Planning and organization of product distribution in the company. Goals and effect

One of the main tasks of the company is to create an effective integrated system of regulation and control of product distribution planning.

A well-established supply system means the possibility (both financial and material) of ensuring the delivery of the right goods to the right places at the right time to ensure the optimal level of customer service, reduce costs and increase the profitability of the company.

A poorly supplied supply system leaves room for extreme situations:

1. The product at the outlet is less than you really need. This leads to the fact that there may be customers that you could not serve, and, therefore, either lost this sale or lost the sale of a customer.

2. The goods at the outlet are more than you really need. This leads to cost overruns of the company: the money buried in the product, the need for large working capital, the inefficient use of storage space and labor resources.

Both of these situations lead to lost money.

')

To prevent this from happening, it is necessary for the managers to keep track of the state of inventories and movements at each outlet, in order to prevent the occurrence of these extreme situations.

And to be able to plan the financial and material burden on the company. Since even if we learned that “we need to order a product, otherwise we will remain without sales,” this does not mean that the company right now has the money for it in the right amount. In this situation, the company has to attract additional credit resources, which means additional costs for monthly payments.

For the purpose of preventing problems, a planning tool is provided. The essence of this is quite simple, at the beginning of the period (year, monthly):

Step 1. You make a sales plan at each of the outlets.

Usually, the sales plan is made monthly. Based on either, according to the expert opinion of the manager responsible for sales, or using automated systems.

Automatic systems (such as ours - Mycroft Assistant ) independently formulate a sales plan. For each product, the history of sales at the analyzed outlet, seasonality, the direction of the sales trend and other factors are taken into account. And regarding this, a forecast of the consumption of goods for future periods is automatically generated.

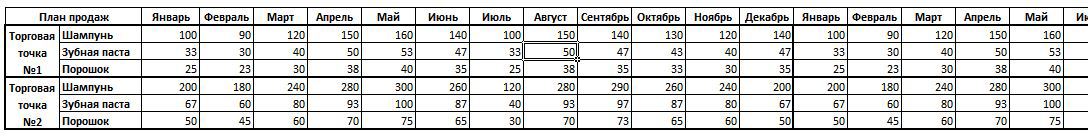

Suppose we are considering a company that sells household chemicals at two retail outlets (TT) in Moscow. We made this sales plan:

Step 2. According to the expected consumption of goods, make a plan to replenish each of the outlets.

Let's pretend that:

We order “shampoo” in France, the delivery time from us to it is 2 months, and we can buy no more than once every six months (6 months) - a container. This means that we need to buy it 2 months before the onset of product starvation and 6 months in advance.

We order “toothpaste” in China - with a delivery period of 3 months, no more than once every 3 months. This means that we need to buy it 3 months before the onset of product starvation and 3 months in advance.

We buy “powder” in Moscow and the delivery time is 1 day from us and we can take it at any time. This means that you can buy it when we need it.

Thus, we can calculate when what goods we need to order from the supplier, so that at each outlet there will always be goods no less than what we have according to the generated Sales Plan.

For this, it is enough to conduct a simulation of the situation for each accounting period (for the example given is the month) for each product and at each outlet. Modeling will allow you to find out with regard to future sales - whether it will be necessary to order any product in a given month for a given outlet. And if necessary, to what extent it should be done, taking into account the specified restrictions.

Here is a table of the procurement plan and commodity movements for outlets:

For simplicity, in order not to overload with figures, let us assume that the price of each of the goods is equal to 1 cu, and we consider the remainder in units.

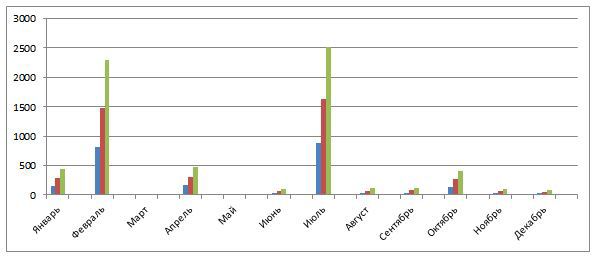

Thus, we have the following histograms:

According to the planned purchase

Indicated separately for TT №1, TT №2 and in total (by company). From here we see:

1) According to our model, the largest volume of purchases at each of the points is expected in February and July, and, therefore, these months need to prepare in advance the financial pillow.

2) You can prepare money in March, May, June, August, September, November and December - as months with the least financial burden on the purchase of goods.

We also see a forecast on stock balances.

Indicated separately for TT №1, TT №2 and in total (by company). From which we can conclude:

1) that at TT No. 1 (blue graph) we do not need a warehouse for more than 1000 units. and less than 200 units.

1) that at TT No. 2 (red graph) we do not need a warehouse for more than 1,700 units. and less than 400 units.

3) if we do everything through a distribution warehouse, then to supply these two outlets, the warehouse can be no more than 3000 units, but not less than 500 units.

4) the main activity of trade is planned in March, April, September and October. So, at least for these months, there is no need to plan the vacation of warehouse workers and not to start repairs

Step 3. In the event of a change in the nature of sales at retail outlets, adjust the sales plan and, accordingly, the replenishment plan changes.

It is important not only to make the plan itself, but also to track the fact of its execution. And according to the result of the period - to adjust the plan. This is a necessary condition in order to avoid the occurrence of extreme situations due to the discrepancy between the sales plan and the actual sales volume: both upward and downward. It is important to track these moments, and adjust the work according to the new conditions.

Step 4. Systematically execute the set replenishment plan.

It is necessary not only to make the plan itself, but in order to get an economic effect, it is necessary to follow it clearly, it will avoid unforeseen situations and improve the manageability of the company as a whole.

Thus, the formulation and execution of the replenishment plan serves the following purposes:

1. Optimization of the warehouse volume. You know when and how much storage space you need to serve your flow of goods. You can get information about how much goods will be at each of the outlets in your maximum, and on average over the period. This will allow you to save on unused space, or plan in advance the expansion of the warehouse.

2. Optimization of the use of labor resources. You know when and to what extent there will be a flow of goods at each of your outlets. Knowing how much your employees are coping with now, you can predict for each of the outlets: holidays, the need to reduce or recruit staff.

3. Reduced credit load. Knowing when and in what volume the purchase of goods will be required, you can predict the burden on the budget. Preparing in advance for the fact that you expect a "gap at the box office." This will allow you to reduce borrowing if you will create a financial buffer in advance for the execution of the plan.

4. Enhance customer service. In the absence of force majeure, and executing the plan, you will provide your customers with the level of availability of goods that you set for yourself, and which corresponds to the quality of customer service in your company. That is, the customer, having come to your store, is less likely to hear that “they have not yet brought the goods” or “they are not there now, but they are in stock - it will be in 3 days” - which means that they will most likely make a purchase and leave satisfied.

5. Improving the manageability of the company. Preventing force majeure situations and understanding what, where and when occurs and is planned to occur is a qualitative step forward for any company. And the opportunity to produce not only a plan, but also an assessment of the execution of the set plan is a step aside to identify problem areas in the management of the company.

Automation of supply planning.

All of the above can be done in Excel, which we showed above. But when you have a growing company with active commodity movements, when you have several outlets and hundreds of goods, it is incredibly time consuming to carry out calculations and planning in Excel. This will require a lot of manpower, which is better directed at solving other problems, and leads to errors caused by human factors. We propose to shift this work entirely to the car.

In our expert automated stock management system Mycroft Assistant , we implemented the planning module so that it could be managed by a person who never worked on plans even in Excel.

Mycroft Assistant is an expert in inventory analysis and management that can help small and medium businesses avoid overstocking and stock shortages, reduce costs and increase company profitability.

Analyzing the history of sales and current balances, Mycroft Assistant makes a forecast and makes recommendations on which products to buy and to which warehouse to take them. It also creates a plan for sales and purchases in future periods. The system replaces the "manual" work and work with excel, and allows the company to develop and work effectively without the involvement of additional staff.

The system gives you recommendations on what you need to do in order to avoid an excess or shortage of goods at each of the outlets - where and how much goods you need to carry, so that the company should be ready to provide the level of service to its customers.

In order to draw up a sales plan and purchase, in fact, you just need to click the “Calculate Plans” button - the system will independently analyze the sales history, current balances, take into account factors affecting the movement of goods. As a result of the calculation, you will receive a ready-made layout for quantitative and financial indicators.

Here is a sample of how we display the monthly sales and purchase plan:

Also, the system monthly analyzes the actual execution of the plan, relative to the calculated plan and shows the amount of its implementation. In the event that a design plan is very different from the actual one, it is necessary to take measures either to adjust the plan, or to adjust the operation of the supply chain.

Thus, competent planning automation in a company can lead to a qualitatively new level of the company's work. A couple of examples of “life”: our client, using our solution, managed to reduce the money “frozen” in the warehouse from 12 to 4.5 million rubles without loss of sales volume, and the other to reduce the attraction of credit funds in circulation by an order of magnitude - to 10 million rubles.

In any case, both manual work planning and automated work is the cornerstone of an efficient trading company, and a specific competitive advantage.

A well-established supply system means the possibility (both financial and material) of ensuring the delivery of the right goods to the right places at the right time to ensure the optimal level of customer service, reduce costs and increase the profitability of the company.

A poorly supplied supply system leaves room for extreme situations:

1. The product at the outlet is less than you really need. This leads to the fact that there may be customers that you could not serve, and, therefore, either lost this sale or lost the sale of a customer.

2. The goods at the outlet are more than you really need. This leads to cost overruns of the company: the money buried in the product, the need for large working capital, the inefficient use of storage space and labor resources.

Both of these situations lead to lost money.

')

To prevent this from happening, it is necessary for the managers to keep track of the state of inventories and movements at each outlet, in order to prevent the occurrence of these extreme situations.

And to be able to plan the financial and material burden on the company. Since even if we learned that “we need to order a product, otherwise we will remain without sales,” this does not mean that the company right now has the money for it in the right amount. In this situation, the company has to attract additional credit resources, which means additional costs for monthly payments.

For the purpose of preventing problems, a planning tool is provided. The essence of this is quite simple, at the beginning of the period (year, monthly):

Step 1. You make a sales plan at each of the outlets.

Usually, the sales plan is made monthly. Based on either, according to the expert opinion of the manager responsible for sales, or using automated systems.

Automatic systems (such as ours - Mycroft Assistant ) independently formulate a sales plan. For each product, the history of sales at the analyzed outlet, seasonality, the direction of the sales trend and other factors are taken into account. And regarding this, a forecast of the consumption of goods for future periods is automatically generated.

Suppose we are considering a company that sells household chemicals at two retail outlets (TT) in Moscow. We made this sales plan:

Step 2. According to the expected consumption of goods, make a plan to replenish each of the outlets.

Let's pretend that:

We order “shampoo” in France, the delivery time from us to it is 2 months, and we can buy no more than once every six months (6 months) - a container. This means that we need to buy it 2 months before the onset of product starvation and 6 months in advance.

We order “toothpaste” in China - with a delivery period of 3 months, no more than once every 3 months. This means that we need to buy it 3 months before the onset of product starvation and 3 months in advance.

We buy “powder” in Moscow and the delivery time is 1 day from us and we can take it at any time. This means that you can buy it when we need it.

Thus, we can calculate when what goods we need to order from the supplier, so that at each outlet there will always be goods no less than what we have according to the generated Sales Plan.

For this, it is enough to conduct a simulation of the situation for each accounting period (for the example given is the month) for each product and at each outlet. Modeling will allow you to find out with regard to future sales - whether it will be necessary to order any product in a given month for a given outlet. And if necessary, to what extent it should be done, taking into account the specified restrictions.

Here is a table of the procurement plan and commodity movements for outlets:

For simplicity, in order not to overload with figures, let us assume that the price of each of the goods is equal to 1 cu, and we consider the remainder in units.

Thus, we have the following histograms:

According to the planned purchase

Indicated separately for TT №1, TT №2 and in total (by company). From here we see:

1) According to our model, the largest volume of purchases at each of the points is expected in February and July, and, therefore, these months need to prepare in advance the financial pillow.

2) You can prepare money in March, May, June, August, September, November and December - as months with the least financial burden on the purchase of goods.

We also see a forecast on stock balances.

Indicated separately for TT №1, TT №2 and in total (by company). From which we can conclude:

1) that at TT No. 1 (blue graph) we do not need a warehouse for more than 1000 units. and less than 200 units.

1) that at TT No. 2 (red graph) we do not need a warehouse for more than 1,700 units. and less than 400 units.

3) if we do everything through a distribution warehouse, then to supply these two outlets, the warehouse can be no more than 3000 units, but not less than 500 units.

4) the main activity of trade is planned in March, April, September and October. So, at least for these months, there is no need to plan the vacation of warehouse workers and not to start repairs

Step 3. In the event of a change in the nature of sales at retail outlets, adjust the sales plan and, accordingly, the replenishment plan changes.

It is important not only to make the plan itself, but also to track the fact of its execution. And according to the result of the period - to adjust the plan. This is a necessary condition in order to avoid the occurrence of extreme situations due to the discrepancy between the sales plan and the actual sales volume: both upward and downward. It is important to track these moments, and adjust the work according to the new conditions.

Step 4. Systematically execute the set replenishment plan.

It is necessary not only to make the plan itself, but in order to get an economic effect, it is necessary to follow it clearly, it will avoid unforeseen situations and improve the manageability of the company as a whole.

Thus, the formulation and execution of the replenishment plan serves the following purposes:

1. Optimization of the warehouse volume. You know when and how much storage space you need to serve your flow of goods. You can get information about how much goods will be at each of the outlets in your maximum, and on average over the period. This will allow you to save on unused space, or plan in advance the expansion of the warehouse.

2. Optimization of the use of labor resources. You know when and to what extent there will be a flow of goods at each of your outlets. Knowing how much your employees are coping with now, you can predict for each of the outlets: holidays, the need to reduce or recruit staff.

3. Reduced credit load. Knowing when and in what volume the purchase of goods will be required, you can predict the burden on the budget. Preparing in advance for the fact that you expect a "gap at the box office." This will allow you to reduce borrowing if you will create a financial buffer in advance for the execution of the plan.

4. Enhance customer service. In the absence of force majeure, and executing the plan, you will provide your customers with the level of availability of goods that you set for yourself, and which corresponds to the quality of customer service in your company. That is, the customer, having come to your store, is less likely to hear that “they have not yet brought the goods” or “they are not there now, but they are in stock - it will be in 3 days” - which means that they will most likely make a purchase and leave satisfied.

5. Improving the manageability of the company. Preventing force majeure situations and understanding what, where and when occurs and is planned to occur is a qualitative step forward for any company. And the opportunity to produce not only a plan, but also an assessment of the execution of the set plan is a step aside to identify problem areas in the management of the company.

Automation of supply planning.

All of the above can be done in Excel, which we showed above. But when you have a growing company with active commodity movements, when you have several outlets and hundreds of goods, it is incredibly time consuming to carry out calculations and planning in Excel. This will require a lot of manpower, which is better directed at solving other problems, and leads to errors caused by human factors. We propose to shift this work entirely to the car.

In our expert automated stock management system Mycroft Assistant , we implemented the planning module so that it could be managed by a person who never worked on plans even in Excel.

Mycroft Assistant is an expert in inventory analysis and management that can help small and medium businesses avoid overstocking and stock shortages, reduce costs and increase company profitability.

Analyzing the history of sales and current balances, Mycroft Assistant makes a forecast and makes recommendations on which products to buy and to which warehouse to take them. It also creates a plan for sales and purchases in future periods. The system replaces the "manual" work and work with excel, and allows the company to develop and work effectively without the involvement of additional staff.

The system gives you recommendations on what you need to do in order to avoid an excess or shortage of goods at each of the outlets - where and how much goods you need to carry, so that the company should be ready to provide the level of service to its customers.

In order to draw up a sales plan and purchase, in fact, you just need to click the “Calculate Plans” button - the system will independently analyze the sales history, current balances, take into account factors affecting the movement of goods. As a result of the calculation, you will receive a ready-made layout for quantitative and financial indicators.

Here is a sample of how we display the monthly sales and purchase plan:

Also, the system monthly analyzes the actual execution of the plan, relative to the calculated plan and shows the amount of its implementation. In the event that a design plan is very different from the actual one, it is necessary to take measures either to adjust the plan, or to adjust the operation of the supply chain.

Thus, competent planning automation in a company can lead to a qualitatively new level of the company's work. A couple of examples of “life”: our client, using our solution, managed to reduce the money “frozen” in the warehouse from 12 to 4.5 million rubles without loss of sales volume, and the other to reduce the attraction of credit funds in circulation by an order of magnitude - to 10 million rubles.

In any case, both manual work planning and automated work is the cornerstone of an efficient trading company, and a specific competitive advantage.

Source: https://habr.com/ru/post/292560/

All Articles