Identification of material objects using optical marker

To identify material objects, many different methods have been invented. They can be divided into two main groups:

- Methods that use the uniqueness property of features inherent in objects that in some way or other can be registered / measured and remain unchanged for a specified period of time within the limits of the permissible error.

This group includes biometric identification methods, optical identification, identification by spatial coordinates, duck test, etc. - Methods based on the marking of objects with identification information that is applied to the surface of the object in various ways: in the form of an inscription and / or image, sticking a label with a barcode, attaching a tag with a number, etc., and the subsequent identification of objects using this information.

The new method of identifying objects using an optical marker, considered in this publication, can be attributed to the second group by formal features, but it is also possible to find in it the signs of the first group of methods.

How it all began

Strangely enough, the idea that society needs another method of identifying material objects arose in the process of reflection on the provisions of Russian law 415-FZ, which introduced interesting changes to the Forest Code of the Russian Federation.

This is Article 50.2. "Marking wood", and more specifically about paragraph 3, which looks like this:

“The marking of wood specified in part 1 of this article shall ensure the possibility of applying and reading information about the marked wood using technical means .”

For a greater understanding of what follows from the above formulation, it is necessary to say that there are not so many industrially applicable technologies that allow to apply and read “information about marked wood using technical means”.

')

Personally, I know only two technologies that could claim to be used according to such a formulation.

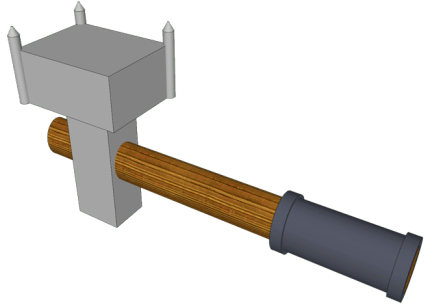

The first technology is based on the use of specialized plastic tags with visual, alphanumeric information and a bar code that are attached to the ends of the wood ridges using a special hammer.

This is what a specialized labeling label (with a barcode) looks like.

The second technology is based on the use of special RFID tags made in the form of nails, which are hammered into the end of the log. The tags are made of radio transparent material and are equipped with an RFID transponder that allows storing data and transmitting it wirelessly.

This is the RFID nail.

It is obvious that in this and in another case, the cost of introducing and using labeling technology implies, to put it mildly, substantial material costs, and if you add to all this various nuances related to protection against forgery, logistics, tagging, etc., This picture emerges not at all bright, especially if we consider the volume of harvesting of wood to be labeled in the Russian Federation.

Solution options

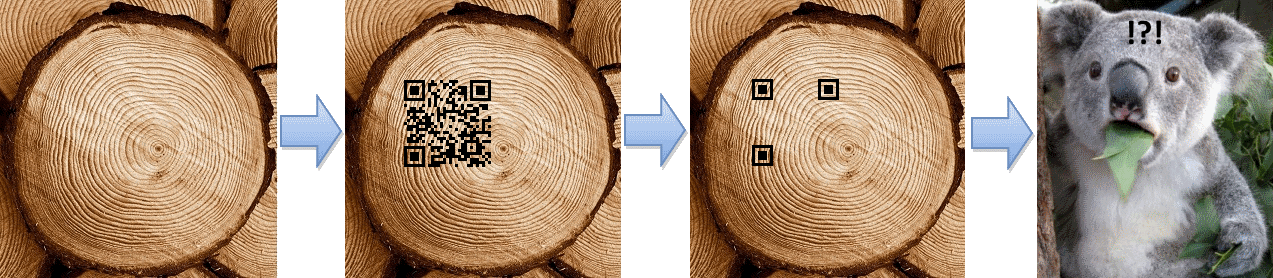

In the process of thinking and talking with colleagues on the subject of how, taking into account all the above, the requirements of the new law will be implemented as a result, among others the option of log identification was discussed according to the same principles used in fingerprinting, because, in fact, the drawing of annual rings at the end of each log is unique and even visually resembles a fingerprint pattern.

However, in the process of studying the fundamentals of fingerprint identification, it turned out that it is hardly possible to use this technology, because, first, a necessary condition for reading a fingerprint is its constant orientation relative to the reader (the finger is applied to the reader only in one position) that in actual operating conditions for the ends of the logs it is almost impossible to provide, and, secondly, the formation of so-called is an important component of the technology. “Convolutions” ( Google ), which is a set of relative coordinates of characteristic intersections of papillary skin patterns, and, alas , have virtually no intersections at the end of the log, alas .

Further, taking into account the peculiarity of the alternation of dark and light bands of annual rings, we considered the use case for identifying a conventional laser barcode scanner.

As you know, the principle of its work lies precisely in determining the width of lines and gaps (in our case it is the alternation of annual rings) by registering the laser beam of the scanner with an optical sensor (the description can be found here ).

However, it became obvious that, as a result, this approach also requires constant orientation of the end face relative to the reader, which is also very difficult to implement in real conditions.

It so happened that at that moment I had to deal with QR codes at work and devote some time to studying them in more detail. In the process of studying, I found on Habré an excellent article on this topic, in which “ Step 0 ”, which describes the use of detection areas , was especially striking.

The study of the standard for the formation of the QR code, which was mentioned at the end of the article, led to the understanding that it is through the use of these areas that the QR code is so quickly and efficiently determined and read even with the help of a completely budget smartphone, such as, for example, my Sony Walkman Live smart phone with a 5 MP camera.

Actually, then somehow all of the factors outlined (the uniqueness of the pattern of annual rings of wood, the use of detection areas in a QR code, the principle of operation of a laser scanner of linear bar codes) were combined into a single whole and eventually formed into a new method of identification including the identification of wood and timber.

Description of the new method

The essence of the method

The essence of the method consists in using the property of the uniqueness of the pattern or texture of the surface of a material object and the original method of processing the image of its surface by applying an optical marker on its surface.

For example, for wood, as the surface area for applying an optical marker, you can choose the end surface of a log or bar, which usually represents a flat cut or saw cut, on which the natural pattern of the wood structure in annual rings is clearly visible.

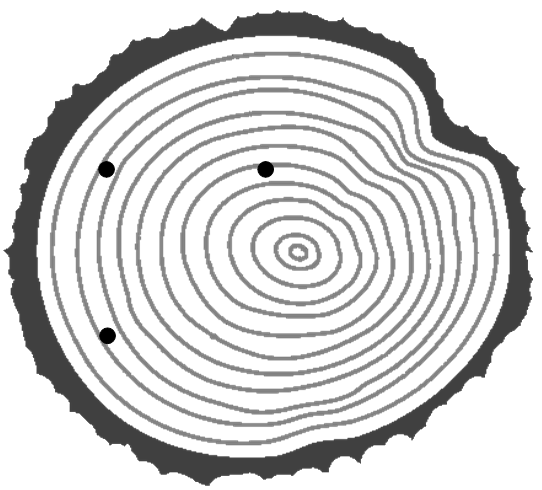

The optical marker is three points that are the vertices of a conditional non-equilateral triangle, one of the corners of which is 90 °.

The marker can be applied to the end of the log with the help of a specialized hammer.

This may look like a specialized hammer for marking.

After the impact, three indentations of the same depth and shape should remain on the surface of the butt.

Based on the location of the points of the marker, you can accurately determine the area of the surface, which will later be used to form the set of identification data (see the shaded area).

Formation of a set of identification data (ID)

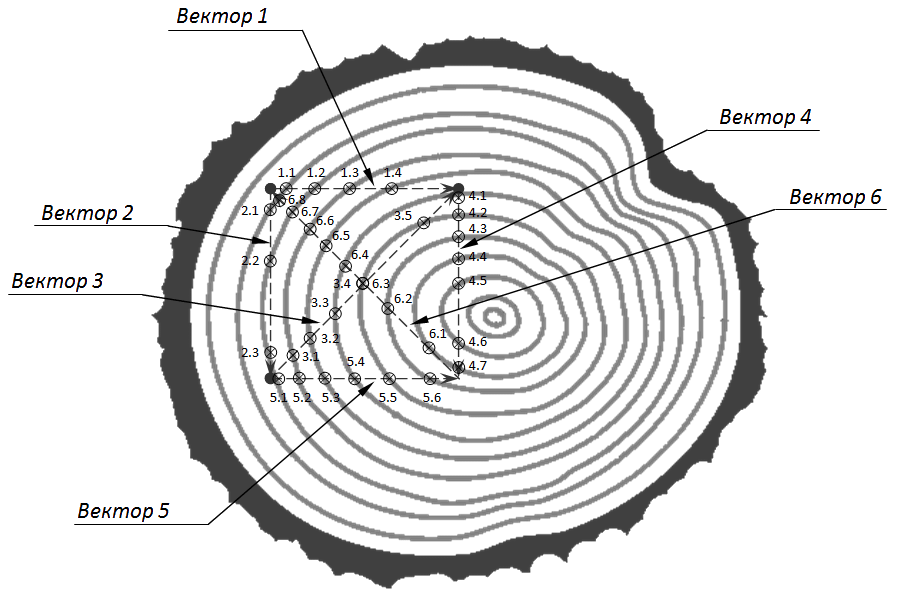

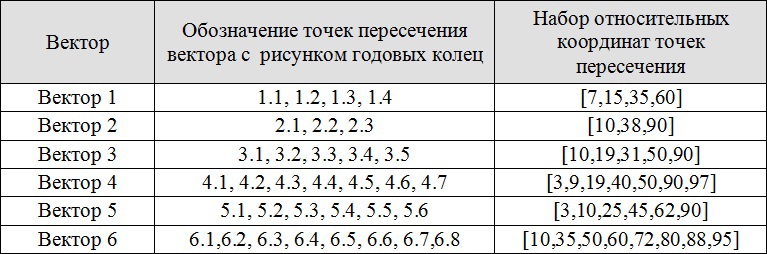

The set of IDs is formed on the basis of the list of relative coordinates of the intersections of the lines of annual rings and the lines of vectors passing through the surface area selected by the optical marker.

To clarify what is meant, consider the procedure of forming a set of ID for example .

For example, we will use a set of six vectors:

For each vector, the points of intersection with the pattern of annual rings are determined and their relative coordinates (the total length of the vector is divided into one hundred equal parts) as follows:

As a result, the set of IDs formed for our example is as follows:

[7,15,35,60],

[10.38.90]

[10,19,31,50,90]

[3,9,19,40,50,90,97]

[3,10,25,45,62,90]

[10,35,50,60,72,80,88,95]

The set of IDs obtained in this way is stored in a database and, subsequently, is used during the identification procedure.

Identification is carried out by comparing the identified set with other sets stored in the database.

In order to more flexibly approach the set matching process and take into account possible interferences, for example, when acquiring a digital image of a surface, you can use a complex criterion during the identification procedure, which allows you to assess the degree of coincidence of the received ID set with one of the sets in the database.

Complex criteria , for example, may be as follows:

- the total number of intersection points recorded in all arrays of the identified set should not differ from the initial one by more than two positions;

- the total number of intersection points recorded in one of the arrays of the set should not differ from the number of intersection points in the original set by more than one position;

- the relative coordinates of any intersection point must not differ from the relative coordinates of the same point of the original set of IDs by more than one part in both directions.

If the sets of identity match for all three subcriteria, it can be concluded that the sets are the same to such an extent that they can be considered identical.

Note also that the resulting sets of identification data have a minimum size and a clear structure, due to which it is possible to provide a significant acceleration of the search for ID sets in the database.

Why is all this necessary?

The key question is why you might need another identification method at all.

The answer is quite simple - the method under consideration assumes small costs, both for labeling and for identifying the marked objects. does not require the use of consumables, complex technical devices for marking and attracting qualified personnel.

Separately, it can be noted that this method is quite versatile and can be used for almost any material objects . It is enough to apply an optical marker on the surface of the object and fix the relative coordinates of the intersection of a set of vectors with visually prominent elements of its surface. The identification procedure will not significantly differ from the procedure considered in the framework of the timber identification method.

PS

The application for the method is registered with Rospatent. I hope the result will be positive.

Source: https://habr.com/ru/post/265209/

All Articles