Optical fiber in industrial communication systems

In our previous article, we looked at the main types of optical fibers. Among other things, attention was drawn to the fact that the scope of optical fiber is not limited to computer networks. A growing number of areas of industry that use fiber-optic communication lines (FOCL).

The company "EFO" has extensive experience in the supply of fiber-optic components for industrial applications. And in this article we will look at the main features of optical fiber from the point of view of the specifics of industrial conditions and give some specific examples of its application in various industries.

Reasons for the use of optical fiber in industry

In industrial applications, there is rarely a need for high-speed signal transmission over long distances. Typical values of the transmission rate are limited to hundreds of Mbps, and the length of the communication link section is tens to hundreds of meters. Standard conditions based on twisted pair or coaxial cable, as well as wireless communication, fully meet these conditions. However, in industrial environments, factors such as the safety and reliability of information transfer are coming to the fore. And in this regard, other advantages of optical fiber make themselves felt, which significantly distinguish it from competitors. First of all, we are talking about the following two features of optical fiber:

- Immunity to electromagnetic radiation (EMR) . Industrial processes are often accompanied by a high level of electromagnetic noise, the source of which can be power plants, radio equipment and other technological equipment. Electromagnetic interference can lead to distortion or even complete loss of data. Unlike its competitors, optical fiber is made of a dielectric material, and therefore absolutely immune to electromagnetic interference. This allows you to lay an optical communication line in close proximity to sources of electromagnetic radiation (in particular, to power lines supplying process equipment). In addition, the fiber itself does not generate electromagnetic fields in the surrounding space, so no crosstalk occurs between adjacent fiber-optic communication lines.

- Galvanic isolation . Since the optical fiber is a dielectric, there is no electrical contact between the transmitting and receiving side. This allows you to solve a large number of problems associated with the potential difference of the connected equipment, the flow of the equalizing current with non-ideal grounding, as well as voltage surges and other emergency situations. Fiber provides isolation of significantly higher voltage than optocouplers and other microcircuits used for electrical isolation.

For these reasons, in many industrial applications, the best, and sometimes the only, correct solution is to use optical fiber. Industrial communication lines based on plastic (polymer) optical fiber (POF) have become very popular because they fully meet the requirements and at the same time attract with relatively low cost of components and ease of working with POF.

The range of possible applications of fiber (in particular, POF) in the industry is very diverse. Next, we briefly consider some specific examples taken from the Application Note (Application Note) , issued by Avago Technologies (now Broadcom Limited), one of the leading manufacturers of industrial fiber-optic components.

1. Process control

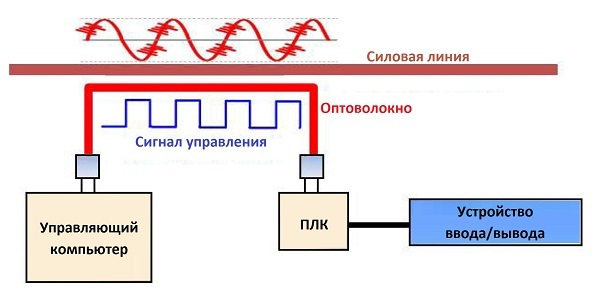

In automated industrial systems, controllers receive control signals from a computer that can be removed for some distance. The communication lines through which these signals are transmitted are often located along the power lines and near technological installations. To eliminate the effect of interference on transmitted signals, an optical fiber is used. So, with the help of optical fiber, you can organize communication between a computer and a programmable logic controller (PLC), as well as communication between several PLCs connected in a common information network.

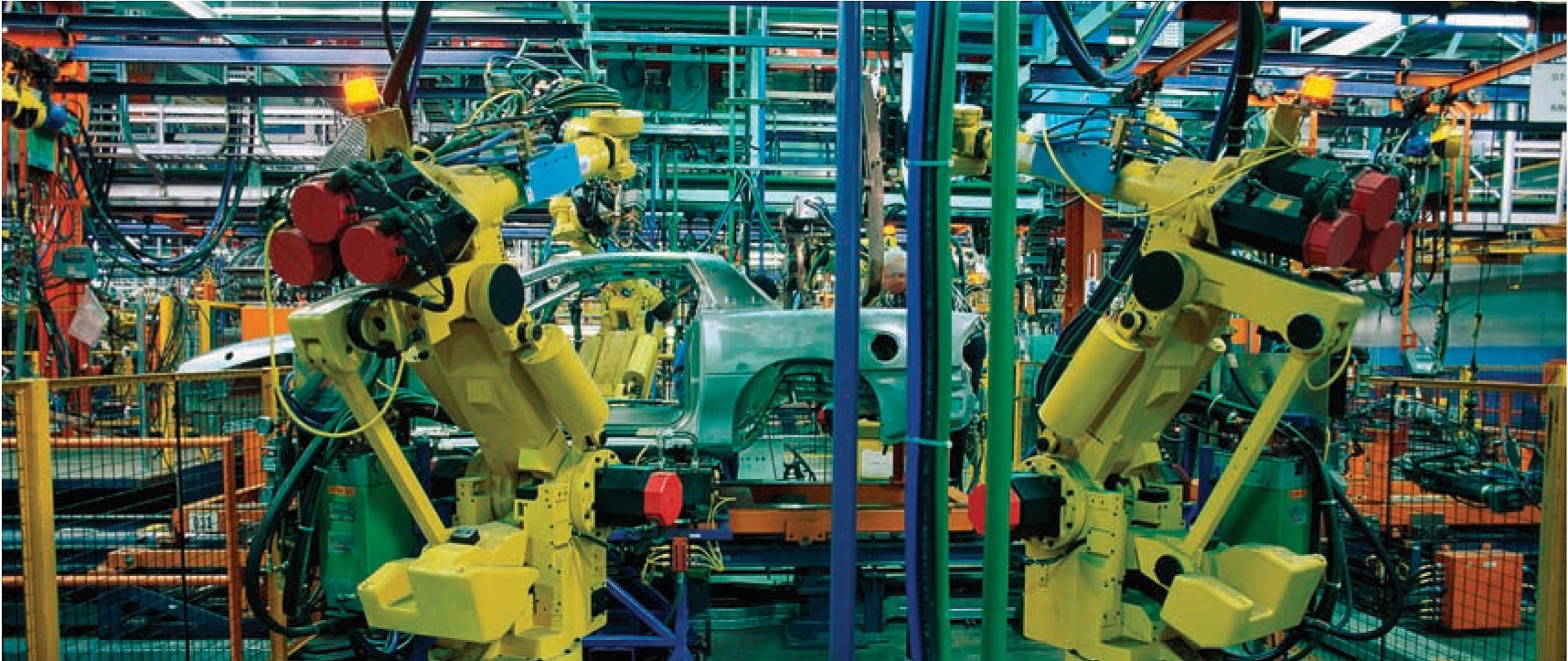

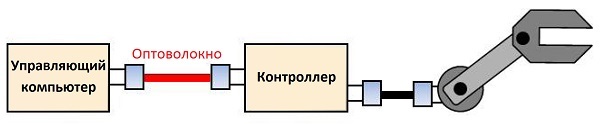

Another example is the control of industrial robots, the design of which includes electric motors, solenoids and other elements that create electromagnetic interference. The relative flexibility of the optical fiber also allows it to be used for communication between moving parts of the robot.

2. Data acquisition and measurement systems

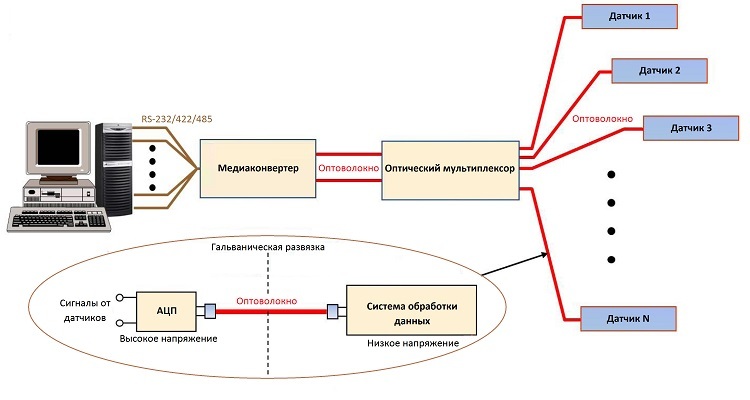

Of great importance in the production also play control systems. Often it is necessary to monitor various parameters of high-voltage equipment. The processing of the data obtained in this case is carried out using low-voltage microprocessor technology. Therefore, signal transmission requires reliable galvanic isolation, which is achieved with the use of optical fiber.

In automated instrumentation systems, the GPIB interface bus (IEEE-488) is also widely used. Using fiber, you can increase the distance between the measuring device and the computer that processes the information. This provides galvanic isolation and protection from electromagnetic interference, which is critical from the point of view of measurement accuracy.

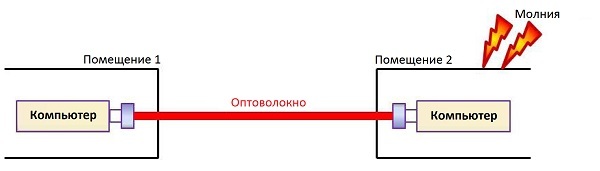

3. Protection against lightning strikes

If the process equipment is located in different rooms, fiber-optic communication between installations provides protection against possible damage caused by lightning strikes.

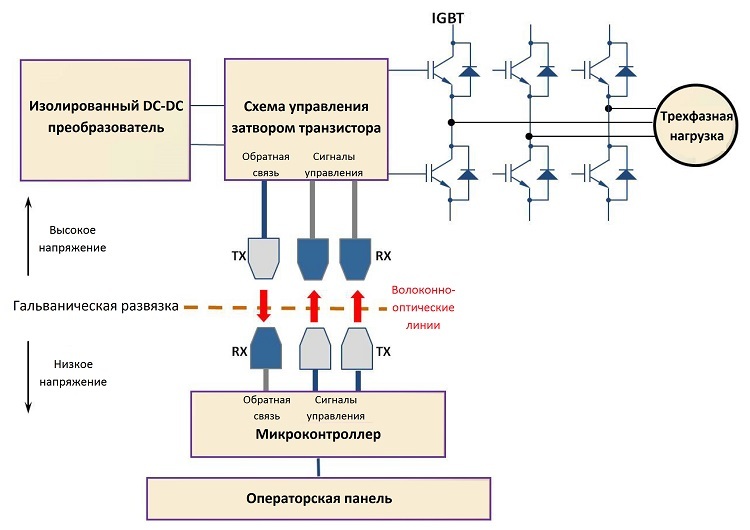

4. Power equipment

Optical fiber is used not only to transmit information from one industrial plant to another. Fiber-optic interfaces are often used inside the equipment for communication between its parts. As an example, IGBT control transistors, serving as electronic switches in inverters, switching power supplies and other power devices. Optical fiber provides reliable galvanic isolation between the low-voltage microcontroller, which forms the control signals, and the gate of the power transistor.

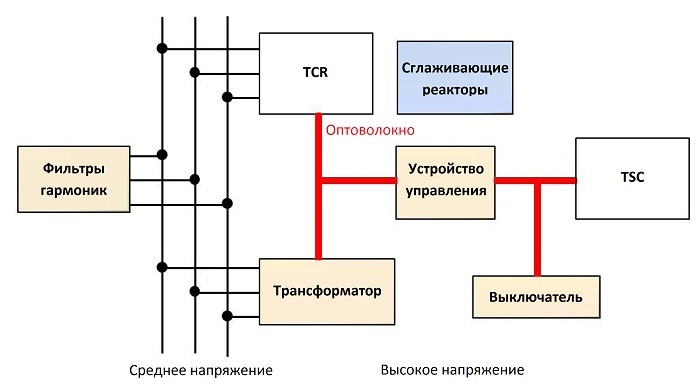

Another power electronics device that uses optical fiber is a static reactive power compensator (SVC - Static VAR Compensator), used in high-voltage systems to reduce the load on the distribution network, improve the quality of the supplied electricity and reduce costs. The main elements of SVC are thyristor switching capacitors (TSC - Thyristor-Switched Capacitors) and thyristor-controlled reactors (TCR - Thyristor-Controlled Reactor), the switching of which leads to the appearance of strong electromagnetic fields. Therefore, to transmit control signals and feedback signals in SVC, an optical fiber is used that is immune to interference and provides galvanic isolation.

5. Installations of alternative energy

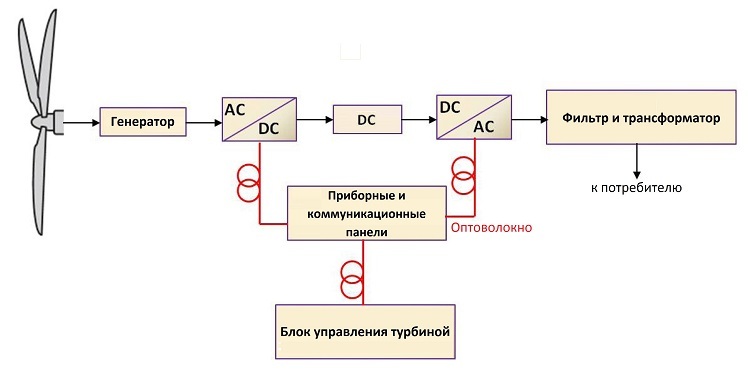

From the above, it can be seen that fiber can be used at different stages of the same process. As an example, let us consider such an area of industry that is gaining popularity in recent years as alternative energy. The most common areas today are wind and solar energy.

A wind generator (wind turbine - wind power installation) converts the kinetic energy of the wind flow into electrical energy. The design of the wind generator includes rectifiers, inverters, transformers and filters that carry out the necessary conversion of the generated electricity for its subsequent transmission over long distances. The connection of the power equipment of wind generators with the help of an optical fiber makes it possible to eliminate the effect of voltage surges and electromagnetic interference on the transmitted signals. Fiber optic components can be located in close proximity to equipment and power lines. Optical fiber can be used in the following wind power equipment:

- Shutter drivers of power transistors in rectifiers and inverters.

- Instrument and communication panels.

- Turbine control units.

- Systems for monitoring environmental conditions and equipment condition.

- Information networks of wind power stations.

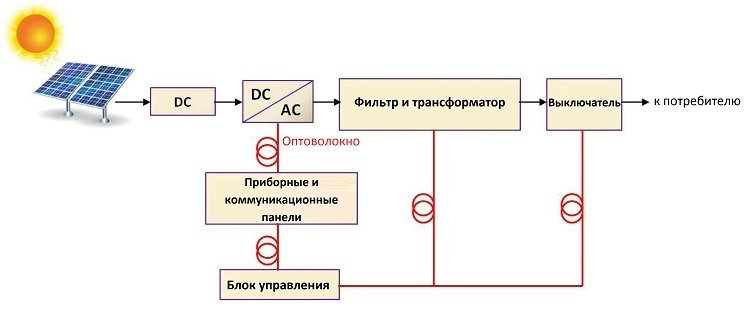

Similarly, optical fiber is used in the equipment of power plants based on solar cells that convert solar energy into electrical current. Optical fiber in solar power plants is used in the following systems:

- Shutter drivers of transistors in power inverters.

- Instrument and communication panels.

- Equipment for substation automation and relay protection.

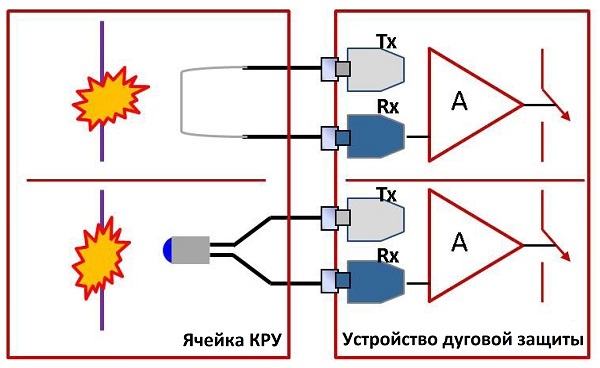

6. Optical arc protection systems

The following example of using optical fiber is somewhat different from all previous ones, because here the fiber acts not only as a communication channel, but as the main element of the system. It is a question of optical systems of protection against an electric arc in complete switchgears (KRU) of electrical substations. Such systems record the optical radiation of a flash of light that occurs during an arc short circuit. This approach minimizes the response time of the switch in the event of an accident. As a sensing element, a lens optical sensor is usually used, which collects flash radiation and transmits fiber to a control device, or a fiber optic sensor, which is a segment of optical fiber in a transparent sheath that detects light with its entire surface. Sensor control can be done remotely. Read more about optical systems for protection against arc faults can be found here .

7. Other automated systems

The need for centralized control of various installations also arises in other systems not related to production and energy. We give two examples in which it is advisable to use an optical fiber.

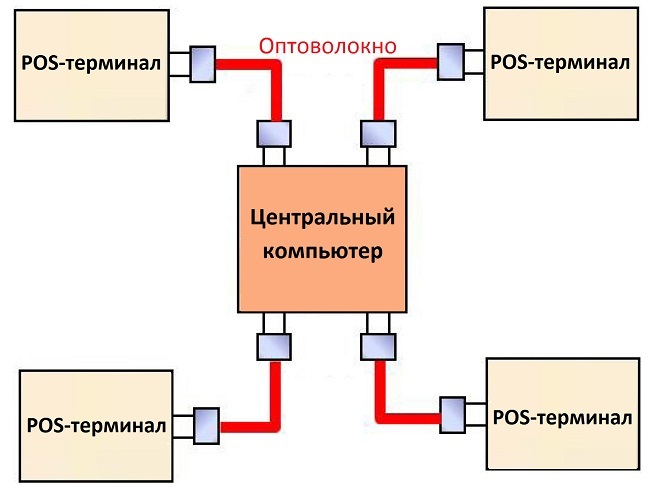

A network of POS-terminals in stores, banks and other institutions. The use of fiber to transmit information between the POS-terminals and the central computer ensures high speed of communication and data integrity of the operations performed. This is especially important in large areas where sources of strong interference may be present.

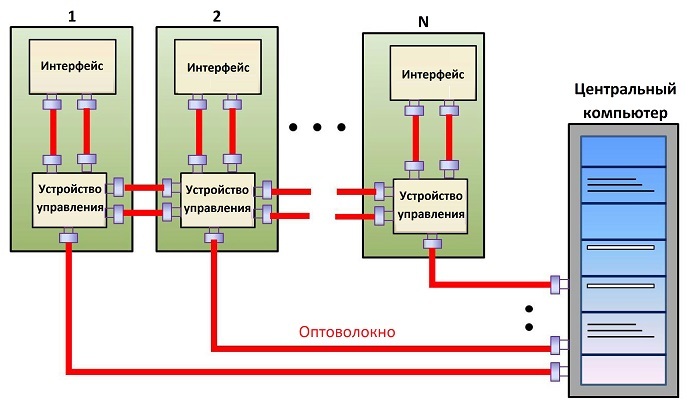

Gaming entertainment centers. Optical fiber can also be used to automate gaming entertainment systems, namely, to connect the central computer with gaming machines, internal connections of the gaming machine, and communication between gaming machines for multiplayer gaming.

8. Medical equipment

Another area in which optical fiber is actively used is medical equipment. The insulating properties of optical fiber protect the patient, personnel and electronics from the high-voltage part of the equipment. An example is an x-ray machine. To generate radiation, a high voltage is applied to the X-ray tube. The fiber provides galvanic isolation between the high voltage source and the low voltage control equipment. This also eliminates the effect of electromagnetic interference arising from the switching of high currents and voltages.

Versatile Link components from Broadcom Limited

Of course, it is impossible to list all possible industrial applications of optical fiber. However, this area of telecommunications is actively developing both throughout the world and in our country.

To implement these and other similar information transmission systems, industrial fiber-optic components are produced that meet the stringent conditions of the industry. The most popular among developers are the components of the Versatile Link line, manufactured by Broadcom Limited (EFO LLC is the official distributor of Broadcom). This line of components is designed to work with plastic optical fiber and includes discrete optical transmitters and receivers, connectors, adapters (sockets) and POF patch cords. Versatile Link components are distinguished by their reliability, cost effectiveness, and ease of use, due to which they can be used in virtually any industry.

In our next article we will make a detailed review of this line of components. You can familiarize yourself with the Versatile Link product range on the EFO company website dedicated to fiber-optic components - InFiber.ru:

')

Source: https://habr.com/ru/post/306896/

All Articles