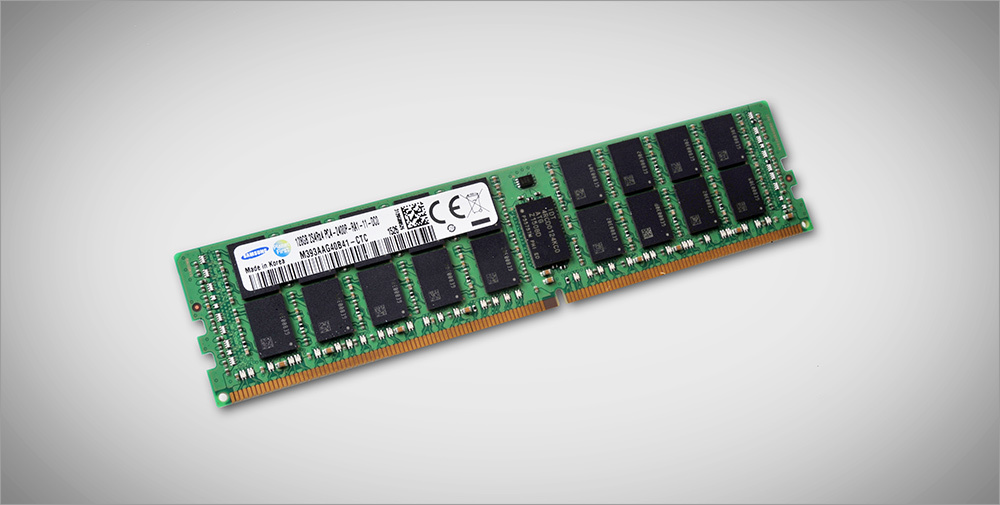

Samsung launched production of TSV DDR4 128 Gb memory modules for servers

November 26 this year, Samsung Electronics announced the beginning of mass production of 128 GB of memory, intended for corporate servers and data centers. TSV DDR4 128 Gb will be produced on the basis of TSV technology (“through silicon via”).

Since 2014, Samsung Electronics has already released 64GB DDR4 RDIMM based on 3D TSV technology. These modules are also designed for corporate servers and cloud applications. RDIMM modules include 36 DDR4 DRAM chips, each of which consists of four 4 Gbps DDR4 DRAM chips. The chips are manufactured using a process class of 20 nm.

What is 3D TSV and what you need to know about it and how it changes our lives?

Compared with the memory modules produced by traditional technology, 3D TSV DDR4 RDIMM with a capacity of 64 GB showed a twofold increase in performance and a twofold decrease in power consumption, reports Solid State Technology . Even then, the company announced the possibility of interconnecting more than four DDR4 crystals using 3D TSV technology, which will allow creating DRAM modules with even higher density.

')

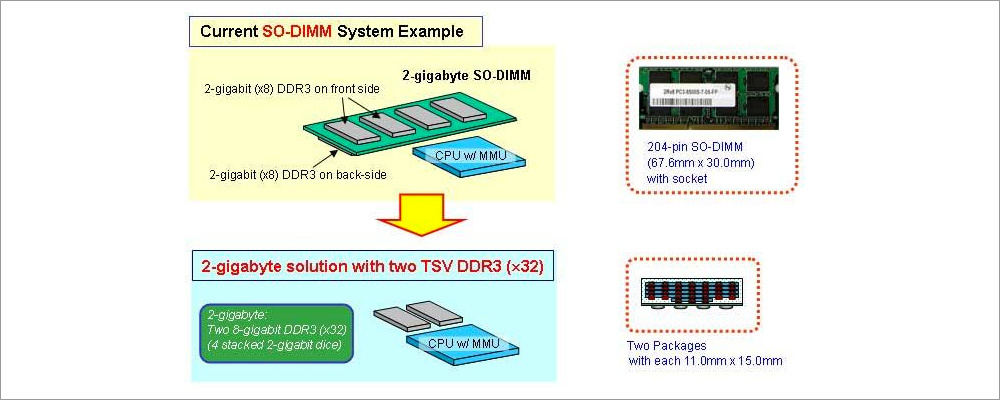

The 128-gigabyte DDR4 memory module using the technology of end-to-end vertical connection of crystals (TSV) and double-row pin layout (RDIMM) consists of 144 DDR4 chips combined into 36 blocks of 4 GB each, each containing four 8-gigabyte chips of class 20 nm .

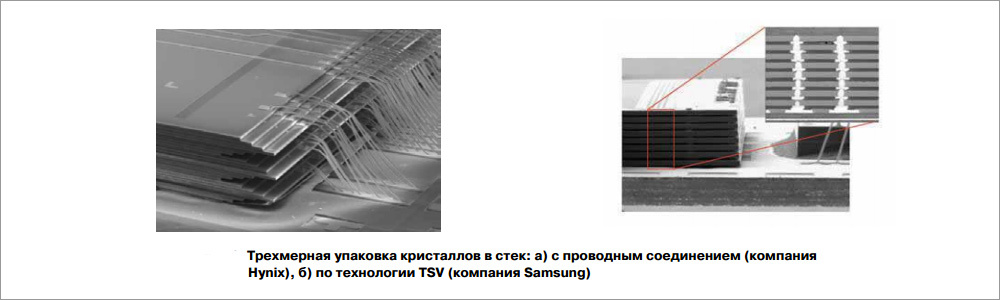

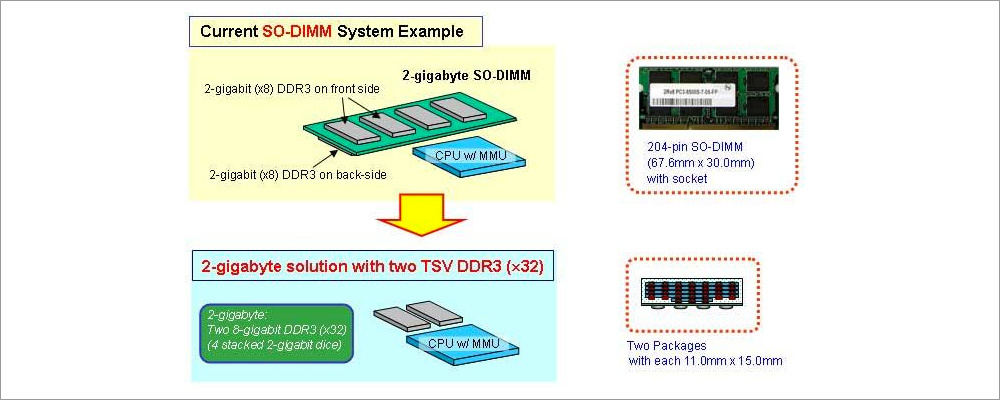

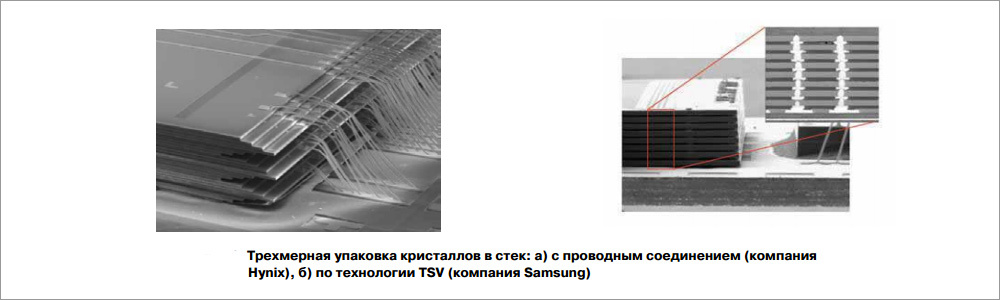

In addition, the main chip of each 4 GB packet serves as a data buffer, which allows optimizing performance and power consumption. The TSV chip packaging technology allows you to vertically connect DDR4 crystals, having a thickness of several tens of microns, using electrodes through several hundred holes.

The industrial development of TSV technology (Through Silicon Via - vias in silicon), which allows to move from a planar arrangement of elements in (in one plane) to a volume (elements are located above each other), IBM announced in 2007.

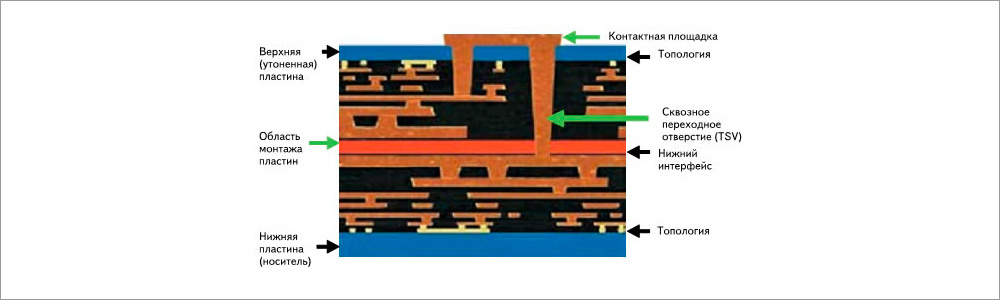

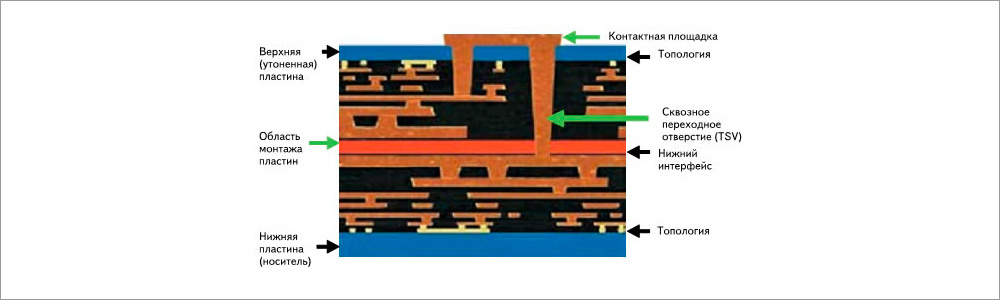

The essence of TSV technology is the formation of vias in silicon chips. These vias are filled with polysilicon or metal (copper, gold, or tungsten), resulting in vertical conductors that bind the crystals in the stack.

The first IBM product to use TSV technology was a power amplifier for wireless telecommunications systems. According to the company, the use of TSV by 40% increased the energy efficiency of the amplifier.

At about the same time, NEC Electronics, Elpida Memory and Oki began developing chips using TSV technology. At the same time, the TSV technology was then recognized as complex (vias occupied additional area of the crystal, so it was necessary to make changes in its topology) and expensive.

The American company Vertical Circuits, along with IBM, patented another technology, thanks to which it was possible to increase the performance and reduce the energy consumption of the chips - Vertical Interconnect Pillar (vertical interconnect speakers). An additional layer of metallization was formed on the finished semiconductor wafer with chips of microcircuits, which brought out the contact pads to one of the chip edges. Then the whole plate was covered with polymer, which opened the windows above the contact pads. Next was the separation of the plate into crystals. The individual crystals were connected vertically, forming a stack. But it did not go further than the patent.

Primacy in the massive use of technology TSV does not belong to Samsung. The first TSV DRAM chip in the industry, combining eight DDR3 SDRAM chips in a single package, was developed by the Japanese company Elpida Memory in 2009. In 2011, the company announced the start of deliveries of DDR3 SDRAM chips, also using TSV mounting technology. The supplied samples consisted of 8-Gbps DDR3 SDRAM chips, which combine four 2-Gbps DDR3 SDRAM chips and an interface unit in one package.

Source: 3dnews.ru

However, despite the promise of technology, 3D TSV, until recently, was widely used only for connection with optical sensors in digital photo / video equipment.

Today, the 128 GB TSV DDR4 RDIMM module is the most energy efficient solution for servers. According to Samsung, the data transfer rate is 2400 Mbps, which makes it possible to almost double the performance, reducing power consumption by 50% compared to 64 GB LRDIMM modules. The significant performance increase is due to the fact that in LRDIMM stacks consist of four packets and are limited in power and data transfer rates due to the traditional wired connection.

Samsung will introduce a line of new high-performance TSV DRAM modules in the next few weeks.

Since 2008, we have been renting dedicated and virtual servers for rent, providing server hosting services in 4 Moscow data centers, including two Tier-III certified data centers. We specialize in large dedicated servers and the creation of private clouds and clusters for our clients based on them.

Since 2008, we have been renting dedicated and virtual servers for rent, providing server hosting services in 4 Moscow data centers, including two Tier-III certified data centers. We specialize in large dedicated servers and the creation of private clouds and clusters for our clients based on them.

We have a hot offer for our readers: Servers available on the basis of T-Platform supercomputers and Intel Xeon E5-2630v2 processors at a 15% discount until the end of December (or until they run out) when using the TMW5U0S8SE promo code

For example, for comparison:

- 2xE5-2630v2 (12x2,6 GHz) / 64Gb RAM / 1x1Tb SSD + 1x1Tb 7.2K HDD = 17000r per month, with a discount of 14450.

- 2xE5-2630v2 (12x2,6 GHz) / 64Gb RAM / 1x1Tb SSD + 1x1Tb 7.2K HDD = 17000r per month, with a discount of 14450.

- 2xE5-2630v2 (12x2,6 GHz) / 128Gb RAM / 1x2Tb SSD + 1x2Tb 7.2K HDD = 25700r per month, with a discount of 21800

- 2xE5-2630v2 (12x2,6 GHz) / 256Gb RAM / 2x2Tb Samsung SSD = 36500r per month, with a discount of 31000

- 2xE5-2630v2 (12x2,6 GHz) / 32Gb RAM / 2x600Gb SAS 10K = 13650r per month, with a discount of 11600r

All prices include VAT, almost any configuration is possible.

All servers are connected on a gigabit channel, the traffic limit is 10TB without restrictions on the band. Each dedicated server is provided with remote access via IPMI, it is possible to organize a VLAN at a speed of up to 10Gbps.

Since 2014, Samsung Electronics has already released 64GB DDR4 RDIMM based on 3D TSV technology. These modules are also designed for corporate servers and cloud applications. RDIMM modules include 36 DDR4 DRAM chips, each of which consists of four 4 Gbps DDR4 DRAM chips. The chips are manufactured using a process class of 20 nm.

What is 3D TSV and what you need to know about it and how it changes our lives?

Compared with the memory modules produced by traditional technology, 3D TSV DDR4 RDIMM with a capacity of 64 GB showed a twofold increase in performance and a twofold decrease in power consumption, reports Solid State Technology . Even then, the company announced the possibility of interconnecting more than four DDR4 crystals using 3D TSV technology, which will allow creating DRAM modules with even higher density.

')

The 128-gigabyte DDR4 memory module using the technology of end-to-end vertical connection of crystals (TSV) and double-row pin layout (RDIMM) consists of 144 DDR4 chips combined into 36 blocks of 4 GB each, each containing four 8-gigabyte chips of class 20 nm .

In addition, the main chip of each 4 GB packet serves as a data buffer, which allows optimizing performance and power consumption. The TSV chip packaging technology allows you to vertically connect DDR4 crystals, having a thickness of several tens of microns, using electrodes through several hundred holes.

What is TSV

The industrial development of TSV technology (Through Silicon Via - vias in silicon), which allows to move from a planar arrangement of elements in (in one plane) to a volume (elements are located above each other), IBM announced in 2007.

The essence of TSV technology is the formation of vias in silicon chips. These vias are filled with polysilicon or metal (copper, gold, or tungsten), resulting in vertical conductors that bind the crystals in the stack.

The first IBM product to use TSV technology was a power amplifier for wireless telecommunications systems. According to the company, the use of TSV by 40% increased the energy efficiency of the amplifier.

At about the same time, NEC Electronics, Elpida Memory and Oki began developing chips using TSV technology. At the same time, the TSV technology was then recognized as complex (vias occupied additional area of the crystal, so it was necessary to make changes in its topology) and expensive.

The American company Vertical Circuits, along with IBM, patented another technology, thanks to which it was possible to increase the performance and reduce the energy consumption of the chips - Vertical Interconnect Pillar (vertical interconnect speakers). An additional layer of metallization was formed on the finished semiconductor wafer with chips of microcircuits, which brought out the contact pads to one of the chip edges. Then the whole plate was covered with polymer, which opened the windows above the contact pads. Next was the separation of the plate into crystals. The individual crystals were connected vertically, forming a stack. But it did not go further than the patent.

Primacy in the massive use of technology TSV does not belong to Samsung. The first TSV DRAM chip in the industry, combining eight DDR3 SDRAM chips in a single package, was developed by the Japanese company Elpida Memory in 2009. In 2011, the company announced the start of deliveries of DDR3 SDRAM chips, also using TSV mounting technology. The supplied samples consisted of 8-Gbps DDR3 SDRAM chips, which combine four 2-Gbps DDR3 SDRAM chips and an interface unit in one package.

Source: 3dnews.ru

However, despite the promise of technology, 3D TSV, until recently, was widely used only for connection with optical sensors in digital photo / video equipment.

Today, the 128 GB TSV DDR4 RDIMM module is the most energy efficient solution for servers. According to Samsung, the data transfer rate is 2400 Mbps, which makes it possible to almost double the performance, reducing power consumption by 50% compared to 64 GB LRDIMM modules. The significant performance increase is due to the fact that in LRDIMM stacks consist of four packets and are limited in power and data transfer rates due to the traditional wired connection.

Samsung will introduce a line of new high-performance TSV DRAM modules in the next few weeks.

A little bit about HOSTKEY

Since 2008, we have been renting dedicated and virtual servers for rent, providing server hosting services in 4 Moscow data centers, including two Tier-III certified data centers. We specialize in large dedicated servers and the creation of private clouds and clusters for our clients based on them.

Since 2008, we have been renting dedicated and virtual servers for rent, providing server hosting services in 4 Moscow data centers, including two Tier-III certified data centers. We specialize in large dedicated servers and the creation of private clouds and clusters for our clients based on them.We have a hot offer for our readers: Servers available on the basis of T-Platform supercomputers and Intel Xeon E5-2630v2 processors at a 15% discount until the end of December (or until they run out) when using the TMW5U0S8SE promo code

For example, for comparison:

- 2xE5-2630v2 (12x2,6 GHz) / 64Gb RAM / 1x1Tb SSD + 1x1Tb 7.2K HDD = 17000r per month, with a discount of 14450.

- 2xE5-2630v2 (12x2,6 GHz) / 64Gb RAM / 1x1Tb SSD + 1x1Tb 7.2K HDD = 17000r per month, with a discount of 14450.- 2xE5-2630v2 (12x2,6 GHz) / 128Gb RAM / 1x2Tb SSD + 1x2Tb 7.2K HDD = 25700r per month, with a discount of 21800

- 2xE5-2630v2 (12x2,6 GHz) / 256Gb RAM / 2x2Tb Samsung SSD = 36500r per month, with a discount of 31000

- 2xE5-2630v2 (12x2,6 GHz) / 32Gb RAM / 2x600Gb SAS 10K = 13650r per month, with a discount of 11600r

All prices include VAT, almost any configuration is possible.

All servers are connected on a gigabit channel, the traffic limit is 10TB without restrictions on the band. Each dedicated server is provided with remote access via IPMI, it is possible to organize a VLAN at a speed of up to 10Gbps.

Source: https://habr.com/ru/post/272717/

All Articles