Why Apple Products are Designed in California, but Assembled in China

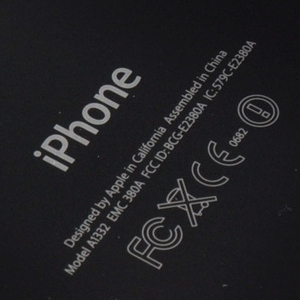

Look at the back of your iPhone, iPad or MacBook. You will see the words “Designed by Apple in California. Assembled in China. ”Many Americans, including the president himself, wondered why Apple brought almost all of its manufacturing facilities abroad. Last year, at a dinner party with the participation of the president and managers of major US technology companies, Obama directly asked Jobs what it would cost to return jobs to the States. According to Jobs, there is no room for this.

Look at the back of your iPhone, iPad or MacBook. You will see the words “Designed by Apple in California. Assembled in China. ”Many Americans, including the president himself, wondered why Apple brought almost all of its manufacturing facilities abroad. Last year, at a dinner party with the participation of the president and managers of major US technology companies, Obama directly asked Jobs what it would cost to return jobs to the States. According to Jobs, there is no room for this.Why does not exist? Why iPhones, iPads and all other Apple Magic Gadgets cannot be made in the USA? And in general, why can't American companies producing consumer electronics and computers collect more of their goods in their home country, creating new jobs and helping the economy in dealing with the crisis?

The New York Times asked this question, and after conducting a very serious study , which included conversations with former and current Apple executives, received a simple and frightening answer: iPhones do not do in America because it is impossible to do them in America. The infrastructure required for such production is missing. And there are no workers in such numbers.

The Chinese plant, where the final assembly of the majority of iPhones, employs 230 thousand people. I asked Siri how many cities in the United States have more than this number. There are only 83 such cities. And the population is not equal to the number of able-bodied people. On average, the working population is 65 percent of the total population. It turns out that only in 50 cities of the country there is a sufficient number of working-age population. At the same time, even in New York, the largest American city, 230 thousand people make up 3% of the total population. Can you imagine that three out of a hundred New Yorkers are sitting by the pipeline every day and collecting iPhones?

')

Over the past couple of years, we have heard enough about the problems with working conditions at Foxconn factories. This Chinese company is responsible for assembling consumer electronics for most large companies, including Apple. About a quarter of these 230 thousand live in factory dormitories or barracks in the factory. That is, almost 60 thousand people live and work in the factory. Many people from Foxconn City work 6 days a week, 12 hours a day and earn less than $ 17 a day. Perhaps such conditions seem inhuman from the point of view of American standards, but jobs in the factory are very popular. So big, that Jennifer Rigoni (Jennifer Rigoni), a former supply manager at Apple, said in an interview with the New York Times that Foxconn "can hire 3,000 people a day."

These are just a couple of examples of how the scalability, speed and efficiency of Chinese manufacturing surpasses everything that production in the States is capable of at the moment. But there are other deadly moments in the newspaper report. Of course, 200 thousand workers sitting by the conveyor and inserting part A into slot B can be considered unskilled labor. But the plant also has 8,700 engineers who control the process. These people can not be considered unqualified. At the same time, according to journalists from the Times, in order to find and hire so many qualified engineers in the States, it will take nine months. The Chinese hired so many engineers in 15 days.

In addition to the notable exception in the form of an A5 processor (produced in Texas - approx. Translator ), most of the components for iPhones are also produced abroad. Many components are made near the place of assembly of the final product. If you deliver these components for assembly in factories in the States, there will be additional costs. And, worse for Apple, additional latency.

Traditionally, advocates of making production abroad bring arguments in one way or another connected with price. “It will be more expensive to do this in America,” they say. "You will have to pay higher salaries, give bonuses, pay insurance, pay higher taxes." Since companies work for profit, the increased cost will necessarily affect the price for buyers.

Exaggerating, many even said that the iPhone, collected in the States, will cost thousands of dollars. It turns out that it is not. According to a study by the New York Times, the additional costs of paying salaries to Americans will add to the price of an iPhone $ 65. And all other additional expenses in the amount, most likely, will not lead to the fact that a 16-gigabyte iPhone 4S will cost more than a thousand dollars without a contract. But not even the price is the main reason why Apple made the production in China. The main reason is that companies need factories where you can quickly produce as many iPhones as possible. This requires flexibility and quick adaptation to the requirements of Apple. According to one of Apple’s current managers: “The United States stopped producing people with the skills we needed.”

Exaggerating, many even said that the iPhone, collected in the States, will cost thousands of dollars. It turns out that it is not. According to a study by the New York Times, the additional costs of paying salaries to Americans will add to the price of an iPhone $ 65. And all other additional expenses in the amount, most likely, will not lead to the fact that a 16-gigabyte iPhone 4S will cost more than a thousand dollars without a contract. But not even the price is the main reason why Apple made the production in China. The main reason is that companies need factories where you can quickly produce as many iPhones as possible. This requires flexibility and quick adaptation to the requirements of Apple. According to one of Apple’s current managers: “The United States stopped producing people with the skills we needed.”The Times newspaper provides a talking example from the early history of iPhones. It all happened before the appearance of iPhones on the market. Now it is hard to believe it, but initially the screens of iPhones were planned to be made of plastic. Same as iPods sold at the time. In mid-2007, a little more than a month before the first appearance of iPhones in stores, Jobs suddenly realized the nonsense of such a decision. Jobs wore an iPhone prototype in his jeans pocket, and the screen of this prototype was covered with dozens of scratches by that time. “I will not sell a product that is so scratched. I want a glass screen, and I want everything to be done perfectly in 6 weeks. ”

Anyone who knows how Jobs worked will understand that Steve was not bluffing. If the product does not meet its standards, then they will not sell it. No options. Six months of waiting for the appearance of the first iPhone on the counters warmed interest to an insane level, so Apple knew that they would have to stamp iPhones as quickly as possible. And the changes in the requirements for one of the most important components, made at the last moment, meant the announcement of such a job, which is simply impossible in American industries. Apple would be a laughing stock for the rest of the delay. But, what it would take several months in the States in China took 6 weeks. Apple agreed with Corning about the supply of scratch-resistant glass, and Chinese factories were able to instantly integrate this glass into the existing iPhone design.

Apple is an American company reaping unprecedented financial success . Therefore, many Americans lament the fact that the country has little to do with this success. Apple employs 43,000 people in the United States. This is less than a fifth of the wage workers collecting iPhones in a Chinese factory. Some may say that Apple has succeeded in something at the expense of American workers (because it saved them - a comment of a translator ). But if you believe the report of the New York Times, it turns out that such a workforce, which Apple needs, never existed in the States.

Note: Reuters and spread shirt images are used in translation.

Source: https://habr.com/ru/post/285450/

All Articles