Energy Efficiency Options from Coolan, MacroAir, AMCA International and Cradle

Companies do their best to improve the energy efficiency of their data center infrastructure. To do this, engineers and data center operators use all sorts of tools, develop and implement innovative technologies. Some companies openly share their achievements in this area, while others keep secret projects to improve the infrastructure of the server farm. But there is a category of companies that do not have their own data centers and earn money by selling technological know-how and inventions to customers or data center owners. In the post we will talk about the proposed solutions to such companies in the field of energy efficiency data centers.

Coolan is committed to providing data center infrastructure optimization services. Its specialists conducted a series of studies in large world data centers, analyzed the load on server power sources from 1600 computing nodes. After conducting these studies, experts concluded that power supply resources are not used very efficiently, most of them are loaded by about 30%. The reason is simple: sometimes operators are too worried about the safety and reliability of the infrastructure of data centers and install more powerful power sources for servers than they really need.

')

If you take the most common power sources - when the maximum load is reached, the efficiency level increases significantly. But when the devices are loaded only by a third, the efficiency will be much less than optimal. Coolan experts recommend saving resources using OpenRack racks based on the new architecture.

In general, Open Rack is a cross between an open rack and a telecommunications cabinet, where power supply resources are common to the entire connected load. With their help, it is possible to flexibly scale the infrastructure, use the available internal space more efficiently, as well as provide a certain potential for the realization of energy-saving ideas and achieve the required power.

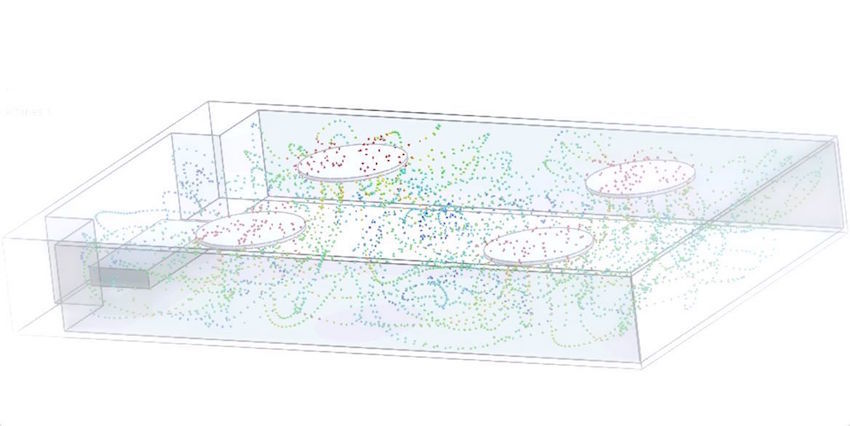

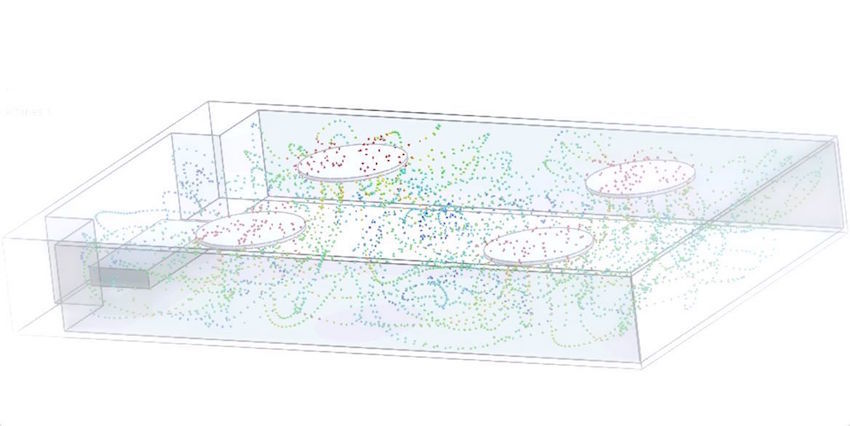

Effective optimization of air flow makes it possible to reduce the load on the cooling system of the server equipment, thereby reducing the cost of operating the data center. That is why MacroAir has updated its service for modeling the flow of air masses inside buildings called AirViz.

AirViz is a 3D modeling and visualization service for airflows that allows you to quickly visualize and analyze the passage of airflow inside a building. This process is implemented with the help of a special automation mechanism, which is sharpened by the visualization of large low-speed fans (High Volume Low Speed; HVLS). Using AirViz will enable operators, designers and data center builders to see how HVLS works with an example.

Virtual model AirViz accurately demonstrates air velocity and other parameters using 3D-animation. The first version of this software solution was released in 2014 and is currently available as a web application implementing 3D modeling using the new cloud computing technology. AirViz algorithms use the principles of computational fluid dynamics to simulate air velocity, temperature, and air flow direction.

The International Movement and Air Control Association AMCA International (Air Movement and Control Association International) is launching a new fan energy efficiency calculator. The tool is called AMCA Fan Energy Waste and will be available on the official website of the association .

With a few mouse clicks on a calculator, users will be able to estimate the cost associated with the inefficiency of the fans, as well as the amount of inefficiently used electricity. This tool will help data center operators improve energy efficiency of the infrastructure.

Cradle, in collaboration with an electrical equipment supplier and designer, Hitachi Mito Engineering, developed a thermal modeling tool for printed circuit boards called PICLS. With its help, it will be possible to secure the “iron” as much as possible from overheating and the formation of so-called “hot spots” in the engineering centers of the data center.

PICLS is fairly simple and easy to use. It works in real time and allows electronics developers to instantly assess how changes in design will affect thermal performance.

Coolan offers resource saving with OpenRack

Coolan is committed to providing data center infrastructure optimization services. Its specialists conducted a series of studies in large world data centers, analyzed the load on server power sources from 1600 computing nodes. After conducting these studies, experts concluded that power supply resources are not used very efficiently, most of them are loaded by about 30%. The reason is simple: sometimes operators are too worried about the safety and reliability of the infrastructure of data centers and install more powerful power sources for servers than they really need.

')

If you take the most common power sources - when the maximum load is reached, the efficiency level increases significantly. But when the devices are loaded only by a third, the efficiency will be much less than optimal. Coolan experts recommend saving resources using OpenRack racks based on the new architecture.

In general, Open Rack is a cross between an open rack and a telecommunications cabinet, where power supply resources are common to the entire connected load. With their help, it is possible to flexibly scale the infrastructure, use the available internal space more efficiently, as well as provide a certain potential for the realization of energy-saving ideas and achieve the required power.

Air flow optimization with AirViz service

Effective optimization of air flow makes it possible to reduce the load on the cooling system of the server equipment, thereby reducing the cost of operating the data center. That is why MacroAir has updated its service for modeling the flow of air masses inside buildings called AirViz.

AirViz is a 3D modeling and visualization service for airflows that allows you to quickly visualize and analyze the passage of airflow inside a building. This process is implemented with the help of a special automation mechanism, which is sharpened by the visualization of large low-speed fans (High Volume Low Speed; HVLS). Using AirViz will enable operators, designers and data center builders to see how HVLS works with an example.

Virtual model AirViz accurately demonstrates air velocity and other parameters using 3D-animation. The first version of this software solution was released in 2014 and is currently available as a web application implementing 3D modeling using the new cloud computing technology. AirViz algorithms use the principles of computational fluid dynamics to simulate air velocity, temperature, and air flow direction.

AMCA International Fan Energy Efficiency Calculator

The International Movement and Air Control Association AMCA International (Air Movement and Control Association International) is launching a new fan energy efficiency calculator. The tool is called AMCA Fan Energy Waste and will be available on the official website of the association .

With a few mouse clicks on a calculator, users will be able to estimate the cost associated with the inefficiency of the fans, as well as the amount of inefficiently used electricity. This tool will help data center operators improve energy efficiency of the infrastructure.

Thermal Cradle Modeling

Cradle, in collaboration with an electrical equipment supplier and designer, Hitachi Mito Engineering, developed a thermal modeling tool for printed circuit boards called PICLS. With its help, it will be possible to secure the “iron” as much as possible from overheating and the formation of so-called “hot spots” in the engineering centers of the data center.

PICLS is fairly simple and easy to use. It works in real time and allows electronics developers to instantly assess how changes in design will affect thermal performance.

Source: https://habr.com/ru/post/303430/

All Articles