Intelligent active noise canceling server cabinet

It is no secret that server hardware is usually installed in a rack / cabinet, which, in turn, are placed in a specially designated place.

It is no secret that server hardware is usually installed in a rack / cabinet, which, in turn, are placed in a specially designated place.The cooling system of server hardware is designed based on the requirements for the efficiency of heat removal from the case, and such a parameter as the noise level is not taken into account. Therefore, the installation of a server cabinet or rack close to the workplaces of employees is excluded.

Basically, the equipment is placed in remote data centers, local server or any other premises of the enterprise, which should be isolated from the office workspace and provide the necessary internal temperature conditions.

In large and medium-sized organizations, there are no problems with allocating space for a server room. Yes, and in small offices you can find a server "pantry" the size of two and a half meters.

But what to do if the IT-infrastructure includes a significant number of rack equipment, and for some reason, there is no room for server-based equipment? How to solve the issue of placing the server cabinet in the office space without compromising the comfort of the workflow of the company's employees? Or there is the task of demonstration at the exhibition events of the rack equipment or complex infrastructure solutions. When installing a classic cabinet / rack, it is not comfortable to negotiate close to such a stand.

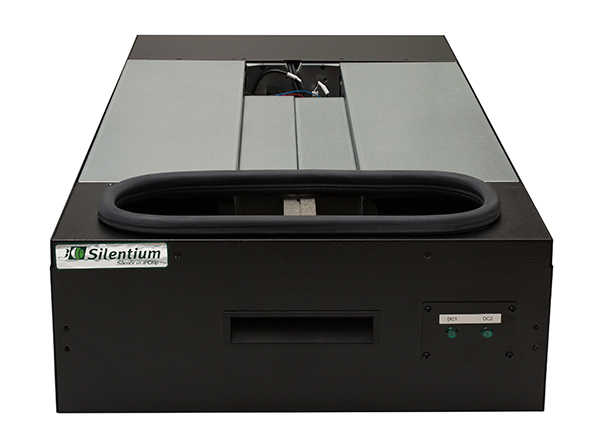

To solve such problems, a unique Silentium AcoustiRACK ACTIVE server cabinet has been developed, which allows for the removal of up to 8 kW of heat while minimizing the noise emitted by the equipment installed in it. The decision is not new, but still I want to dedicate this article to him, because the cabinet is already in the STSS laboratory and I tested its abilities on real-life tasks.

The secret lies not only in the design of the cabinet: the glass in the front door, insulation of all walls, plugs and the back door certainly reduce sound conduction. But there must be openings in the cabinet for the unobstructed passage of the air flow, which ensures effective cooling of the equipment. How to deal with the suppression of noise coming through them?

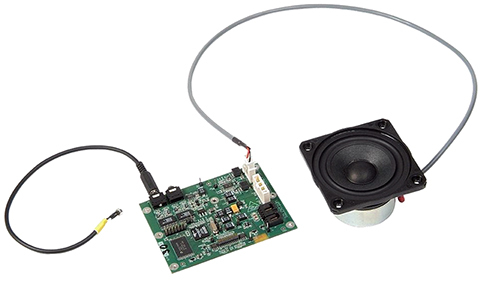

For these tasks, unique fan units equipped with an intelligent acoustic active noise cancellation system have been developed.

The principle of operation is to analyze through the built-in microphone the total noise of the equipment and its own fans, and to form an antiphase acoustic signal that compensates for this noise.

Declared specifications

- Dissipated heat output: up to 8kW

- Number of fans: 4pcs.

- Passive noise attenuation of low and high frequencies

- Protection against vibration

- Active noise reduction of low and high frequencies

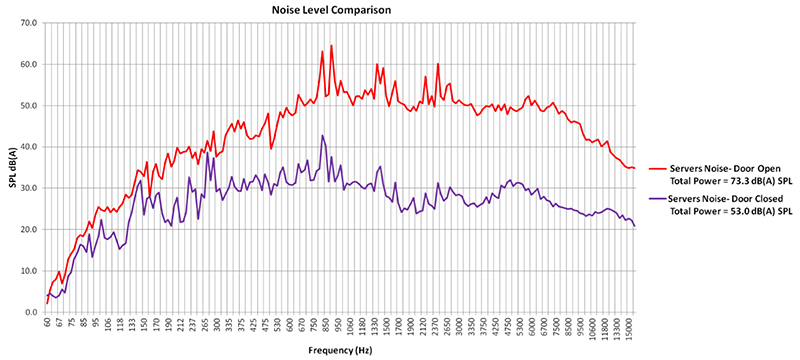

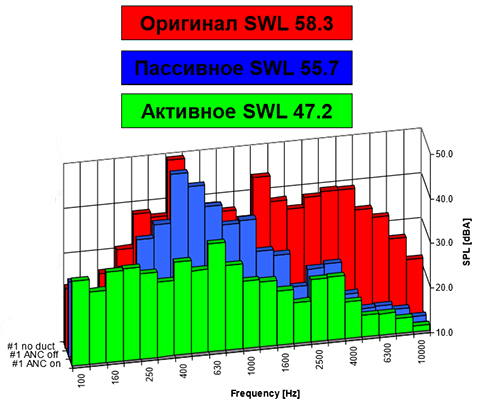

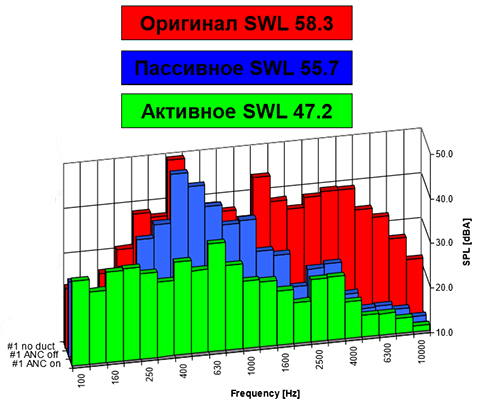

Below is a diagram of the efficiency of cabinet noise reduction, as declared by the manufacturer.

Silentium source

')

Cabinet design

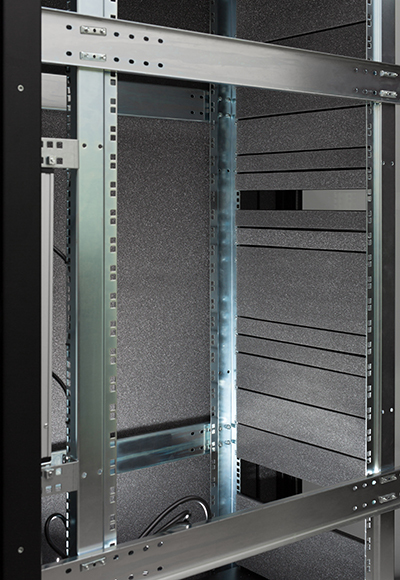

The base of the cabinet consists of a welded frame and a 19-inch rack, which has a distance of 745 mm between the frames. If necessary, the frame can be moved apart or moved in increments of 25-30mm.

More photos of the cabinet in disassembled form

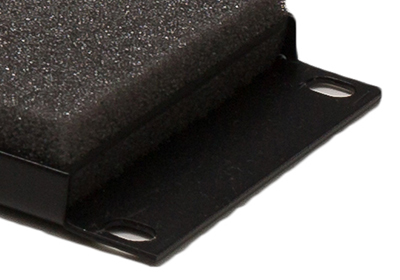

All internal surfaces of the cabinet are covered with a three-layer noise insulating material.

The entrance group also has noise isolation. And on the air intake, which is located at the bottom of the cabinet, a filter is installed.

The side walls are mounted outside, but have a lock inside, which eliminates the possibility of removing the walls without opening the doors.

The front and rear doors have 3 hinges and a 4-point locking system. Both doors are locked and have the ability to change the type of opening (right-left).

Since the mass of an empty cabinet is more than 200 kg, it has powerful wheels for movement and retractable rubber stoppers.

The power supply system of the cabinet is made with redundancy of the main components. Two blocks of sockets are designed to connect to different UPS. The power supply units of the fan modules are also duplicated - each fan has its own power supply unit, and are connected to different power sources.

The cabinet has a height of 41U, but 8 of them are occupied by Silentium ASFT fan units. The blocks are identical, have a height of 4U, but are set differently.

Characteristics of Silentium ASFT blocks

- Reduced noise to 30dB (A)

- 2 360CFM fans each (total air flow per unit is 650CFM)

- Active fan noise suppression up to 20dB, installed equipment noise up to 30dB

- Vibration protection

- 24V DC, 220W

- 47dB (A) generated noise

The test results of the fan in the channel with passive noise isolation and active noise cancellation:

Silentium source

- 2 360CFM fans each (total air flow per unit is 650CFM)

- Active fan noise suppression up to 20dB, installed equipment noise up to 30dB

- Vibration protection

- 24V DC, 220W

- 47dB (A) generated noise

The test results of the fan in the channel with passive noise isolation and active noise cancellation:

Silentium source

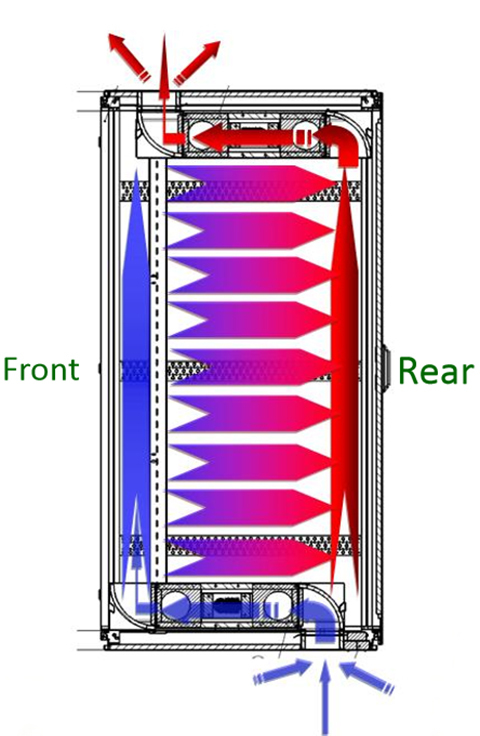

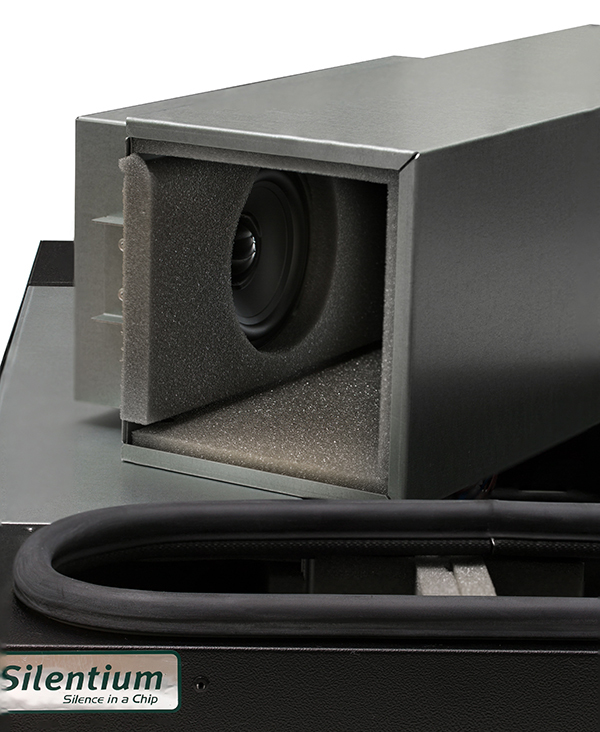

The bottom module is pushed forward to force cold air into the front of the cabinet. Installed equipment pulls air through itself to the back of the cabinet. For the intake of heated air, the upper exhaust module is shifted back - it leads the air out through the outlet in the cabinet lid.

These modules are of particular interest because they are equipped with an active noise cancellation system.

Removing the cover of the fan module, we will see two boxes and a control controller.

Each box is soundproofed from the inside. At the entrance is equipped with a high-speed fan Delta FFB1424UHE (367CFM, 5500RPM, 3.35A, 80.4W)

At the exit of the box there is an acoustic unit with a powerful speaker.

Silentium source

The intelligent system evaluates the characteristics of the fan noise through the built-in microphone, and the speaker reproduces an anti-phase signal that dampens the noise of the equipment.

Testing and results

To test the solution, typical server hardware was installed in the cabinet:

2 x 2U server, 2 x Xeon E5

1 x 4U server, 2 x Xeon E5

1 x 5U server, 2 x Xeon E5

For the test, all server fans were set to the maximum number of revolutions.

In addition, to ensure maximum noise and to be able to quickly change it, two powerful speakers with an amplifier were installed in the rack. Columns reproduced the standard noise emitted by the server room with open racks.

Testing was conducted in 20 modes with noise measurement from a distance of 1 meter from the front door of the cabinet:

The last 8 measurement steps were repeated to create a demonstration video:

For metering, a Testo 816-1 sound level meter was used.

For recording - Panasonic HC-V750 camcorder, built-in microphone, automatic sound adjustment is disabled

findings

Work passive noise reduction

Soundproofing of the cabinet showed high efficiency in all modes of testing. The difference with open and closed doors when the cabinet was turned off was from 13 to 437 times. The main noise came out just through the top cover of the cabinet, where the exhaust fan module is located.

Active noise cancellation operation

Here the results were not so clear. In general terms, the efficiency with open and closed doors with cabinet cooling turned on was from 10 to 575 times. But if we consider each measurement in comparison with the cabinet ventilation turned off, the following picture is observed:

- when the servers worked with dynamic settings of the fan rotation speed, switching on the cabinet cooling added 2.7 dB, which is almost 2 times louder (this is understandable - it is impossible to remove actively up to 8 kW of heat)

- with an increase in the speed of cooling servers to the maximum, this difference almost disappeared

- Further, with an increase in the level of artificial noise, the delta in favor of acoustic noise cancellation only grew: from 1.5 to 1.86 times - with the doors closed, and from 1.26 to 1.41 times - with the doors open.

Minuses

- the cabinet fans themselves are far from being silent, and in cases of a small number of servers inside, only the cooling of the cabinet is heard in fact

- the air filter is located at the bottom of the cabinet under the inlet fan unit, for its replacement it is necessary to disconnect and partially remove the unit from the cabinet (it moves along the corner rails)

pros

- three-layer insulation of the inner surface of the cabinet perfectly reduces the noise of any volume level (in tests, the noise of not one server rack, but the whole data center was simulated)

- active noise reduction showed a positive result at medium and high load levels

- the cabinet is perfectly protected from unauthorized access - it cannot be opened or unwound without a key, this allows it to be installed in common areas: corridor, office, warehouse, exhibition stand, etc.

Positioning

When evaluating test results, you should take into account the environmental conditions:

- testing was conducted in an office area of 12 square meters. meters, almost without furniture, with a ceiling height of 3.5 meters, walls of concrete; when operating in larger premises the noise level will be several times lower

- measurements were taken from a distance of 1 meter, when moving away from the noise source, the volume is multiply reduced

Considering all the data obtained as a result of tests, and the conditions for testing, the following options for using this cabinet with active noise cancellation can be distinguished:

- silent server (in the presence of any partitions and doors - the noise emitted by the cabinet, is absent)

- server in the office (when using 4-5 4U-servers with dynamic settings of the rotational speed of the fans, the noise from the cabinet installed in the air-conditioned office space does not exceed 55 dB, which does not exceed the long-term exposure to noise)

- Demonstration stand for exhibition events requiring the placement of noisy equipment.

To be able to calculate the cost of the cabinet with additional equipment, we have prepared a convenient concise solution configurator - STSS Flagman RQ41A-6W11D .

The wardrobe is available in our demo zone in Moscow on Berezhkovskaya Embankment.

Come see, listen, touch.

Thank you for your attention, waiting for your comments.

Source: https://habr.com/ru/post/279245/

All Articles