Moore's Diamond Resuscitation

Silicon, since 1960, is the most popular material for semiconductors, and its market share, still, is 95%. But the use of silicon imposes on the industry several intractable long-playing problems. The most famous problem, popularly known as the “Law of Moore” . This rule of thumb emphasizes the tendency to periodically miniaturize and increase the speed of electronics, physically limited by the capabilities of silicon. Moore's law was repeatedly tried to bury, but in a strange way, manufacturers managed to prolong its effect. Not everyone knows that Moore in 1965 deduced two laws. And just the second law of Moore is a more serious problem. He says that the cost of production capacity used to create microchips grow faster than the demand for microchips.

Silicon, since 1960, is the most popular material for semiconductors, and its market share, still, is 95%. But the use of silicon imposes on the industry several intractable long-playing problems. The most famous problem, popularly known as the “Law of Moore” . This rule of thumb emphasizes the tendency to periodically miniaturize and increase the speed of electronics, physically limited by the capabilities of silicon. Moore's law was repeatedly tried to bury, but in a strange way, manufacturers managed to prolong its effect. Not everyone knows that Moore in 1965 deduced two laws. And just the second law of Moore is a more serious problem. He says that the cost of production capacity used to create microchips grow faster than the demand for microchips.Previously, the cost of organizing production, although significant, was an insignificant part of the total cost of manufacturing and distributing electronics. In the current environment, the cost of new production facilities can reach very significant amounts, comparable to a substantial part of the entire chip market, which is why the question arises whether further financing is advisable. At the same time, manufacturers are not ready to completely abandon silicon, since the development of a new material takes about ten years and requires large financial investments.

An even more urgent and visible problem of using silicon is its heating. Historically, thermal management of silicon semiconductors has always been a big problem in electronics. Necessary cooling methods, which are the main source of energy losses, proved to be inefficient. Industry requires an alternative to silicon, which will allow production of more powerful, faster, cleaner (with fewer impurities) and less heating devices. These qualities are able to provide diamond semiconductors. Diamond is a genuine alternative to silicon today, both as a substrate for silicon structures, and as a separate platform for semiconductor materials.

While hulking giants are trying to delay the inevitable end of the silicon industry, scientists are experimenting with alternative materials on the sidelines of laboratories and research institutes. One of which is diamond.

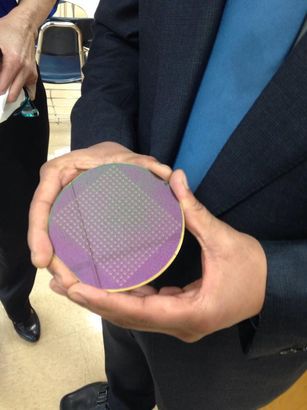

For several decades, scientists have been exploring this material and methods for its artificial manufacture.

')

Previously, the problem of using diamonds in electronics was of a triple nature:

- The cost of natural diamonds, due to the policy of the monopolist De Beers, who does not want to release prices on the market, is very high.

Decision

Inexpensive production of high-quality synthetic diamonds will solve this problem.

- In fact, we generally do not have a reliable source of large and clean stones. Fossil diamonds have different electrical characteristics, that for the mass market of electronics, as you understand, there is no gut.

Decision

Beginning in the 1950s, engineers learned how to produce small crystals for industrial use, and in the summer of 2003 the first wave of gem-quality artificial diamonds hit the market. Two companies, Gemesis in Florida and Apollo Diamond in Boston, learned how to make them. At the moment, the production of synthetic diamonds is rapidly gaining momentum.

The American company Apollo Diamond, Inc. developed and patented a method of growing extremely pure gem-quality diamonds with a crystal structure without flaws, using the method of chemical vapor deposition (CVD). This CVD method allows you to convert carbon into a plasma, which is then deposited on the substrate in the form of diamond.

List of companies producing synthetic diamonds

- Above the third problem materialists of the whole world were puzzled To make a microcircuit, p- and n-type semiconductors are needed, and diamond is a natural insulator.

Decision

To ensure conductivity, scientists injected diamond into the crystal lattice, which creates the desired type of p-type conductivity. Until some time, no one was able to create n-type conductivity in a diamond, but in June 2003 a breakthrough was made. Scientists have found a way to invert the natural conductivity of boron and create boron-doped n-type diamonds. Thus, the pn-pair required for chip production has been developed.

There is another implicit, and perhaps the most dangerous problem for the industry - corporations, or rather their financial interests. Here, a great example is the story of the oil lobbyists , who for a long time have inserted electric vehicle developers into the wheels.

As a result of simple logical constructions, it is clear that this problem is not eternal, because electric cars are gradually gaining momentum, which is perfectly shown to us by Tesla. And this means that a breakthrough is inevitable in this area.

Already, many experts believe that the industry is entering the diamond era. It is difficult to select a well-known natural material with such exceptional electronic properties that can take various industries to a new level of productivity.

Why did we decide to treat diamond as a starting material?

Diamond semiconductors are able to work in conditions of five times the operating temperature of silicon devices without degrading performance. They have higher breakdown voltage and higher thermal conductivity. The diamond-based semiconductor devices available are far superior to similar silicon samples. Also, the use of new semiconductor devices is capable of throwing fuel into the already almost extinct fire of Moore's law (miniaturization and speed, you remember).

As a result, the market for diamond materials for semiconductors can easily overshadow the market for silicon materials, in particular silicon carbide, which has shown very significant growth last year.

Natural and synthetic industrial diamonds differ significantly in price. The price of natural diamonds ranges from an average of $ 1 per carat for diamond fragments to $ 2.50 - $ 10 per carat for most of the stones, although some large stones are sold for up to $ 200 per carat. The price of synthetic industrial diamonds varies depending on the strength of particles, size, shape, crystallinity and the absence or presence of metallic coatings. In general, prices for synthetic diamonds for grinding and polishing are in the range of $ 0.40 to $ 2.00 per carat.

Future is here

One of the promising areas for the use of diamond as an active element of microelectronics is high-current and high-voltage electronics. Using diamond semiconductors can help extend battery life for a wide range of devices, including telephones, cameras and vehicles. Also, automakers are already eyeing their use in electric vehicle control modules.

The potential of new materials in the production of cloud computing servers used in data centers that consume huge amounts of energy in an extremely wasteful way is invaluable. Wide opportunities are revealed for manufacturers of consumer electronics, from washing machines to TVs and digital cameras. What can we say about military technology, which is destined to possess high reliability and performance and meet the most extreme conditions of operation.

As a result, the diamond semiconductor industry will significantly reduce energy costs. Our abilities and capabilities will change. The use of our phones, laptops and other personal electronic devices will be completely different. Some devices that were impossible earlier will only be invented.

In general, such bright prospects for the market are quite good for themselves, but the problems described above, which we basically solved, are broken down into a number of smaller problems that need to be resolved and impede the immediate wide distribution of this technology.

- the lack of affordable single-crystal diamond plates with a diameter suitable for mass production of devices (> 100 mm).

- graphitization at temperatures above 600 ° C in the presence of oxygen and conversion to graphite at 900 ° C.

- difficulties of machining (grinding, polishing) and carrying out traditional technological operations (forming p- and n-type areas, diffusion, ion doping, dry and wet etching), since diamond is the hardest and most chemically resistant material.

- the complexity of controlled directional doping with p- and n-type impurities, which are already fully activated at room temperature. Most of the diamond impurities studied have very deep impurity energy levels, which do not allow the creation of instruments that operate stably at ordinary temperatures.

- lack of industrial diamond technology.

The development of devices on synthetic single-crystal diamond has been underway for many years. However, before their mass production there is still a long way to go and to solve a whole range of scientific and technological problems. However, natural and synthetic diamond monocrystals have already succeeded in creating microwave transistors, Schottky diodes, photodetectors "blind" to sunlight, X-ray sensors, etc. The beginning of the commercial release of devices on these materials shows that the main technological problems have already been solved.

All major industry innovations have been developed by small companies such as Apollo Diamond and AKHAN Technolgies . Many of them need to complete construction of their own production technology: investment, management, production base, special industrial R & D, special marketing that has been developed for high-tech markets, and so on.

In the light of all the above, you can argue a little with my previous article , where Peter Thiel talks about stagnation in technical progress.

PS Thank you for your attention to those who could finish reading this opus.

Source: https://habr.com/ru/post/285984/

All Articles