Reverse engineering flashing LED (+ RGB)

1.5 years ago on Habré they wrote about an attempt to reverse engineering a randomly flickering LED. Then attempts to analyze the blinking patterns of the LED as a black box did not succeed with final success - however, the distribution of brightness modulation duty rates was established, and an emulator was written. Since then, different groups have opened flickering LEDs - and a little more has become known about their work. Finally, my hands reached them.

1.5 years ago on Habré they wrote about an attempt to reverse engineering a randomly flickering LED. Then attempts to analyze the blinking patterns of the LED as a black box did not succeed with final success - however, the distribution of brightness modulation duty rates was established, and an emulator was written. Since then, different groups have opened flickering LEDs - and a little more has become known about their work. Finally, my hands reached them.Since that time, it has been found that “random blink” crystals are quite a few varieties. Photos and thoughts of the authors on the principle of operation of similar crystals - siliconpr0n.org , cpldcpu.wordpress.com , hackaday.com . It is surprising that not only is someone engaged in the development and mass production of such a seemingly insignificant thing as a flickering LED - there is still progress / competition!

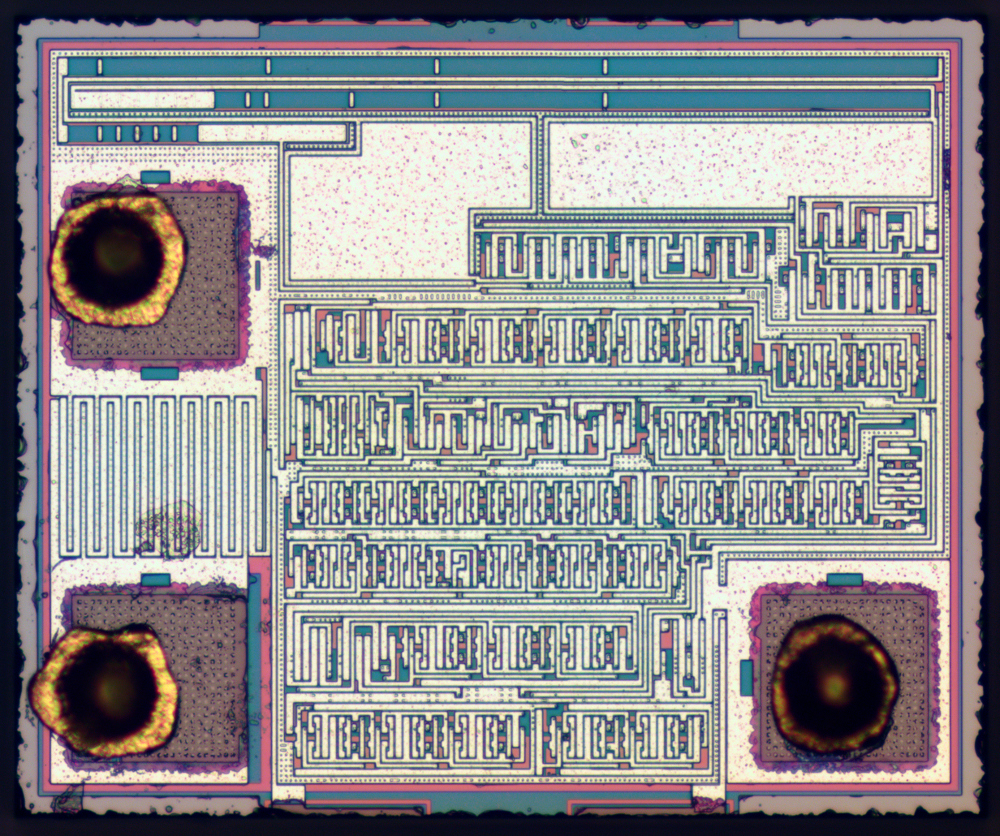

Red flickering led

The crystal size is 580x476 µm, 3µm technology. 3 contacts - plus, minus and output to the crystal LED.

')

It seems that the phase difference between two RC generators is used indirectly as a source of random data, and the behavior is not determined. There are many options for implementing this chip, for example, you can find a variant with LFSR and one generator (16-bit shift register with linear feedback - requires 16-bit shift register and one multi-pass XOR for implementation, the repetition cycle of the generated pseudo-random sequence is 65536 with optimal configuration, the simplest hardware pseudo-random number generator).

Crystal photo without metallization:

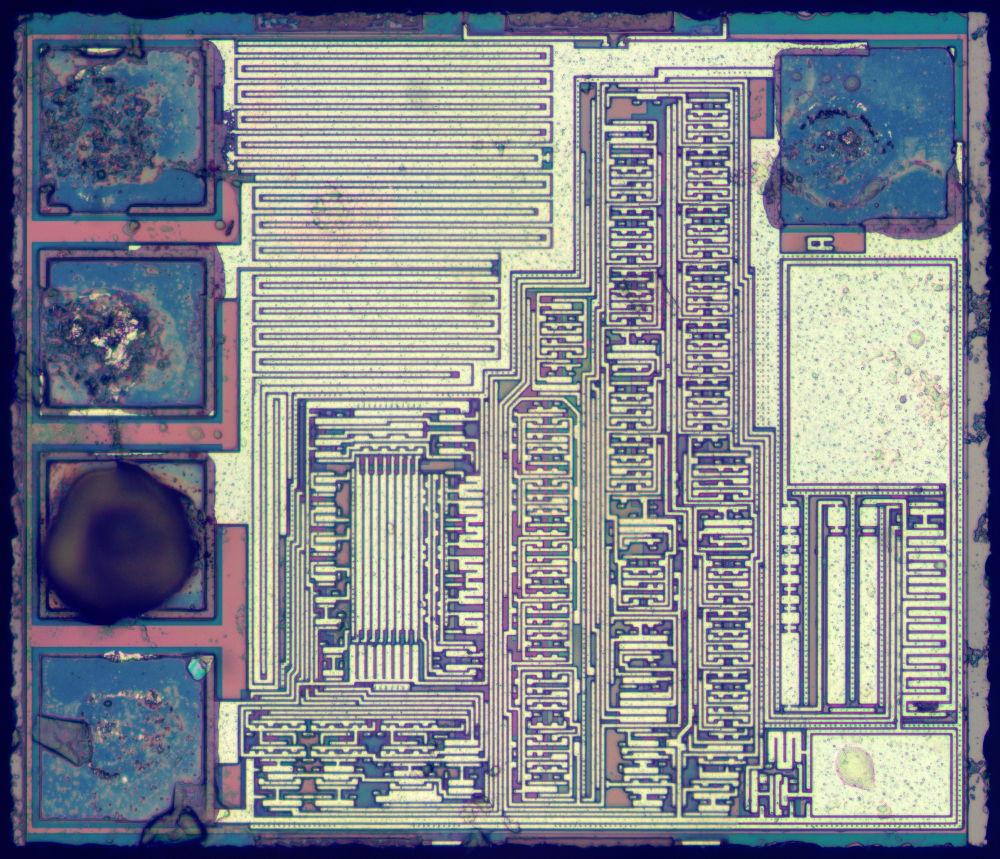

RGB LED blinking

The behavior of this LED is completely deterministic: the differences in behavior between different LEDs are only in the frequency variation of the built-in RC generator (~ ± 10%). The lower left part resembles a ROM-based microcode. Those. This LED resembles old processors - sequential switching of operating modes through this microcode at the right time activates various combinations of flicker subcircuits. And, just like the processor, starting a program from 0 - here each LED goes through the same state graph, just at a slightly different speed.

The crystal size is 553x474 µm, technology 1.5µm. Despite the complexity of the scheme - the crystal turned out less. This chip was normally captured only from the 3rd attempt: with such small crystals (area ~ 0.25mm²), the work turns out to be very nervous: 1 , 2 .

Photo crystal without metallization.

Ps. The faculty of ASOI GSU helped in obtaining LEDs.

Summary

All crystals (like those that caught me, and others) are produced using relatively old production technologies, from 1.5 to 3 microns (1500-3000nm!) - which emphasizes that not always thin production standards are economically justified for a new product: area Crystals - approximately 0.25mm², a smaller crystal is already difficult to cut, and accordingly thinner production standards will not be cheaper / better (the RGB technology has been improved only to 1500 nm so that approximately this crystal size is obtained). It is also a good example that even with simple products someone earns - but it is probably as difficult to do something simple than everyone else, as well as doing something most difficult.The control chips themselves are more complicated than I expected: I wouldn’t be surprised if I saw something analog at all, from several transistors (for the monochrome version of course), but apparently these solutions make it difficult to ensure temperature stability and the desired visual effect.

Source: https://habr.com/ru/post/259405/

All Articles