How to solder "bridges" and chips on motherboards using a soldering station

When examining their first computers, many saw different “bridges” - southern, northern, graphics chips, and often it was thought: what about this soldering and, most importantly, what? And those who took the chance to try it with a soldering iron, then carried their motherboards to the service, where they soldered a new chip, if, of course, they didn’t kill the whole motherboard with their home soldering. So how are chips soldered? Under the cut story, as well as photos and videos about it. In the main role we will have a soldering station ERSA IR550a.

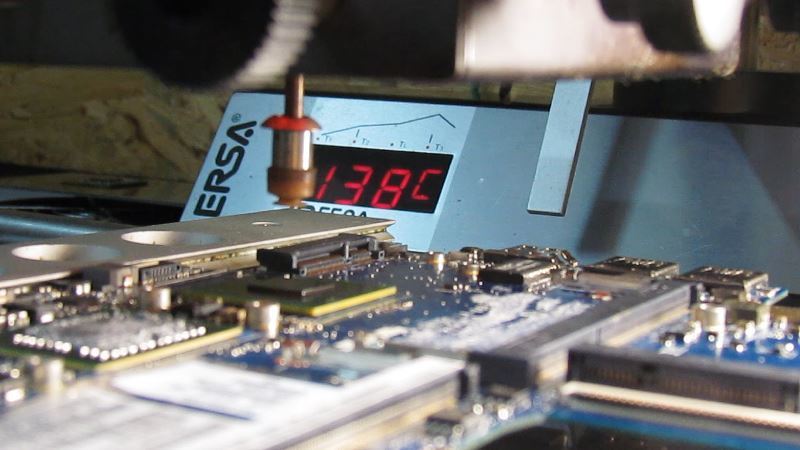

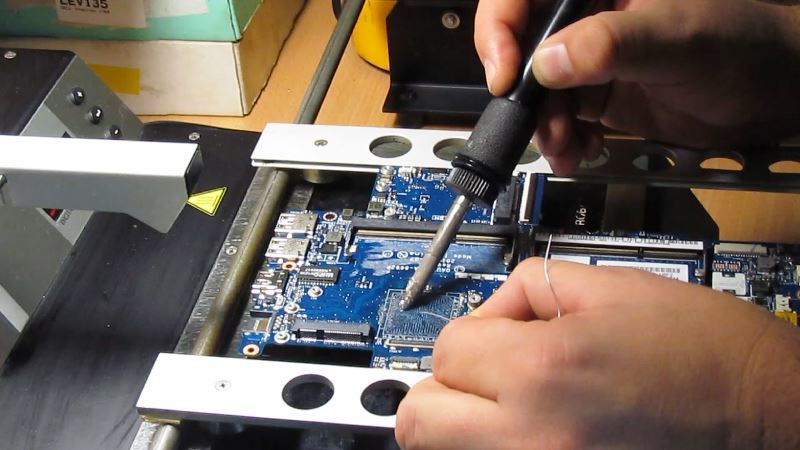

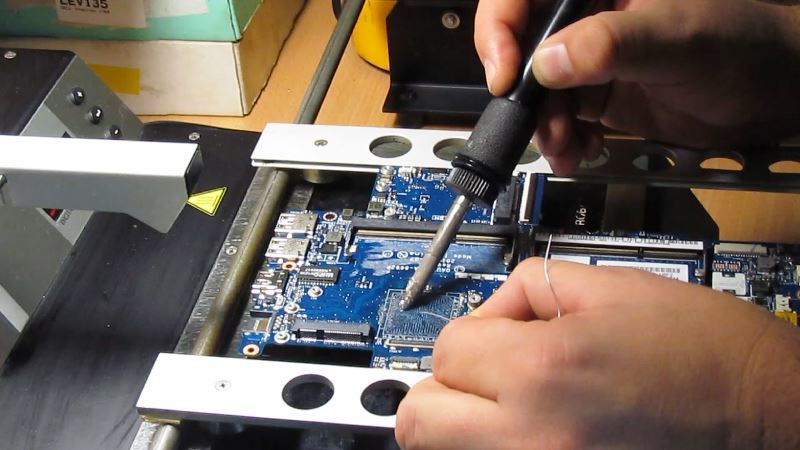

First, we remove the old chip. For this, it is heated by the station to the desired temperature. We select the desired profile in the management (there are several of them for different types of soldering).

')

At the station there are two “heads” - one to solder / solder something, the second to cool.

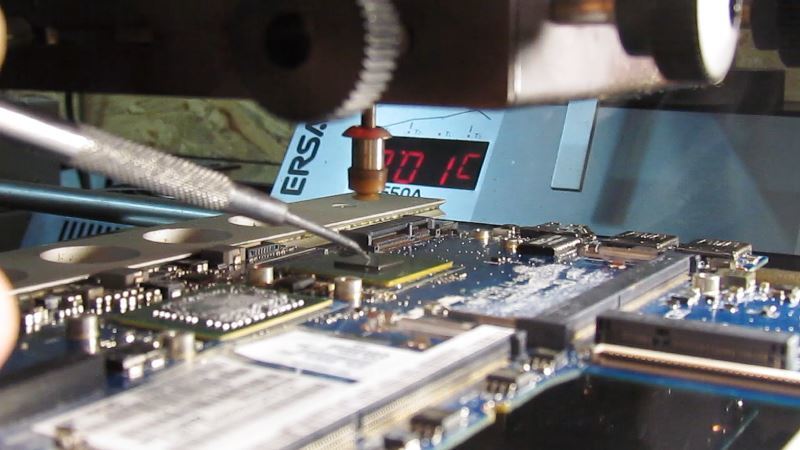

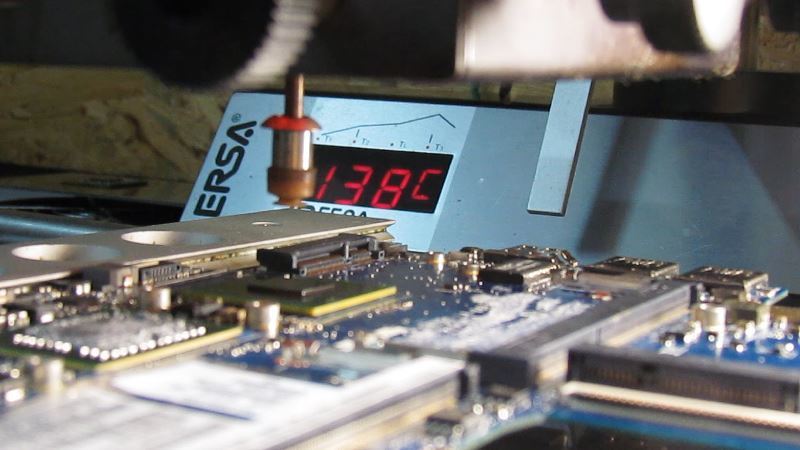

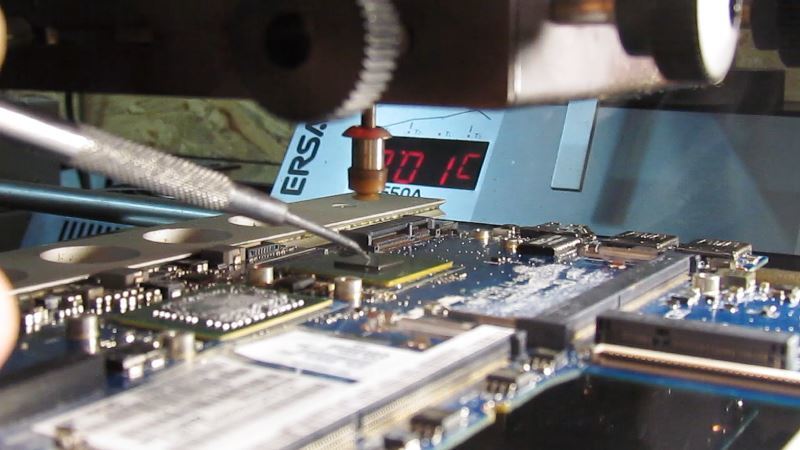

We install the soldering station “head” above the necessary chip in order not to miss - the red point of the station is shown by the red laser.

The station begins to heat the chip.

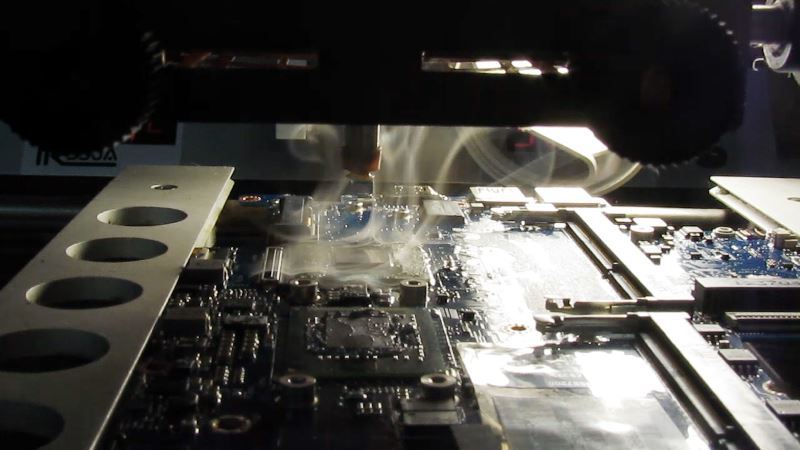

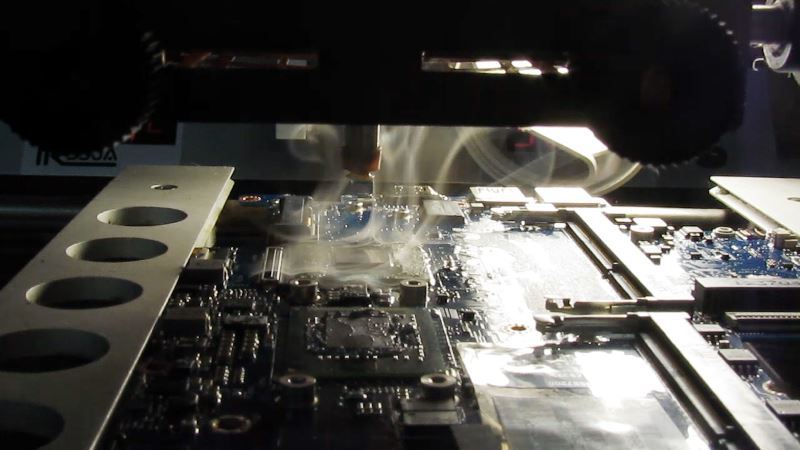

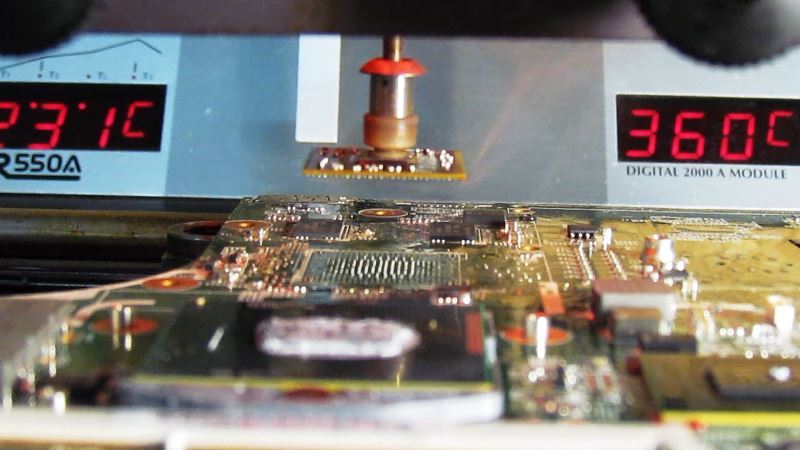

When the temperature reaches 200+ degrees, lower the suction cup, grab the chip and remove it.

Visible smoke from the fact that the chip is discharged. (360 is the temperature of the auxiliary soldering iron, which stands next to the station).

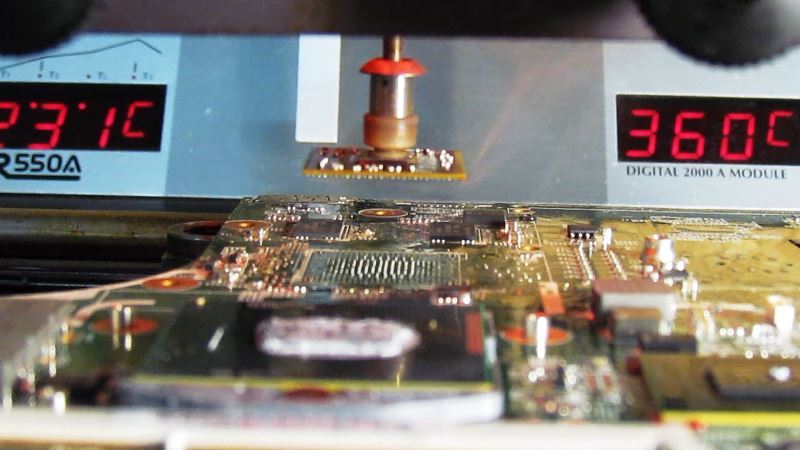

Capture the chip.

We transfer it to the site.

Here is the shot chip.

After that, over the place where the chip was, we put the cooling head and the fan automatically turns on to cool the board, since it is understood that the less time the board is heated, the better. This station has very tight temperature control during the entire soldering process.

Thermal sensor to monitor the temperature over the entire surface of the motherboard.

Now we are preparing a board for soldering. Remove the compound. Video process.

Then you need to clear the pad for the chip (the pad is higher than the processor).

Here is a site preparation video.

You also need to make the chip edge. Those. so that there will be balls at the place of contacts, which will be soldered into the seat on the board. This is a separate operation, about this vidos:

After the contact balls of the chip are ready, we set it strictly according to the mask. Even micron matters - you can spoil the chip, if you do not get into the connectors.

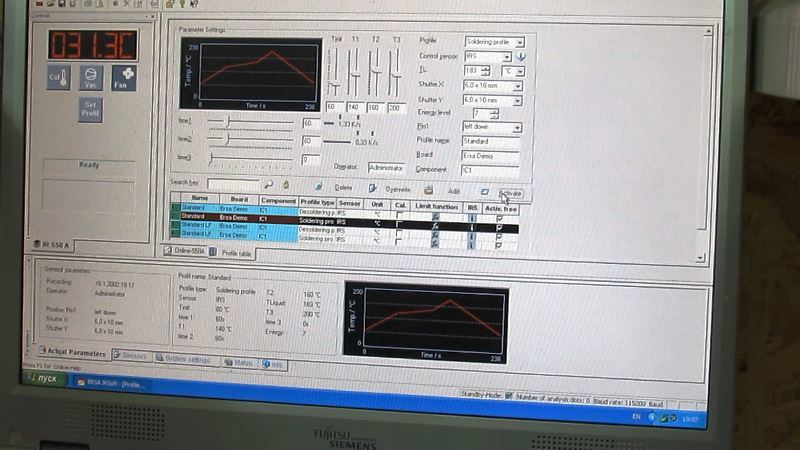

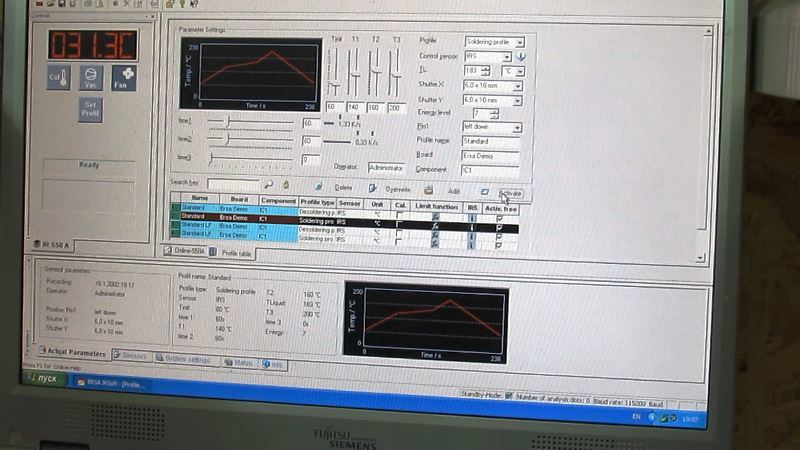

Then we begin to solder. As usual - choose the soldering profile. We move the head for soldering, direct the rays strictly on the chip and solder is turned on.

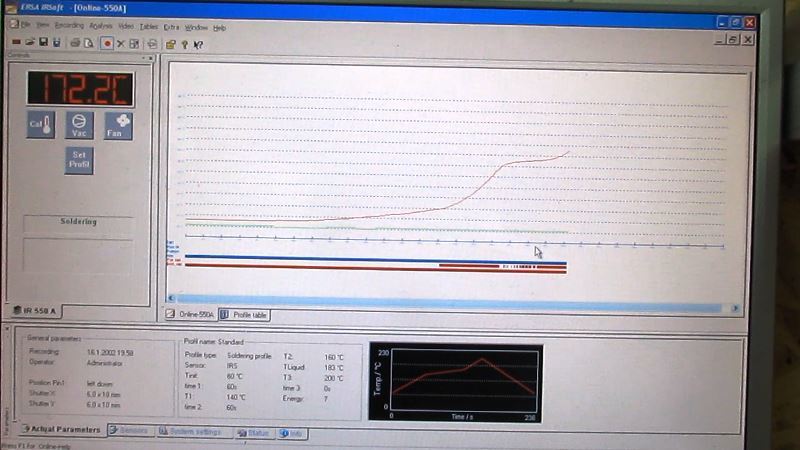

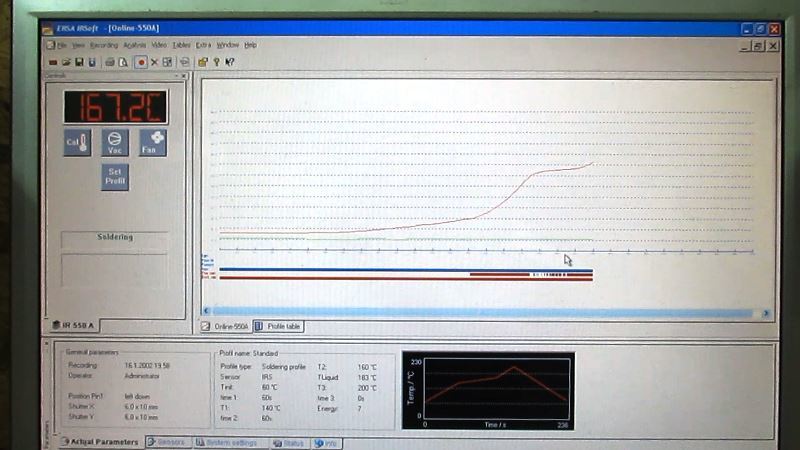

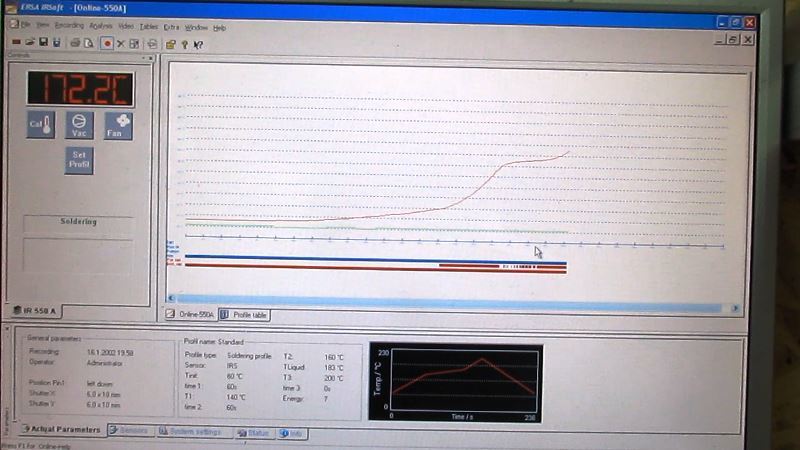

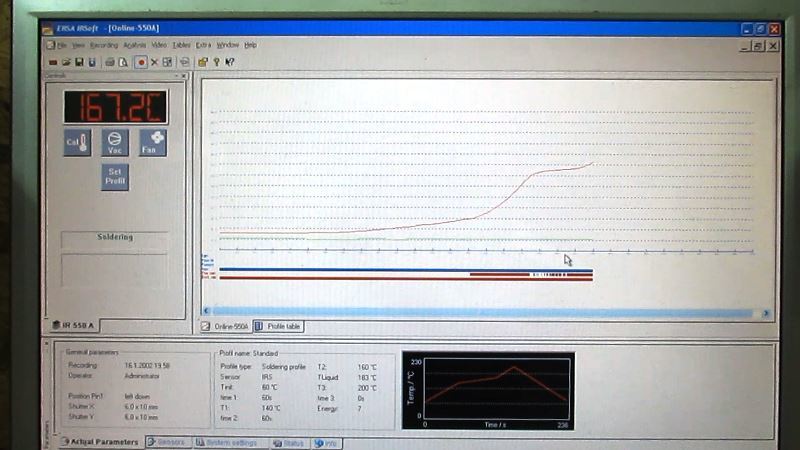

First, the lower part is heated, and it heats the strictly allocated space under the chip, and does not warm the entire surface, otherwise there would be a risk of failure of the entire board. When using the PL550A on the screen, you can observe the type of soldering in real time. Here we see the graph of the increase in temperature.

Red is a graph of the lower panel heating.

Scale height "head" for soldering. The height of the “head” position depends on the board profile.

In some stations of a lower class, the lower platform heats the entire area of the board, so when soldering at such stations you need to remove everything from the board - right down to the stickers with part numbers. As already mentioned, our station heats a strictly selected area below. When the platform from the bottom heats the section of the board under the chip to 60 degrees, the upper “head” turns on and begins to solder the chip itself.

The red tint is the infrared rays that heat the contacts of the chip for soldering. The idea is that the chip itself should sit in the nests of the contacts under its own weight, but in order not to overheat the board, the engineer checks the shrinkage of the chip when the contacts are fully warmed up to solder, without waiting for the chip's boundary temperature.

When we check that the chip has sat down, remove the heating “head” and set the cooling one.

All - graphics chip soldered.

I need to say a few words about the good qualities of our soldering station, not for advertising, but for praising a good tool. It is certainly not cheap, but worth the money. The best thing about this station is that it’s very hard to "screw up" a board or chip - you need to try hard for it. Whereas in other stations a class lower to make a mistake with the risk of spoiling the chip or the entire board is much easier.

Cemetery chips.

Description of the advantages of this station.

Why ERSA IR technology? Five key benefits:

• uniform infrared heating during local brazing as a winning alternative to the turbulence of the air flow in convection systems. Most critical for large BGA, and especially with lead-free soldering, which is performed at higher temperatures;

• accurate testing of the thermal profile due to temperature feedback directly from the soldering object;

• the possibility of visual monitoring of the soldering process (which is unattainable for convection systems, where the microcircuit is tightly closed with a nozzle during soldering);

• universality and sufficiency (it does not require a multitude of expensive nozzles for today's and tomorrow's chip sizes, as in convection systems);

• the ability to work with complex components (screens, connectors, etc.), including plastic ones.

The presence of an integrated microprocessor unit for contact soldering with the ability to connect five tools (soldering irons of different power MicroTool / TechTool / PowerTool, ChipTool thermopweezers or X-Tool thermal suction) turns the IR550Aplus infrared station into a universal repair center.

Next to it is a lower class station. They solder on it where such accuracy and delicacy are not needed, such as soldering the keyboard (by the way, if you want us to remove / write about soldering the keyboard, monitor or something else, write - we will remove).

Videoview of the whole process of video chip soldering.

We also have a channel on YouTube , where we ship various videos about technical operations. Subscribe - there will be new vidos.

In addition to technical videos, we record repairs for customers, because people often have doubts: didn’t I need good spare parts for the “left” in my favorite gadget? To avoid such questions, we record the repair itself on video at the request of the client.

Training courses / trainings / workshops in various areas of IT infrastructure - Training center MUK (Kiev)

MUK-Service - all types of IT repair: warranty, non-warranty repair, sale of spare parts, contract service

First, we remove the old chip. For this, it is heated by the station to the desired temperature. We select the desired profile in the management (there are several of them for different types of soldering).

')

At the station there are two “heads” - one to solder / solder something, the second to cool.

We install the soldering station “head” above the necessary chip in order not to miss - the red point of the station is shown by the red laser.

The station begins to heat the chip.

When the temperature reaches 200+ degrees, lower the suction cup, grab the chip and remove it.

Visible smoke from the fact that the chip is discharged. (360 is the temperature of the auxiliary soldering iron, which stands next to the station).

Capture the chip.

We transfer it to the site.

Here is the shot chip.

After that, over the place where the chip was, we put the cooling head and the fan automatically turns on to cool the board, since it is understood that the less time the board is heated, the better. This station has very tight temperature control during the entire soldering process.

Thermal sensor to monitor the temperature over the entire surface of the motherboard.

Now we are preparing a board for soldering. Remove the compound. Video process.

Then you need to clear the pad for the chip (the pad is higher than the processor).

Here is a site preparation video.

You also need to make the chip edge. Those. so that there will be balls at the place of contacts, which will be soldered into the seat on the board. This is a separate operation, about this vidos:

After the contact balls of the chip are ready, we set it strictly according to the mask. Even micron matters - you can spoil the chip, if you do not get into the connectors.

Then we begin to solder. As usual - choose the soldering profile. We move the head for soldering, direct the rays strictly on the chip and solder is turned on.

First, the lower part is heated, and it heats the strictly allocated space under the chip, and does not warm the entire surface, otherwise there would be a risk of failure of the entire board. When using the PL550A on the screen, you can observe the type of soldering in real time. Here we see the graph of the increase in temperature.

Red is a graph of the lower panel heating.

Scale height "head" for soldering. The height of the “head” position depends on the board profile.

In some stations of a lower class, the lower platform heats the entire area of the board, so when soldering at such stations you need to remove everything from the board - right down to the stickers with part numbers. As already mentioned, our station heats a strictly selected area below. When the platform from the bottom heats the section of the board under the chip to 60 degrees, the upper “head” turns on and begins to solder the chip itself.

The red tint is the infrared rays that heat the contacts of the chip for soldering. The idea is that the chip itself should sit in the nests of the contacts under its own weight, but in order not to overheat the board, the engineer checks the shrinkage of the chip when the contacts are fully warmed up to solder, without waiting for the chip's boundary temperature.

When we check that the chip has sat down, remove the heating “head” and set the cooling one.

All - graphics chip soldered.

I need to say a few words about the good qualities of our soldering station, not for advertising, but for praising a good tool. It is certainly not cheap, but worth the money. The best thing about this station is that it’s very hard to "screw up" a board or chip - you need to try hard for it. Whereas in other stations a class lower to make a mistake with the risk of spoiling the chip or the entire board is much easier.

Cemetery chips.

Description of the advantages of this station.

Why ERSA IR technology? Five key benefits:

• uniform infrared heating during local brazing as a winning alternative to the turbulence of the air flow in convection systems. Most critical for large BGA, and especially with lead-free soldering, which is performed at higher temperatures;

• accurate testing of the thermal profile due to temperature feedback directly from the soldering object;

• the possibility of visual monitoring of the soldering process (which is unattainable for convection systems, where the microcircuit is tightly closed with a nozzle during soldering);

• universality and sufficiency (it does not require a multitude of expensive nozzles for today's and tomorrow's chip sizes, as in convection systems);

• the ability to work with complex components (screens, connectors, etc.), including plastic ones.

The presence of an integrated microprocessor unit for contact soldering with the ability to connect five tools (soldering irons of different power MicroTool / TechTool / PowerTool, ChipTool thermopweezers or X-Tool thermal suction) turns the IR550Aplus infrared station into a universal repair center.

Next to it is a lower class station. They solder on it where such accuracy and delicacy are not needed, such as soldering the keyboard (by the way, if you want us to remove / write about soldering the keyboard, monitor or something else, write - we will remove).

Videoview of the whole process of video chip soldering.

We also have a channel on YouTube , where we ship various videos about technical operations. Subscribe - there will be new vidos.

In addition to technical videos, we record repairs for customers, because people often have doubts: didn’t I need good spare parts for the “left” in my favorite gadget? To avoid such questions, we record the repair itself on video at the request of the client.

Training courses / trainings / workshops in various areas of IT infrastructure - Training center MUK (Kiev)

MUK-Service - all types of IT repair: warranty, non-warranty repair, sale of spare parts, contract service

Source: https://habr.com/ru/post/271515/

All Articles