A piece of space in your pocket: the results of the experiment

More than a month has passed since the day we launched the project on 3D printing of modem covers with particles of a real meteorite. Time to take stock of this unusual experiment.

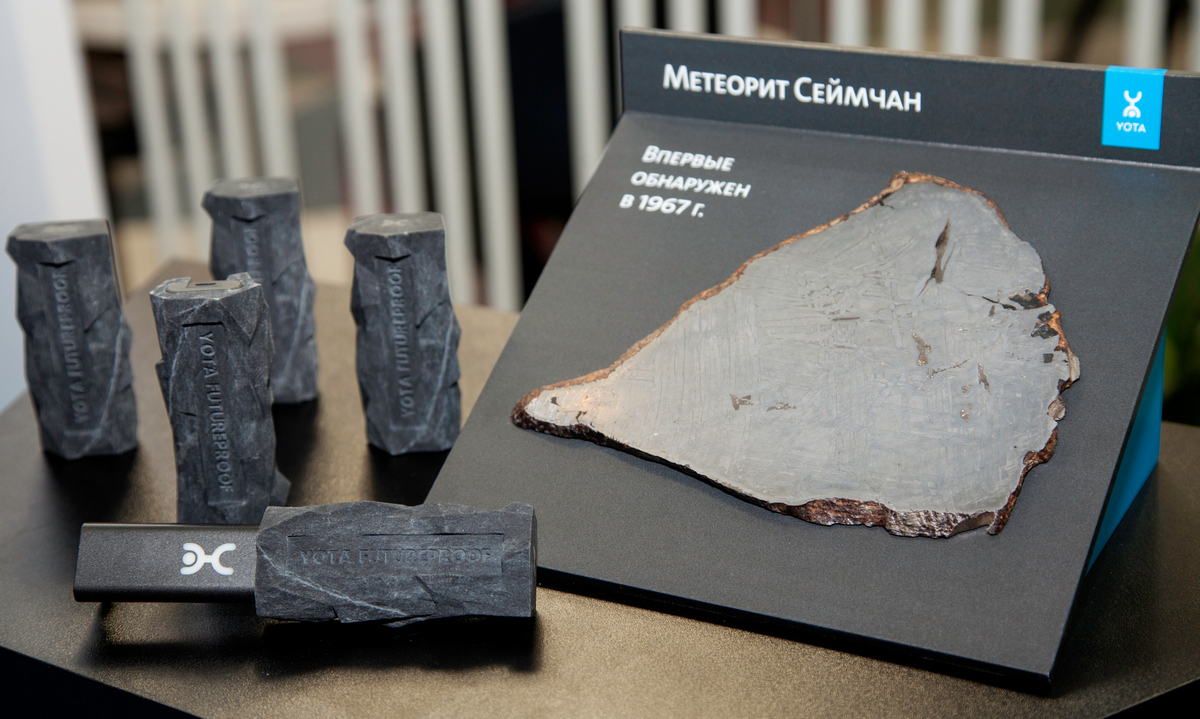

On Cosmonautics Day, we launched a new experiment as part of the Yota FutureProof program: when buying our 4G modem online or at the Atrium shopping center, it was possible to order a cover made on a 3D printer for it. In a specially designed online designer, anyone could create a three-dimensional model of the case with a unique inscription - for example, with his nickname or name. After confirming the order, the case was sent to print, without additional processing of the layouts in a special editor for 3D modeling. The material contained particles of this meteorite, found in 2005 in the Magadan region. The shard is a type of iron-stone meteorites and, presumably, is a fragment of the Seymchan meteorite. For two weeks in the Atrium shopping center in Moscow, at the Yota sales point, one could see the meteorite used to create the 3D covers.

')

As with all Yota FutureProof experiments, we were interested in the possibility of using advanced technologies in everyday life and business. During the 3D printing project, we wanted to find out whether modern technologies and personalized accessories created with their help influence the demand for devices.

During the month of the experiment, 9,541 unique sketches of 3D covers were created; users spent a total of 239 man-hours on design (an average of 1.5 minutes per layout). In the course of the experiment, almost 73 kilograms of material — a composite with meteoric powder — was used. 473 cases were printed, each was created about 4 hours (the total duration of the work is 1,892 man-hours, about 78 days). In the process of creating the cover, the printing directly took about an hour: during this time the printer printed a product about 25 mm high. Then the cover was cleaned with compressed air and soaked with special glue for strength. In the experiment, a single 3D printer was used, which simultaneously produced an average of 2-3 cases each. The cost of each case was 1260 rubles. The growth in sales of modems through online channels during the experiment was 14%.

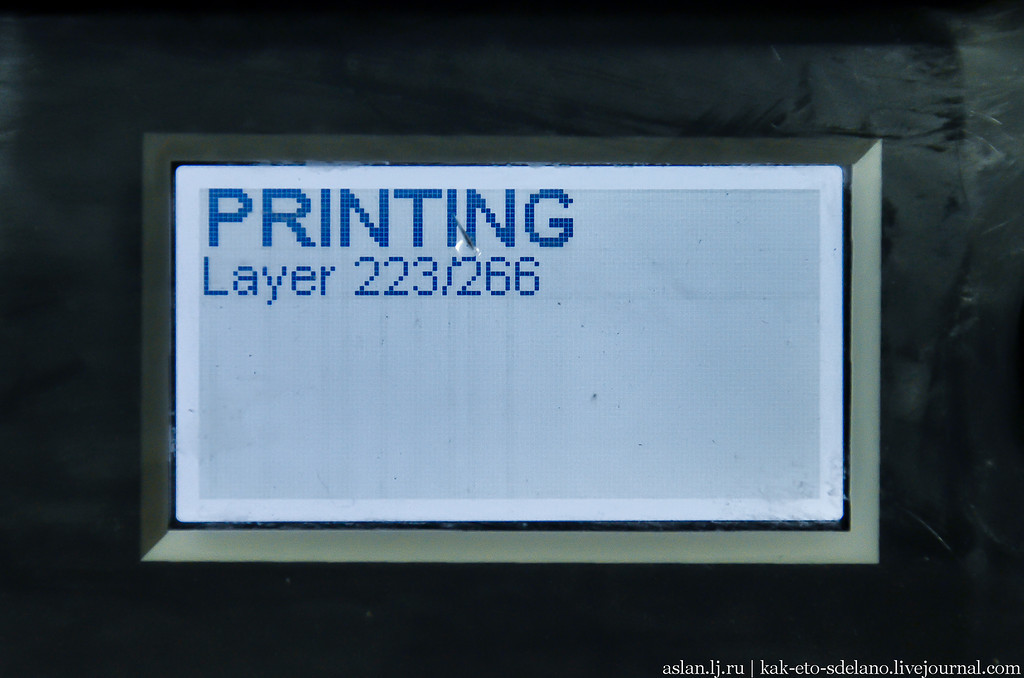

Covers were printed using CJP technology: first a very thin layer of composite powder is applied, then it is impregnated with dye and binder. And so layer by layer. Each case consists of approximately 270 layers. The final touch is product impregnation with cyanoacrylate glue to increase strength.

Here's what it looks like:

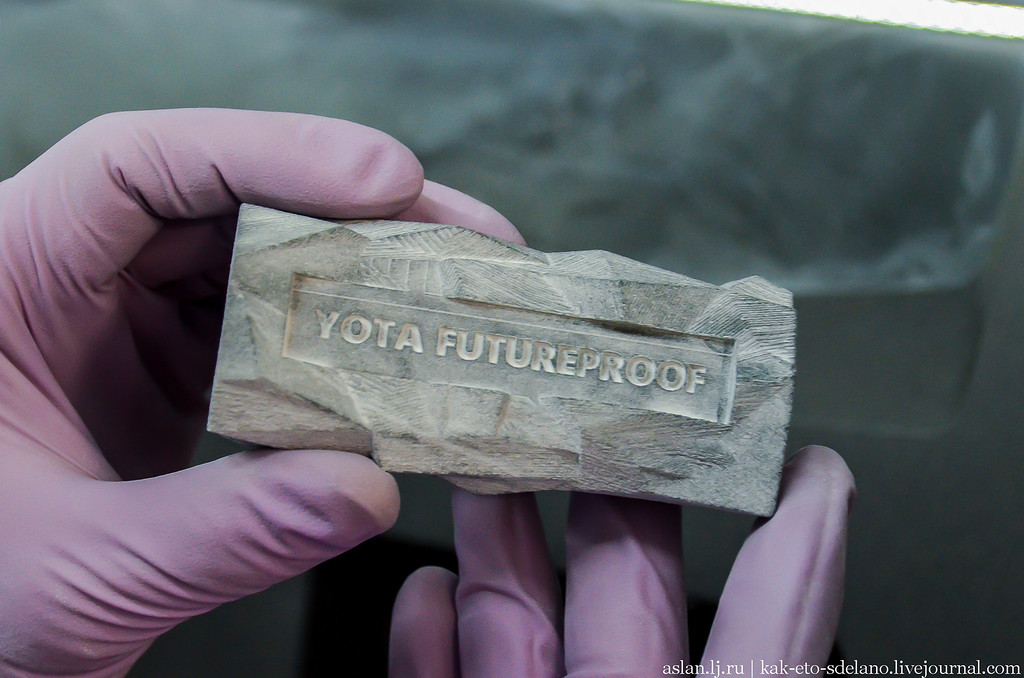

The printed cover is cleaned from the remnants of the composite:

Washing and treatment with cyanoacrylate:

A fragment of a meteorite was crushed in a crusher to get a fairly small fraction:

The cover is ready!

The interest of our customers to unique customized accessories is confirmed by several thousand created designs of 3D covers. In our opinion, in this experiment, users were primarily attracted by the use of particles of a meteorite and, of course, the ability to print the case with its own, unique design. We have seen that, despite the high cost of production, 3D printing can be effectively used for business, and we are already working on new ways to integrate modern technologies into business processes.

Source: https://habr.com/ru/post/301836/

All Articles