Rack KVM for the budget

Thanks to our OpSoSu (mobile operator), which delivered a base station to our 2G / 3G office, we finally had a normal connection. In addition, together with the station we have gained a new rack. There was an agreement that we would also transfer our equipment to this rack, because there was little space and the third rack was in the way. And if the server hardware fit without problems, then attach the monitor was difficult. Some 5U of free space remained in the rack, which is not enough for a shelf with a monitor.

Actually, we really love rack-mount KVM - maximum functionality at 1U size, but I don’t like prices at all. 80 thousand rubles for what would suit us.

And what ifyou try to do something similar on your own? After checking the warehouse, we found that:

')

We had an old D-link KVM, a bunch of VGA-PS2-mouse-wires, a set of HSS seals, a pile of rack fasteners of all shapes and sizes, acquired (by overwork), flatron LG 17 ", household iron loops, steel withdrawable shelf, stamped perforated corner, pliers and a Chinese screwdriver. Not that it was a complete set for making roll-out rack KVM, but if you started to handle it, it is difficult to stop. The only thing that caused concern was the fastening of the M5 from the APC interrupters. There is nothing more helpless and evil than an engineer trying I, c zombies tenacity screw screwdriver standard M6 screw in the M5 nut APC 19 "rack. I knew that someday we will move on to this rubbish ...

The strategic plan was simple: to tear off a monitor's leg, somehow fasten a hinge to it, which needs to be taken somewhere , to somehow set the shelf in the cabinet, the benefit of the fastener to it was lost in time and space, while everything should move out and out without interfering with cables. And we must understand that at our disposal there is not a machine shop with punching machines and presses, at worst - with a vice (with this every fool can), but a standard tool for an IT person, in which the most durable tool are pliers heavy - a hammer, and the most technically sophisticated - a screwdriver.

In addition, the final design should be strong, reliable and, preferably, not very ugly, so as not to injure the innate sense of beauty.

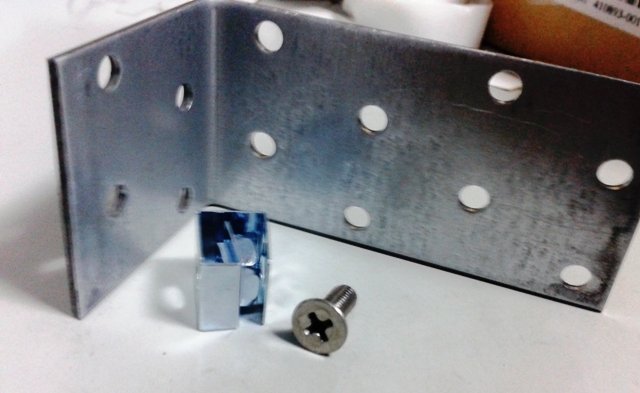

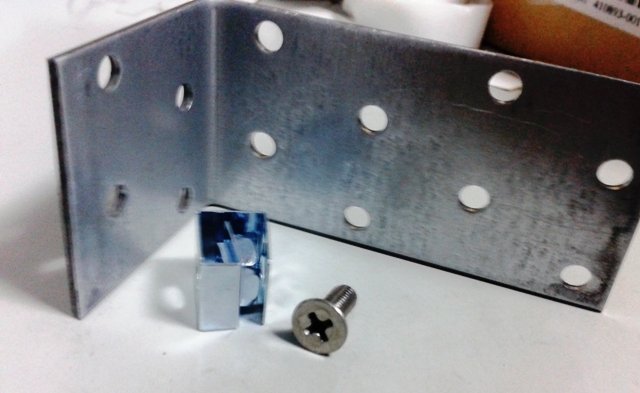

We need a corner 40x40x75mm. There is a perforation, an M5 screw passes into it, but the M6 no longer climbs. Price - 8 rubles.

Nuts for old HP cabinets, they are so old that HP called them old already in 2005. Previously, Hewlett-Packard showered them heartily in the Proliant model. The nut has the size of M5 and is an absolutely useless thing in the household, but here it turned out to be very helpful.

Countersunk screws for APC M5 UPS. They are always in the economy a lot.

Unfortunately, the corner is asymmetrical, so I had to drill a double corner on the hole. It also shows how the nuts are installed.

Behind the same way. In one corner I had to drill two holes to be able to adjust in length. Shelf 10 mm longer than the depth of the rack. Shelf enters and exits.

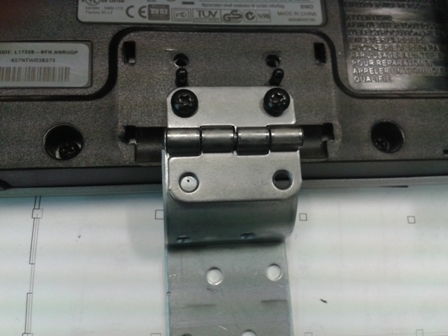

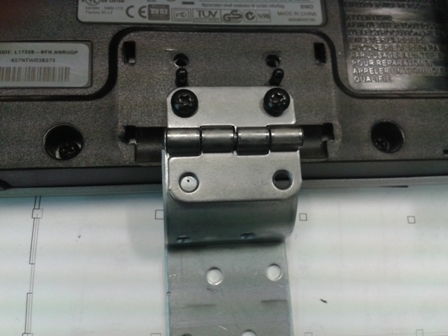

Unscrewing the leg mount on the monitor, we found that God had revealed his Greatness, and inspired the Korean designers of LG and the designer of the hinges of the Russian hardware plant with the idea of a single landing size. Well, as ... almost revealed ... With a slight fit (about half a millimeter mismatch somewhere) the loop got up. (I love when nothing needs to be drilled). Price loop - 14 rubles.

Now it is necessary to fasten it to something. Let it be our favorite corner.

But to bend his problem - to do something with pressed iron 1 mm thick, without a vice, is extremely difficult. Here Poddubny could, yes. He made a similar corner out of the pennies.

This problem was helped by the “ears” more precisely, the rack-mount kit from APC.

From the two "ears" they collected the clamp, tightened it with the rack screws on the M6 and curved the corner to the desired shape. Now he bends normally with his hands. We work, in order to avoid injuries, in string gloves. It is necessary to bend somewhere around 110 degrees.

We drill one hole on the left, the right one is well aligned with the original one.

We put the monitor with our fasteners on the shelf. Unfortunately, we don’t get into the holes on the shelf. We drill two holes and fasten the two screws with screws.

Check the opening and closing. The cables do not interfere - they will not be damaged.

That's how it looks in the finished form. Of course, there is not much room to work with a mouse, but the need for a presence next to the counter is rare. It is all controlled by us remotely. Great convenience is not required. In the retracted state, the mouse with the keyboard lies behind the folded monitor without interfering with the maintenance.

The total purchase price of additional components: a loop 14 rubles + 5 corners * 8 rubles = 54 rubles.

Solution design and shit-and-sticks technology is priceless.

Actually, we really love rack-mount KVM - maximum functionality at 1U size, but I don’t like prices at all. 80 thousand rubles for what would suit us.

And what if

')

We had an old D-link KVM, a bunch of VGA-PS2-mouse-wires, a set of HSS seals, a pile of rack fasteners of all shapes and sizes, acquired (by overwork), flatron LG 17 ", household iron loops, steel withdrawable shelf, stamped perforated corner, pliers and a Chinese screwdriver. Not that it was a complete set for making roll-out rack KVM, but if you started to handle it, it is difficult to stop. The only thing that caused concern was the fastening of the M5 from the APC interrupters. There is nothing more helpless and evil than an engineer trying I, c zombies tenacity screw screwdriver standard M6 screw in the M5 nut APC 19 "rack. I knew that someday we will move on to this rubbish ...

The strategic plan was simple: to tear off a monitor's leg, somehow fasten a hinge to it, which needs to be taken somewhere , to somehow set the shelf in the cabinet, the benefit of the fastener to it was lost in time and space, while everything should move out and out without interfering with cables. And we must understand that at our disposal there is not a machine shop with punching machines and presses, at worst - with a vice (with this every fool can), but a standard tool for an IT person, in which the most durable tool are pliers heavy - a hammer, and the most technically sophisticated - a screwdriver.

In addition, the final design should be strong, reliable and, preferably, not very ugly, so as not to injure the innate sense of beauty.

Shelf

We need a corner 40x40x75mm. There is a perforation, an M5 screw passes into it, but the M6 no longer climbs. Price - 8 rubles.

Nuts for old HP cabinets, they are so old that HP called them old already in 2005. Previously, Hewlett-Packard showered them heartily in the Proliant model. The nut has the size of M5 and is an absolutely useless thing in the household, but here it turned out to be very helpful.

Countersunk screws for APC M5 UPS. They are always in the economy a lot.

Unfortunately, the corner is asymmetrical, so I had to drill a double corner on the hole. It also shows how the nuts are installed.

Behind the same way. In one corner I had to drill two holes to be able to adjust in length. Shelf 10 mm longer than the depth of the rack. Shelf enters and exits.

Monitor

Unscrewing the leg mount on the monitor, we found that God had revealed his Greatness, and inspired the Korean designers of LG and the designer of the hinges of the Russian hardware plant with the idea of a single landing size. Well, as ... almost revealed ... With a slight fit (about half a millimeter mismatch somewhere) the loop got up. (I love when nothing needs to be drilled). Price loop - 14 rubles.

Now it is necessary to fasten it to something. Let it be our favorite corner.

But to bend his problem - to do something with pressed iron 1 mm thick, without a vice, is extremely difficult. Here Poddubny could, yes. He made a similar corner out of the pennies.

This problem was helped by the “ears” more precisely, the rack-mount kit from APC.

In general, APC UPS is a source of various useful nishtyakov

For example, the bar that holds the batteries together is an excellent bracket for installing 19 "power outlets, it is well-placed between the standard HP or APC racks along the holes, and the standard power panel is attached to it with self-tapping screws.

From the two "ears" they collected the clamp, tightened it with the rack screws on the M6 and curved the corner to the desired shape. Now he bends normally with his hands. We work, in order to avoid injuries, in string gloves. It is necessary to bend somewhere around 110 degrees.

We drill one hole on the left, the right one is well aligned with the original one.

We put the monitor with our fasteners on the shelf. Unfortunately, we don’t get into the holes on the shelf. We drill two holes and fasten the two screws with screws.

Check the opening and closing. The cables do not interfere - they will not be damaged.

That's how it looks in the finished form. Of course, there is not much room to work with a mouse, but the need for a presence next to the counter is rare. It is all controlled by us remotely. Great convenience is not required. In the retracted state, the mouse with the keyboard lies behind the folded monitor without interfering with the maintenance.

The total purchase price of additional components: a loop 14 rubles + 5 corners * 8 rubles = 54 rubles.

Solution design and shit-and-sticks technology is priceless.

Source: https://habr.com/ru/post/306890/

All Articles