Innovations in the Russian oil industry through the eyes of a startup

With the advent of each new crisis in modern Russia, they recall the import substitution. However, today, to the already characteristic feature of hard times - the collapse of the ruble, Western sanctions have also been added. They threaten oil production not only on the shelf, but also in traditional fields. Taking into account hidden imports, when providing services by Russian subsidiaries of foreign companies, the share of imported equipment and technologies reaches 80%, and for individual projects it can exceed 90%.

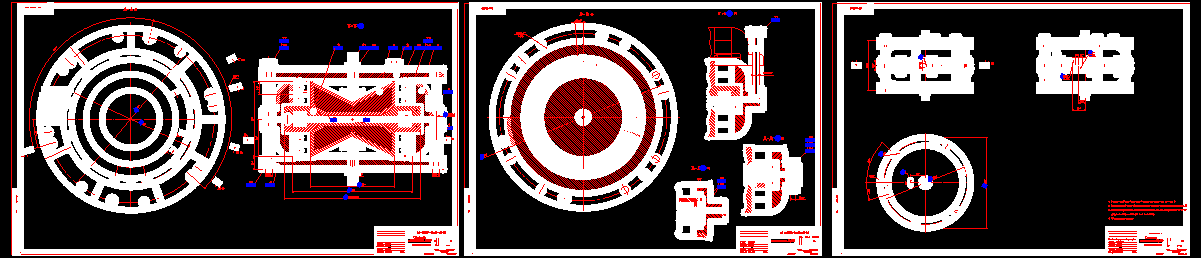

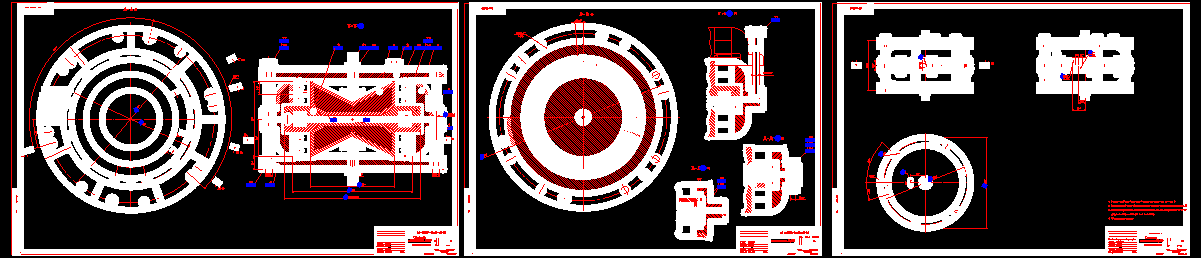

“Already in the medium term, there is a risk of reducing production,” the Ministry of Industry and Trade acknowledged and decided to reduce this dependence by at least 2018–2020 to 50-60%, and to the very close 2035, to bring it to 10 percent. All this is good, but what about IT here you say? But look at the chart.

')

This is surprising, but according to the Ministry of Industry and Trade, the largest share of the western product is observed far from pipes and even in offshore drilling equipment. Most of all oilmen are dependent on imports of pump-compressor equipment, equipment for geological and seismic exploration, software and hardware systems and automation systems, equipment and technologies for offshore drilling.

Our authorities understand the danger of this situation and even began to take preventive measures even before the onset of the crisis. As a result, today the total amount of annual state support for civilian research and development, according to Mr. Medvedev, is more than 370 billion rubles. As part of this process, the implementation of a number of “road maps” in priority areas that are interdisciplinary in nature has begun. Let me remind you that in the honorable sixth place in the list of these areas are located “high technologies in the fuel and energy complex”. So there is a chance for the explosive growth of high-tech start-ups in the strategic oil industry?

In this article I will try to understand this in more detail, looking at the difficulties of introducing high technologies into our oil industry through the prism of my eight-year experience in developing electronics for startups in this field and even venture to give some unsolicited advice to those who are ready to try their luck in this field.

A little more magic speeches of higher persons and cash flow:

Dvorkovich argues that in a fairly limited time frame, Russia has managed to create a generally basic infrastructure to support development in priority areas. In addition to Skolkovo, the Russian venture company, Rosnano, and Vnesheconombank in terms of their competence, the Innovation Assistance Fund, and a number of other institutions are engaged in supporting innovative projects.

An investment of 2.5 trillion dollars by 2035 should be directed to products that have yet to be developed for machine-building enterprises of the fuel and energy complex. Already today, 60 companies with state participation are implementing innovative development programs with funding of more than 1 trillion 300 billion rubles. The task that they are trying to solve at such a price is to ensure the growth of investment in research and thereby increase labor productivity.

Personally, I was already dizzy from the number of zeros. The numbers we allocate for innovation are comparable to the holy of holies - the military budget! Things are easy - to master them for the benefit of the Motherland, well, and not to forget yourself ... Is it worth starting with the search for problems to be solved?

In order to start the development it is necessary to at least find the actual problem that there is a chance to solve by spending a reasonable amount of forces and means. It is clear that to design a drilling rig for mining in the Arctic ice until 2018 with a budget of several hundred million is unlikely to work. But do not despair, not everything is so bad, because even at the stage of primary oil processing, where I had to work, there are still a lot of unsolved problems for IT and electronics. Either existing solutions are very unreliable.

Here are just three serious problems faced:

As even our prosecutors already know (remember how Khodorkovsky demonstrated three-liter with a mysterious liquid in court), not pure oil is extracted from the overwhelming majority of wells, but some substance, which is a mixture of at least three components — salt water, gas and the oil itself. Depending on the specifics, in this well fluid a large amount of other impurities (up to sand) can be observed, which greatly complicate the process of oil refining. In the majority of currently active domestic fields, the oil content ranges from 85 to 15 percent. If the well is located in an easily accessible place and the oil contains few harmful impurities, then the development can be carried out up to 8 percent, but this can be considered an exception to the rule. As a rule, the wells do not stand alone in the open field, but form a bush. Pipelines from several nearby wells are combined into one, and through it the product enters the primary processing. The effectiveness and duration of the well depends on the mode of its operation, and in order to properly configure it, it is highly desirable to know the percentage of gas, oil and water at the output of EVERY from the wells. So, this is not surprising, but the problem of determining this ratio on the fly, that is, on-line, still does not have a satisfactory solution. But the majority of wells work autonomously and put around each laboratory or even constantly pour samples into test tubes and carry them to the laboratory is extremely unpleasant and not cheap. By the way, this task was attempted by my first startup.

Go on the chain further. The well fluid, in most cases, from the pipe enters the septic tanks, the purpose of which is to separate the oil from the gas, reduce the water content to two percent or less and reduce the salinity to an acceptable value. And here we are faced with new problems.

First, associated gas utilization. It’s inconsistent and very environmentally unfriendly to just flare, and it turns out to be quite difficult to use for useful purposes! It is hampered by high humidity and harmful impurities; a large and expensive installation with such volumes is unprofitable.

Secondly, it would seem that a completely trivial task is to determine the phase boundary in the sump. That is, the boundaries above which there is oil with the water content we need and below which there is relatively clean water that can be drained. It would seem that what could be simpler, but despite the fact that there are hundreds of devices based on completely different principles of operation, there are constant problems with this. Most installations still have to use archaic floats as sensitive elements! There are huge problems with this, especially in fields with high viscosity or a large amount of harmful impurities. Floats quickly overgrown with sediments, due to which their balance is disturbed. At times, they simply begin to jam. We solved this problem in my second project.

You can continue for a long time, but I hope I have already managed to convince you that there is still something to do for innovators, even in the very traditional oil industry, I generally keep quiet about shale oil.

So, let's say the first stage has been completed, you have found an actual task for yourself, which you can do and you already understand that you can solve it. The next step is naturally to show potential investors and customers what indisputable advantages your device will have in comparison with existing analogues on the market. Well, we got to the first problems!

When you buy a penny Chinese tester on the radio market, in many cases the accuracy of its testimony is even higher than the passport, at least as long as the batteries are fresh, the test probe sockets remain in contact and it does not begin to fall apart like almost any other Chinese junk. Naturally, one should expect that in such a regulated industry as industrial automation everything is much more serious ... I also thought so at first. And ... badly mistaken.

As it is not surprising, the following stories are completely in order of things:

The most honest manufacturers in my opinion are the Germans. However, even the inscription “Made in Germany” does not guarantee that in the summer, when the level of steam in the tank rises significantly, the inscription on the upper limit of coal tar does not go insane because the heaped-up radar cost more than ten thousand euros. By the way, this is another seemingly simplest unsolved problem. On the Gubakha coking plant, this problem is still being solved in an extremely innovative way - “Uncle Vasya” periodically climbs onto a tall tank and lowers into a container on a long cable a piece of pipe with a powerful light bulb tied to it. Then he raises and measures the distance to the mark on the pipe with a tape measure.

It remains a mystery to me - how are all these devices certified? Honestly, I thought earlier that this process is much stricter than ours, but judging by how often the stated characteristics of the instruments differ from the real ones, this is not so. Perhaps they are conducting certification only in perfect laboratory conditions. It is possible, as we often have, that the need for thorough testing is replaced with a thick wad of pleasantly rustling bills and a banquet.

It would not be worthwhile to spend as many printed characters on these nuances as if this fact did not have several unpleasant consequences:

First, faced with similar stories and throwing a lot of money into the pipe, the leaders of large companies become hard-boiled conservatives. At their insistence, lists of trusted suppliers are created and a company not included in this pool is practically impossible to sell.

Secondly, for me personally, it is completely unclear what characteristics to declare with the device you are developing? Suppose it gives accuracy not 1, but 5 percent, but it works steadily in such extreme conditions in which others are not able to provide any kind of sane result. If you honestly mention in the presentation of your device about these 5 percent, then you cause the anger of your marketers and investors perplexity. Yes, and potential customers wonder why they are offered devices that are worse than the existing analogs in performance? If you promise the impossible, then already at the stage of “field trials” you can get a negative feedback from the client.

How to solve this dilemma, I do not know.

When creating devices for the oil industry it is always necessary to remember that in the overwhelming majority of cases your device will be in an explosive zone, which means that, among other things, an explosion protection certificate will MUST be required. With the receipt of this document, there is a very different picture from certification for a measuring instrument or electromagnetic compatibility, where the ball is ruled by a golden calf. No one wants to be extreme in a situation where a drilling rig, and especially a petrochemical plant, takes off into the air. Hacking will not work. This does not mean that you will not be able to spend extra money on this process. Good self-detained from a certifying organization will be happy to help you make the necessary changes to the hull or find the right spark loop, of course, not for free.

If from the very beginning you did not determine in which explosive zone your device will work and did not begin to develop, considering the appropriate type of explosion protection, in most cases serious additional financial costs await you at the stage when “almost everything is ready.” In a separate case, it may be necessary to simply redo the entire project from scratch. Believe me, this is very serious!

It is highly desirable to have a team of two or three people with experience in developing or at least working in the industry who know the nuances. And there will be a lot of them, believe me. So the electronics engineer will have to try to adjust his device to the strict requirements of spark-breaking chains, and if this is not possible, then try to fit into the framework, due to the use of shells with a flameproof enclosure.

An even bigger stumbling block could be a building for designers. So I happened in the first startup. Despite the fact that it was developed by experienced designers, when it came to certification for explosion protection, five iterations of explosion tests passed, after each of which modifications were made according to the suggestions of experienced experts. It took a lot of time and money. If the design was originally taken into account the construction of analogues with similar dimensions, it would hardly need more than two iterations.

If there is a possibility, it is best to choose housings from the standard range and, considering their size, to design electronics, but even in this case there will be a lot of problems, for example, with the selection of cable glands and cable type ... The hermetic housing requires special measures to combat the occurrence of condensate and its consequences. Operation in the conditions of the northern territories makes it extremely responsible to treat reliable operation in the condition of low temperatures. By the way, not only hypothermia, but also overheating under the action of direct sunlight can become a serious problem.

The project to develop a new high-tech equipment for oil refining is very expensive, compared with a start-up in the field of IT ... We need a lot of money for numerous certificates, the organization of pilot tests and, finally, the establishment of production. Therefore, you should not save on experienced professionals with special education. However, young people as an injection of fresh blood, of course, will not interfere.

Once the lab tests are completed in oil, your prototype is waiting for the next step. Testing on a specially created laboratory bench with a real well fluid with all the truth taken out of the object. And so, when you are trying to bring the quality of determination of the parameter you need to perfection, and the investor finally loses patience, it will certainly reach the stage of trial operation. This is a very responsible and difficult moment.

It is not at all easy to persuade people on the ground to put your device to the test until you have at least an explosion protection certificate. And you can get it already on the finished product. If you spend a lot of time and money certifying a sample, then in case of making changes you will have to go through the procedure again! Vicious circle. Real life is very different from experiments in the laboratory and presents many unexpected surprises.

“Uncle Kolya” can knock off the terminal block when connecting the cable to the device, it can break the threads. The connecting cable may be longer than you expected or not at all of that type. In the settling basins of depleted fields and fields with high oil content, very different processes can occur. A 24 volt power supply available can produce all forty at a small load current ... Unexpected large and minor dirty tricks are waiting for you at literally every step. In this situation, the human factor is very important.

Most likely, the developer of the equipment will have to take the most direct part in the business trip. This is a huge stress for people of technical mentality and character. It is very difficult during the day to experiment experimentally under the supervision of curious Aborigines and their impatient bosses, and in the evening to feverishly correct errors in the code, putting patches on non-controlling unexpected processes in the reservoir. We must do everything possible to establish good relations with local KIPovtsami. Talking heart to heart on technical and abstract topics, as well as small, but useful gifts in everyday activities, such as Japanese side cutters or pocket RLC meters, are very helpful in building relationships that will pay back later.

Business trips tend to overload, and you have to spend more than a week in a terrible mode - during the day, look for the cause of incorrect work and try to fix physical defects with improvised means, and at night to correct the code often in conditions far from ideal. The most extreme thing I had to experience was living in a room designed for the rest of the work shift. Passage yard faces change every two hours. Someone wants to watch TV, someone to chat, to whom footcloths to dry ... And so on all night. And to get up early in the morning at the object, despite the fact that the road from Moscow to the object took almost a day and you have a roof from the time difference.

If we don’t go anywhere, we should at least try to minimize the damage. On a business trip, it is desirable to travel at least two. One person at the same time solves technical issues, and the second organizational. Agrees on access to the facility, distracts the local authorities with conversations, knocks out papers for taking samples in the laboratory or permits to temporarily stop the control system or change the parameters to close to critical, to check the response of the device to serious deviations ...

Well, good advice - do not spare funds to encourage employees involved in commissioning, especially in the case of a successful outcome. Otherwise, it will be extremely difficult to send them there next time.

The energy industry now lives in conditions of state capitalism. On the one hand, it lowers the level of competition, on the other hand, it can theoretically help with entering the market.

In recent years, leading companies in the field of oil and gas production, such as Rosneft, Lukoil, Bashneft, Gazprom, have a distribution list for innovation. In practice, this is reflected in the fact that there are people on the ground responsible for innovation. They try to encourage ordinary employees to make various kinds of rational proposals and provide assistance for their subsequent implementation. The most promising, from their point of view, ideas are sent higher up the career ladder, where, based on them, they are trying to organize the development of new equipment. The system is highly bureaucratic and works with a lot of squeak, however you can try to use this mechanism to build partnerships to promote your project.

We tried, but got an unexpected result. It turned out that in the depths of Lukoil was born a draft solution to the same problem on which we worked. Their option came out more expensive and less reliable, but a nth amount of money was already invested in it and, despite the fact that the work on it had actually reached a dead end, they no longer had the opportunity to participate in financing our project.

Recently, various types of technoparks for organizing a private-state partnership have been growing like yeasts in the regions, but in practice it is very difficult to use their services to develop a serious project. First, it is very difficult to get a serious amount. Secondly, the conditions on which the money offered can not be called particularly attractive. The conversation is approximately in this way:

Need money? We will give a couple of millions to certify a prototype and conduct tests, but on condition that you yourself invest the same amount. Yes, and we want half of your business for it. Ah, you have already invested 5 million in development and 10 million more will be needed in the organization of production. And it does not concern us. Who in general needs money you or us. Once for you, these are your problems.

Such appetites, however, do not have the most toothy sharks of the venture capital business in the Wild West. But it would have been half the trouble if it were not for our glorious organs. They are vigilant to ensure that the money is returned on time, and the production of the product was launched no later than the designated X hour. Did you fail? So you are a fraudster brother and a place for you in a government house, and not in the ranks of startups ...

Import substitution is a good thing, but this is a matter for the future, even the closest one, if you believe the most optimistic forecasts. It takes several years to bring the product to industrial design in this industry, and equipment is needed today so that we will not get tomorrow, to all our troubles, in addition, and a reduction in oil production.

Today, the Ministry of Industry and Trade has prepared a list of foreign companies that could replace American and European suppliers. It mentions three companies from South Korea, Daewoo, LHE and KwangShin (compressors and plate heat exchangers), one each from India (Indore Composite, reagents), Belorusi (Naftan, additives) and Singapore (NuStar, diving equipment).

For most of the positions, Chinese manufacturers are called as alternative suppliers: a total of several dozen companies, including CNPC, China National Logging Corporation, Shanghai Electric Heavy Industry, Huawei.

Russian oilmen are in a hurry and can be understood. Already, they are negotiating with new suppliers. Rosneft is discussing with CNPC the possibility of combining efforts in the field of oilfield services, equipment manufacturing and R & D. Because of the sanctions of alternative suppliers, including in Asia, Gazprom Neft is also seeking.

For several years, Chinese manufacturers have been supplying the Russian market with mobile and stationary drilling rigs in small batches, but they have not yet been allowed to enter serious projects.

It is worth noting that currently up to 80 percent of the products of famous western brands are made in China. We are talking about material-intensive and energy-intensive parts of the equipment. Then all this is equipped with a high-tech component - electronics, computer systems, software, and enters the market under the brand name of famous companies.

Ideally, Russian companies for the rapid organization of import substitution should go the same way - to organize the assembly production of Chinese equipment in Russia, and the "brains" to do it yourself. We have a similar joint production is now trying to organize in Ufa, the notorious Uralvagonzavod, which has everything in order with state investments.

However, the Chinese are striving for something quite different. They have been waiting for a long time and today they want to take advantage of the moment to conquer our market with our help. So, Huawei announced one of its most important priorities to develop integrated solutions in the field of communication technologies for the oil and gas industry. So far, she has very few completed projects in Russia, but the process of actively testing its solutions by the largest companies is already underway. The representative of Huawei does not disclose final customers, but claims that they began to consider Huawei's proposals even before the imposition of sanctions and the company is ready to provide them “now.

Russian producers fear that a turn of oilmen to the East will hinder the development of domestic production. There is a serious danger that the Russians will have to compete for the customer with Chinese suppliers in unequal conditions, primarily financial ones. From 2015, China will cease the state support program for subsidizing its industry in the fuel and energy sector, but for a long time, tied loans from Chinese banks will act, which they willingly issue for oil and gas projects involving the supply of Chinese equipment.For oil companies, it will now be easier to work with Chinese manufacturers, but in the long and medium term, this is the danger of a new dependence on imports: China may simply begin to dictate its conditions both on equipment supplies and on prices.

By the way, the price of Chinese equipment will not be much cheaper than Western equipment, but it is inferior in quality. On the one hand, they understand above that they need to focus on localizing the production of oil and gas equipment in Russia, firstly, because the industry is strategic, and secondly, to create jobs within the country and receive taxes here. But Russian manufacturers will not be able to cope with the required development time. So, today our country is at a very serious fork. Officials decide who will save our oil industry Chinese suppliers or Russian manufacturers and developers.

But how do investors assess the situation? Let's look at the results of one of the polls of the “Russian Venture Company”.

69% of projects in Russia are low-quality start-ups (17% are of very low quality), the share of medium-quality projects, in their opinion, is 24%, above average - 7%. But even that small part of Russian projects, which is recognized by investors as successful, does not see prospects for further development of business in Russia. The state does not create a sufficiently comfortable environment for the development of innovative entrepreneurship, state participants in the innovation market. Only 16% of respondents believe that the effectiveness of government spending over the past 10 years has grown. The efficiency of tax incentives and benefits that Russian innovators can take advantage of leaves much to be desired. Most market participants (45%) consider such measures insufficient. Another 16% of them rated as "very low." Only 6% of respondents indicated high efficiency of preferences.Low-comfort and legal regime of innovation activity in Russia. 55% of respondents estimate it negatively. 38% of respondents consider the level of development of legal regulation of innovation activity as “insufficient and requiring additional state efforts”, and only 7% consider it “comfortable”. The combination of problems leads to the fact that the Russian innovative business is disappointed in the domestic business environment. Almost 60% of respondents believe that the incentives to preserve Russian jurisdiction are not enough, and only 7% believe that they have enough.The combination of problems leads to the fact that the Russian innovative business is disappointed in the domestic business environment. Almost 60% of respondents believe that the incentives to preserve Russian jurisdiction are not enough, and only 7% believe that they have enough.The combination of problems leads to the fact that the Russian innovative business is disappointed in the domestic business environment. Almost 60% of respondents believe that the incentives to preserve Russian jurisdiction are not enough, and only 7% believe that they have enough.

?

, ?

And most importantly. Who will carry out the breakthrough transformations described above? Exactly those who brought the situation to the present situation? And there are no other personnel in the system with completely blocked up social elevators.

Well, let's do what we can and hope for the future. I do not want to finish the article on a minor note. I will try to raise the spirit to make a digest and analysis of Russian startups related to the oil industry. Despite all the difficulties of the TOP-50 Russian, according to the Russian Startup Rating, as many as five are closely related to developments in the oil sector.

PS And I also have some instructive stories in the reserve of attempts to make breakthroughs in projects with different sources of funding. One developed under the wing of the Bortnik and Transneft Foundation. The second is in the framework of public-private partnership with Gazprom and Rosnano. The third one was financed by BusinessAngel. I am sure that acquaintance with them will be interesting, to find only time!

“Already in the medium term, there is a risk of reducing production,” the Ministry of Industry and Trade acknowledged and decided to reduce this dependence by at least 2018–2020 to 50-60%, and to the very close 2035, to bring it to 10 percent. All this is good, but what about IT here you say? But look at the chart.

')

This is surprising, but according to the Ministry of Industry and Trade, the largest share of the western product is observed far from pipes and even in offshore drilling equipment. Most of all oilmen are dependent on imports of pump-compressor equipment, equipment for geological and seismic exploration, software and hardware systems and automation systems, equipment and technologies for offshore drilling.

Our authorities understand the danger of this situation and even began to take preventive measures even before the onset of the crisis. As a result, today the total amount of annual state support for civilian research and development, according to Mr. Medvedev, is more than 370 billion rubles. As part of this process, the implementation of a number of “road maps” in priority areas that are interdisciplinary in nature has begun. Let me remind you that in the honorable sixth place in the list of these areas are located “high technologies in the fuel and energy complex”. So there is a chance for the explosive growth of high-tech start-ups in the strategic oil industry?

In this article I will try to understand this in more detail, looking at the difficulties of introducing high technologies into our oil industry through the prism of my eight-year experience in developing electronics for startups in this field and even venture to give some unsolicited advice to those who are ready to try their luck in this field.

Just a couple of buckets of honey in our barrel!

A little more magic speeches of higher persons and cash flow:

Dvorkovich argues that in a fairly limited time frame, Russia has managed to create a generally basic infrastructure to support development in priority areas. In addition to Skolkovo, the Russian venture company, Rosnano, and Vnesheconombank in terms of their competence, the Innovation Assistance Fund, and a number of other institutions are engaged in supporting innovative projects.

An investment of 2.5 trillion dollars by 2035 should be directed to products that have yet to be developed for machine-building enterprises of the fuel and energy complex. Already today, 60 companies with state participation are implementing innovative development programs with funding of more than 1 trillion 300 billion rubles. The task that they are trying to solve at such a price is to ensure the growth of investment in research and thereby increase labor productivity.

Personally, I was already dizzy from the number of zeros. The numbers we allocate for innovation are comparable to the holy of holies - the military budget! Things are easy - to master them for the benefit of the Motherland, well, and not to forget yourself ... Is it worth starting with the search for problems to be solved?

Has everyone come up with us?

In order to start the development it is necessary to at least find the actual problem that there is a chance to solve by spending a reasonable amount of forces and means. It is clear that to design a drilling rig for mining in the Arctic ice until 2018 with a budget of several hundred million is unlikely to work. But do not despair, not everything is so bad, because even at the stage of primary oil processing, where I had to work, there are still a lot of unsolved problems for IT and electronics. Either existing solutions are very unreliable.

Here are just three serious problems faced:

As even our prosecutors already know (remember how Khodorkovsky demonstrated three-liter with a mysterious liquid in court), not pure oil is extracted from the overwhelming majority of wells, but some substance, which is a mixture of at least three components — salt water, gas and the oil itself. Depending on the specifics, in this well fluid a large amount of other impurities (up to sand) can be observed, which greatly complicate the process of oil refining. In the majority of currently active domestic fields, the oil content ranges from 85 to 15 percent. If the well is located in an easily accessible place and the oil contains few harmful impurities, then the development can be carried out up to 8 percent, but this can be considered an exception to the rule. As a rule, the wells do not stand alone in the open field, but form a bush. Pipelines from several nearby wells are combined into one, and through it the product enters the primary processing. The effectiveness and duration of the well depends on the mode of its operation, and in order to properly configure it, it is highly desirable to know the percentage of gas, oil and water at the output of EVERY from the wells. So, this is not surprising, but the problem of determining this ratio on the fly, that is, on-line, still does not have a satisfactory solution. But the majority of wells work autonomously and put around each laboratory or even constantly pour samples into test tubes and carry them to the laboratory is extremely unpleasant and not cheap. By the way, this task was attempted by my first startup.

Go on the chain further. The well fluid, in most cases, from the pipe enters the septic tanks, the purpose of which is to separate the oil from the gas, reduce the water content to two percent or less and reduce the salinity to an acceptable value. And here we are faced with new problems.

First, associated gas utilization. It’s inconsistent and very environmentally unfriendly to just flare, and it turns out to be quite difficult to use for useful purposes! It is hampered by high humidity and harmful impurities; a large and expensive installation with such volumes is unprofitable.

Secondly, it would seem that a completely trivial task is to determine the phase boundary in the sump. That is, the boundaries above which there is oil with the water content we need and below which there is relatively clean water that can be drained. It would seem that what could be simpler, but despite the fact that there are hundreds of devices based on completely different principles of operation, there are constant problems with this. Most installations still have to use archaic floats as sensitive elements! There are huge problems with this, especially in fields with high viscosity or a large amount of harmful impurities. Floats quickly overgrown with sediments, due to which their balance is disturbed. At times, they simply begin to jam. We solved this problem in my second project.

You can continue for a long time, but I hope I have already managed to convince you that there is still something to do for innovators, even in the very traditional oil industry, I generally keep quiet about shale oil.

The best strategy is true?

So, let's say the first stage has been completed, you have found an actual task for yourself, which you can do and you already understand that you can solve it. The next step is naturally to show potential investors and customers what indisputable advantages your device will have in comparison with existing analogues on the market. Well, we got to the first problems!

When you buy a penny Chinese tester on the radio market, in many cases the accuracy of its testimony is even higher than the passport, at least as long as the batteries are fresh, the test probe sockets remain in contact and it does not begin to fall apart like almost any other Chinese junk. Naturally, one should expect that in such a regulated industry as industrial automation everything is much more serious ... I also thought so at first. And ... badly mistaken.

As it is not surprising, the following stories are completely in order of things:

- Innovative Israeli three-dimensional ultrasound scanner for tens of thousands of dollars is terribly buggy, and the process of transferring data from it hangs more often than the mobile Internet in Ust-Uryupinskaya train if it has not yet been optimized.

- The American gas generator, which is still an order of magnitude more expensive, when burning the associated gas fails at intervals of every few months.

- The American sensor for determining the water cut of oil, from a firm that, according to advertising brochures, has been a leader in this field for 20 years, not only fails to deliver the promised accuracy of 1 percent over the entire range, but it is not even suitable as a phase separation sensor. determine where the emulsion ends, and where the water begins for most fields.

The most honest manufacturers in my opinion are the Germans. However, even the inscription “Made in Germany” does not guarantee that in the summer, when the level of steam in the tank rises significantly, the inscription on the upper limit of coal tar does not go insane because the heaped-up radar cost more than ten thousand euros. By the way, this is another seemingly simplest unsolved problem. On the Gubakha coking plant, this problem is still being solved in an extremely innovative way - “Uncle Vasya” periodically climbs onto a tall tank and lowers into a container on a long cable a piece of pipe with a powerful light bulb tied to it. Then he raises and measures the distance to the mark on the pipe with a tape measure.

It remains a mystery to me - how are all these devices certified? Honestly, I thought earlier that this process is much stricter than ours, but judging by how often the stated characteristics of the instruments differ from the real ones, this is not so. Perhaps they are conducting certification only in perfect laboratory conditions. It is possible, as we often have, that the need for thorough testing is replaced with a thick wad of pleasantly rustling bills and a banquet.

It would not be worthwhile to spend as many printed characters on these nuances as if this fact did not have several unpleasant consequences:

First, faced with similar stories and throwing a lot of money into the pipe, the leaders of large companies become hard-boiled conservatives. At their insistence, lists of trusted suppliers are created and a company not included in this pool is practically impossible to sell.

Secondly, for me personally, it is completely unclear what characteristics to declare with the device you are developing? Suppose it gives accuracy not 1, but 5 percent, but it works steadily in such extreme conditions in which others are not able to provide any kind of sane result. If you honestly mention in the presentation of your device about these 5 percent, then you cause the anger of your marketers and investors perplexity. Yes, and potential customers wonder why they are offered devices that are worse than the existing analogs in performance? If you promise the impossible, then already at the stage of “field trials” you can get a negative feedback from the client.

How to solve this dilemma, I do not know.

Explosion protection certification. It's all for an adult!

When creating devices for the oil industry it is always necessary to remember that in the overwhelming majority of cases your device will be in an explosive zone, which means that, among other things, an explosion protection certificate will MUST be required. With the receipt of this document, there is a very different picture from certification for a measuring instrument or electromagnetic compatibility, where the ball is ruled by a golden calf. No one wants to be extreme in a situation where a drilling rig, and especially a petrochemical plant, takes off into the air. Hacking will not work. This does not mean that you will not be able to spend extra money on this process. Good self-detained from a certifying organization will be happy to help you make the necessary changes to the hull or find the right spark loop, of course, not for free.

If from the very beginning you did not determine in which explosive zone your device will work and did not begin to develop, considering the appropriate type of explosion protection, in most cases serious additional financial costs await you at the stage when “almost everything is ready.” In a separate case, it may be necessary to simply redo the entire project from scratch. Believe me, this is very serious!

Frames decide everything.

It is highly desirable to have a team of two or three people with experience in developing or at least working in the industry who know the nuances. And there will be a lot of them, believe me. So the electronics engineer will have to try to adjust his device to the strict requirements of spark-breaking chains, and if this is not possible, then try to fit into the framework, due to the use of shells with a flameproof enclosure.

An even bigger stumbling block could be a building for designers. So I happened in the first startup. Despite the fact that it was developed by experienced designers, when it came to certification for explosion protection, five iterations of explosion tests passed, after each of which modifications were made according to the suggestions of experienced experts. It took a lot of time and money. If the design was originally taken into account the construction of analogues with similar dimensions, it would hardly need more than two iterations.

If there is a possibility, it is best to choose housings from the standard range and, considering their size, to design electronics, but even in this case there will be a lot of problems, for example, with the selection of cable glands and cable type ... The hermetic housing requires special measures to combat the occurrence of condensate and its consequences. Operation in the conditions of the northern territories makes it extremely responsible to treat reliable operation in the condition of low temperatures. By the way, not only hypothermia, but also overheating under the action of direct sunlight can become a serious problem.

The project to develop a new high-tech equipment for oil refining is very expensive, compared with a start-up in the field of IT ... We need a lot of money for numerous certificates, the organization of pilot tests and, finally, the establishment of production. Therefore, you should not save on experienced professionals with special education. However, young people as an injection of fresh blood, of course, will not interfere.

Once the lab tests are completed in oil, your prototype is waiting for the next step. Testing on a specially created laboratory bench with a real well fluid with all the truth taken out of the object. And so, when you are trying to bring the quality of determination of the parameter you need to perfection, and the investor finally loses patience, it will certainly reach the stage of trial operation. This is a very responsible and difficult moment.

It is not at all easy to persuade people on the ground to put your device to the test until you have at least an explosion protection certificate. And you can get it already on the finished product. If you spend a lot of time and money certifying a sample, then in case of making changes you will have to go through the procedure again! Vicious circle. Real life is very different from experiments in the laboratory and presents many unexpected surprises.

“Uncle Kolya” can knock off the terminal block when connecting the cable to the device, it can break the threads. The connecting cable may be longer than you expected or not at all of that type. In the settling basins of depleted fields and fields with high oil content, very different processes can occur. A 24 volt power supply available can produce all forty at a small load current ... Unexpected large and minor dirty tricks are waiting for you at literally every step. In this situation, the human factor is very important.

Most likely, the developer of the equipment will have to take the most direct part in the business trip. This is a huge stress for people of technical mentality and character. It is very difficult during the day to experiment experimentally under the supervision of curious Aborigines and their impatient bosses, and in the evening to feverishly correct errors in the code, putting patches on non-controlling unexpected processes in the reservoir. We must do everything possible to establish good relations with local KIPovtsami. Talking heart to heart on technical and abstract topics, as well as small, but useful gifts in everyday activities, such as Japanese side cutters or pocket RLC meters, are very helpful in building relationships that will pay back later.

Business trips tend to overload, and you have to spend more than a week in a terrible mode - during the day, look for the cause of incorrect work and try to fix physical defects with improvised means, and at night to correct the code often in conditions far from ideal. The most extreme thing I had to experience was living in a room designed for the rest of the work shift. Passage yard faces change every two hours. Someone wants to watch TV, someone to chat, to whom footcloths to dry ... And so on all night. And to get up early in the morning at the object, despite the fact that the road from Moscow to the object took almost a day and you have a roof from the time difference.

If we don’t go anywhere, we should at least try to minimize the damage. On a business trip, it is desirable to travel at least two. One person at the same time solves technical issues, and the second organizational. Agrees on access to the facility, distracts the local authorities with conversations, knocks out papers for taking samples in the laboratory or permits to temporarily stop the control system or change the parameters to close to critical, to check the response of the device to serious deviations ...

Well, good advice - do not spare funds to encourage employees involved in commissioning, especially in the case of a successful outcome. Otherwise, it will be extremely difficult to send them there next time.

National features

The energy industry now lives in conditions of state capitalism. On the one hand, it lowers the level of competition, on the other hand, it can theoretically help with entering the market.

In recent years, leading companies in the field of oil and gas production, such as Rosneft, Lukoil, Bashneft, Gazprom, have a distribution list for innovation. In practice, this is reflected in the fact that there are people on the ground responsible for innovation. They try to encourage ordinary employees to make various kinds of rational proposals and provide assistance for their subsequent implementation. The most promising, from their point of view, ideas are sent higher up the career ladder, where, based on them, they are trying to organize the development of new equipment. The system is highly bureaucratic and works with a lot of squeak, however you can try to use this mechanism to build partnerships to promote your project.

We tried, but got an unexpected result. It turned out that in the depths of Lukoil was born a draft solution to the same problem on which we worked. Their option came out more expensive and less reliable, but a nth amount of money was already invested in it and, despite the fact that the work on it had actually reached a dead end, they no longer had the opportunity to participate in financing our project.

Recently, various types of technoparks for organizing a private-state partnership have been growing like yeasts in the regions, but in practice it is very difficult to use their services to develop a serious project. First, it is very difficult to get a serious amount. Secondly, the conditions on which the money offered can not be called particularly attractive. The conversation is approximately in this way:

Need money? We will give a couple of millions to certify a prototype and conduct tests, but on condition that you yourself invest the same amount. Yes, and we want half of your business for it. Ah, you have already invested 5 million in development and 10 million more will be needed in the organization of production. And it does not concern us. Who in general needs money you or us. Once for you, these are your problems.

Such appetites, however, do not have the most toothy sharks of the venture capital business in the Wild West. But it would have been half the trouble if it were not for our glorious organs. They are vigilant to ensure that the money is returned on time, and the production of the product was launched no later than the designated X hour. Did you fail? So you are a fraudster brother and a place for you in a government house, and not in the ranks of startups ...

The threat of the Great Chinese Expansion

Import substitution is a good thing, but this is a matter for the future, even the closest one, if you believe the most optimistic forecasts. It takes several years to bring the product to industrial design in this industry, and equipment is needed today so that we will not get tomorrow, to all our troubles, in addition, and a reduction in oil production.

Today, the Ministry of Industry and Trade has prepared a list of foreign companies that could replace American and European suppliers. It mentions three companies from South Korea, Daewoo, LHE and KwangShin (compressors and plate heat exchangers), one each from India (Indore Composite, reagents), Belorusi (Naftan, additives) and Singapore (NuStar, diving equipment).

For most of the positions, Chinese manufacturers are called as alternative suppliers: a total of several dozen companies, including CNPC, China National Logging Corporation, Shanghai Electric Heavy Industry, Huawei.

Russian oilmen are in a hurry and can be understood. Already, they are negotiating with new suppliers. Rosneft is discussing with CNPC the possibility of combining efforts in the field of oilfield services, equipment manufacturing and R & D. Because of the sanctions of alternative suppliers, including in Asia, Gazprom Neft is also seeking.

For several years, Chinese manufacturers have been supplying the Russian market with mobile and stationary drilling rigs in small batches, but they have not yet been allowed to enter serious projects.

It is worth noting that currently up to 80 percent of the products of famous western brands are made in China. We are talking about material-intensive and energy-intensive parts of the equipment. Then all this is equipped with a high-tech component - electronics, computer systems, software, and enters the market under the brand name of famous companies.

Ideally, Russian companies for the rapid organization of import substitution should go the same way - to organize the assembly production of Chinese equipment in Russia, and the "brains" to do it yourself. We have a similar joint production is now trying to organize in Ufa, the notorious Uralvagonzavod, which has everything in order with state investments.

However, the Chinese are striving for something quite different. They have been waiting for a long time and today they want to take advantage of the moment to conquer our market with our help. So, Huawei announced one of its most important priorities to develop integrated solutions in the field of communication technologies for the oil and gas industry. So far, she has very few completed projects in Russia, but the process of actively testing its solutions by the largest companies is already underway. The representative of Huawei does not disclose final customers, but claims that they began to consider Huawei's proposals even before the imposition of sanctions and the company is ready to provide them “now.

Russian producers fear that a turn of oilmen to the East will hinder the development of domestic production. There is a serious danger that the Russians will have to compete for the customer with Chinese suppliers in unequal conditions, primarily financial ones. From 2015, China will cease the state support program for subsidizing its industry in the fuel and energy sector, but for a long time, tied loans from Chinese banks will act, which they willingly issue for oil and gas projects involving the supply of Chinese equipment.For oil companies, it will now be easier to work with Chinese manufacturers, but in the long and medium term, this is the danger of a new dependence on imports: China may simply begin to dictate its conditions both on equipment supplies and on prices.

By the way, the price of Chinese equipment will not be much cheaper than Western equipment, but it is inferior in quality. On the one hand, they understand above that they need to focus on localizing the production of oil and gas equipment in Russia, firstly, because the industry is strategic, and secondly, to create jobs within the country and receive taxes here. But Russian manufacturers will not be able to cope with the required development time. So, today our country is at a very serious fork. Officials decide who will save our oil industry Chinese suppliers or Russian manufacturers and developers.

Painting by investors

But how do investors assess the situation? Let's look at the results of one of the polls of the “Russian Venture Company”.

69% of projects in Russia are low-quality start-ups (17% are of very low quality), the share of medium-quality projects, in their opinion, is 24%, above average - 7%. But even that small part of Russian projects, which is recognized by investors as successful, does not see prospects for further development of business in Russia. The state does not create a sufficiently comfortable environment for the development of innovative entrepreneurship, state participants in the innovation market. Only 16% of respondents believe that the effectiveness of government spending over the past 10 years has grown. The efficiency of tax incentives and benefits that Russian innovators can take advantage of leaves much to be desired. Most market participants (45%) consider such measures insufficient. Another 16% of them rated as "very low." Only 6% of respondents indicated high efficiency of preferences.Low-comfort and legal regime of innovation activity in Russia. 55% of respondents estimate it negatively. 38% of respondents consider the level of development of legal regulation of innovation activity as “insufficient and requiring additional state efforts”, and only 7% consider it “comfortable”. The combination of problems leads to the fact that the Russian innovative business is disappointed in the domestic business environment. Almost 60% of respondents believe that the incentives to preserve Russian jurisdiction are not enough, and only 7% believe that they have enough.The combination of problems leads to the fact that the Russian innovative business is disappointed in the domestic business environment. Almost 60% of respondents believe that the incentives to preserve Russian jurisdiction are not enough, and only 7% believe that they have enough.The combination of problems leads to the fact that the Russian innovative business is disappointed in the domestic business environment. Almost 60% of respondents believe that the incentives to preserve Russian jurisdiction are not enough, and only 7% believe that they have enough.

?

?

- . , , .

- , , , .

- .

- , «», «», , . .

- , - , . .

, ?

- .

- , , .

- , .

- .

- - . , , .

- . , .

And most importantly. Who will carry out the breakthrough transformations described above? Exactly those who brought the situation to the present situation? And there are no other personnel in the system with completely blocked up social elevators.

Madness of the brave we sing songs

Well, let's do what we can and hope for the future. I do not want to finish the article on a minor note. I will try to raise the spirit to make a digest and analysis of Russian startups related to the oil industry. Despite all the difficulties of the TOP-50 Russian, according to the Russian Startup Rating, as many as five are closely related to developments in the oil sector.

PS And I also have some instructive stories in the reserve of attempts to make breakthroughs in projects with different sources of funding. One developed under the wing of the Bortnik and Transneft Foundation. The second is in the framework of public-private partnership with Gazprom and Rosnano. The third one was financed by BusinessAngel. I am sure that acquaintance with them will be interesting, to find only time!

Source: https://habr.com/ru/post/290188/

All Articles