Choosing a strategy for working with procurement and its implementation

One of the main objectives of the company is to create and implement an effective strategy for working with the purchase of goods. The issue of supply is one of the most painful issues for any business. Practice shows that this question is also one of the least developed in most companies. At the same time, studies have shown that $ 1 invested in improving supplies brings no less effect than $ 3 invested in sales development.

There are two main concepts that can be implemented in the formation of the procurement strategy.

1. That the size of the order is calculated through the economic justification, which takes into account the costs of the order itself, the cost of storing it, discounts per lot, and so on. This scheme is more typical for companies engaged in production and repair. Working in this scenario means that you may have a short surplus of goods, but this is economically feasible. The strategy operates on the concept of “effectively invested money” and is designed for a long implementation cycle.

2. That a product must be exactly where it is needed, precisely when it is needed, and its quantity must be exactly as much as is really necessary — no more, no less. The correct implementation of this concept means that the company effectively invests its funds in inventories, and it allows you to avoid extreme situations associated with a shortage of goods (and missed sales), and with an excess of goods (dead goods that can only be sold at a discount) . This approach is more characteristic of commercial enterprises. Working in this scenario means that you spend money exactly to the extent that it should be spent - no more, no less. Designed to cover the current needs of the company in the goods.

')

Below we consider the implementation of each strategy.

Strategy 1: Addition on the basis of the economically reasonable order size

Specialists in inventory management, of course, are well aware of the dependence of costs on the volume of the ordered consignment. On the presented interpretation (Fig.):

q - order size; z - unit costs; line chart - unit costs for storage of the order; hyperbolic graph - unit costs of placing an order; graph with optimum - total unit costs; q * is the point at which storage costs are equal to order placement costs.

Obviously, with a certain size of the order there are optimal conditions for the purchase. The optimum is clearly visible on the graph. This optimum is an EOQ (economical order quantity).

Techniques for calculating an economical order size (EOQ or Wilson / Wilson / model) are not applied in practice, although in the scientific literature on supply chain management and inventory, these techniques occupy significant amounts and are completely uncontested. The reasons for the negligent attitude of business towards EOQ are obvious and "lying on the surface." Firstly, the greater complexity of calculations, and, secondly, the low accuracy of the results.

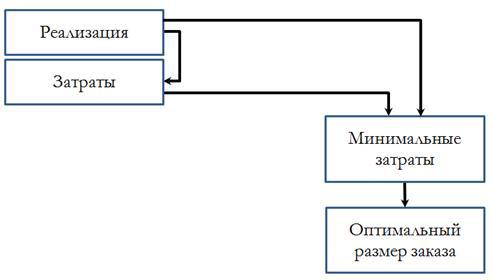

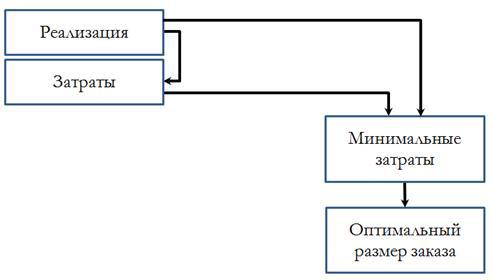

In the EOQ formula and other analogues, it is proposed to determine the required order quantity directly (by minimum costs) (Fig. 1). The relationship between cost and optimal size, of course, exists, but it is not so direct. At the same time, the system error of EOQ is extremely high.

Fig. 1. The scheme of the algorithm for calculating the EOQ.

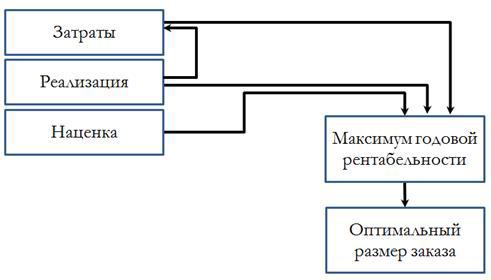

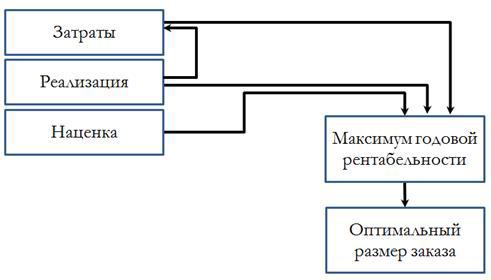

To raise the quality of calculations, it was proposed to use not the cost minimum, but the maximum annual profitability (Fig. 2). The cost, margin and implementation of the function is based on the profitability of the size of the order. On the graph of the function is determined by the optimum point. It is believed that this point corresponds to the most profitable volume of the order.

Using this method can significantly improve the accuracy of calculating the economically reasonable order size. But the complexity of the calculations according to the new method has increased. After all, now it is required to take into account the trading margin and all costs, and not just the costs of procurement and storage.

If we consider the optimal size of the order for each ordered item, then the labor costs for the preparation of orders will be an enormous amount. An enterprise that has a nomenclature of 10 thousand items and replenishes its reserves on a monthly basis would have to produce 10 thousand calculations of cost or profitability depending on the size of the order each month. Naturally, no one can afford such luxury.

Fig. 2. The scheme of the algorithm for calculating the optimal order for profitability.

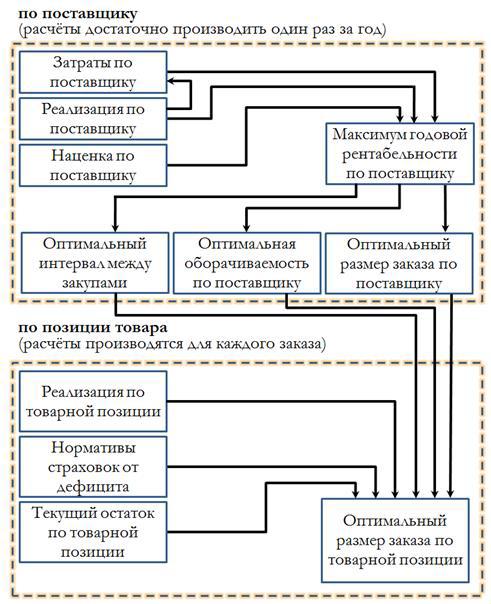

Solution to the problem. You can get rid of the high complexity of the calculations if you use the two-step method. Then the complexity of the calculations will be reduced by hundreds of times (to an acceptable level).

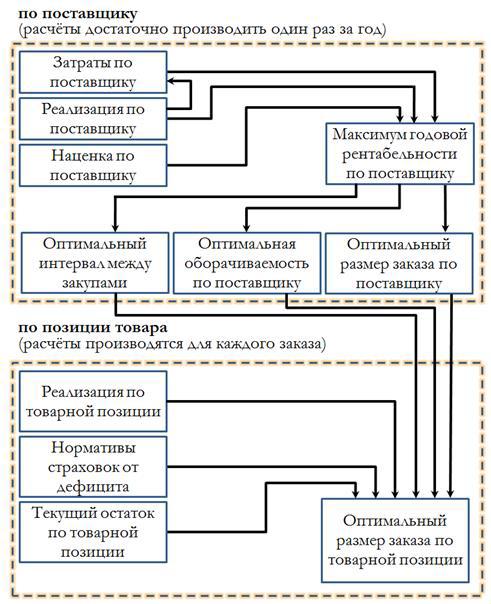

At the first stage, the calculation is made not of the optimal order of a commodity position, but of the optimal size of a consignment of goods (Fig. 3). As a rule, one supplier supplies prefabricated batches - in one order several items of goods are completed at once. One lot consists of 5-10, and sometimes hundreds of items of goods. Therefore, if you make an economic rationale for the size of the batch of goods, rather than each position, then the number of calculations is reduced by the appropriate number of times.

For costs, sales and markup, a schedule of profitability versus order size is developed. By the point of maximum profitability is determined by the optimal size of the order. And by the optimal size of the order, you can find the appropriate turnover and (or) the best from an economic point of view, the interval between purchases.

If the demand for goods of the analyzed supplier is subject to strong seasonal fluctuations, it is quite reasonable to use not a single end-to-end indicator for the whole year, but to create a schedule in which the requirements for the size of the order (turnover) would be adjusted depending on the expected seasonal change in demand.

Having after completing the work of the first stage standards of turnover, order size and (or) the interval between purchases, it will not be difficult to carry out calculations of the required order volume of a specific position for a specialist. It remains only to find out the expected implementation and current balances, as well as the size of the safety stock.

The method of finding the size of the order by EOQ has too much error and, moreover, requires tremendous effort. The method of finding the optimal size of the order by profitability improves the quality of calculations, but does not reduce their complexity. The method, in which the process is divided into two stages (first, once a year, profitability is determined by optimal turnover, the size of the collective order to the supplier or the interval between purchases, and then the calculation of the size of the order of the commodity item for each shipment) and reduces the second problem to an acceptable level.

Strategy 2: Replenishment on the principle of Just In Time.

To implement this concept, the managers responsible for the supply need to make daily calculations - for each outlet, to make an assessment of sales in future periods. Taking into account the time of delivery of the goods, and based on the sales forecast, the manager, starting from the current state of the balance, should assess how long the current inventory is enough, and is it not time to order the goods so that by the time he arrives at the store, not only the old the batch has already ended, but no stockpiling has been formed.

Daily calculations need to be made, since current demand and delivery times for goods, and the quantity of goods on the way can fluctuate — these components need to be taken into account, as well as the time factor.

One of the important components of an order is the safety stock. Safety stock - this is an additional stock of goods, formed in case of unforeseen circumstances. Whether it is a sudden increase in demand, a delay in the goods on the way, or problems in production, the safety stock is needed so that the company can work (the time chosen by the operator) without interruption.

To understand the essence of the safety stock, we can offer an analogy: if your car's consumption is 10 l / 100 km, then you will never fill exactly 20 liters for a trip of 200 km, and you will always fill up a little more for unforeseen circumstances - this is safety stock.

The safety stock is calculated either in a fixed volume for each outlet, or depending on the delay in delivery, or depends on other factors (demand variability). Sometimes as a safety stock they use such a thing as “minimum balance in stock”.

The second important component is time. Time is involved in the formation of the sales forecast and the order period. The universal concept is “logistic leverage”, i.e. time during which the ordered goods will be delivered to the store

The total order size formula is quite simple:

Order size (RZ) = TO + TP - SZ - PP , where

THEN is the current balance. The size of the goods that you can dispose of. If you are working with the possibility of reserving goods, then you will have to exclude reserves from the current balance;

TP - goods in transit. It is important to consider only the goods that arrive in the store during the time of delivery of the goods (logistical leverage);

SZ - safety stock;

PP - sales forecast. It is calculated as “Daily Sales Forecast” multiplied by the number of delivery days (logistic leverage). Here it is important to note that if the product has a pronounced seasonality, then daily forecasts should be adjusted for seasonal factors;

The formula is easy to use: if the received “Order Size” is less than zero, then this means a shortage of goods in the future period, and RH * (- 1) = the quantity of goods that the supplier needs to order.

Thus, the manager will be able to easily track the need for the delivery of goods at the exact moment when it really became necessary.

When using this approach, the main difficulties arise from the large amount of data and the need for a large amount of calculations. Calculations must be made daily to take into account fluctuations in demand for each of the goods at each of the outlets, the volume of goods in transit, the reserves and the calculated safety stock. If you have an assortment of 5,000 SKUs and 5 stores, then you need to carry out (365 x 5 x 5000) about 9,000,000 calculations per year.

There are also problems associated with the correct prediction of sales in the future, since the methods associated with the "manual" evaluation usually have a large margin of error that can offset all the advantages of other computational volume. But professional tools are either expensive or their daily use may be too difficult for managers.

Most companies use Excel to perform this kind of calculation. We do not recommend doing this, as a large amount of computation and the need for human participation in the formation of data to fill in excel, does not sufficiently reduce the influence of the human factor on the calculation. And the result of working with excel is an opportunity to grow only through an increase in the number of managers.

Thus, we can find the answer to the question “how much goods and where to deliver?”.

We recommend using highly automated solutions that are sufficiently easy for everyday use, aimed at solving a specific procurement task and drastically reducing the influence of the human factor. One of such systems is Mycroft Assistant, http://mycroftbs.ru .

The second problem facing the company, which decided to correctly set the supply strategy - is limited resources.

What do companies do when the need is $ 10,000,000, and in fact there is only $ 3,000,000? What goods need to be purchased in the first place, and in which outlets to carry them?

To find the answer to these questions, it is necessary to introduce a gradation of goods according to the degree of their influence on the company's activities. A more important product is a product that is most often taken, which brings more profit, and which should be in the company's assortment. The most popular method is the clustering of goods by ABC groups, but it does not answer the question “what should I do if I don’t have enough money for all the products of group A?”.

To solve these problems, there are several “through” indicators that can be easily calculated for all products. These are indicators: turnover of goods and liquidity of goods.

The turnover of goods can be calculated as the ratio of the speed of sales of goods to the average stock for a certain period. That is, this is the period of time for which the average stock of the goods in stock is sold, and, consequently, the time of return on investment.

Turnover shows how many days are needed to sell the average inventory. It is defined as the ratio of the product of the average inventory and the number of days in the month to the turnover during this period.

In = (CrOst * Period) / ObPro , where

Average - Average inventory for the selected period,

Sample - Sales for the selected period.

Period - the number of days in the analysis period

For example, the average stock of goods was 100 pieces, and sales - 300 pieces. So, the turnover will be: 100 * 31/300 = 10.3 (days), i.e. It takes about 10 days to sell an average stock of goods.

Usually, the higher the rate of turnover of goods (the lower the rate in days) - the better for the company. This means that the goods are not stale in warehouses, and the shipment has arrived quickly. Ideally, analyze the indicator over the previous periods. Thus, the more wrapped product - so it is preferable for the purchase.

On the other hand, the liquidity indicator approaches this question, its logic is about the same - the faster a product leaves, the higher the indicator. And the conclusions from it are exactly the same: the more liquid a product is, the more preferable it is to purchase.

To calculate the liquidity of stocks, it is proposed to consider the so-called “need” of the goods - the ratio of the quantity of arrival of the goods to its sales - the Usability Index. The index is considered for a certain period, the default is 1 year, but different companies may consider it differently.

In = (ObProd - ObPost) / ObPro , where

Sample - Sales for the selected period,

ObPost - Receipts for the selected period.

The interpretation of the coefficient is proposed as follows:

Separately allocated goods, the remainder of which is in stock, but its sales are zero for the selected period, - such a product is considered a "dead balance".

Thus, owning the specified indicators, you can select the most significant products: Actively used (by liquidity), with a high turnover rate, as well as generally accepted indicators - profit and share in the company's turnover. A competent procurement organization is the investment of working capital in particular these goods in the first place.

The difficulties associated with the use of predetermined ones are related to the fact that each of the indicators must be calculated individually for each of the goods for each of the outlets at each formation of the purchase order. And even better - every day, to be able to control the current state of stocks in the company and to be able to respond in advance to a change in the status of a product (so that you can sell a product at a discount through any marketing tools before it becomes “ illiquid "). Thus, if you have an assortment of 5,000 SKUs and 5 stores, then you need to carry out (365 x 5 x 5000 x 2) about 18,000,000 calculations of indicators per year.

We recommend using highly automated solutions aimed at solving a specific procurement task, which will be able to automatically monitor the current state of stocks and effectively form an order to the supplier based on current estimates. One of such systems is Mycroft Assistant, http://mycroftbs.ru .

Mycroft Assistant is a complex inventory management system that can help small and medium-sized businesses avoid overstocking and stock shortages, reduce costs and increase company profitability.

Analyzing the history of sales and current balances, Mycroft Assistant makes a forecast and makes recommendations on which products to buy and to which warehouse to take them. It also creates a plan for sales and purchases in future periods. The system replaces the "manual" work and work with excel, and allows the company to develop and work effectively without the involvement of additional staff.

The system gives you recommendations on what you need to do in order to avoid an excess or shortage of goods at each of the outlets - where and how much goods you need to carry, so that the company is ready to provide the level of service to its customers.

In order to draw up a sales plan and purchase, in fact, you just need to click the “Calculate Plans” button - the system will independently analyze the sales history, current balances, take into account factors affecting the movement of goods. As a result of the calculation, you will receive a ready-made layout for quantitative and financial indicators.

Co-authored with Vladimir Chemeris

There are two main concepts that can be implemented in the formation of the procurement strategy.

1. That the size of the order is calculated through the economic justification, which takes into account the costs of the order itself, the cost of storing it, discounts per lot, and so on. This scheme is more typical for companies engaged in production and repair. Working in this scenario means that you may have a short surplus of goods, but this is economically feasible. The strategy operates on the concept of “effectively invested money” and is designed for a long implementation cycle.

2. That a product must be exactly where it is needed, precisely when it is needed, and its quantity must be exactly as much as is really necessary — no more, no less. The correct implementation of this concept means that the company effectively invests its funds in inventories, and it allows you to avoid extreme situations associated with a shortage of goods (and missed sales), and with an excess of goods (dead goods that can only be sold at a discount) . This approach is more characteristic of commercial enterprises. Working in this scenario means that you spend money exactly to the extent that it should be spent - no more, no less. Designed to cover the current needs of the company in the goods.

')

Below we consider the implementation of each strategy.

Strategy 1: Addition on the basis of the economically reasonable order size

Specialists in inventory management, of course, are well aware of the dependence of costs on the volume of the ordered consignment. On the presented interpretation (Fig.):

q - order size; z - unit costs; line chart - unit costs for storage of the order; hyperbolic graph - unit costs of placing an order; graph with optimum - total unit costs; q * is the point at which storage costs are equal to order placement costs.

Obviously, with a certain size of the order there are optimal conditions for the purchase. The optimum is clearly visible on the graph. This optimum is an EOQ (economical order quantity).

Techniques for calculating an economical order size (EOQ or Wilson / Wilson / model) are not applied in practice, although in the scientific literature on supply chain management and inventory, these techniques occupy significant amounts and are completely uncontested. The reasons for the negligent attitude of business towards EOQ are obvious and "lying on the surface." Firstly, the greater complexity of calculations, and, secondly, the low accuracy of the results.

In the EOQ formula and other analogues, it is proposed to determine the required order quantity directly (by minimum costs) (Fig. 1). The relationship between cost and optimal size, of course, exists, but it is not so direct. At the same time, the system error of EOQ is extremely high.

Fig. 1. The scheme of the algorithm for calculating the EOQ.

To raise the quality of calculations, it was proposed to use not the cost minimum, but the maximum annual profitability (Fig. 2). The cost, margin and implementation of the function is based on the profitability of the size of the order. On the graph of the function is determined by the optimum point. It is believed that this point corresponds to the most profitable volume of the order.

Using this method can significantly improve the accuracy of calculating the economically reasonable order size. But the complexity of the calculations according to the new method has increased. After all, now it is required to take into account the trading margin and all costs, and not just the costs of procurement and storage.

If we consider the optimal size of the order for each ordered item, then the labor costs for the preparation of orders will be an enormous amount. An enterprise that has a nomenclature of 10 thousand items and replenishes its reserves on a monthly basis would have to produce 10 thousand calculations of cost or profitability depending on the size of the order each month. Naturally, no one can afford such luxury.

Fig. 2. The scheme of the algorithm for calculating the optimal order for profitability.

Solution to the problem. You can get rid of the high complexity of the calculations if you use the two-step method. Then the complexity of the calculations will be reduced by hundreds of times (to an acceptable level).

At the first stage, the calculation is made not of the optimal order of a commodity position, but of the optimal size of a consignment of goods (Fig. 3). As a rule, one supplier supplies prefabricated batches - in one order several items of goods are completed at once. One lot consists of 5-10, and sometimes hundreds of items of goods. Therefore, if you make an economic rationale for the size of the batch of goods, rather than each position, then the number of calculations is reduced by the appropriate number of times.

For costs, sales and markup, a schedule of profitability versus order size is developed. By the point of maximum profitability is determined by the optimal size of the order. And by the optimal size of the order, you can find the appropriate turnover and (or) the best from an economic point of view, the interval between purchases.

If the demand for goods of the analyzed supplier is subject to strong seasonal fluctuations, it is quite reasonable to use not a single end-to-end indicator for the whole year, but to create a schedule in which the requirements for the size of the order (turnover) would be adjusted depending on the expected seasonal change in demand.

Having after completing the work of the first stage standards of turnover, order size and (or) the interval between purchases, it will not be difficult to carry out calculations of the required order volume of a specific position for a specialist. It remains only to find out the expected implementation and current balances, as well as the size of the safety stock.

The method of finding the size of the order by EOQ has too much error and, moreover, requires tremendous effort. The method of finding the optimal size of the order by profitability improves the quality of calculations, but does not reduce their complexity. The method, in which the process is divided into two stages (first, once a year, profitability is determined by optimal turnover, the size of the collective order to the supplier or the interval between purchases, and then the calculation of the size of the order of the commodity item for each shipment) and reduces the second problem to an acceptable level.

Strategy 2: Replenishment on the principle of Just In Time.

To implement this concept, the managers responsible for the supply need to make daily calculations - for each outlet, to make an assessment of sales in future periods. Taking into account the time of delivery of the goods, and based on the sales forecast, the manager, starting from the current state of the balance, should assess how long the current inventory is enough, and is it not time to order the goods so that by the time he arrives at the store, not only the old the batch has already ended, but no stockpiling has been formed.

Daily calculations need to be made, since current demand and delivery times for goods, and the quantity of goods on the way can fluctuate — these components need to be taken into account, as well as the time factor.

One of the important components of an order is the safety stock. Safety stock - this is an additional stock of goods, formed in case of unforeseen circumstances. Whether it is a sudden increase in demand, a delay in the goods on the way, or problems in production, the safety stock is needed so that the company can work (the time chosen by the operator) without interruption.

To understand the essence of the safety stock, we can offer an analogy: if your car's consumption is 10 l / 100 km, then you will never fill exactly 20 liters for a trip of 200 km, and you will always fill up a little more for unforeseen circumstances - this is safety stock.

The safety stock is calculated either in a fixed volume for each outlet, or depending on the delay in delivery, or depends on other factors (demand variability). Sometimes as a safety stock they use such a thing as “minimum balance in stock”.

The second important component is time. Time is involved in the formation of the sales forecast and the order period. The universal concept is “logistic leverage”, i.e. time during which the ordered goods will be delivered to the store

The total order size formula is quite simple:

Order size (RZ) = TO + TP - SZ - PP , where

THEN is the current balance. The size of the goods that you can dispose of. If you are working with the possibility of reserving goods, then you will have to exclude reserves from the current balance;

TP - goods in transit. It is important to consider only the goods that arrive in the store during the time of delivery of the goods (logistical leverage);

SZ - safety stock;

PP - sales forecast. It is calculated as “Daily Sales Forecast” multiplied by the number of delivery days (logistic leverage). Here it is important to note that if the product has a pronounced seasonality, then daily forecasts should be adjusted for seasonal factors;

The formula is easy to use: if the received “Order Size” is less than zero, then this means a shortage of goods in the future period, and RH * (- 1) = the quantity of goods that the supplier needs to order.

Thus, the manager will be able to easily track the need for the delivery of goods at the exact moment when it really became necessary.

When using this approach, the main difficulties arise from the large amount of data and the need for a large amount of calculations. Calculations must be made daily to take into account fluctuations in demand for each of the goods at each of the outlets, the volume of goods in transit, the reserves and the calculated safety stock. If you have an assortment of 5,000 SKUs and 5 stores, then you need to carry out (365 x 5 x 5000) about 9,000,000 calculations per year.

There are also problems associated with the correct prediction of sales in the future, since the methods associated with the "manual" evaluation usually have a large margin of error that can offset all the advantages of other computational volume. But professional tools are either expensive or their daily use may be too difficult for managers.

Most companies use Excel to perform this kind of calculation. We do not recommend doing this, as a large amount of computation and the need for human participation in the formation of data to fill in excel, does not sufficiently reduce the influence of the human factor on the calculation. And the result of working with excel is an opportunity to grow only through an increase in the number of managers.

Thus, we can find the answer to the question “how much goods and where to deliver?”.

We recommend using highly automated solutions that are sufficiently easy for everyday use, aimed at solving a specific procurement task and drastically reducing the influence of the human factor. One of such systems is Mycroft Assistant, http://mycroftbs.ru .

The second problem facing the company, which decided to correctly set the supply strategy - is limited resources.

What do companies do when the need is $ 10,000,000, and in fact there is only $ 3,000,000? What goods need to be purchased in the first place, and in which outlets to carry them?

To find the answer to these questions, it is necessary to introduce a gradation of goods according to the degree of their influence on the company's activities. A more important product is a product that is most often taken, which brings more profit, and which should be in the company's assortment. The most popular method is the clustering of goods by ABC groups, but it does not answer the question “what should I do if I don’t have enough money for all the products of group A?”.

To solve these problems, there are several “through” indicators that can be easily calculated for all products. These are indicators: turnover of goods and liquidity of goods.

The turnover of goods can be calculated as the ratio of the speed of sales of goods to the average stock for a certain period. That is, this is the period of time for which the average stock of the goods in stock is sold, and, consequently, the time of return on investment.

Turnover shows how many days are needed to sell the average inventory. It is defined as the ratio of the product of the average inventory and the number of days in the month to the turnover during this period.

In = (CrOst * Period) / ObPro , where

Average - Average inventory for the selected period,

Sample - Sales for the selected period.

Period - the number of days in the analysis period

For example, the average stock of goods was 100 pieces, and sales - 300 pieces. So, the turnover will be: 100 * 31/300 = 10.3 (days), i.e. It takes about 10 days to sell an average stock of goods.

Usually, the higher the rate of turnover of goods (the lower the rate in days) - the better for the company. This means that the goods are not stale in warehouses, and the shipment has arrived quickly. Ideally, analyze the indicator over the previous periods. Thus, the more wrapped product - so it is preferable for the purchase.

On the other hand, the liquidity indicator approaches this question, its logic is about the same - the faster a product leaves, the higher the indicator. And the conclusions from it are exactly the same: the more liquid a product is, the more preferable it is to purchase.

To calculate the liquidity of stocks, it is proposed to consider the so-called “need” of the goods - the ratio of the quantity of arrival of the goods to its sales - the Usability Index. The index is considered for a certain period, the default is 1 year, but different companies may consider it differently.

In = (ObProd - ObPost) / ObPro , where

Sample - Sales for the selected period,

ObPost - Receipts for the selected period.

The interpretation of the coefficient is proposed as follows:

Separately allocated goods, the remainder of which is in stock, but its sales are zero for the selected period, - such a product is considered a "dead balance".

Thus, owning the specified indicators, you can select the most significant products: Actively used (by liquidity), with a high turnover rate, as well as generally accepted indicators - profit and share in the company's turnover. A competent procurement organization is the investment of working capital in particular these goods in the first place.

The difficulties associated with the use of predetermined ones are related to the fact that each of the indicators must be calculated individually for each of the goods for each of the outlets at each formation of the purchase order. And even better - every day, to be able to control the current state of stocks in the company and to be able to respond in advance to a change in the status of a product (so that you can sell a product at a discount through any marketing tools before it becomes “ illiquid "). Thus, if you have an assortment of 5,000 SKUs and 5 stores, then you need to carry out (365 x 5 x 5000 x 2) about 18,000,000 calculations of indicators per year.

We recommend using highly automated solutions aimed at solving a specific procurement task, which will be able to automatically monitor the current state of stocks and effectively form an order to the supplier based on current estimates. One of such systems is Mycroft Assistant, http://mycroftbs.ru .

Mycroft Assistant is a complex inventory management system that can help small and medium-sized businesses avoid overstocking and stock shortages, reduce costs and increase company profitability.

Analyzing the history of sales and current balances, Mycroft Assistant makes a forecast and makes recommendations on which products to buy and to which warehouse to take them. It also creates a plan for sales and purchases in future periods. The system replaces the "manual" work and work with excel, and allows the company to develop and work effectively without the involvement of additional staff.

The system gives you recommendations on what you need to do in order to avoid an excess or shortage of goods at each of the outlets - where and how much goods you need to carry, so that the company is ready to provide the level of service to its customers.

In order to draw up a sales plan and purchase, in fact, you just need to click the “Calculate Plans” button - the system will independently analyze the sales history, current balances, take into account factors affecting the movement of goods. As a result of the calculation, you will receive a ready-made layout for quantitative and financial indicators.

Co-authored with Vladimir Chemeris

Source: https://habr.com/ru/post/293914/

All Articles