Safe doors, or continue to design ACS TP

Hi, Habr!

Since the UFO allowed me to write articles, we continue the stories about the design. I’m in trouble with making headlines. This time it will be about security doors. I hope the reader will forgive me a free translation of the term Safety (or Protective) Door.

Speaking of safety at work, I mean emergency shutdown or emergency shutdown to prevent an accident. There are a number of technologies and devices that make life responsible for TB cloudless and calm, and plant workers to ensure the safety of life and limbs.

')

These devices are used to perform the following tasks:

- emergency stop and shutdown buttons, which I wrote about a little earlier ;

- monitoring of security doors;

- control of the working area with laser scanners;

- access control using light barriers;

- control of safe speed of rotation and movement;

- control of the performance of work with two hands (yes, the translator from me is absolutely no).

Maybe the list is incomplete, but sufficient for today. So, talking about the door.

Let's take a look at the picture, estimate the pretty yellow wicket in the foreground and envy the guys in bathrobes who trust this wicket so much that they don’t even wear helmets. In principle, if one of the guys walks through a door that is not equipped with a monitoring system, the robot in the background can deliver a lot of discomfort and unpleasant moments.

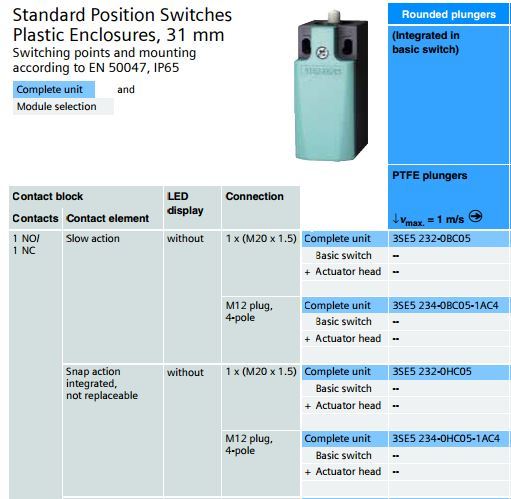

In order to avoid such situations, and to exclude equipment downtime due to an unscheduled call of cleaners, the special limit switches enclose the dangerous zone and put on the door. For example, such (232-0HC05):

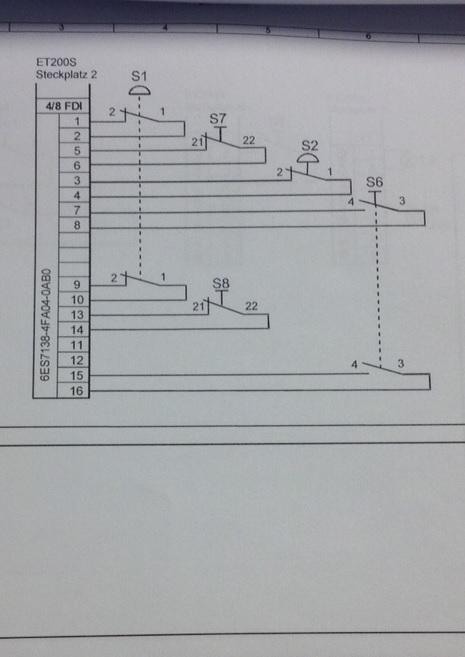

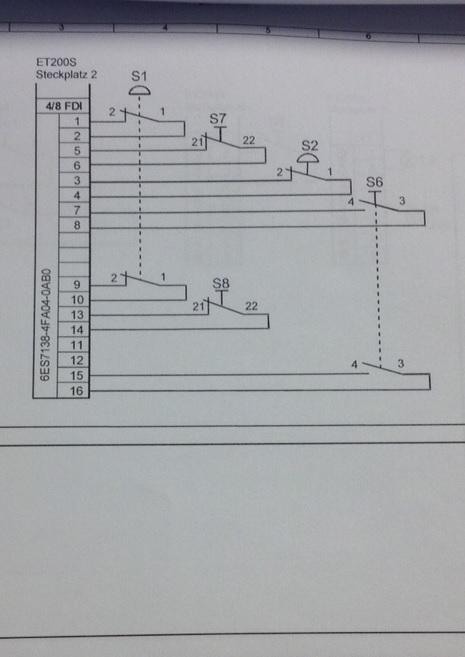

The principle of operation is simple: when the door is closed, the limit switches are in one position, if slightly open - in the other. Depending on the needs, the switches are either mechanical or non-contact with RFID technology. In my example, I will use normally-closed contacts of conventional mechanical switches S7 / S8, as shown in this diagram:

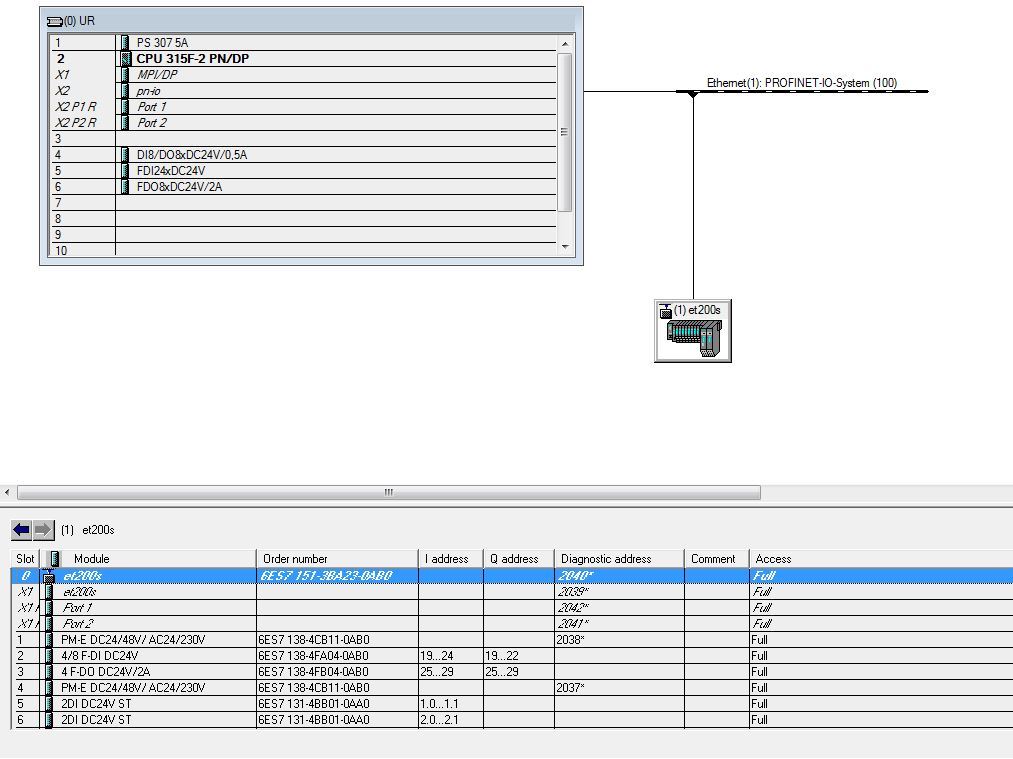

I will make a reservation that for one zone and one door it is not at all necessary to use such a powerful hardware configuration as mine, but it is enough to use a simple safety relay (of course, properly certified). The appearance of my hardware is in the last article, let's take a look at the configuration in Step7:

So, our limit switches are connected to the 4/8 FDI module (Failsafe Discrete / Digital Input) as two single-channel sensors with a rating of 1oo1 and have the addresses I19.1, I19.5. You can start programming.

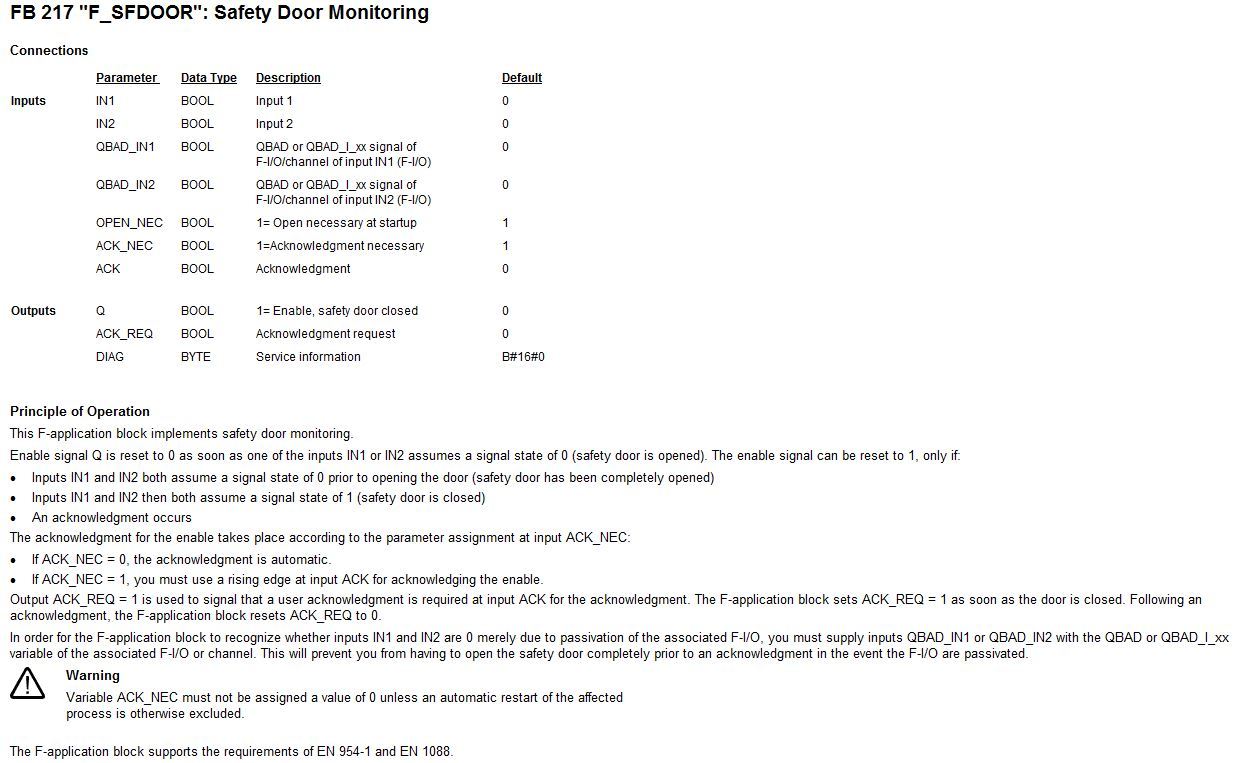

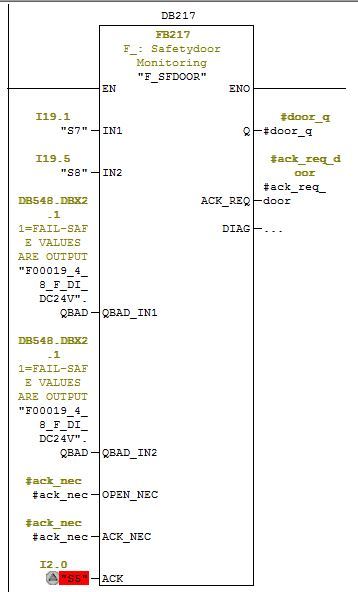

Since failsafe is not about improvisation at all, we will use the standard library block FB 217 "F_SFDOOR": Safety Door Monitoring, which is included in the Distributed Safety package. The help for this block looks like this:

I will not translate it entirely (please ask a question if you need to clarify something), but the block in short works like this: the output Q of our block will be reset to 0 as soon as the unit disappears on one of the inputs IN1 / IN2. In order for the unit to start, it is necessary to fully open the door (reset IN1 / IN2 inputs), fully close the door (turn IN1 / IN2 inputs), set the ACK input to the unit.

Call block in the program:

Let's save, compile and fill our block into the controller.

Done! Now, in case of any failure, breakage of one of the cables, or even loops hanging on the door, the contact will open and the controller will stop our robot from the first picture.

Next time I will try to talk about light barriers and laser scanners, if of course it's interesting.

Since the UFO allowed me to write articles, we continue the stories about the design. I’m in trouble with making headlines. This time it will be about security doors. I hope the reader will forgive me a free translation of the term Safety (or Protective) Door.

Speaking of safety at work, I mean emergency shutdown or emergency shutdown to prevent an accident. There are a number of technologies and devices that make life responsible for TB cloudless and calm, and plant workers to ensure the safety of life and limbs.

')

These devices are used to perform the following tasks:

- emergency stop and shutdown buttons, which I wrote about a little earlier ;

- monitoring of security doors;

- control of the working area with laser scanners;

- access control using light barriers;

- control of safe speed of rotation and movement;

- control of the performance of work with two hands (yes, the translator from me is absolutely no).

Maybe the list is incomplete, but sufficient for today. So, talking about the door.

Let's take a look at the picture, estimate the pretty yellow wicket in the foreground and envy the guys in bathrobes who trust this wicket so much that they don’t even wear helmets. In principle, if one of the guys walks through a door that is not equipped with a monitoring system, the robot in the background can deliver a lot of discomfort and unpleasant moments.

In order to avoid such situations, and to exclude equipment downtime due to an unscheduled call of cleaners, the special limit switches enclose the dangerous zone and put on the door. For example, such (232-0HC05):

The principle of operation is simple: when the door is closed, the limit switches are in one position, if slightly open - in the other. Depending on the needs, the switches are either mechanical or non-contact with RFID technology. In my example, I will use normally-closed contacts of conventional mechanical switches S7 / S8, as shown in this diagram:

I will make a reservation that for one zone and one door it is not at all necessary to use such a powerful hardware configuration as mine, but it is enough to use a simple safety relay (of course, properly certified). The appearance of my hardware is in the last article, let's take a look at the configuration in Step7:

So, our limit switches are connected to the 4/8 FDI module (Failsafe Discrete / Digital Input) as two single-channel sensors with a rating of 1oo1 and have the addresses I19.1, I19.5. You can start programming.

Since failsafe is not about improvisation at all, we will use the standard library block FB 217 "F_SFDOOR": Safety Door Monitoring, which is included in the Distributed Safety package. The help for this block looks like this:

I will not translate it entirely (please ask a question if you need to clarify something), but the block in short works like this: the output Q of our block will be reset to 0 as soon as the unit disappears on one of the inputs IN1 / IN2. In order for the unit to start, it is necessary to fully open the door (reset IN1 / IN2 inputs), fully close the door (turn IN1 / IN2 inputs), set the ACK input to the unit.

Call block in the program:

Let's save, compile and fill our block into the controller.

Done! Now, in case of any failure, breakage of one of the cables, or even loops hanging on the door, the contact will open and the controller will stop our robot from the first picture.

Next time I will try to talk about light barriers and laser scanners, if of course it's interesting.

Source: https://habr.com/ru/post/275165/

All Articles