Integrated Design with EMC Capital Projects and AVEVA NET Workhub and Dashboard

In one of the previous publications, we talked about the EMC Capital Projects software product included in the EMC Documentum EPFM (Engineering, Plant and Facilities Management) package. It allows the following:

- design companies - prepare the documentation and coordinate it before transferring it to contractors,

- contracting companies - to accept this documentation, check its completeness, review, make edits.

But the more complicated the design spiral is , that is, the more participants make changes and additions to the project, the higher the likelihood of errors: incompatibility and conflict of equipment requirements with selected models for the project, weight and size incompatibility of construction objects, inconsistencies of the elements of the object with relief features, and so on. d. The situation is much more complicated if several geographically distributed teams working across multiple project disciplines are involved in the work simultaneously: it is required to manage the changes with the help of Digital Enterprise solutions in order not to disrupt or delay the work process. In EMC Capital Projects, this problem is solved through the use of AVEVA NET technologies.

What is AVEVA NET Workhub and Dashboard?

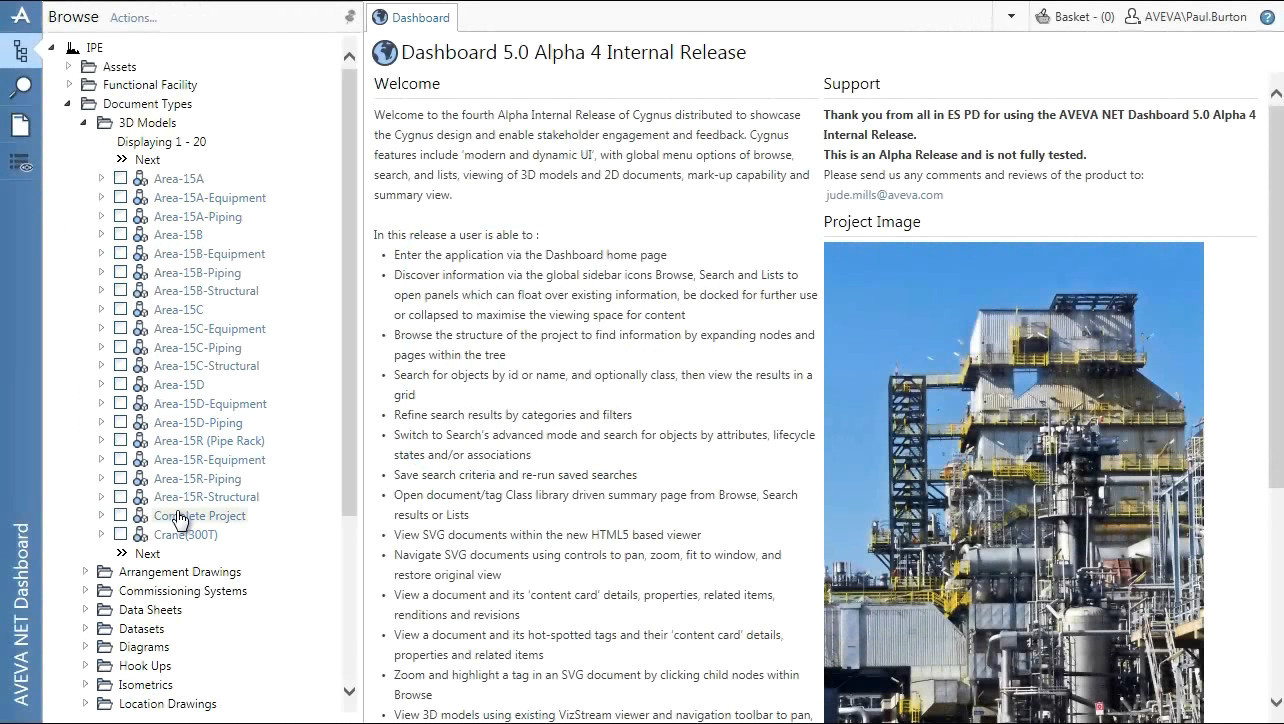

This is an integration complex that helps users organize collaborative work on project data and documents. Information can come from various sources - tables, databases, and other structured repositories. The basis of the complex is the idea of accumulation and systematization of knowledge about the object, with parallel extraction of metadata for each element.

')

AVEVA NET Workhub and Dashboard can work with data of any format, including:

- 3D models

- laser scan data

- digital photos,

- 2D drawings

- scanned documents

- data from ERP systems, etc.

All information is systematized and combined in a single workspace. The specialist can immediately see all the characteristics of the element and all the documents in which it appears: drawings, 3D models, photos, etc. Saving time is tremendous, because design engineers usually spend from 50% to 80% of their time searching for information, sorting through deposits of documents, tables and databases.

In addition, the complex contains tools for analyzing, verifying and controlling technical information, which makes it possible to avoid engineering decisions based on erroneous initial data.

Integration of Capital Projects and AVEVA NET Workhub and Dashboard

So, AVEVA NET Workhub and Dashboard serves as a tool for combining and visualizing all the technical information on a project, with data verification and automatic assignment of cross-references to documents. This complex also allows you to control the completeness of documentation and carry out checks on the metadata of objects. But, besides this, in order to effectively work on a project, it is necessary to precisely manage all stages of the work on preparing documents:

- organize the process of receiving and sending documents,

- to route,

- assign tasks to employees

- schedule deadlines for each document,

- track the timeliness of execution,

- review and verify documentation.

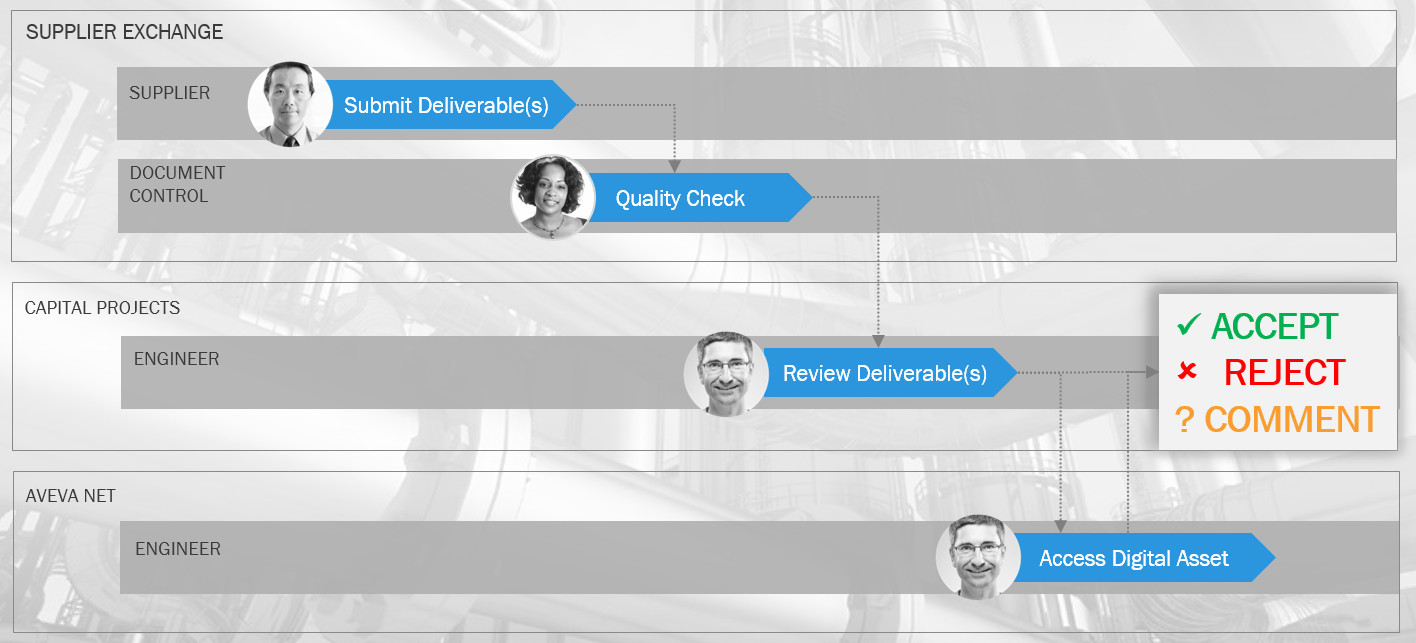

Capital Projects solves all these problems: it plays the role of a transport, allowing designers and contractors to exchange documentation with the customer, and the customer to send the documentation for consideration to the right specialists within the organization. At the same time, Capital Projects allows you to manage all stages of the document preparation process - from creating a template to approval of the final version.

Sample workflow:

When planning work on a project, the customer, knowing what documents he wants to receive from the contractor, creates in Capital Projects caps for future documents. This information is automatically transmitted to the Supplier Exchange portal, where the contractor is informed that filling is required for the stub — the document itself, for example, a DWG drawing.

The developer of the documentation (Supplier) loads the document. A preliminary check (Document control) for errors in versions, validation of names, etc. The document is then passed to Capital Projects, where it is evaluated by the customer’s engineer. In accordance with the routing rules, this document is submitted to the engineer as a PDF file. Let's say this is some kind of drawing. To check the accuracy of the range of equipment, all parameters and dimensions, the engineer is forced to independently find, open and analyze a variety of other documentation relating to the equipment and structures shown in the drawing. Depending on the complexity of the resulting drawing, manual search and verification of data can take from several hours to several days.

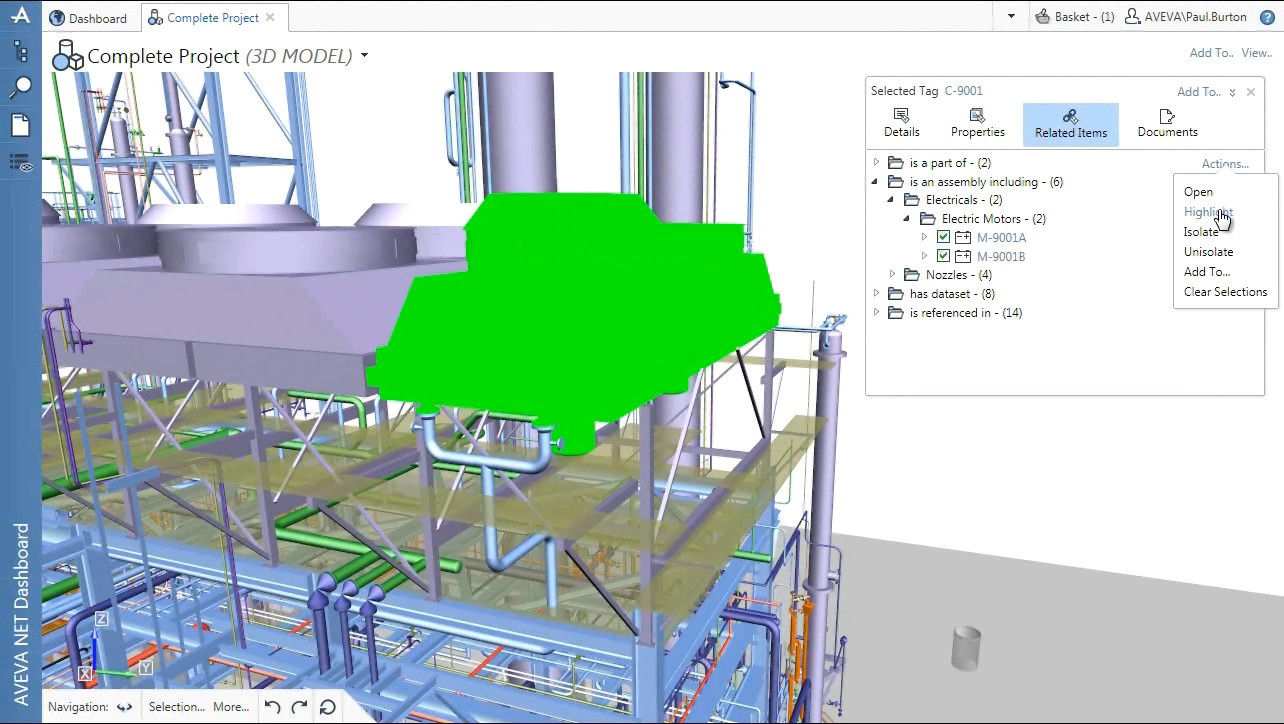

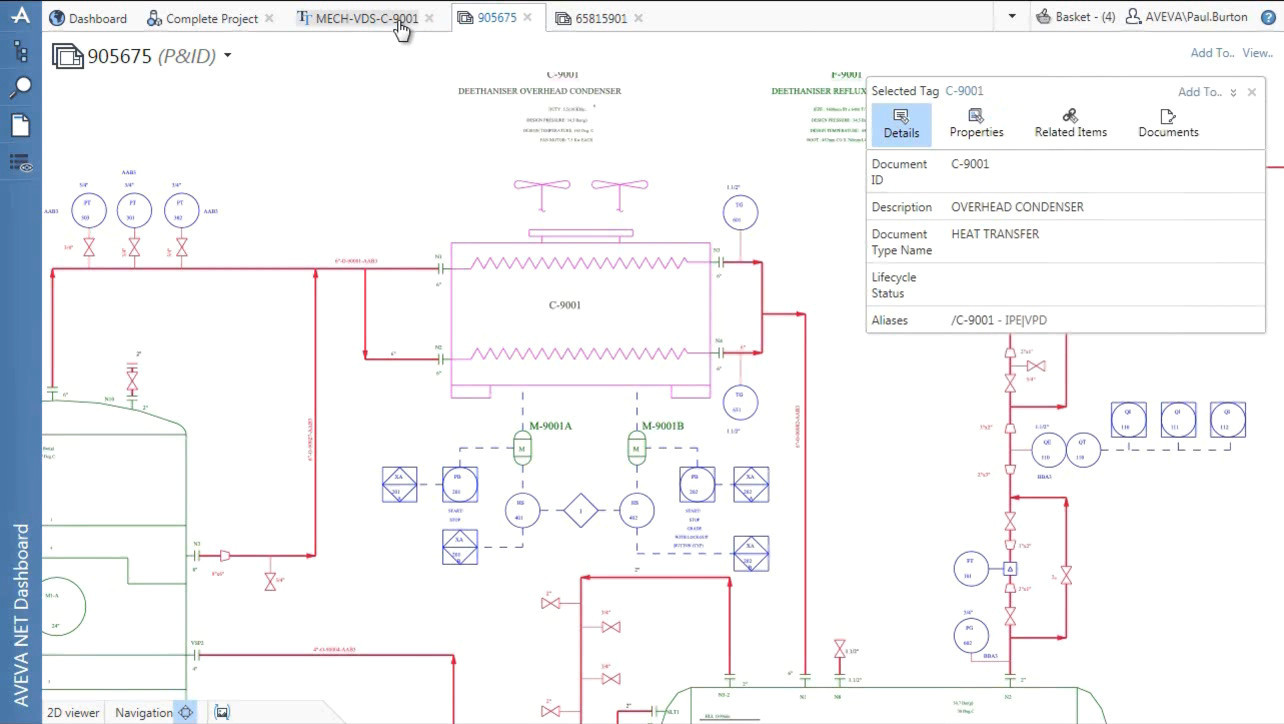

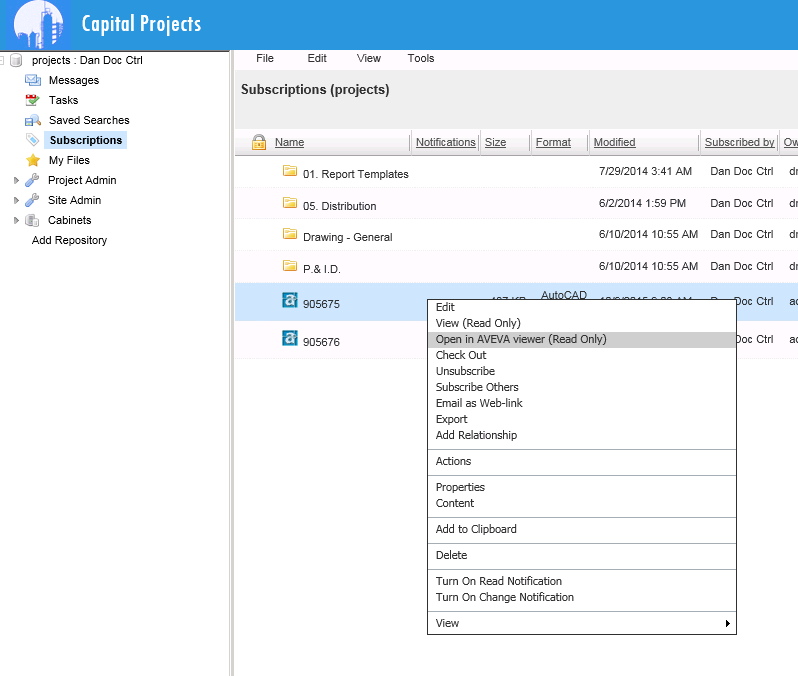

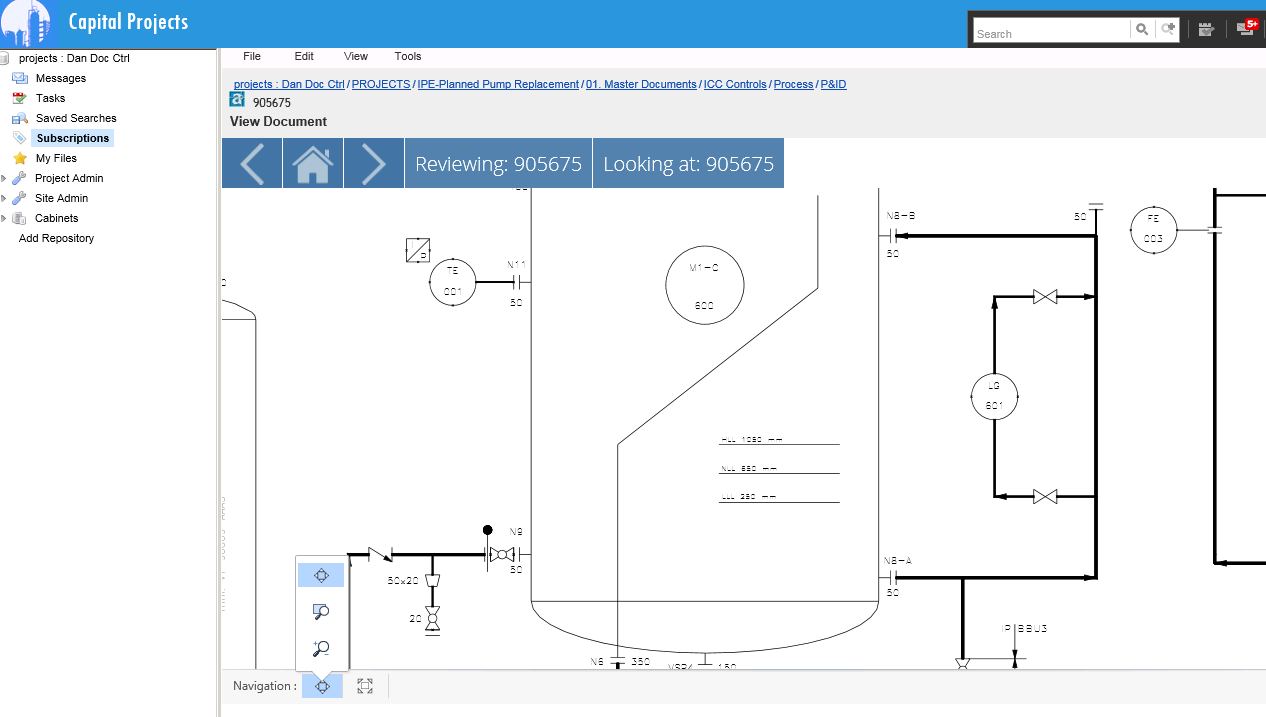

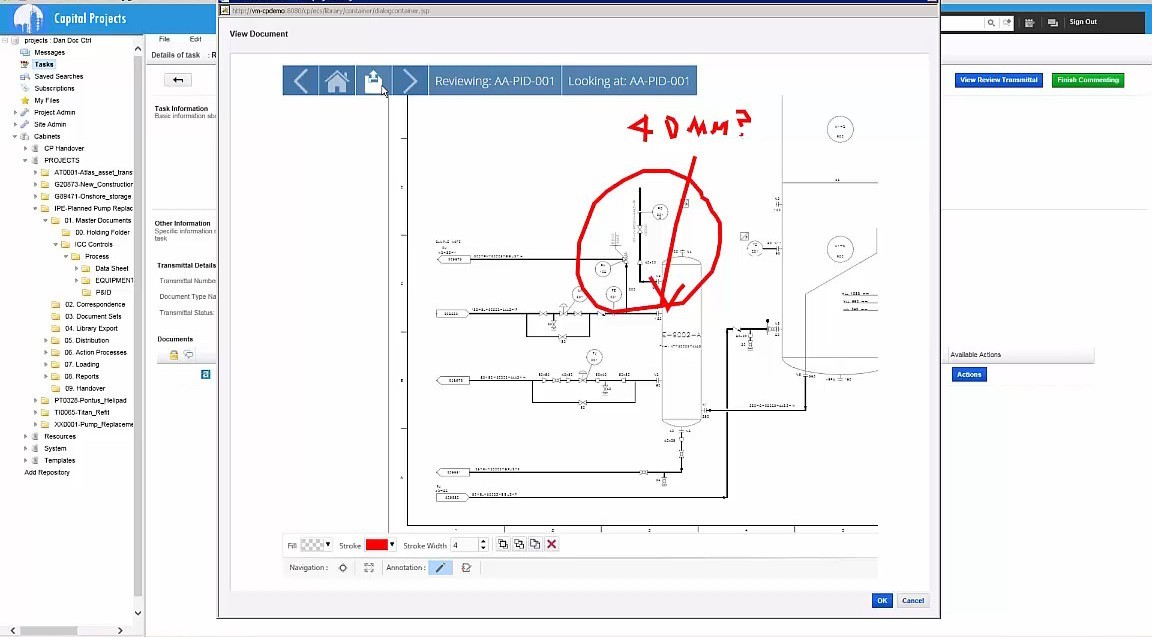

By integrating with AVEVA NET Workhub and Dashboard, the review process can be much easier. Integration allows you to open and view documents uploaded to Capital Projects received from a contractor using a special viewer. From the incoming drawings, the system retrieves all engineering data. Each element is recognized by a unique name, and all new information complements the existing metadata downloaded earlier.

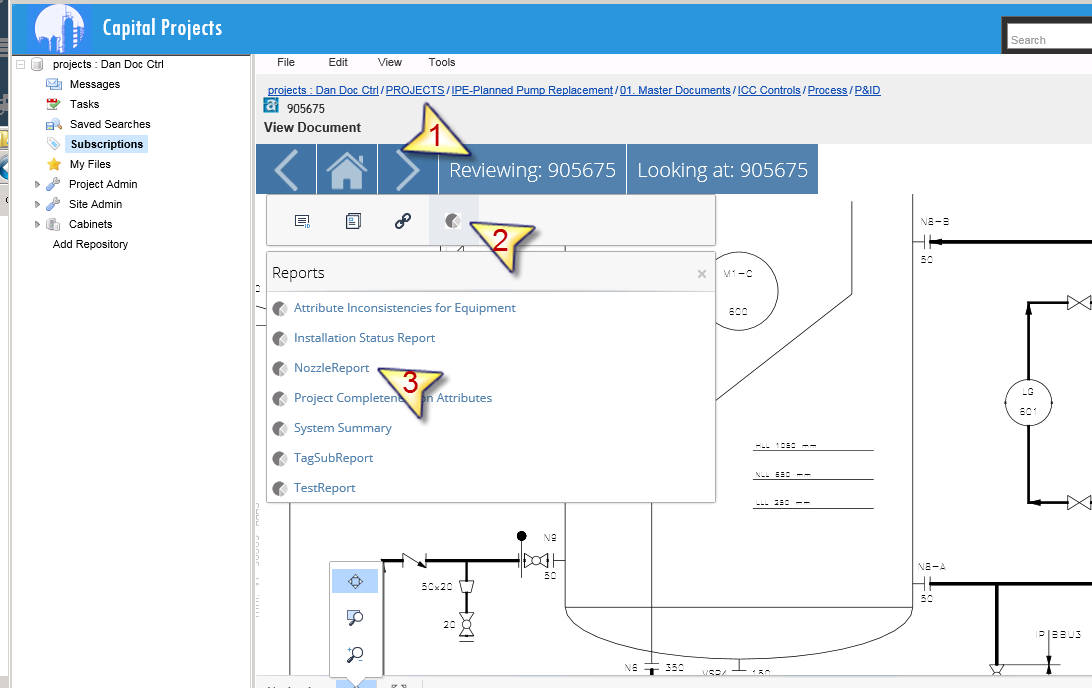

Now the engineer operates not with a simple PDF file, but with a full-fledged drawing, for each element of which you can immediately obtain the necessary technical information, related documents from any design disciplines: electrician, ventilation, heat supply, etc. In addition, it is possible to view three-dimensional models of objects represented in the drawing, which are embedded in the overall model of the entire project.

The system independently checks the compliance of data in the drawings and specifications, saving the engineer from long searches and reconciliations of paper documents:

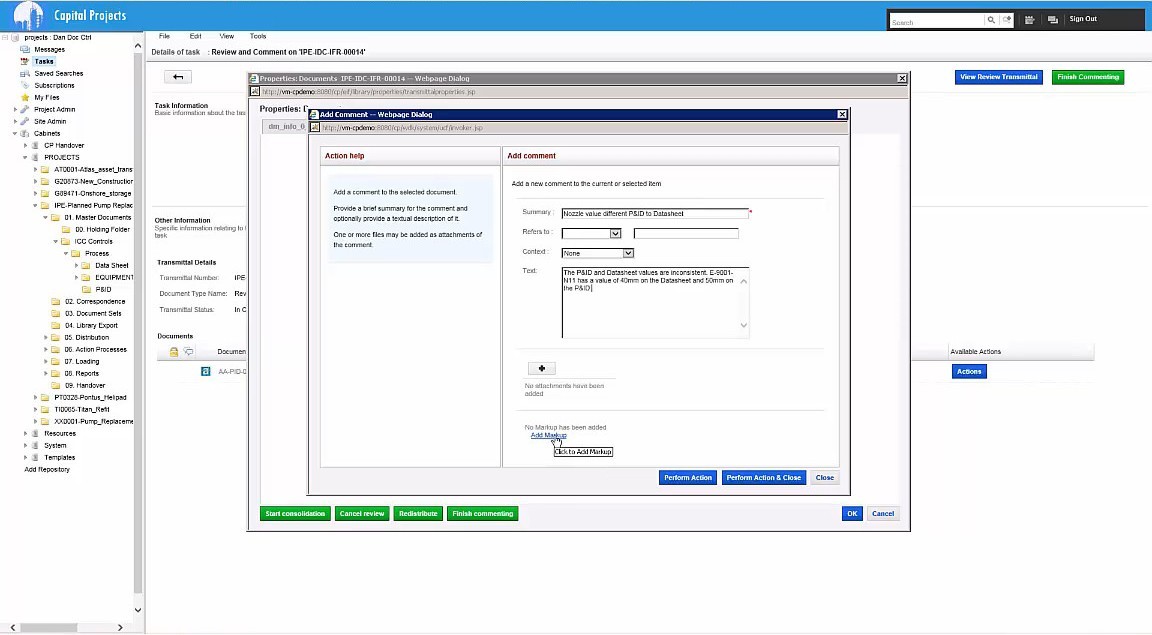

Upon completion of the analysis of the drawing, the engineer makes his comments and sends the drawing for revision.

Conclusion

Integrating EMC Capital Projects with AVEVA NET Workhub and Dashboard allows you to:

- View documents in the form of drawings or three-dimensional models, immediately receiving all the related technical information on each element.

- Automatically detect data inconsistencies obtained at different stages of the project from different disciplines and specialists.

- Repeatedly accelerate the verification of project documentation and reduce the likelihood of design, construction and further operation errors

Source: https://habr.com/ru/post/303696/

All Articles