parameters, I suggested in the last part to consider the minimum dimensions of 42U, 800x1000. This will help meet typical needs:

I would recommend everyone to take the maximum height, since units are a precious resource that cannot be increased. But it is necessary to take into account the distance to the mesh trays, so that they would not become an obstacle to stand up cabinets "in full growth."

Naturally there are needs for which it is possible to apply racks, both single-frame, and two-frame. If you want to take out cross over crosses, place an equipment stand, make a power supply rack (if you have several relatively small elements of its support, but already large ones, that would waste space in the cabinet with the equipment).

Last time I mentioned that the input must be done with the possibility of emergency input reserve - DGU you need power / size. If you do not want to pay for a finished electrical product with a passport, you can collect it yourself at your own risk. The web is full of instructions with diagrams and assembly rules. But you need to remember one important point - if you implement mechanical and electrical interlocks - the switching time will be noticeable for the equipment. That is, we must remember about the operational reserve - UPS and inverters with battery.

Telecommunication equipment is very sensitive to the quality of the power supply, so you should choose the UPS not lower than the online version of their implementation. Such UPSs work in two stages of converting the type of current - first to a constant, at this stage a circuit is connected with internal and external (via a special connector) battery, then the internal inverter converts it back to an alternating one. This UPS gives a number of buns:

Such UPSs are expensive. But because of their level, they usually allow a lot:

The advantages may seem small, but what else do you need from the power backup system? For me, the biggest mystery is why, for example, the APC Symmetra series is so expensive compared to the APC smart-ups (now I would choose another brand of UPS, but if we compare, then two product lines from one manufacturer). If suddenly someone understands why the UPS has to pay several hundred thousand rubles to feed 1-2kW consumers for just 15 minutes, please tell us.

In order for your installation to be of high quality, it is not enough just good materials, knowledge of cases on the organization and installation of the cable system. It is necessary to have suitable tools that do not let you down.

I will not argue that I have given below all the necessary set of tools, as I myself use a rather limited set in everyday life. Perhaps I just list it and explain what the nuances of choice.

For everything else that may come in handy for a communications engineer, I can’t say anything important, and I don’t need to - all the same there’s no overview of tools.

Of course, I am not going to advise this or that equipment for organizing communications - this is everyone’s business, and who am I to create these holivars? Of course, you will first choose according to their TX, for the sake of which the purchase is made. But still, some of the principles can be followed with any normal equipment, simply by paying more money.

1. The most important point, in my opinion, is the ability to connect 2 power sources. This can be as two power supplies, and output to the battery circuit. As for the first, everyone probably knows that there are two power supplies in the equipment. Often, you can even insert blocks of different types - AC or DC. I use wherever possible, two different types of power supply units. And both units are powered. I don’t understand why colleagues from Ukraine, who built and transferred data centers for hosting provider , used only one power supply unit. After all, the second is in standby mode and does not consume electricity, but it works in hot pickup and without interruption is included in the work, if the first power supply is de-energized. The profit from this is quite tangible:

I have practically no devices with one power supply at the communication centers. There is only one TDM switch in which there is nothing to break, since it operates from direct current and its chassis is simply a bus for powering independent signal-processing processors. As well as a couple of switches from cisco and juniper, which in turn are used only for the needs of the office or they are reserved by bonding on servers or media gateways by another switch. In addition, I can even give an example when a number of vendor products (Russian, by the way) work on the same power supply units — both trunk gateways (sip-to-PRI) and switches of different levels. Thanks to this, it is not necessary to keep the SPU BP for each type of equipment separately, but you can take a certain percentage of the total mass (for example, I have a 10% reserve of what can fly out).

But if you have to come to terms with the need to use equipment with one power supply unit - install a small AVR for it right inside the rack. I got this idea from this article. In general, if I had seen it before, I would not have written anything about power supply at all, but advised me to read that work. In other matters, I write all this from the position of a small business engineer, where a lot of things have to be done not by their specialization. Maybe someone wants to delve a little deeper into the nuances.

')

2. I understand that there may not be very many engineers involved in TDM or classic telephony (or they have not yet had the opportunity to leave comments), but I consider it necessary to leave my opinion on this topic: if you are planning to buy equipment, where there is a choice PRI / BRI or analog interfaces in physical performance with an amphemol connector or RJ- * - choose amphemol) Someone will say that I am an old farmer, but even if you do not need to periodically transfer the subscriber / station line from one port to another - amphemol embroidered on the cross, boo The children are much more reliable in connection quality and unsurpassed in cross-port density. And to throw a linear path from the subscriber cross to the station or transport is much more correct than the cross, which does not affect anything except the port it serves.

True, I encountered this possibility only once - it was the LG-Ericsson IPECs station ... then at the insistence of the customer’s engineer we ordered boards with 8p8c connectors - he himself suffered with it (and then others suffer after it).

3. Absolutely all the equipment should allow you to mount it in a rack for 19 "(or the size that you use) mounting profile. In an extreme case, it is necessary to allocate a console shelf for this equipment on which to place it, with fixation (for example). From the same series - it is necessary to avoid equipment with external power units.In addition to the fact that it is a headache for organizing the inclusion in the socket blocks (a rare power supply unit can boast of modest dimensions and not interfere with its neighbors), they also fall out without problems. I tie them to the socket block.

In my practice, I have met a ban on placing equipment in rented racks if it cannot be mounted on a profile. There's something about it.

4. Servers. I will list, in my opinion, the most important points:

Disks, raid level, memory sizes and etc. - here I would have talked with someone on occasion. In one of those topics about the data center and the server were comments on the topic of Tower or Rack execution. Both options are valid in certain cases. I looked at the prices of cabinets - for some reason, even domestic production began to cost twice as much (35k on average for a 24U cabinet). This money is better to invest in server TX.

Probably we all love to look at the pictures of the beautiful branch of the wires from the servers and patch panels. But if everything is clear with the patch panels, you immediately make a stationary placement of the cable harness and ports, when you can be confused, think of how you will be given twisted pairs in a harness and then the harness itself will go along the rack. What to do if you have non-spherical servers in a vacuum, where you only need to plug in the power cord and the ethernet network? And let's say you don't have KVM in the rack, i.e. you as required connect the monitor and the keyboard here and there. And they can be from a different manufacturer and these or other ports will be from different sides. And in some servers you want to plug in USB-to-COM adapters for emergency management of equipment consoles through the server. As a result - on the back side you have an interlacing of cables, both power and for data transmission, in one form or another. Those. in fact, you have no uniformity like this:

In my opinion, absolutely no reason to strive for uniform beauty. For you, the most important thing is the reliability of the connection and the practicality of operation. By diverting the data cables to one side, and the power cords from the power supplies to the other, in a vertical organizer, you are quite to ensure the accuracy of installation. And if you manage to tie a group of cords with a velcro fastener, it will be quite good.

I am sure that on some points many will disagree with me. , — , . - (, ), :

. , 10-15 , , , , - ? - ( PRI ). , , , 10-15 . ? ( , ), « — PON». , , , . 800 5-10% ( — ). , . . . ( — 10 ) , . , ( ) , . .

, :

, .

PS: - , , — . , .

Thanks to those who read the first part to the end and could understand me. In this part, I will try to set out the principles for the selection and placement of equipment so that you can spend less time searching for options that I think are right. And I am writing on this topic in order to read the alternative opinion in the comments.

Let me remind you that the articles for those who have to work are faced with the need to solve completely different problems in the construction and maintenance of small server / avtozalov. It will also be useful to read the blogs of CROC and Dataline on the topic of data center infrastructure.

(maybe someone else is there, did not see, sorry) .

So, it is necessary to summarize the first part. You have a room that will satisfy the following points:

- withstand point loads on the floor and floors, as well as built of fire-resistant building materials (this is for the building project).

- cable entry routes (various) to racks are organized. (this is to the PUE, BCH 116-93)

- the floor level is raised above the floor level of adjacent rooms and racks are raised above the floor on the frames or using the common raised floor system.

- there is a power supply system with this type of reserve that suits you or is prescribed to you by regulatory documents of the Ministry of Communications. (This is a bundle of quotes from the previous article)

- air conditioning with a reserve.

- lack of sanitary communications in dangerous proximity.

This is the minimum set to start. If you have a communication center, you need to follow the regulatory documentation quite clearly. Suppose now that small telecom operators can hand over their nodes using a simplified system, without projects for everything and everyone (with the exception of the project for the required type of communications center, in which it still mentions power supply, fire extinguishing, lighting, and other infrastructure of the gates, but projects for many separate engineering systems are no longer needed).

A little about cabinets.

In the last article, I mentioned why we need cabinets, i.e. racks with external walls and doors that close.

I myself do not have much experience with different brands. At the exhibition, svyazexpo used to present many brands and everyone has everything beautiful and a set of accessories usually satisfies any need ... But all this is very expensive! When we were looking for suitable cabinets for ourselves - everything was against us: starting from the exchange rate, ending with the fact that all stores selling Hyperline (which were simply cheaper than the rest and there is a feeling that these Chinese want to keep their brand at the right level) seems purchased at the same warehouse, where, as we were told, there were 10 racks at that time and all of them were reserved by some of the stores for the project. As a result, we bought something "under the license of a company from the USA made in China." After finishing a bit (namely, by welding the base instead of the bent legs and tightly linking the cabinets with each other over the roofs with a metal plate), we got cabinets that suit us by physical parameters.

In terms of parameters, I suggested in the last part to consider the minimum dimensions of 42U, 800x1000. This will help meet typical needs:

- Place a vertical organizer, or just have a place to divert not only single cables, but also a whole bundle of equipment. After all, if you have a width of 800, then approximately 10 cm of space will remain on the left and right sides, which is usually closed by vertical organizers.

- Deepen the mounting profiles by 10cm, in order not to affect the patch cords and other cables that are included in the equipment, both front and rear. At the same time should be placed long servers (up to 800mm).

- Such cabinets must be heavy.

- They have a place to set the ground bus.

- Mandatory numbering of units on mounting plates, both front and rear. This will greatly facilitate the life and the process of installation and operation.

- Removable side panels. Yes, I said that they should always be closed and in no case through them not to pull anything. But at the extreme racks in the row, this can be useful and even once helped me to create a multi-level construction of mesh trays inside the cabinet, so that it would be nice and neat to place the “sausages” from the telephone station and transport, with a 19 "cross-frame connection

- Usually manufacturers are produced together with cabinets and a minimum set of accessories for them. Most likely, you will only need vertical organizers and ventilation modules, if cold air is supplied from the bottom of the rack. Everything else can be done with mesh trays and standard fasteners.

I would recommend everyone to take the maximum height, since units are a precious resource that cannot be increased. But it is necessary to take into account the distance to the mesh trays, so that they would not become an obstacle to stand up cabinets "in full growth."

Naturally there are needs for which it is possible to apply racks, both single-frame, and two-frame. If you want to take out cross over crosses, place an equipment stand, make a power supply rack (if you have several relatively small elements of its support, but already large ones, that would waste space in the cabinet with the equipment).

A little about the power supply equipment.

Last time I mentioned that the input must be done with the possibility of emergency input reserve - DGU you need power / size. If you do not want to pay for a finished electrical product with a passport, you can collect it yourself at your own risk. The web is full of instructions with diagrams and assembly rules. But you need to remember one important point - if you implement mechanical and electrical interlocks - the switching time will be noticeable for the equipment. That is, we must remember about the operational reserve - UPS and inverters with battery.

Telecommunication equipment is very sensitive to the quality of the power supply, so you should choose the UPS not lower than the online version of their implementation. Such UPSs work in two stages of converting the type of current - first to a constant, at this stage a circuit is connected with internal and external (via a special connector) battery, then the internal inverter converts it back to an alternating one. This UPS gives a number of buns:

- the correct sinusoid (in other matters its correctness is still on the manufacturer’s conscience)

- seamless reserve switching

- the ability to adjust the frequency and voltage output

Such UPSs are expensive. But because of their level, they usually allow a lot:

- monitor power status

- connect external battery assemblies, both handmade and accessories from the manufacturer

- protect lines for power distribution (sometimes even disconnect and turn on remotely)

The advantages may seem small, but what else do you need from the power backup system? For me, the biggest mystery is why, for example, the APC Symmetra series is so expensive compared to the APC smart-ups (now I would choose another brand of UPS, but if we compare, then two product lines from one manufacturer). If suddenly someone understands why the UPS has to pay several hundred thousand rubles to feed 1-2kW consumers for just 15 minutes, please tell us.

The principle of choice of any sections of the cable and distribution devices. Power.

- The power cable must have a GOST certificate. As I mentioned in the last part, no TU can be taken - you fall on low operating performance.

- A mono-core cable necessary for ensuring the transfer of all phases (1 or 3), N and PE conductors separately, suitable for the section at the maximum load that must be provided on this line, is laid on stationary objects. Of course, if you need to maneuver in places where it is difficult to lay a hard cable, you can use a cable with stranded conductors. But note that the conductors of such a cable, before being clamped to the terminal, must be crimped with a tip (NShVI, TML, etc.) with special (suitable for the tip) pliers. I saw how the NShVI tip was simply put on and clamped with a screw in the bus or an AV (circuit breaker) - this is devilry complete and is not a collapsible joint, which is required to be achieved according to the requirements of PUE.

- I would recommend to choose the maximum fireproof cable - VVGNG-RFLS (with mono-conductor) and PVA LS (with multicore)

- The lines immured into the wall or found in easy accessibility in a passable place (where they can be believed by trolleys, other equipment by carelessness or simply acting on them accidentally) are laid in a corrugation (PUE-7-Electric wiring and cable lines - 7.1.37). Corrugation is different - choose to fit your needs. I always take either UV protection (does not shatter from it, like a normal gray corrugation) or orange, which is usually very durable (100kg of a person’s weight in a running shoe withstands, if not jumping, but this by itself depends on the diameter).

- Outlets, as a rule, all buy Chinese, with variations of the “wired” cable or with connector C13, with or without a switch. First, the switch will never need anyone on consumers who should never be turned off. But most of all (from my practice) they are simply touched and quenched by the floor of the rack (yes, there are covers on them, but then immediately seal them with a poxypol and do not create the likelihood of emergency situations on this basis. Secondly, you are unlikely to buy such blocks and special cables of the desired length (and what is it if you don’t know in advance?), where there will be a special frame on the outlet that will hold the cable. Accordingly, take outlets with the terminal block, so that you can connect your cable that you lay from your power source, located I looked for such a very long time and bought all kinds of nonsense, which I simply store now, because I don’t want to use it on my nodes. Thirdly, there is a problem with most of the outlet blocks where the cable is embedded. As a rule, these units are 10A, which is basically not enough (2.2kW). And even if you find sockets on which 16A is written - where is the document confirming this (concerns both the unit itself and the cable that feeds it)?

- Try to buy power equipment with a wide range of input voltages. The fact is that the standard for power quality in Europe is much tougher and device operation is allowed at voltages from 190–200 to 240–250V. At the same time, for the US market, some models of the same APC are available with input ranges from 140 to 260V. Such wide ranges make regular situations when, for more “delicate” devices for the European market, they will trigger protective mechanisms.

- Embossing the cable and AV to connect the UPS or inverter to the mains - read the recommendations in the instructions. The fact is that the cable must be chosen not by the current that the transformers (power modules) will take in normal mode. Suppose you connected the UPS to a 5.5 kW cable 4mm 2 , 25A AB, and the voltage drops to 140? You will get 40A on current. The AV will work, although not immediately (the trip unit has a time lag depending on the category AB), the line will be de-energized. How long will the batteries last? And if at night you do not have a shift on the node? And what will the shift duty do? I suspect that nothing but back to turn on AB. In general, in terms of the choice of cross-section, it is necessary to rely on the PEA-7 p.1.3.10-1.3.11 , but it is also necessary to take into account a number of other reasons and conditions, it seems to me quite clearly explained on one form of electricians / power engineers, where I myself started to enter the topic because of the desire / need to do it correctly and independently.

The principle of choice of any sections of the cable and distribution devices. Low current.

- On a low-current cable (UTP / FTP, etc.), a declaration of conformity in the field of communication is mandatory.

- Patch panels are best chosen with a frame supporting the outgoing cables for individual fixation, which will improve the quality and reliability of installation. This is especially noticeable when the panel with 24 or 48 ports - the harness is quite massive and can weaken the contacts of some of the cores with a clip in the connector.

- For the transport of a large number of E1 (PRI) streams, do not use the 4-pair UTP if the connector to the equipment does not allow this. For example, I have equipment where in one RJ-48 connector (45, 8p8c, and others like them) two PRI streams are combined. It is very convenient to use the red and blue pairs for one, green and brown for another. But if you have one PRI in one connector, then use a 2-pair UTP. This will significantly reduce the amount of harness and allow beautifully embroider the threads on the skirting.

- Plinths, of course, use as high as possible, from proven manufacturers. I try to use skins like LSA Plus from krone. In the last part, I wrote that a bad alloy of metals and plastics will eventually manifest itself in the form of an oxide film (with consequences for the deterioration of the quality of the compound) and drying of the plastic (small elements will keep bad on the mounting profile and break down small elements, especially if they are in active operation). Although I have several rexant plinths dismantled from the old cross-country, which have worked well for about 6-7 years (of course I can’t check the terminals themselves, especially with a fresh installation).

- And the point is similar to corrugation for power lines - nylon ties. They also come in different qualities. This manifests itself both in the initial strength of the fastener (you can check it by pulling something and try to break it), and with time from the drying of the plastic. Of course, the low-point harnesses should live without loads of their own weight and run along special tracks so that nothing would affect them. In other words, they should always be attracted to trays both on a horizontal track and when descending onto racks and crosses. As an alternative, I can advise the Velcro fasteners . The first they seemed to appear at Hyperline, and now it seems to be full of all sorts of different in price and color - it is very convenient to assemble a beam departing from the front ports of multiport equipment, when the patch cords are periodically on / off.

Tool.

In order for your installation to be of high quality, it is not enough just good materials, knowledge of cases on the organization and installation of the cable system. It is necessary to have suitable tools that do not let you down.

I will not argue that I have given below all the necessary set of tools, as I myself use a rather limited set in everyday life. Perhaps I just list it and explain what the nuances of choice.

- Crimper for crimping "RJ-45". In addition to being lightweight, it is necessary to take into account its mechanism. I use the NT-L2182R, because its “head” is made with the minimum required volume of light metal, and the plate with slots for pressing the terminals into the cores is connected with two handles, which ensures a smoothly vertical lift of this plate, which in turn ensures uniform pinch on all sides of the connector. In this case, you do not need two, or even three holes for different types of connectors, since all types of jacks are normally inserted and crimped in the hole under the 8-pin connector. But ideally you don’t need to use RJ-12 type convectors (or whatever they are called correctly), because it is cheaper and easier to use 8p8c everywhere (RJ-45 among the people). In good tongs, there are also high-quality knives, well fitted for parallel reduction in compression, both for cable lengths and for removing external insulation.

- Clothespin for removal of isolation. I use the simplest, so I can not advise anything here. Maybe I just got a good copy and he does an excellent job with his work. Periodically during installation, I check the integrity of the insulation of the cores on the shear line of the external insulation. In principle, I always succeed in such a way that the clothespin only scratches the insulation, and I take it off with a break in the place of the “cut”, which 100% saves from damage to the insulation of the wires.

- Side cutters Biting off periodically still need something. The most frequent thing I have to do is to remove the ties or cut off their tails after tightening. The essence of the choice of side cutters for such purposes - they must be small, with sharp ends and the most important thing - a flat platform when closing the jaws. This is necessary in order to cut off the tail of the tie and not leave a “stump” from it, about which then everyone will scratch their hands. When I see in my farm a coupler with a stump after the lock, I'm straight korezhit straight :)

- Crossing knife. Here I can say that you only need to buy the original krone, in order to get consistently high-quality results of driving the cross to the plinth and they would not fall apart over time. Over the past 3 months, I had to punch about 5000 lived in skirting boards or patch panels, and they never failed me (port 1 on the patch panel for some reason does not work, but so far it’s not reached because of the loyal Lan tester) . For all my practice, I came across cheap replicas of the Kronov knife, and each time I just threw them away after working with them, so that they would no longer catch my eye.

For everything else that may come in handy for a communications engineer, I can’t say anything important, and I don’t need to - all the same there’s no overview of tools.

Equipment.

Of course, I am not going to advise this or that equipment for organizing communications - this is everyone’s business, and who am I to create these holivars? Of course, you will first choose according to their TX, for the sake of which the purchase is made. But still, some of the principles can be followed with any normal equipment, simply by paying more money.

1. The most important point, in my opinion, is the ability to connect 2 power sources. This can be as two power supplies, and output to the battery circuit. As for the first, everyone probably knows that there are two power supplies in the equipment. Often, you can even insert blocks of different types - AC or DC. I use wherever possible, two different types of power supply units. And both units are powered. I don’t understand why colleagues from Ukraine, who built and transferred data centers for hosting provider , used only one power supply unit. After all, the second is in standby mode and does not consume electricity, but it works in hot pickup and without interruption is included in the work, if the first power supply is de-energized. The profit from this is quite tangible:

- salvation from not a neat engineer or poor-quality connection to the power grid and other local disasters.

- There is always a need for cable management, and when connected to two power lines, reorganizing the power cords will never be a problem. It will even help to move the piece of iron to another rack in some late evening even in another rack (if it is a server, for example), if you really need and do not want to turn it off. In this case, to maintain uptime and complete transfer (along with data transfer patch cords), you will need to have a bonding.

- using a different type of power supply network, you are backed up not only for a power supply failure, but also for the entire power supply network of a particular type of power supply (for example, the UPS will bend, or it must be serviced, or vice versa, everything is the same with a DC network inverter).

I have practically no devices with one power supply at the communication centers. There is only one TDM switch in which there is nothing to break, since it operates from direct current and its chassis is simply a bus for powering independent signal-processing processors. As well as a couple of switches from cisco and juniper, which in turn are used only for the needs of the office or they are reserved by bonding on servers or media gateways by another switch. In addition, I can even give an example when a number of vendor products (Russian, by the way) work on the same power supply units — both trunk gateways (sip-to-PRI) and switches of different levels. Thanks to this, it is not necessary to keep the SPU BP for each type of equipment separately, but you can take a certain percentage of the total mass (for example, I have a 10% reserve of what can fly out).

But if you have to come to terms with the need to use equipment with one power supply unit - install a small AVR for it right inside the rack. I got this idea from this article. In general, if I had seen it before, I would not have written anything about power supply at all, but advised me to read that work. In other matters, I write all this from the position of a small business engineer, where a lot of things have to be done not by their specialization. Maybe someone wants to delve a little deeper into the nuances.

')

2. I understand that there may not be very many engineers involved in TDM or classic telephony (or they have not yet had the opportunity to leave comments), but I consider it necessary to leave my opinion on this topic: if you are planning to buy equipment, where there is a choice PRI / BRI or analog interfaces in physical performance with an amphemol connector or RJ- * - choose amphemol) Someone will say that I am an old farmer, but even if you do not need to periodically transfer the subscriber / station line from one port to another - amphemol embroidered on the cross, boo The children are much more reliable in connection quality and unsurpassed in cross-port density. And to throw a linear path from the subscriber cross to the station or transport is much more correct than the cross, which does not affect anything except the port it serves.

True, I encountered this possibility only once - it was the LG-Ericsson IPECs station ... then at the insistence of the customer’s engineer we ordered boards with 8p8c connectors - he himself suffered with it (and then others suffer after it).

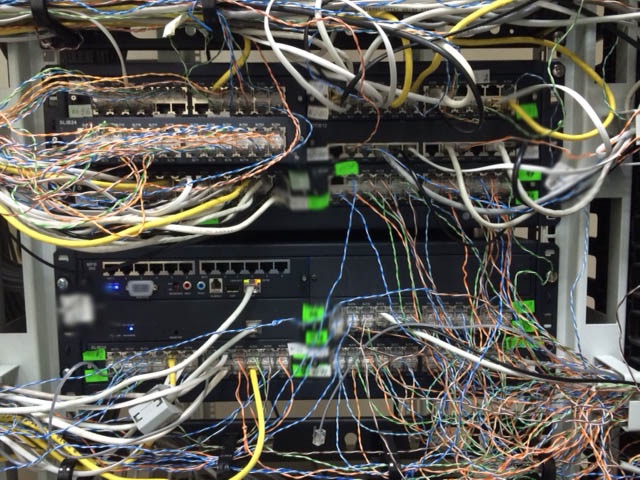

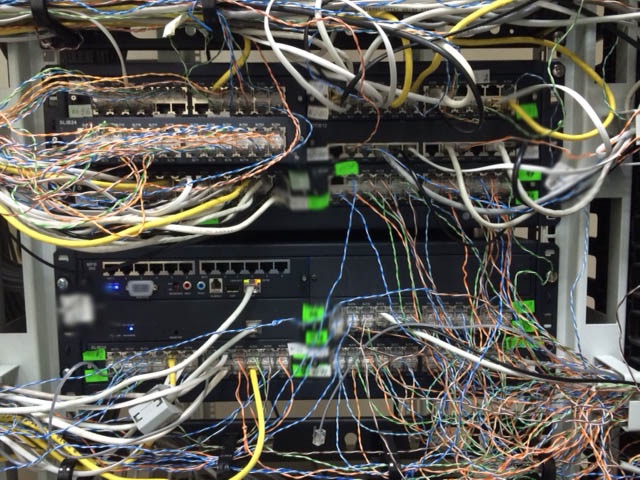

sorry that the picture turned out this way, but I had to mark many marks of the engineers of this object

3. Absolutely all the equipment should allow you to mount it in a rack for 19 "(or the size that you use) mounting profile. In an extreme case, it is necessary to allocate a console shelf for this equipment on which to place it, with fixation (for example). From the same series - it is necessary to avoid equipment with external power units.In addition to the fact that it is a headache for organizing the inclusion in the socket blocks (a rare power supply unit can boast of modest dimensions and not interfere with its neighbors), they also fall out without problems. I tie them to the socket block.

In my practice, I have met a ban on placing equipment in rented racks if it cannot be mounted on a profile. There's something about it.

4. Servers. I will list, in my opinion, the most important points:

- should manage remotely in the off state - IPMI, iKVM, IDRAC, ...

- two power supply units

- there must be a hardware raid (after all, they understand the difference between a raid in a motherboard and a separate controller?)

- it would be nice to be able to insert full-size expansion cards (but then think about server tasks)

- the number of eth ports also depends on the server's tasks - for fault tolerance, you may need bonding, which takes 2 ports. You may also need to connect the server to other networks, make LAG, vrrp with other servers ... in general, 2 ports are good, and 4 will most likely cover all your tasks. So why limit yourself?

- we use servers with declarations of conformity in the field of communications, which, in general, not everyone needs. But the servers, where the work of ASR (the automated system of calculations, in the common people - billing), should have such a declaration for the application in the package of documents for registration of the communication node.

Disks, raid level, memory sizes and etc. - here I would have talked with someone on occasion. In one of those topics about the data center and the server were comments on the topic of Tower or Rack execution. Both options are valid in certain cases. I looked at the prices of cabinets - for some reason, even domestic production began to cost twice as much (35k on average for a 24U cabinet). This money is better to invest in server TX.

A little thought on cable management inside cabinets.

Probably we all love to look at the pictures of the beautiful branch of the wires from the servers and patch panels. But if everything is clear with the patch panels, you immediately make a stationary placement of the cable harness and ports, when you can be confused, think of how you will be given twisted pairs in a harness and then the harness itself will go along the rack. What to do if you have non-spherical servers in a vacuum, where you only need to plug in the power cord and the ethernet network? And let's say you don't have KVM in the rack, i.e. you as required connect the monitor and the keyboard here and there. And they can be from a different manufacturer and these or other ports will be from different sides. And in some servers you want to plug in USB-to-COM adapters for emergency management of equipment consoles through the server. As a result - on the back side you have an interlacing of cables, both power and for data transmission, in one form or another. Those. in fact, you have no uniformity like this:

In my opinion, absolutely no reason to strive for uniform beauty. For you, the most important thing is the reliability of the connection and the practicality of operation. By diverting the data cables to one side, and the power cords from the power supplies to the other, in a vertical organizer, you are quite to ensure the accuracy of installation. And if you manage to tie a group of cords with a velcro fastener, it will be quite good.

Conclusion

I am sure that on some points many will disagree with me. , — , . - (, ), :

- , «»,

- , ,

- , /

- ,

- — … ( )

. , 10-15 , , , , - ? - ( PRI ). , , , 10-15 . ? ( , ), « — PON». , , , . 800 5-10% ( — ). , . . . ( — 10 ) , . , ( ) , . .

, :

- . , . .

- Documentation. . . - , , . - , ( — ). - , , .

- , , , . . , — . . .

, .

PS: - , , — . , .

Source: https://habr.com/ru/post/313924/

All Articles