Time of unexpected analogies: river crayfish and electrical conductivity sensors

Dear experts, attention, question:

For what engineering task are river crayfish used at the same time (yes, with a mustache and claws) and electrical conductivity sensors?

Surely someone has already realized what was going on, but I will not be tormenting other readers for a long time.

Both crayfish and electrical conductivity sensors are used to monitor water quality.

')

River crayfish have been working for St. Petersburg water canal cleaning systems for many years - they live in aquariums at water intakes and control the level of toxicity of Neva waters.

Electrical conductivity sensors are also used to monitor the composition of aqueous solutions, because the ability of a fluid to conduct current is one of the parameters for determining the amount of impurities.

In the article I talk about the Neva crayfish (thanks to the Vodokanal site), and about electrical conductivity sensors. We have nothing to do with crayfish, but the sensors of the Swiss company IST are quite self-supplied.

Crayfish are used by St. Petersburg water utility as biosensors. These animals are very sensitive to pollution of their habitat, and therefore are used to monitor water quality. The principle of biomonitoring is described on the water utility website:

Among animals, bioindicators - not only cancers. Water quality is also controlled by fish and bivalve mollusks, and snails monitor the air condition in the area of the sewage sludge incineration plant.

Of course, biomonitoring is not a substitute for classical methods of instrumentation and laboratory control.

Water quality assessment is a rather difficult task, for which a set of indirect features is always used. Among such signs are pH (pH), oxidability, mineralization, electrical conductivity and many other indicators. Below we will discuss the measurement of conductivity.

Sensors of electrical conductivity (they are conductometers) are devices for measuring the ability of a solution to conduct electrical current. This ability is determined by the number of ions contained in the solution, and the number of ions is one of the parameters that is used to determine the amount of impurities in a liquid.

A pair of current electrodes is placed in the solution, to which alternating voltage is applied. The ions contained in the solution begin to move, an electric current appears i.

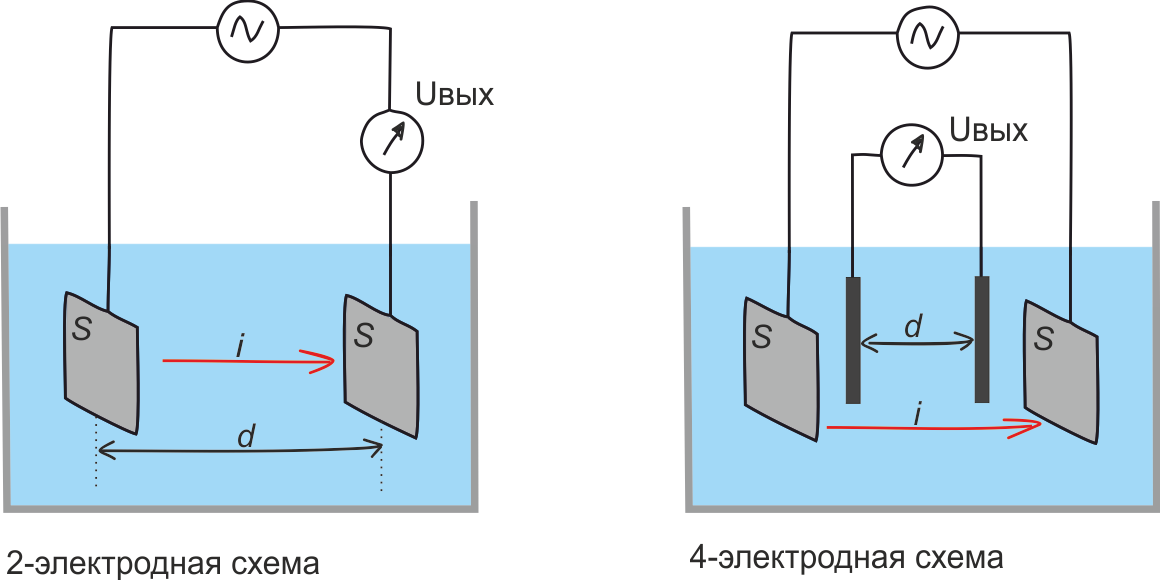

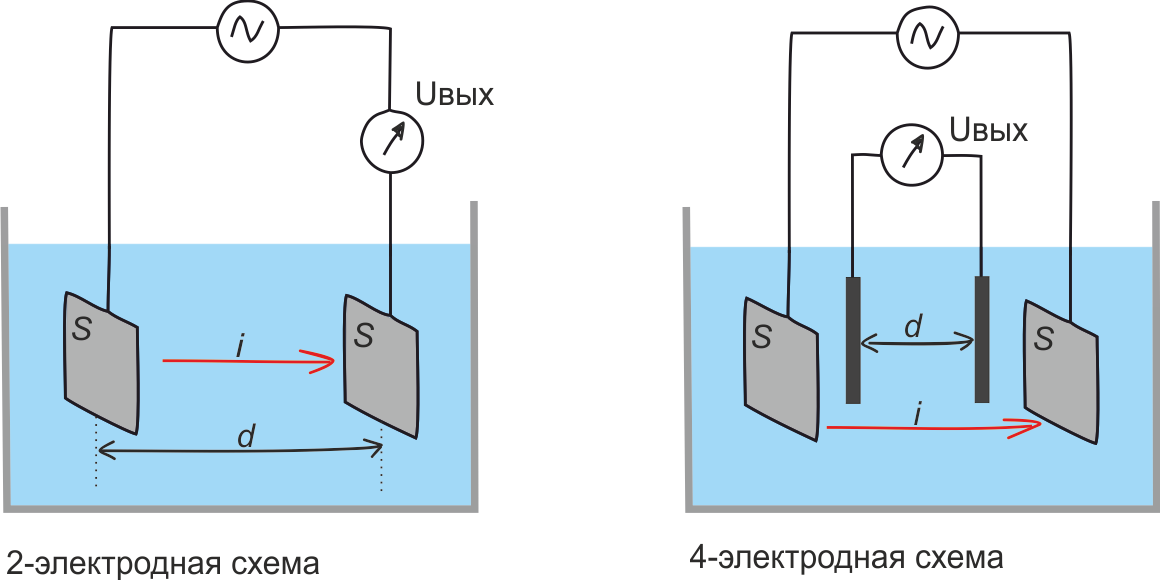

There are two schemes for measuring conductivity: 2-electrode and 4-electrode. In the first case, the voltage drop Uout is measured between the current electrodes, and in the 4-electrode circuit, an additional pair of potential electrodes is used for measurements.

The voltage drop Uout is an indicator of the conductivity of the solution:

Electrical conductivity σ is defined as the reciprocal of the resistance in a given cell. A cell is a volume bounded by current electrodes that have an area S and are separated from each other by a distance d. The values of S and d are determined by the geometry of the sensor, therefore, they are constant and are expressed through the constant cell k:

k = d / S - cell constant, cm-1

Thus, the conductivity is calculated by the formula

σ = k / R or σ = (k * i) / Uout, where the variable is the voltage Uout.

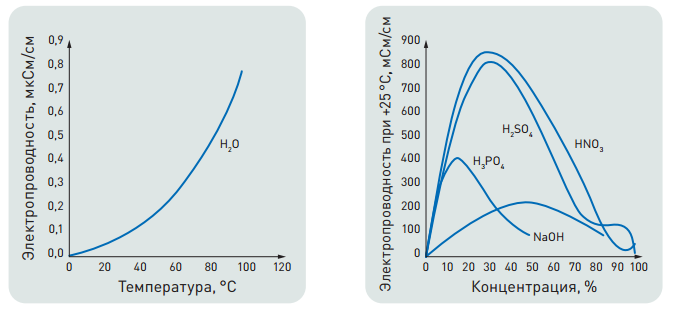

Conductivity is determined by both the concentration of ions contained in the solution and their mobility. Both of these parameters depend on the temperature of the solution, so the measurement of the electrical conductivity must be carried out together with the control of the temperature of the liquid.

Starting a conversation about a specific series of sensors, we will clarify the very concept of "sensor". In Russian, the meaning of this word is blurred and is used to designate all devices from the primary converter to the finished measuring unit.

I draw the reader's attention to the fact that in this article, a sensor means precisely a sensitive element - a transducer, on the basis of which various devices are built.

The Swiss sensor manufacturer IST is a company specializing in the production of thin-film sensors. About flow rate sensors, for example, have already been discussed in Habré .

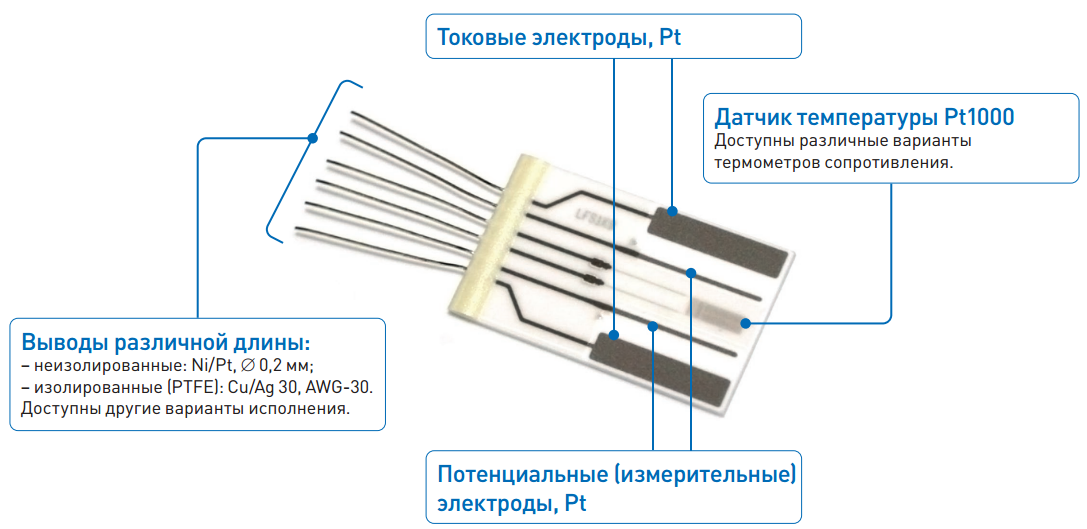

The manufacturing technology of thin-film components originates in the semiconductor industry: a thin metal layer is sprayed onto the ceramic substrate, from which conductive paths (resistors) or platforms (electrodes) are formed.

Photolithography methods are used to form the geometric structure of the elements, and the maximum deposition accuracy is achieved due to laser fitting. Metal elements are covered with an insulating (passivation) layer of glass that is resistant to temperature and chemical attack. Specially selected glass composition is also used to fix the findings.

Using such a sensor, it is possible to measure conductivity in the range from 100 µS / cm to 200 mS / cm. Approximate values of conductivity for various solutions are given in the table.

Two types of conductivity sensors are produced - LFS155 and LFS117, their characteristics can be found on our website .

In conclusion, I traditionally thank the reader for his attention and remind you that questions about the use of products, about which we write on Habré, can also be asked by email, specified in my profile.

upd: all mentioned sensors and modules are available from stock. More information on efo-sensor.ru

For what engineering task are river crayfish used at the same time (yes, with a mustache and claws) and electrical conductivity sensors?

Surely someone has already realized what was going on, but I will not be tormenting other readers for a long time.

Both crayfish and electrical conductivity sensors are used to monitor water quality.

')

River crayfish have been working for St. Petersburg water canal cleaning systems for many years - they live in aquariums at water intakes and control the level of toxicity of Neva waters.

Electrical conductivity sensors are also used to monitor the composition of aqueous solutions, because the ability of a fluid to conduct current is one of the parameters for determining the amount of impurities.

In the article I talk about the Neva crayfish (thanks to the Vodokanal site), and about electrical conductivity sensors. We have nothing to do with crayfish, but the sensors of the Swiss company IST are quite self-supplied.

About crayfish

Crayfish are used by St. Petersburg water utility as biosensors. These animals are very sensitive to pollution of their habitat, and therefore are used to monitor water quality. The principle of biomonitoring is described on the water utility website:

A fiber-optic sensor is attached to the carapace of a cancer sitting in an aquarium, which allows you to record its heartbeat imperceptibly for an animal for a long time. The already processed results of heart rate indicators and the crayfish stress-index in the form of a “traffic light” system are continuously displayed on the screen of the shift manager's computer: red, yellow or green light signals. The normal heart rate of cancer that is not concerned about anything (corresponding to the green signal) varies, depending on the water temperature, from 30 to 60 beats per minute, and the stress index is usually close to zero. In case of danger, the heart rate rises sharply by at least 50%, and the stress index rises to several thousand. When toxic substances enter the water, the cancers react within 1.5-2 minutes (this time, taking into account the data processing). Their heart rate increases, the devices give an alarm (a red signal on the monitor of the shift manager), which automatically selects water samples for subsequent detailed laboratory analysis of water by chemical and biological methods, and all water station services are alerted. Fortunately, for all the time the crayfish worked in Vodokanal, there were no abnormal situations, and such “high stress indicators” specialists of the St. Petersburg Ecological Safety Research Center of the Russian Academy of Sciences, who developed this method of biomonitoring water quality, receive only weekly preventive tests. crayfish screenings.

In addition to the biomonitoring station, there is also a farm at the Main Waterworks, the main task of which is to breed its own, adapted to industrial noise and people of crayfish. So animals from birth get used to communicating with people, the natural fluctuations of the quality of the Neva water, the noise of the station's pumps. Cancers also react to stimuli that are not related to water pollution - for example, to the noise of the equipment being switched on. To cut off the false alarms of the system (false in terms of toxicological danger of water), scientists created a special analytical station that measures a number of water characteristics - alkalinity, temperature, turbidity, and also equipped with noise and vibration sensors. If the equipment registers the vibration, the danger signal will not go to the control room, because the sensors record the moment when the increased heart rate of the cancer coincides with the noise effect, and cut it off as not related to toxicological danger. At the service in Vodokanal take the most ordinary crayfish. These are quite well-studied animals in terms of physiology and toxicology. However, in order to get a job in Vodokanal, crayfish undergo a thorough biochemical and physiological examination of health. Only males aged 3-5 years work, three days after six. Their service life is about a year. The fact is that, in their physiology, crayfish must overwinter, falling into a state of "hibernation" during this cold period, and depriving them of what is invented by nature naturally weakens the animal. And only healthy individuals in good functional condition are allowed on duty.

At the end of 2010, the biomonitoring system using crayfish was improved. If earlier there were two cancers in the work shift, now there are six of them. However, the modernization of the biomonitoring system is not only in quantitative changes. Since the launch of biomonitoring, scientists from the St. Petersburg Research Center for Environmental Safety of the Russian Academy of Sciences have developed new developments. And in 2010, Vodokanal introduced these developments at waterworks. Modernization of the biomonitoring system includes new signal processing algorithms. All this together - a more advanced data processing system, an increase in the number of on-duty crayfish - increases the reliability of biomonitoring, provides new opportunities for the operational management of the water treatment system.

Among animals, bioindicators - not only cancers. Water quality is also controlled by fish and bivalve mollusks, and snails monitor the air condition in the area of the sewage sludge incineration plant.

Of course, biomonitoring is not a substitute for classical methods of instrumentation and laboratory control.

Water quality assessment is a rather difficult task, for which a set of indirect features is always used. Among such signs are pH (pH), oxidability, mineralization, electrical conductivity and many other indicators. Below we will discuss the measurement of conductivity.

About sensors

Sensors of electrical conductivity (they are conductometers) are devices for measuring the ability of a solution to conduct electrical current. This ability is determined by the number of ions contained in the solution, and the number of ions is one of the parameters that is used to determine the amount of impurities in a liquid.

Principle of operation

A pair of current electrodes is placed in the solution, to which alternating voltage is applied. The ions contained in the solution begin to move, an electric current appears i.

There are two schemes for measuring conductivity: 2-electrode and 4-electrode. In the first case, the voltage drop Uout is measured between the current electrodes, and in the 4-electrode circuit, an additional pair of potential electrodes is used for measurements.

The voltage drop Uout is an indicator of the conductivity of the solution:

Electrical conductivity σ is defined as the reciprocal of the resistance in a given cell. A cell is a volume bounded by current electrodes that have an area S and are separated from each other by a distance d. The values of S and d are determined by the geometry of the sensor, therefore, they are constant and are expressed through the constant cell k:

k = d / S - cell constant, cm-1

Thus, the conductivity is calculated by the formula

σ = k / R or σ = (k * i) / Uout, where the variable is the voltage Uout.

Conductivity is determined by both the concentration of ions contained in the solution and their mobility. Both of these parameters depend on the temperature of the solution, so the measurement of the electrical conductivity must be carried out together with the control of the temperature of the liquid.

Conductivity Sensor Structure

Starting a conversation about a specific series of sensors, we will clarify the very concept of "sensor". In Russian, the meaning of this word is blurred and is used to designate all devices from the primary converter to the finished measuring unit.

I draw the reader's attention to the fact that in this article, a sensor means precisely a sensitive element - a transducer, on the basis of which various devices are built.

The Swiss sensor manufacturer IST is a company specializing in the production of thin-film sensors. About flow rate sensors, for example, have already been discussed in Habré .

The manufacturing technology of thin-film components originates in the semiconductor industry: a thin metal layer is sprayed onto the ceramic substrate, from which conductive paths (resistors) or platforms (electrodes) are formed.

Photolithography methods are used to form the geometric structure of the elements, and the maximum deposition accuracy is achieved due to laser fitting. Metal elements are covered with an insulating (passivation) layer of glass that is resistant to temperature and chemical attack. Specially selected glass composition is also used to fix the findings.

Using such a sensor, it is possible to measure conductivity in the range from 100 µS / cm to 200 mS / cm. Approximate values of conductivity for various solutions are given in the table.

| Solution | Conductivity (µS / cm) | Recommended wiring diagram |

| Purified water | 0.05–0.1 | 2-wire |

| Tap water | 300-800 | 2-wire / 4-wire |

| NaCl solution (0.2 g / liter) | 4,000 | 4-wire |

| NaCl solution (2 g / liter) | 38 600 | 4-wire |

| Sea water | 56,000 | 4-wire |

| Silver [for comparison] | 62 500 000 | - |

Two types of conductivity sensors are produced - LFS155 and LFS117, their characteristics can be found on our website .

Conclusion

In conclusion, I traditionally thank the reader for his attention and remind you that questions about the use of products, about which we write on Habré, can also be asked by email, specified in my profile.

upd: all mentioned sensors and modules are available from stock. More information on efo-sensor.ru

Source: https://habr.com/ru/post/282235/

All Articles