When it's all about quantity. Nonlinear arithmetic of large quantities of electronic devices

The dream of any developer, regardless of experience and field of activity, is to make a project for a large company that will go into mass production. Even if you fail to get hold of this serious dividends immediately, then subsequently such a project will be your calling card. The transition from a prototype to a product produced in serial batches is a very complicated process, especially for those who pass it for the first time. Especially for a product that has a complex electronic filling. The likelihood of success of such a project is greatly increased if both the designer and the investor are well aware of all the steps on their way.

Moving from a prototype to a serial product, we fall into the area of "nonlinear mathematics" with a large number of factors that must be considered to correctly calculate the amount of investments. This conclusion seems obvious, but in practice I often come across the love of unacceptable simplifications in the calculations. In the future, it leads to serious financial problems, friction in the team, often the end of the project becomes the final.

Last week I received a request from the customer to calculate the cost of production of an experimental batch for one hundred products and the cost of production at the rate of ten thousand products per year. Well, I figured out a hundred rather quickly,

It is impossible to calculate the cost of production of 10,000 pieces simply by multiplying the cost of the sample by the quantity, and then by the reduction rate of the bundling when purchased in large quantities. Even with the cost of creating a prototype, we were mistaken almost twice, though largely due to the fact that the calculations were done before a landslide devaluation.

In a short time I have to prepare a material in which I have to convince the customer that the cost price of one prototype, an experimental batch of one hundred products and the industrial production of ten thousand products per year are completely different things. This article was a side result of the preparation of the material for my communication with the customer.

What factors need to be taken into account in order to calculate the cost of the product during the production of such circulations? How on the one hand not to scare the customer too high price, on the other hand not to mislead him unnecessarily low? The contribution of literally every extra cent to the cost of a single payment increases many times with similar volumes

')

Perhaps the first thing to consider is that the circuit of your prototype may

Birthmarks development.

There were times when I first took up the device containing a seemingly simple, but as it turned out later, quite tricky analog part. Fourteen years have passed, and as I remember it, it was a micro PBX with power from a telephone line. In those days, even producing a double-sided board was quite expensive and time consuming, so the prototypes were soldered on dummies.

Soon very curious things surfaced. First of all, I used a zener diode in the circuit of microcurrent stabilization. The sample on the test board worked fine, but the batch went a terrible variation in the voltage of stabilization in this abnormal mode of operation. Secondly, in the process of tracing, I placed a via in a very unsuccessful place of the microcurrent generator node. The case was aggravated by the imperfection of the production technology of printed circuit boards at that time - vias in this batch of boards had an anomalously large resistance. The result was a very high level of interference in the audio path circuits.

Why did I tell this bike? To the fact that the development today is usually conducted in the mode of " everything must be done yesterday ." While the customer's enthusiasm has not dried up and competitors have not outstripped you, it is necessary to give a prototype to the mountain, which can be demonstrated to investors and sent for certification. During such a race it is very difficult and in most cases it is not very necessary at the first stage to take into account absolutely all the nuances. Especially if the topic is complex, the device is original, and the developer does not have a wealth of experience in this field.

Between swan and cancer.

Before starting development, I am always interested in a potential client by what parameter we will optimize it. Minimum cost / manufacturability of the final product, or time / cost of the development itself?

When the goal is to create a unique device in a single copy, or in the amount of several pieces, it makes sense to optimize for the second parameter. The same, if it is necessary to submit a working sample in the shortest possible time. In these cases, the use of ready-made solutions and modules is justified. If the sample came to the customer's liking and he is ready to start production of the product in large batches, you will most likely have to look for a replacement.

For example, in my case, it was quite logical for a sample to use a panel computer instead of a monitor and a thin client, and to use a ready-made Ethernet module to communicate with it.

During the testing of the prototype, it often turns out that it lacks any functions. The opposite is also true, because it is not uncommon for both the customer and the developer to create redundant features during the manufacture of a prototype device, since it is difficult to predict what needs to be done in advance of the tests. In the course of the ill-fated development of the above-mentioned micro PBX, we neglected this rule and laid down the very popular PIC microcontroller 16C622 in the scheme. This microcontroller had only one drawback - there were no pin-to-pin compatible microcontrollers with a larger amount of program memory in the microchip family. In the course of working on the project, it turned out that, based on our circuit design, you can implement a large number of convenient functions. Theoretically, if I hadn’t rested on writing the code into the ceiling of the memory of two kilograms, when writing code. It happened quickly and programming after that turned into an endless process of optimizing the code in order to search, sometimes with just a few extra bytes.

Thus, there is a very high probability that the circuit diagram, even of a well-functioning sample, will be subjected to a profound modification during the transition to a serial product.

You can optimize not only medicine, but also purchases!

At one time, even in the role of a brand manager, I had to participate in large projects, though not in the role of developer, but from the component supplier, and since then I killed myself that with production volumes of the order of half a million boards per year, everything matters ! The most insignificant trifle.

The cost of electronic components is in direct connection with the volume of purchases, so you should think about how:

- Ready modules are the logical first victims of optimization. If you need Ethernet, then go to the microcontroller that supports it. If you can do without it, then on a less productive and cheaper interface.

- Next, microcontrollers. Choose the youngest model from the line that meets our requirements. Pay attention if you have not lost sight of the emergence of new products focused on budget solutions. In extreme cases, it is justified even to switch to another architecture — for example, to a PIC instead of an ARM.

- We reduce brands. When the number of microcontrollers you purchase per year reaches several thousand, not to mention tens of thousands, a project is registered for you with a component manufacturer with a delivery schedule plan for which you can get substantial discounts, about 30-40 percent of the product price. If we are talking about hundreds of thousands a year, then you will get from the MARKET to BAZAAR. It is all individually. Operating with similar volumes, you can bargain for very substantial discounts, both from the manufacturer and the dealer, but this fascinating process becomes more like a game of poker. Sometimes you have to bluff, change intractable, or not too clean partners, optimize logistics. Another step to reduce costs is to tie up the supply of discrete components to the supply of microcontrollers. For example, if you buy microcontrollers from STM, then it would be logical to purchase diodes from the same company, include them in the project and require distribution of discounts on them.

- The advantages of project work are low prices and no need to choose lots of hundreds of thousands at a time, or you can distribute purchases for a year, taking into account seasonality. Particularly persistent may even agree on a phased payment of the goods delivered. Perhaps one minus - the compiled schedule will have to adhere. The manufacturer takes into account your needs in their production plans, therefore, simply to refuse the next batch of deliveries will not work - you will run into fines. It will not be possible to double the volume for the summer due to excessive demand. That is, you will most likely be able to buy those extra 10 thousand chips, but most likely already on the market and it is unlikely that they will be able to distribute your design special. price So, the preparation of supply plans must be approached with great seriousness.

- The last stage of optimization is in nominal. It makes sense to reduce their number to a minimum and, if possible, get rid of the exotic, for large volumes you can get big discounts, and working with a smaller list of picking is always easier. For example, ten-kilohm resistors can be used as all pull-up and opening transistors, and without detriment to the operation of the podsokrasit circuit variety of tantalum capacitors. Often this is beneficial even when it is necessary to use higher voltage capacitors in low-voltage circuits than is required by the supply voltage.

Chinese wall or native birch?

In the global world, both the production and sale of your goods can be located at any point, not only of our vast Motherland, but at least for the time being, of the globe. What is more profitable for you depends on a huge number of factors. Consider some of them, boldly excluding the geopolitical factor.

Production in Russia.

In Russia, it makes sense to produce a material-intensive product that does not require too high technology. Despite the fact that in recent times modern production facilities have begun to appear in Russia, capable of offering good prices for the manufacture of both metal and plastic products, the production culture for them is still significantly lagging behind the Western ones. Today, prices for the services of our manufacturers are lower than ever, however, they have a steady tendency to smooth but steady growth.

The cost of installing large batches of boards at the moment is not too different from the Chinese, but with the purchase of electronic components, not everything is so joyful. You will have to deal with domestic distributors who are accustomed to impressive rates of return. Self-procurement of equipment abroad is not a very good idea, since our customs regulations are very complicated. Components are divided into a huge number of categories, each of which will have to fill in a separate declaration. The result - direct purchases of components for a somewhat complex product turn into hell.

Production abroad.

In today's conditions, this will most likely be China. If your product is primarily export oriented, then you should not hesitate to choose this option. Otherwise, you need to take into account the disadvantages of this solution. Prepayment for the goods will have to be made not only taking into account the production cycle, but also taking into account logistics. Unpleasant surprises can present customs. Air delivery is expensive, and the sea route takes a lot of time. For full control over the production and the quality of the product obtained, it is necessary to keep a representative in production. Chinese comrades are people with a peculiar mentality and should be taken into account when concluding contracts. For the Chinese, the optimization sits deeper in the blood than our officials. One can never be sure for one hundred percent that they have not approached creatively to finalize the circuitry of your product in the next installment.

And ours and yours.

For many products today it is preferable. Hotel types of operations are more profitable to carry out in Russia, and others in China.

- Development of electronic devices today is more profitable to produce in Russia. After a nearly two-fold devaluation of the ruble, the work of our engineers is cheaper than ever, while Chinese wages are growing by leaps and bounds. In addition, the development process by Russian engineers is much easier to control. You are guaranteed to receive a full package of documentation and the risk that the results of the development will go to the left faster than you release your product, in this case many times lower.

- Creating a prototype and even a party is also often easier to organize in Russia. Yes, it will be somewhat more expensive than in China, but taking into account logistics and with the right approach faster.

- It is more profitable to create some complicated mold and fit your three-dimensional part to it from the Chinese. It will be cheaper, more qualitative and, most likely, faster.

- Production of metal products and molding plastics of medium complexity at the current price level in Russia will cost even less than in China. Production time, taking into account the delivery will be lower.

- Manufacturing of printed circuit boards and their installation, taking into account the purchase of components in most cases it is advantageous to carry out in China. At the same time, it is highly desirable to perform output quality control of products on the manufacturer’s territory At the stage of setting up production, I strongly recommend keeping a personal representative in China, in the future it is permissible to transfer this process to outsourcing and entrust one of the many Russian representatives in these regions.

- The final testing, programming, and setting up the boards is best done in Russia, as well as screwdriver assembly and final inspection of finished products.

Related costs.

When planning the organization of production we should not forget about the overhead costs that invariably arise during its preparation.

First, it is a certification that takes a decent time and money. The more complex and expensive a product is, the more problems it can cause. So, in the oil industry, the cost of certification and trial operation often exceeds the cost of the development itself.

Secondly, the organization of activities to monitor the production of products. With large production volumes of a rather complex product, it is obligatory to test, at a minimum, each board included in the kit, separately and output control of the finished product, in general, using specially developed stand equipment. Recommended as much as possible. to automate the process of adjustment and adjustment, in order to reduce the cost of the now expensive working time to a minimum. But this is not important. Automatic or, more often, automated testing minimizes the influence of the human factor on the production of complex products and simplifies reporting. So, if the devices require calibration, the constants loaded into the memory of the microcontroller and the settings for this device are written into the database during the automatic testing operation. You will always have confidence that all the necessary tests were performed in full, and the repair / verification, replacement of individual modules is greatly simplified. If according to the results of such a check, the reject rate exceeds the preliminary estimate, then the production technology is adjusted and the next trial batch of devices is launched. And so in several iterations.

Testing is generally a separate and very serious question. To get to know it, I recommend reading a very good article published on Habré in a bit more detail.

Finally, at the final stage, you will need to organize the service center and screwdriver assembly.

Total. Rested in the pyramid.

I hope I was able to convince you that even if you are not a fan of product development based on the MVP theory, then in the evolutionary process of “mock-up sample -> experimental batch -> mass production”, the circuitry of the device usually undergoes significant changes. Often, such metamorphosis occurs with the product design.

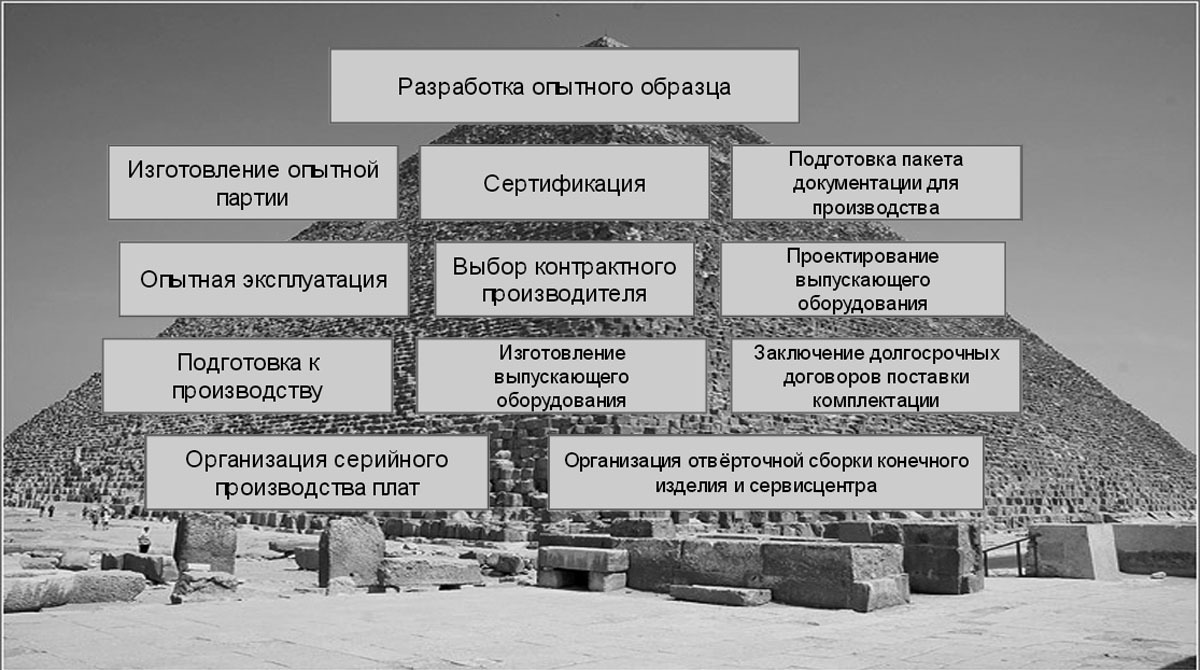

The process consists of several stages during which several parallel tasks are usually started. A typical pyramid of organizing the release of a new electronic product of medium complexity on the basis of a contract manufacturer will look something like this:

Only by taking into account the need for all the works shown in the figure can we estimate both the required volume of investments in the project and the time taken to start mass production. When deciding on the exclusion of individual stages from the figure above, it must be remembered that the cost of correcting errors made at higher levels increases at least exponentially when lowering to the base of the pyramid. Practice shows that trying to save, say, on the process of development or trial operation, is subsequently very costly.

The topic I have touched on is too extensive to cover it in detail in a single article, so my goal was simply to attract the attention of beginning developers and potential investors. Explain that you can not just come to the contract manufacturer with a working sample and without the hassle and investment to get a serial product.

Source: https://habr.com/ru/post/261055/

All Articles