Versatile Link - universal connection

The fiber optic components of the Versatile Link (VL) line, manufactured by Broadcom Limited (formerly Avago Technologies), are deservedly popular among developers of industrial information transmission systems around the world. The use of optical fiber in various areas of industry, energy and medicine was covered in our previous article . In the same article, we will review the Versatile Link component line for data transmission over plastic optical fiber (POF) in industrial environments.

LLC "EFO" is the official distributor of Broadcom Limited and has extensive experience in the supply of fiber-optic components (in particular, VL components) for representatives of various industries.

Versatile Link Components - from Hewlett Packard to Broadcom Limited

The line of fiber-optic components Versatile Link was developed by Hewlett Packard (HP) more than 20 years ago specifically for industrial data transmission systems and gradually began to gain more and more popularity. The components were designed to transmit data via a plastic optical fiber (POF) with a core and cladding diameter of 980/1000 μm, as well as a 200/230 μm quartz optical fiber in a polymer jacket (HCS) for longer communication lines (more about optical fiber types can find out here ).

The line included discrete optical transmitters and receivers, as well as interconnects (connectors and adapters), which are structurally different from all other fiber-optic components manufactured at that time. Looking ahead a bit, we note that it was precisely the special design of the VL components that was the main reason for their widespread distribution, since it made it possible to quickly and simply organize the transfer of information even in the field. Also, developers were attracted by the relatively low cost of components and their reliability.

HP's semiconductor component division later became part of Agilent Technologies, and then was transformed into Avago Technologies. In February 2016, the merger of Avago Technologies and Broadcom Corporation formed Broadcom Limited. Despite significant changes in the company's product portfolio over time, the Versatile Link product line did not lose its position, but, on the contrary, expanded, modernized and mastered all new areas of application. To this day, Versatile Link components firmly occupy their place among Broadcom's huge range.

So, let's look at the main features of the components of the Versatile Link line, thanks to which they are widely used in industry. We will not discuss the features of specific components, but give a general description of each group (active components, connecting products, cable) and note information that helps to get an idea of the range of VL components. You can familiarize yourself with the VL component catalog on the infiber.ru website (the EFO website for fiber optic products) or on the Broadcom official website .

Transmitters and receivers

In computer networks, optical transceivers are usually used as active equipment. They are transmitter and receiver in the same package. But in industrial applications, the need for two-way transmission of information does not always arise. Therefore, for more economical use of funds and space on the board, discrete transmitters and receivers are used. Such modules are included in the Versatile Link line.

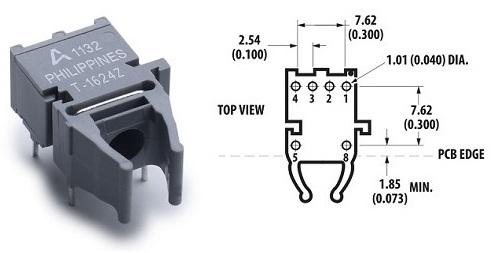

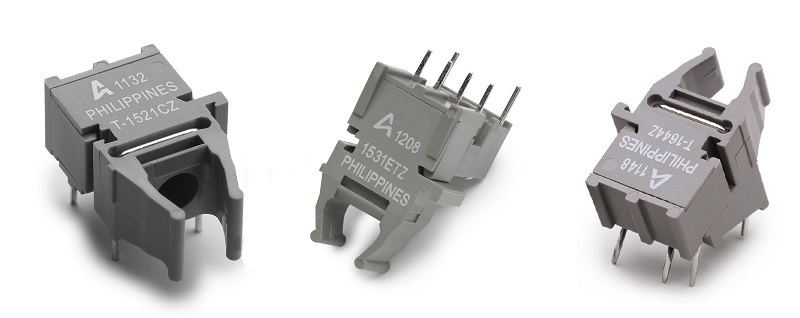

Both the transmitter and receiver have the same design. The body is made of durable flame resistant plastic that can withstand harsh operating conditions. The module has four outputs for control and two pins for additional fixation to the board. The distance between the terminals is the same as in the standard DIP8 package (2.54 mm). To identify the transmitting and receiving modules of their body have different colors. All VL components manufactured today comply with RoHS (directive on the restriction of harmful substances). The first modules were designed to operate at temperatures from 0 to 70 ° C. Subsequently, components operating in the industrial temperature range (from -40 to +85 ° C) were developed.

Cases are of three types, depending on the location of the optical port relative to the printed circuit board: horizontal, vertical and inclined. The port of the horizontal module when mounted on the board is oriented parallel to the surface of the board, and the vertical port is perpendicular. Some models also have a third modification, in which the port is located at an angle of 30 °. The possibility of such a choice gives additional freedom when designing a system.

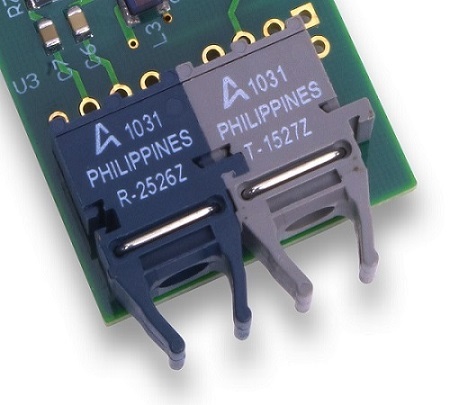

An interesting feature of the VL components is the ability to connect them together to save space on the board. This is possible due to the presence of an L-shaped protrusion on one side of the housing, which is inserted into the corresponding groove located on the opposite side of the adjacent module. It is not recommended to combine more than four modules together.

VL components have a special optical connector design. The input port has two flaps that align and secure the connector in the optical connector when it snaps into place. Such a mechanism minimizes losses at the junction and protects against accidental disconnection of the connector.

As mentioned earlier, Versatile Link components are designed to transmit data over plastic fiber. Some modules are also optimized for 200/230 micron HCS fiber.

VL transmitters and receivers are divided into several groups depending on the maximum transmission rate: up to 40 kbps, up to 1, 5, 10, 12, 50 or 160 Mbps. The transmission distance also differs, which depends not only on the characteristics of the active components, but also on the cable used and the operating temperature. The typical length of the communication line based on the VL components is tens to hundreds of meters, which satisfies most industrial applications.

Next, we consider the characteristics of transmitters and receivers in more detail.

Transmitters

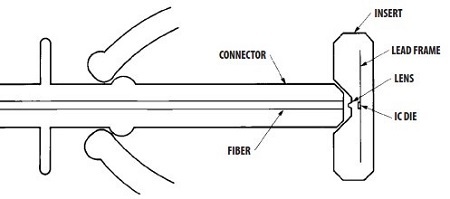

As a radiator in VL transmitters, an LED (LED) with a wavelength of 650 (660) nm is used. At this wavelength there is a minimum of attenuation in a plastic optical fiber. In addition, these LEDs are low cost. At the output of the transmitter is installed a lens that focuses the radiation of the LED into the optical fiber.

Most transmitters are emitting LEDs and do not have a built-in driver, which contributes to design flexibility. The exception is 50-megabit transmitters, which have a driver with a TTL input, and some models have a non-inverted input (the high level of the electric signal corresponds to the inclusion of the LED) and the inverted ones to the other (the low level of the electric signal corresponds to the inclusion of the LED).

Receivers

The receiving module contains a photodetector and a signal processing circuit of varying complexity. Most receivers have an output compatible with standard logic types. 50 Mbit receivers have TTL output (non-inverted or inverted). TTL output is also available for some 5-megabit receivers. 160 megabyte receivers have an analog output.

Transceivers

Broadcom also produces optical transceivers (transceivers) with a VL connector, designed to work with plastic optical fiber. However, they are structurally very different from the modules described above.

Connectors

Optical connectors VL are made of plastic and have a special design that is compatible with the connector of the optical module.

Broadcom produces VL connectors for POF 980/1000 microns and HCS 200/230 microns, and the connectors for POF have several modifications. Connectors differ in how they are mounted on the end of an optical cable. Part of the connectors is fixed with a metal crimp ring, but there are also models that do not require crimping with a special tool. In the latter case, the fiber is securely fixed by the connector body itself. Some VL connectors also have a latch, which is fixed in a special recess of the module case and gives the connection additional strength. The company manufactures simplex (single) and duplex (dual) VL connectors.

One of the main advantages of VL connectors is their ease of installation. The manufacture of an optical patch cord (cord) is possible in the field, does not require great skills and takes a few minutes. Importantly, epoxy adhesive is not used when mounting VL connectors. The necessary accessories (cleaver, polishing accessories and, if necessary, crimping tools) are significantly less expensive than in the case of quartz optical fiber. As an example, below is a video instruction of mounting a VL connector from the Broadcom company (the video uses a connector that is only suitable for transceivers with a VL connector).

To connect the line sections to each other, Broadcom also manufactures simplex and duplex adapters (sockets) with VL type connectors.

Cable

With VL components, POF 980/1000 µm and HCS 200/230 µm are mainly used. Broadcom offers several POF cable modifications. These are simplex cables in black plastic sheath with a diameter of 2.2 mm, as well as duplex cables of the zip-cord type (two cables connected by a jumper). According to the properties of the used fiber cables are of three types:

- POF cable with standard attenuation (0.22 dB / m);

- POF cable with reduced attenuation (0.19 dB / m);

- halogen-free POF cable with reduced attenuation (0.19 dB / m).

For the optical sensor of arc protection and other similar applications, POF cable is additionally available in a transparent sheath.

It is also possible to purchase ready-made POF patch cords. HCS fiber cables and patch cords can be purchased from other manufacturers.

Debug boards

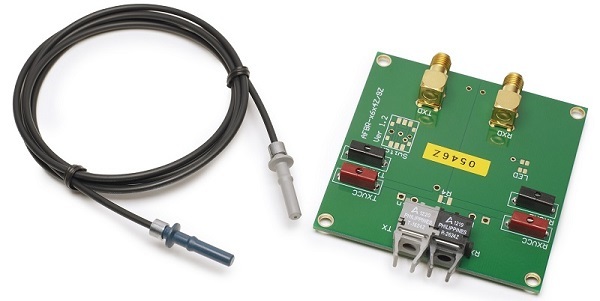

To test the capabilities of Versatile Link components and quickly create prototypes of devices, Broadcom also produces handy demo kits, consisting of a debugging board, a transmitting and receiving modules, and an optical patch cord.

"Universal Connection"

The Versatile Link line rightly bears its name ("universal connection"). The optical characteristics and design features of the VL components, together with their low cost and wide range of products, allow them to be used in countless many different industrial communication lines, as evidenced by more than twenty years of experience of developers around the world.

In the company "EFO" you can purchase components of this line, as well as get qualified technical advice on their use in industrial networks. The assortment of VL components can be found on our website:

Materials used:

- Versatile Link Family. Application Note 1035 (document Broadcom AV02-0730EN , 08.27.2015 )

- Broadcom Limited website: http://www.avagotech.com/products/industrial-fiber-optics

')

Source: https://habr.com/ru/post/308902/

All Articles