Honda has improved the management of the power plant of a Formula 1 car with the help of IBM Watson IoT

Honda R & D uses IBM Watson Internet of Things (IoT) to collect and analyze data from more than 160 sensors installed on each Honda car for Formula 1 racing. Now drivers and technical teams can use data and analytics in real time to optimize performance. engine and fuel efficiency. In particular, this will allow you to quickly make decisions in the course of the race, for example, to regulate the speed of movement and to choose the points of arrival at pit stops.

The reaction time of drivers in professional motorsport is calculated in fractions of a second, this determines the winning or losing the race. After the race, engineers extract the necessary data from the power plant, for example, information about adjusting distribution phases and fuel consumption in order to adjust behavior strategies in the next race. However, by now, motorcycling has evolved to a level where it is very much data driven, and the pilots have a permanent network connection. Now technical teams can analyze fast-moving data from the power plant and from the driver in order to adjust race strategies (including fuel-saving methods), which are among the critical factors determining victory, in real time. In 2014, the International Automobile Federation (Fédération Internationale de l'Automobile, FIA), under the leadership of which Formula 1 races are held, published new requirements, according to which all Formula 1 cars must use hybrid engines and not go beyond the established limits on fuel consumption during races. This forced motorcycling to focus on developing more energy efficient automotive technologies.

')

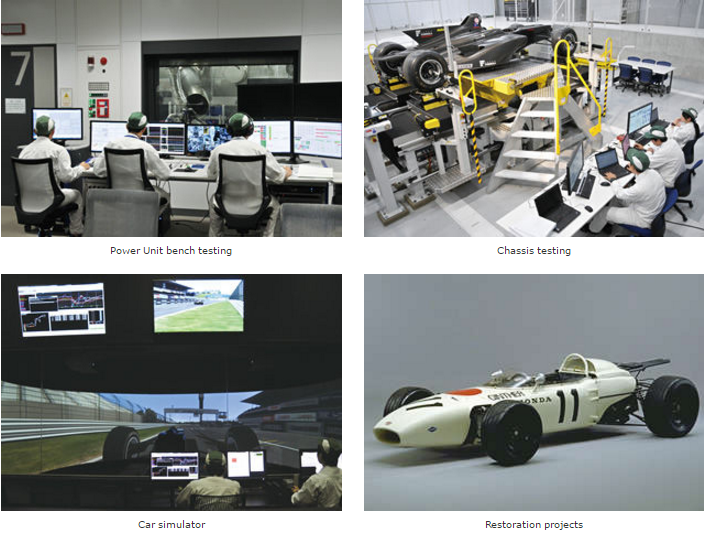

To mark its return to the Formula 1 race and in order to achieve new frontiers in efficiency, both for racing cars and for future consumer models, Honda R & D has developed a new system for analyzing data from hybrid engines. It allows you to quickly and efficiently check the residual fuel level and assess the likelihood of mechanical problems. Honda R & D uses IBM IoT for Automotive based on IBM Watson IoT technology to transfer vehicle-generated data (including temperature, pressure and power) directly to the cloud for real-time analysis.

“Honda R & D is very pleased to be working with IBM at the crucial time of returning to Formula 1 racing. Advanced IoT technologies guarantee our drivers and technical teams a permanent connection,” says Satoru Nada, chief engineer and manager of the Power Unit Development Division at Honda R & D Co. , Ltd. HRD Sakura. “All over the world, fans admire the performance of our power plant and the achievements of our drivers, while the importance of data and the importance of processing them in real time becomes a critical factor for winning races.”

Honda's powerplant for Formula 1 racing will be able to restore and save energy for later use during the race, which will help increase power. For example, every time a driver uses brakes, the heat generated by friction can be collected and stored in a battery — much like the hybrid cars that Honda offers to consumers. In addition, the system can extract heat from the exhaust gases and also store it as additional energy in the battery. After that, the system will be able to provide the pilot with more power at the right time, for example, when overtaking another car.

Watson features are also used for other motorsport tasks.

During the race, data is streamed to the cloud and shared by members of technical teams on tablets and mobile devices. This data is analyzed in real time by researchers from HRD Sakura, a research unit of Honda R & D in Japan, as well as Honda employees who follow the race on the track. Transferring the results of this analysis using the IBM Streams platform, implemented by IBM Global Business Services, during the race, allows you to adjust basic parameters such as temperature, pressure and power to improve power plant performance. In addition, Honda’s research team is now able to create very sophisticated performance models that measure the energy recovery in a power plant and ensure its longevity.

“As a result of the rapid growth of the Internet of Things, by 2025 each car will be connected to the network in one way or another. This will generate huge amounts of streaming data containing information about road traffic, vehicle condition, driver actions and many others, ”says Harriet Green, head of Watson IoT, Commerce & Education at IBM. - We are very excited to work with Honda. Based on our IoT solution, we offer companies the complex cognitive capabilities of the Internet of Things and analytics tools that allow you to combine the data of the Formula 1 car powerplant with information from other sources. This allows Honda not only to improve its power plants, aimed at achieving high speed, but also to establish a more environmentally friendly production. "

Source: https://habr.com/ru/post/281232/

All Articles