ACS: from sadness to joy. History of Russian Automation

Modern developers of automation systems have rich possibilities: these are numerous programming languages, libraries, huge open source repositories, and finally, almost any equipment available for development and testing is relatively accessible. In the 1950s, when the idea of creating an automated control system was born in the USSR and cybernetics began to actively develop, all these resources were lacking. Scientists of that time were not only dry pragmatists, but also dreamers - they wanted positive changes in the socio-economic relations that the ACS was intended to provide. However, the entire subsequent history of the creation of an automated management system within the framework of a command economy and an endless bureaucracy is not so optimistic. But first things first.

These were difficult years both for the entire state and for the economic sphere. The collection and processing of data on the state of affairs in business entities was carried out manually, paper was the main information carrier, and computing power was the accounts. To the aid of accountants, bookkeepers and economists came machine counting devices: arithmometers and mechanical counting machines. Shortly before the beginning of the Great Patriotic War, the industrial production of keyboard and perforating mechanical computing was adjusted. Information was collected and processed in the machine-counting bureau - that was how the economy of the USSR was measured before the prewar period. Further, the history of the development of machine-counting devices for the national economy is interrupted - the tasks of the core designers were reduced to the development of automated control systems for weapons that were created, developed and functioned in absolute secrecy.

')

Arithmometer "Felix" - the most common in the USSR arithmometer. It was produced, taking into account numerous modifications, from 1929 to 1978 at the factories of calculating machines in Kursk (Countemash), in Penza (Penza computer plant) and in Moscow

However, military progress and the development of military control systems could not but affect the state of the ACS as a whole - after the war, scientists were able to return to the issue of developing systems. This is what V. Isaev, a leading specialist in military ACS, writes about this time:

Despite the command economy and “collective everything”, during this period the future of the ACS was determined by scientists whose names are inextricably linked with the domestic automation: the ideologist, the dreamer and, perhaps, the genius of the ACS A.I. Kitov, A.A. Lyapunov, A.I. Berg, an outstanding scientist V.M. Glushkov and many others. We will not say lofty words about their personal struggle for the concept of ACS, but when setting forth historical milestones, let us remember that it was these people who determined the history of automated control systems of the USSR and even post-Soviet Russia. So, in 1955, scientists draw the attention of colleagues to the possibility of using computers and cybernetics to automate the management of the national economy. It was a bold act, because in those days, cybernetics was going through disgrace and criticized in scientific circles. And now, in 1956, Kitov wrote a book (the first book on programming in the USSR), which tells in detail about the concept of using ACS in a socialist society:

In early 1959, Kitov sent Khrushchev a letter. In it, he talks about the huge financial losses that the country bears because of the shortcomings of the administrative apparatus. Immediately, in a letter, he proposes a solution: the transition from manual and personal forms of management to automated, computer-based. According to the scientist, a single network of computers should be created, which will collect and process statistical and accounting data both in the country as a whole and in each enterprise. This will allow to analyze the indicators, assess the needs for labor, materials, availability of funds. He proposed to install separate computers in government and at enterprises, and then merge them, thereby obtaining a cluster that will help reduce management and administrative personnel (human factor) and eliminate part of government agencies.

Surprisingly, the letter was accepted favorably and commissions were established to work on the proposal. Such is it, the Soviet, and perhaps the originally Russian, bureaucracy. And in the autumn of 1959, A. I. Kitov sent a second letter with the signature “Top Secret” to N. S. Khrushchev, containing a project to automate the management of the armed forces and the national economy of the USSR using the national network of dual-use computer centers. Of course, the military department rejected the idea of dual use - the computing centers of the Ministry of Defense were to become independent.

Already by 1965 there was an urgent need for the ACS, which arose in the wake of the first information revolution. The amount of information increased and it was necessary to increase the speed of its processing. According to the estimates of scientists, the external document circulation of an average industrial enterprise in 1965 was approximately 100 thousand documents and 1 million indicators.

However, the following are just a lot of productive and serious reports, projects, monographs and publications. In 1966, the Avanproject of the State Network of Computing Centers (GSVTS) was approved by the USSR Ministry of Radio Industry and the Central Statistical Board of the USSR. The scientific leaders of this advance project were A.I. Kitov and A.Ya. Boyarsky. In 1967, A. I. Kitov was approved by the Chief Designer of the “Typical Industrial Automated Control System - OACS”, and V. M. Glushkov was approved as the scientific leader of this OAU. In 1967, A.I. Kitov, on the instructions of the Central Committee of the Communist Party, prepared a report in which he openly showed a strong lag in the USSR computer system and the United States. The main reasons for this lag were also identified: the lack of coordination of work in the field of computer creation and software, the disconnection of developers.

Approximate scheme of the organization of information flows and information files in a computer to ensure the management of the main production, as well as labor and material resources of one of the automated control systems ("Sigma")

The ACS was supposed to be one of the symbols of the post-industrial society that was formed. In 1971, the directives of the XXIV Congress of the CPSU on the five-year plan for the development of the national economy of the USSR for 1971–1975. it was planned to increase the production of computers by 2.6 times. It was supposed to “ensure the wide use of economic and mathematical methods, the use of electronic computing and organizational technology” in order to improve the planning and management of industries, enterprises, associations. The task was to commission 1600 automatic control systems by enterprises and about 700 technological processes. First of all, it was planned to introduce automated control systems at industrial enterprises, which provided 40% of commercial products in the country.

But the plan did not set. On August 22, 1975, the USSR Council of Ministers reports a mismatch in the pace of development of automation with the needs of the state’s economy. A plan for the 75-80 five-year plan was made - three times as compared with the previous period, to increase the scope of work on the development and implementation of process control systems, aggregates and production in the industry of automated control systems. The automated control system demanded improvement of the entire production structure of the enterprise: according to scientists' calculations, it was organizational measures that provided 60–80% of the total effect from the introduction of automated control systems. However, the interest of most enterprises in the ACS remained infinitely low.

However, it was in the 60s that the first ACS appeared, going further than the paper - the Lviv ACS , the development of which lasted from 1965 to 1967. In 1967, the first phase of the system was successfully implemented, and in 1969 the second phase was commissioned. The implementation of the first stage addressed the tasks of operational planning and production scheduling, as well as its logistics. With the introduction of the second stage in operation, the task of automating accounting and reporting at the enterprise, feasibility planning and forecasting was solved. The technical base for the work of the Lviv automated control system was two modified Minsk-22 mainframes, additionally equipped with various units, which made it possible to solve control problems in real time. ACS "Lviv" solved many problems of the plant: production management, planning, work schedule; logistics planning and inventory planning; work with financial, management and procurement reporting.

Computer Minsk-22: On-board software: auto code for solving engineering problems, symbolic coding system with macro tools, COBOL-based automatic data processing system. TTH: RAM - ferrite core 8192 words, NML (magnetic tape drive) - 1.6 million words, speed - 56 thousand operations per second.

Following the Lviv automated control system, work on the Kuntsevo automated control system for the Kuntsevo radio plant begins. This system was designed to solve as many tasks as possible in the group of instrument and machine-building industries. The tasks assigned to the developers required a huge amount of work, literally enormous. Compared with the automated control system for the Lviv Television Plant, the Kuntsevo project required a greater amount of resources, both human and industrial, and was considered more voluminous in terms of the number of operations to be automated within the enterprise. In addition, during the design it was necessary to develop a computer under the Minsk-32 computer, which further tightened the work.

Minsk-32 computer: Onboard software: COBOL, Fortran with debugging tools, auto code for solving engineering problems, symbolic coding system with macro tools, first implemented multiprogram mode in small class computer operating systems, the first software / hardware compatibility system was created. TTH: RAM - ferrite core 16384 - 65536 words, NML (magnetic tape drive) - 80 million words, speed - 65 thousand operations per second.

It was an unprecedented ACS in scale, the development of which was imposed in the most directive manner by Yu.M. Repyev, who had created by that time several automated control systems for defense and space needs. He was initially unable to assemble a team and interest the management of the plant, which simply needed an ACS, without much understanding how to link it with the production and management process. However, despite many problems, in 1969, the project of the Kuntsevo ACS in 150 volumes was handed over. Only separate parts of the system could be implemented - it was ahead of its time by 20 years and most of the project proposals (and even then not all!) Were able to be implemented only on the first IBM computers. The Kuntsevo ACS, a technically ingenious project, revealed the problems that vendors and companies still face today: the formality of implementation and development, the inconsistency of the system with the production processes, the inconsistency of the ACS and the computing power, and so on.

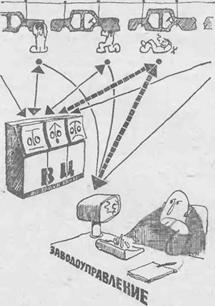

At the same time, the Cold War and the arms race poses its challenges: military-designed ACSs are actively designed and implemented for launching space and strategic missiles, the navy, and accounting in the military-industrial complex. All these projects are successful. It begs the thought: what is wrong with the national economy? And then the answer arises: formal interest puts obstacles in the way of development of management systems. In addition, at the top of that government there were fears that the creation of a single automated control system consisting of a computer network would show the true state of affairs in individual subjects and the economy as a whole. And by the mid-70s there was nothing good there.

Despite this, a new stage in the development of automated control systems fell on the second half of the 70s and 80s. These were complex automated control systems, which integrated the tasks of computer-aided design of new products (CAD), technological preparation of production (ASPP), automation of testing of finished products and automation of organizational enterprise management (ASUP). These systems used more powerful hardware, including imported equipment, and are close relatives of modern ERP systems that flooded the Russian market in the 90s and 2000s.

We are particularly proud of this unit, since AvtoVAZ is now located in the same city as the Ruli24 development office in Togliatti. He is connected with them in another way, but more on that later.

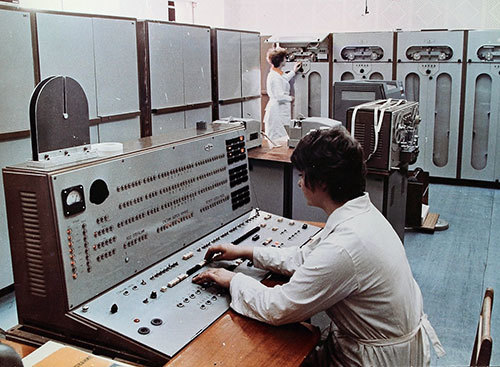

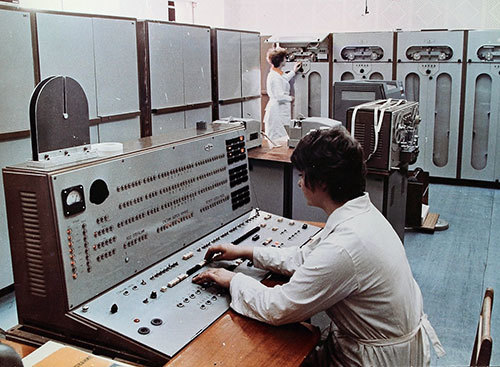

One of the first full-fledged and successful implementations of the ACS was held at the Volga Automobile Plant named after the 50th anniversary of the USSR (VAZ, now AvtoVAZ). It is not surprising - a giant of this magnitude simply could not do without automating work processes.

The ACS at the plant solved several key operational and production tasks: operational calendar planning and control of the main production, control of assembly lines in real time, technical and economic planning and accounting, supply of basic and auxiliary materials and components, personnel movement accounting and payroll calculation, organization of repair of technological equipment, organization, planning and accounting of production and distribution of spare parts, p anirovanie and accounting orders promote auxiliary production's design and technological preparation of production, and so on. The ASU-VAZ technical support had a hierarchical structure of construction and ensured a technologically interconnected cycle of registration, collection, processing, and issuing information in the daily mode.

The ACS at the plant solved several key operational and production tasks: operational calendar planning and control of the main production, control of assembly lines in real time, technical and economic planning and accounting, supply of basic and auxiliary materials and components, personnel movement accounting and payroll calculation, organization of repair of technological equipment, organization, planning and accounting of production and distribution of spare parts, p anirovanie and accounting orders promote auxiliary production's design and technological preparation of production, and so on. The ASU-VAZ technical support had a hierarchical structure of construction and ensured a technologically interconnected cycle of registration, collection, processing, and issuing information in the daily mode.

The “iron” park comprised 9 General Electric computers, a set of traditional equipment (perforators - 8 units, controllers - 4, decoding punched cards and reproducers - 2 units) and over 400 units of peripheral devices. The average daily useful time of the computer, excluding the time of preventive maintenance, was 21.5 hours; the daily number of registrations per unit of peripheral equipment reached 1000-1500. The system ensured the accuracy of information transfer, the number of erroneous registrations for technical reasons did not exceed 0.1% of their total number. The high reliability of the ASU-VAZ complex was ensured by the possibility of flexible redundancy of external devices and computer processors, which made it possible to promptly change the configurations of computing systems using peripheral and channel switches.

Of course, the success of the implementation was due not only to the interest of the leadership of the plant-leader, but also by a number of factors, among which separately should be mentioned the exceptional attention to the training of personnel (2680 factory workers). Project groups were created, between which the subsystems of the ACS were rationally distributed, the work proceeded in accordance with the zone-centralized principle of maintenance and repair of computer and peripheral equipment. The training of management personnel went on in continuous mode, and functional workers took an active part in the development of the ACS.

As a result of the introduction, manual accounting operations were completely excluded. The same success, only a few on a smaller scale, was repeated at several food and industrial productions, where the work of production lines, standard cost estimates, planned costs, and other settlement tasks were automated. There were erroneous stories when the management and functional structure subordinated ACS. However, it is not uncommon today. But employees of all organizations where successful implementation took place, noted that the main factor was still the interest of the units and their assistance in the design and implementation.

Alexander Nefedov, Director General of ILADA LLC and the author of the Ruli24 xRM system, tells :

Special attention in the review deserves OGAS (nationwide automated system of accounting and information processing), conceived by A.I. Kitov, and designed by V.M. Glushkov. It was an ambitious project, the work on which took more than two decades and for which funding was allocated more than space exploration and nuclear energy combined. Needless to say about the scale of this attempt of informatization of the entire Soviet economy. However, apart from the general history, OGAS had an initial prerequisite for failure: extensive development (raw material orientation, excessively developed defense industry) brought the Soviet economy, the arms race simply exhausted it. OGAS could give macroeconomic indicators to scientists, which would shed light on the crisis of the current economic system.

Special attention in the review deserves OGAS (nationwide automated system of accounting and information processing), conceived by A.I. Kitov, and designed by V.M. Glushkov. It was an ambitious project, the work on which took more than two decades and for which funding was allocated more than space exploration and nuclear energy combined. Needless to say about the scale of this attempt of informatization of the entire Soviet economy. However, apart from the general history, OGAS had an initial prerequisite for failure: extensive development (raw material orientation, excessively developed defense industry) brought the Soviet economy, the arms race simply exhausted it. OGAS could give macroeconomic indicators to scientists, which would shed light on the crisis of the current economic system.

The development of the project took place in two major stages. At the first stage, a system was proposed for combining several computer centers into a single network for collecting and processing information for the purposes of managing the national economy. The first stage ended with the economic councils being abolished and the ministries returned. At the second stage (1966–1969), the departments (Central Statistical Board of the USSR, the State Planning Committee of the USSR, and others) entrusted with the task of finalizing the project offered to limit the creation of sectoral (ministerial) computing systems, which contradicted the original OGAS project as a single national automated system. The whole concept, on which prominent scientists worked, was falling apart before our eyes. But at the end of 1969 it became known that the USA had created ARPANET, which linked defense objects, universities and government bodies. In the midst of the Cold War, it was a clear low blow to the Soviet leadership. Which did not fail to turn the gaze back to OGAS. Now all departments had to create their own GAS, and then merge them into a nationwide network.

The OGAS project was not fully implemented, and in 1991 it lost its meaning - the transition to a market economy indicated its own rules of the game. However, some functional units still surrendered to operation. For the period from 1966 to June 1984, 6900 automated control systems for various purposes were created, of which more than 3300 automatic control systems at enterprises and about 3200 departmental automatic control systems. The construction of a network of computer centers started in the late 1970s; 21 reference EC was built to service 2000 enterprises. The average effect of the work of one reference EC was approximately 2 million rubles. In December 1978, for the first time in the USSR, machine-to-machine data exchange between ECs located in Moscow, Riga, Kiev, Tashkent and Tomsk was carried out.

The last attempt to "reach heaven" was made by a desperate scientist Whale in 1985, in a letter to Gorbachev. After 1991, all was not up to this, and automation began to take on the forms that we are witnessing today.

, . , . .

ERP-systems allow you to organize a vicious circle of planning and try to resolve the conflict of interests of three directors: financial director (reduce inventory), director of production (keep capacity loaded), director of sales (reduce the volume of outstanding orders).

In the information technology market of Russia, system integrators offering solutions to global suppliers of ERP systems (SAP R / 3, Baan, Scala, Axapta, Salesforce) were among the first to emerge.

ERP «», «», «1», «», «». , 2015 , «», «», «» . , , (, ) . 1 — , , .

ERP , ( , ), , , , , , ). , , XRM .

Ruli24 , . , XRM « ».

CRM (Customer Relationship Management) , sometimes almost not separated from SFA (SalesForce Automation). This is the most well-known class of systems, the interest in which does not weaken even in times of crisis, since the automation of small and medium-sized businesses brings tangible effect, arising from the saving of resources and the strength of employees. The real demand for CRM appeared in 1998-2000, when the crisis broke all possibilities of price competition and it was necessary to look for methods of intensive development. Formally, the first Russian CRM is Sales Expert, but if you look at the history of other companies, they all appeared on the market at the same time and developed simultaneously - from planners to full-fledged CRM.

PM (Project Management).Perhaps one of the most sought after types. Systems of different levels of complexity and cost, aimed at project management: the project - the task - a milestone. Strongly divided by industry and business. In domestic practice, as a rule, they are part of large systems of other types.

BPMS (Business Process Management Systems) is a universal company management system focused on building a business process as an automated chain of actions. Among the domestic and post-Soviet systems, we can distinguish ELMA, Terrasoft, as well as our Ruli24, in which the construction of business processes is carried out in BPMN 2.0 notation.

And again BPM (but already Business Performance Management), it’s also Enterprise Performance Management (EPM), Strategic Enterprise Management (SEM) and Corporate Performance Management (CPM). These are enterprise performance management systems. A complex that combines all the processes, methodologies and metrics needed to measure the performance of an organization and to manage these indicators. In essence, this is a tool for financiers and top managers of corporations and banks: developing a strategy based on KPI, planning and budgeting, monitoring and controlling budget execution, analysis and regulation in accordance with the obtained indicators.

EDMS (Document Management System, Electronic Document Management System).This is the same as the previous one, the company's business management system, but the management process is based on human-readable documents containing instructions for the organization’s employees that are necessary for execution. In fact, all processes are tied to the coordination of various kinds of documents. The system can be the basis of automation or be one of the tools. The leader among domestic developers (slightly less than half of the market) is the company “Electronic Office Systems” (EOS), which supplies a complex of electronic document management systems for various purposes. As a rule, such systems are implemented in companies with enormous volumes of workflow and an impressive number of employees, up to several tens of thousands: banks, factories, cellular operators.

, . , , — . , , , , . : , , , , , .

, , . . , — . , 150 «».

Robots inject - happy man?

1930 - 1940

These were difficult years both for the entire state and for the economic sphere. The collection and processing of data on the state of affairs in business entities was carried out manually, paper was the main information carrier, and computing power was the accounts. To the aid of accountants, bookkeepers and economists came machine counting devices: arithmometers and mechanical counting machines. Shortly before the beginning of the Great Patriotic War, the industrial production of keyboard and perforating mechanical computing was adjusted. Information was collected and processed in the machine-counting bureau - that was how the economy of the USSR was measured before the prewar period. Further, the history of the development of machine-counting devices for the national economy is interrupted - the tasks of the core designers were reduced to the development of automated control systems for weapons that were created, developed and functioned in absolute secrecy.

')

Arithmometer "Felix" - the most common in the USSR arithmometer. It was produced, taking into account numerous modifications, from 1929 to 1978 at the factories of calculating machines in Kursk (Countemash), in Penza (Penza computer plant) and in Moscow

1950s

However, military progress and the development of military control systems could not but affect the state of the ACS as a whole - after the war, scientists were able to return to the issue of developing systems. This is what V. Isaev, a leading specialist in military ACS, writes about this time:

... numerous specialized computers, computing systems and automated systems for anti-missile and anti-space defense, as well as the ACS of the High Command, the General Staff, the Strategic Missile Forces, the management of the Navy and aviation, including the missile early warning system were created ...

Since 1960, the

Despite the command economy and “collective everything”, during this period the future of the ACS was determined by scientists whose names are inextricably linked with the domestic automation: the ideologist, the dreamer and, perhaps, the genius of the ACS A.I. Kitov, A.A. Lyapunov, A.I. Berg, an outstanding scientist V.M. Glushkov and many others. We will not say lofty words about their personal struggle for the concept of ACS, but when setting forth historical milestones, let us remember that it was these people who determined the history of automated control systems of the USSR and even post-Soviet Russia. So, in 1955, scientists draw the attention of colleagues to the possibility of using computers and cybernetics to automate the management of the national economy. It was a bold act, because in those days, cybernetics was going through disgrace and criticized in scientific circles. And now, in 1956, Kitov wrote a book (the first book on programming in the USSR), which tells in detail about the concept of using ACS in a socialist society:

The use of electronic machines for automatic control of production processes will lead to a significant increase in labor productivity, improved product quality and savings in materials and energy. Unlike capitalist society, where the introduction of electronic automatic devices entails the dismissal of workers and the deterioration of their living conditions, in a socialist society electronic automation and, in particular, electronic computers facilitate the working conditions of people, free them from the most laborious, tedious and monotonous mental work and contribute, ultimately, improve the material well-being of workers. In our country, electronic machines are used for the automated management of production processes that pose a danger to the health and life of people, such as in some types of chemical industry. An important area of the future application of electronic digital machines is the mechanization and automation of administrative processes, including government planning, accounting and control.

In early 1959, Kitov sent Khrushchev a letter. In it, he talks about the huge financial losses that the country bears because of the shortcomings of the administrative apparatus. Immediately, in a letter, he proposes a solution: the transition from manual and personal forms of management to automated, computer-based. According to the scientist, a single network of computers should be created, which will collect and process statistical and accounting data both in the country as a whole and in each enterprise. This will allow to analyze the indicators, assess the needs for labor, materials, availability of funds. He proposed to install separate computers in government and at enterprises, and then merge them, thereby obtaining a cluster that will help reduce management and administrative personnel (human factor) and eliminate part of government agencies.

Surprisingly, the letter was accepted favorably and commissions were established to work on the proposal. Such is it, the Soviet, and perhaps the originally Russian, bureaucracy. And in the autumn of 1959, A. I. Kitov sent a second letter with the signature “Top Secret” to N. S. Khrushchev, containing a project to automate the management of the armed forces and the national economy of the USSR using the national network of dual-use computer centers. Of course, the military department rejected the idea of dual use - the computing centers of the Ministry of Defense were to become independent.

Already by 1965 there was an urgent need for the ACS, which arose in the wake of the first information revolution. The amount of information increased and it was necessary to increase the speed of its processing. According to the estimates of scientists, the external document circulation of an average industrial enterprise in 1965 was approximately 100 thousand documents and 1 million indicators.

However, the following are just a lot of productive and serious reports, projects, monographs and publications. In 1966, the Avanproject of the State Network of Computing Centers (GSVTS) was approved by the USSR Ministry of Radio Industry and the Central Statistical Board of the USSR. The scientific leaders of this advance project were A.I. Kitov and A.Ya. Boyarsky. In 1967, A. I. Kitov was approved by the Chief Designer of the “Typical Industrial Automated Control System - OACS”, and V. M. Glushkov was approved as the scientific leader of this OAU. In 1967, A.I. Kitov, on the instructions of the Central Committee of the Communist Party, prepared a report in which he openly showed a strong lag in the USSR computer system and the United States. The main reasons for this lag were also identified: the lack of coordination of work in the field of computer creation and software, the disconnection of developers.

Approximate scheme of the organization of information flows and information files in a computer to ensure the management of the main production, as well as labor and material resources of one of the automated control systems ("Sigma")

1971-1975 - five years with varying success

The ACS was supposed to be one of the symbols of the post-industrial society that was formed. In 1971, the directives of the XXIV Congress of the CPSU on the five-year plan for the development of the national economy of the USSR for 1971–1975. it was planned to increase the production of computers by 2.6 times. It was supposed to “ensure the wide use of economic and mathematical methods, the use of electronic computing and organizational technology” in order to improve the planning and management of industries, enterprises, associations. The task was to commission 1600 automatic control systems by enterprises and about 700 technological processes. First of all, it was planned to introduce automated control systems at industrial enterprises, which provided 40% of commercial products in the country.

But the plan did not set. On August 22, 1975, the USSR Council of Ministers reports a mismatch in the pace of development of automation with the needs of the state’s economy. A plan for the 75-80 five-year plan was made - three times as compared with the previous period, to increase the scope of work on the development and implementation of process control systems, aggregates and production in the industry of automated control systems. The automated control system demanded improvement of the entire production structure of the enterprise: according to scientists' calculations, it was organizational measures that provided 60–80% of the total effect from the introduction of automated control systems. However, the interest of most enterprises in the ACS remained infinitely low.

Completed projects

However, it was in the 60s that the first ACS appeared, going further than the paper - the Lviv ACS , the development of which lasted from 1965 to 1967. In 1967, the first phase of the system was successfully implemented, and in 1969 the second phase was commissioned. The implementation of the first stage addressed the tasks of operational planning and production scheduling, as well as its logistics. With the introduction of the second stage in operation, the task of automating accounting and reporting at the enterprise, feasibility planning and forecasting was solved. The technical base for the work of the Lviv automated control system was two modified Minsk-22 mainframes, additionally equipped with various units, which made it possible to solve control problems in real time. ACS "Lviv" solved many problems of the plant: production management, planning, work schedule; logistics planning and inventory planning; work with financial, management and procurement reporting.

Computer Minsk-22: On-board software: auto code for solving engineering problems, symbolic coding system with macro tools, COBOL-based automatic data processing system. TTH: RAM - ferrite core 8192 words, NML (magnetic tape drive) - 1.6 million words, speed - 56 thousand operations per second.

Following the Lviv automated control system, work on the Kuntsevo automated control system for the Kuntsevo radio plant begins. This system was designed to solve as many tasks as possible in the group of instrument and machine-building industries. The tasks assigned to the developers required a huge amount of work, literally enormous. Compared with the automated control system for the Lviv Television Plant, the Kuntsevo project required a greater amount of resources, both human and industrial, and was considered more voluminous in terms of the number of operations to be automated within the enterprise. In addition, during the design it was necessary to develop a computer under the Minsk-32 computer, which further tightened the work.

Minsk-32 computer: Onboard software: COBOL, Fortran with debugging tools, auto code for solving engineering problems, symbolic coding system with macro tools, first implemented multiprogram mode in small class computer operating systems, the first software / hardware compatibility system was created. TTH: RAM - ferrite core 16384 - 65536 words, NML (magnetic tape drive) - 80 million words, speed - 65 thousand operations per second.

It was an unprecedented ACS in scale, the development of which was imposed in the most directive manner by Yu.M. Repyev, who had created by that time several automated control systems for defense and space needs. He was initially unable to assemble a team and interest the management of the plant, which simply needed an ACS, without much understanding how to link it with the production and management process. However, despite many problems, in 1969, the project of the Kuntsevo ACS in 150 volumes was handed over. Only separate parts of the system could be implemented - it was ahead of its time by 20 years and most of the project proposals (and even then not all!) Were able to be implemented only on the first IBM computers. The Kuntsevo ACS, a technically ingenious project, revealed the problems that vendors and companies still face today: the formality of implementation and development, the inconsistency of the system with the production processes, the inconsistency of the ACS and the computing power, and so on.

At the same time, the Cold War and the arms race poses its challenges: military-designed ACSs are actively designed and implemented for launching space and strategic missiles, the navy, and accounting in the military-industrial complex. All these projects are successful. It begs the thought: what is wrong with the national economy? And then the answer arises: formal interest puts obstacles in the way of development of management systems. In addition, at the top of that government there were fears that the creation of a single automated control system consisting of a computer network would show the true state of affairs in individual subjects and the economy as a whole. And by the mid-70s there was nothing good there.

Despite this, a new stage in the development of automated control systems fell on the second half of the 70s and 80s. These were complex automated control systems, which integrated the tasks of computer-aided design of new products (CAD), technological preparation of production (ASPP), automation of testing of finished products and automation of organizational enterprise management (ASUP). These systems used more powerful hardware, including imported equipment, and are close relatives of modern ERP systems that flooded the Russian market in the 90s and 2000s.

Great success autocar VAZ

We are particularly proud of this unit, since AvtoVAZ is now located in the same city as the Ruli24 development office in Togliatti. He is connected with them in another way, but more on that later.

One of the first full-fledged and successful implementations of the ACS was held at the Volga Automobile Plant named after the 50th anniversary of the USSR (VAZ, now AvtoVAZ). It is not surprising - a giant of this magnitude simply could not do without automating work processes.

The ACS at the plant solved several key operational and production tasks: operational calendar planning and control of the main production, control of assembly lines in real time, technical and economic planning and accounting, supply of basic and auxiliary materials and components, personnel movement accounting and payroll calculation, organization of repair of technological equipment, organization, planning and accounting of production and distribution of spare parts, p anirovanie and accounting orders promote auxiliary production's design and technological preparation of production, and so on. The ASU-VAZ technical support had a hierarchical structure of construction and ensured a technologically interconnected cycle of registration, collection, processing, and issuing information in the daily mode.

The ACS at the plant solved several key operational and production tasks: operational calendar planning and control of the main production, control of assembly lines in real time, technical and economic planning and accounting, supply of basic and auxiliary materials and components, personnel movement accounting and payroll calculation, organization of repair of technological equipment, organization, planning and accounting of production and distribution of spare parts, p anirovanie and accounting orders promote auxiliary production's design and technological preparation of production, and so on. The ASU-VAZ technical support had a hierarchical structure of construction and ensured a technologically interconnected cycle of registration, collection, processing, and issuing information in the daily mode.The “iron” park comprised 9 General Electric computers, a set of traditional equipment (perforators - 8 units, controllers - 4, decoding punched cards and reproducers - 2 units) and over 400 units of peripheral devices. The average daily useful time of the computer, excluding the time of preventive maintenance, was 21.5 hours; the daily number of registrations per unit of peripheral equipment reached 1000-1500. The system ensured the accuracy of information transfer, the number of erroneous registrations for technical reasons did not exceed 0.1% of their total number. The high reliability of the ASU-VAZ complex was ensured by the possibility of flexible redundancy of external devices and computer processors, which made it possible to promptly change the configurations of computing systems using peripheral and channel switches.

Of course, the success of the implementation was due not only to the interest of the leadership of the plant-leader, but also by a number of factors, among which separately should be mentioned the exceptional attention to the training of personnel (2680 factory workers). Project groups were created, between which the subsystems of the ACS were rationally distributed, the work proceeded in accordance with the zone-centralized principle of maintenance and repair of computer and peripheral equipment. The training of management personnel went on in continuous mode, and functional workers took an active part in the development of the ACS.

As a result of the introduction, manual accounting operations were completely excluded. The same success, only a few on a smaller scale, was repeated at several food and industrial productions, where the work of production lines, standard cost estimates, planned costs, and other settlement tasks were automated. There were erroneous stories when the management and functional structure subordinated ACS. However, it is not uncommon today. But employees of all organizations where successful implementation took place, noted that the main factor was still the interest of the units and their assistance in the design and implementation.

Alexander Nefedov, Director General of ILADA LLC and the author of the Ruli24 xRM system, tells :

I worked in the management of the organization of the production of Avtopaz UOP from 1977 to 1990 and participated in the creation of the automated control system and automated process control system. In particular, the subsystem of the “Quality” automated control system was created, in which not only defects and defects were taken into account, but a forecast and a quality plan were calculated for all productions and workshops of the plant. In addition, it was the VAZ that prompted me to develop a single information system with a single repository, since at that time, each department of OPS was engaged in the automation of its activities. Someone supplies, someone production, someone sales, etc. We had to do a lot of “bridges” between these subsystems. In addition, there was a large fleet of computers: CM2, CM4, PDP 11/70, EC 1055, etc. Our department was also involved in automating the work of the main assembly line and creating control systems for CNC machine tool sections. In the period 1998 to 2003, we already in the company InfoLada did for AvtoVAZ the ACS “Accounting”, which is still in use. AvtoVAZ experts are already modifying it.

Honestly, I do not know much examples of the implementation of MRP standards in our country! At VAZ, JSC "TZTO" - works. Where else? All that is said about the implementation of ERP is at best a financial unit, personnel management and logistics. But not MRP and CRP.

Automation dictionary:

CRP (Capacity Requirements Planning) - capacity planning based on product demand forecast and production schedule. Based on the existing production capacity, the production technology of the final product, an optimal distribution plan of production capacity is calculated. Formed reports on opportunities and weak spots in the production process.

MRP (Material Requirements Planning) - planning the need for materials based on the volume-calendar plan, design specifications of products. Calculates the need for materials and components; taking into account data on stocks, a plan for the purchase of raw materials - materials and components is calculated.

MRP (Material Requirements Planning) - planning the need for materials based on the volume-calendar plan, design specifications of products. Calculates the need for materials and components; taking into account data on stocks, a plan for the purchase of raw materials - materials and components is calculated.

OGAS - another strangled dream

Special attention in the review deserves OGAS (nationwide automated system of accounting and information processing), conceived by A.I. Kitov, and designed by V.M. Glushkov. It was an ambitious project, the work on which took more than two decades and for which funding was allocated more than space exploration and nuclear energy combined. Needless to say about the scale of this attempt of informatization of the entire Soviet economy. However, apart from the general history, OGAS had an initial prerequisite for failure: extensive development (raw material orientation, excessively developed defense industry) brought the Soviet economy, the arms race simply exhausted it. OGAS could give macroeconomic indicators to scientists, which would shed light on the crisis of the current economic system.

Special attention in the review deserves OGAS (nationwide automated system of accounting and information processing), conceived by A.I. Kitov, and designed by V.M. Glushkov. It was an ambitious project, the work on which took more than two decades and for which funding was allocated more than space exploration and nuclear energy combined. Needless to say about the scale of this attempt of informatization of the entire Soviet economy. However, apart from the general history, OGAS had an initial prerequisite for failure: extensive development (raw material orientation, excessively developed defense industry) brought the Soviet economy, the arms race simply exhausted it. OGAS could give macroeconomic indicators to scientists, which would shed light on the crisis of the current economic system.The development of the project took place in two major stages. At the first stage, a system was proposed for combining several computer centers into a single network for collecting and processing information for the purposes of managing the national economy. The first stage ended with the economic councils being abolished and the ministries returned. At the second stage (1966–1969), the departments (Central Statistical Board of the USSR, the State Planning Committee of the USSR, and others) entrusted with the task of finalizing the project offered to limit the creation of sectoral (ministerial) computing systems, which contradicted the original OGAS project as a single national automated system. The whole concept, on which prominent scientists worked, was falling apart before our eyes. But at the end of 1969 it became known that the USA had created ARPANET, which linked defense objects, universities and government bodies. In the midst of the Cold War, it was a clear low blow to the Soviet leadership. Which did not fail to turn the gaze back to OGAS. Now all departments had to create their own GAS, and then merge them into a nationwide network.

The OGAS project was not fully implemented, and in 1991 it lost its meaning - the transition to a market economy indicated its own rules of the game. However, some functional units still surrendered to operation. For the period from 1966 to June 1984, 6900 automated control systems for various purposes were created, of which more than 3300 automatic control systems at enterprises and about 3200 departmental automatic control systems. The construction of a network of computer centers started in the late 1970s; 21 reference EC was built to service 2000 enterprises. The average effect of the work of one reference EC was approximately 2 million rubles. In December 1978, for the first time in the USSR, machine-to-machine data exchange between ECs located in Moscow, Riga, Kiev, Tashkent and Tomsk was carried out.

The last attempt to "reach heaven" was made by a desperate scientist Whale in 1985, in a letter to Gorbachev. After 1991, all was not up to this, and automation began to take on the forms that we are witnessing today.

It is useless to hope that everything will settle down by itself and the computer technology itself will gradually restructure the structure of economic management ... More than ten years of experience in our country shows that, apart from talking, promises and individual, mostly illustrative tasks, nothing happens, although big money is spent There are a lot of highly qualified specialists. At the same time, capitalist countries are almost widely using automation and computer technology in the field of management and are moving further ahead compared to the USSR.

Market economy: new realities of automation

, . , . .

:

ERP Enterprise Requirements Planning ( ) – , . ERP . , ERP MRP II , . .

MPS master planning scheduling — — , .

MPS master planning scheduling — — , .

ERP-systems allow you to organize a vicious circle of planning and try to resolve the conflict of interests of three directors: financial director (reduce inventory), director of production (keep capacity loaded), director of sales (reduce the volume of outstanding orders).

In the information technology market of Russia, system integrators offering solutions to global suppliers of ERP systems (SAP R / 3, Baan, Scala, Axapta, Salesforce) were among the first to emerge.

ERP «», «», «1», «», «». , 2015 , «», «», «» . , , (, ) . 1 — , , .

ERP , ( , ), , , , , , ). , , XRM .

Ruli24 , . , XRM « ».

| Function | «24» | ||

|---|---|---|---|

| , | CRM — customer relationship management | ( CRM) | 24 CRM |

| HRM — human resource management | 24 | ||

| WMS — warehouse management system | 24 | ||

| FIM — Finans management | 24 | ||

| ECM — Enterprise content management | 24 | ||

| SCM — supply chain management | - | ||

| Design | PM — project management | 24 | |

| ERP — enterprise resource lanning | 24 | ||

| MES — manufacturing execution system | , | 24 | |

| BPM — business process management | - | 24 | |

| HRM — human resource management | 24 | ||

| FIM — Finans management, Accounting, Accountancy | 24 |

CRM (Customer Relationship Management) , sometimes almost not separated from SFA (SalesForce Automation). This is the most well-known class of systems, the interest in which does not weaken even in times of crisis, since the automation of small and medium-sized businesses brings tangible effect, arising from the saving of resources and the strength of employees. The real demand for CRM appeared in 1998-2000, when the crisis broke all possibilities of price competition and it was necessary to look for methods of intensive development. Formally, the first Russian CRM is Sales Expert, but if you look at the history of other companies, they all appeared on the market at the same time and developed simultaneously - from planners to full-fledged CRM.

PM (Project Management).Perhaps one of the most sought after types. Systems of different levels of complexity and cost, aimed at project management: the project - the task - a milestone. Strongly divided by industry and business. In domestic practice, as a rule, they are part of large systems of other types.

BPMS (Business Process Management Systems) is a universal company management system focused on building a business process as an automated chain of actions. Among the domestic and post-Soviet systems, we can distinguish ELMA, Terrasoft, as well as our Ruli24, in which the construction of business processes is carried out in BPMN 2.0 notation.

And again BPM (but already Business Performance Management), it’s also Enterprise Performance Management (EPM), Strategic Enterprise Management (SEM) and Corporate Performance Management (CPM). These are enterprise performance management systems. A complex that combines all the processes, methodologies and metrics needed to measure the performance of an organization and to manage these indicators. In essence, this is a tool for financiers and top managers of corporations and banks: developing a strategy based on KPI, planning and budgeting, monitoring and controlling budget execution, analysis and regulation in accordance with the obtained indicators.

EDMS (Document Management System, Electronic Document Management System).This is the same as the previous one, the company's business management system, but the management process is based on human-readable documents containing instructions for the organization’s employees that are necessary for execution. In fact, all processes are tied to the coordination of various kinds of documents. The system can be the basis of automation or be one of the tools. The leader among domestic developers (slightly less than half of the market) is the company “Electronic Office Systems” (EOS), which supplies a complex of electronic document management systems for various purposes. As a rule, such systems are implemented in companies with enormous volumes of workflow and an impressive number of employees, up to several tens of thousands: banks, factories, cellular operators.

, . , , — . , , , , . : , , , , , .

, , . . , — . , 150 «».

:

Source: https://habr.com/ru/post/273593/

All Articles